Contents

Manufacturing Insight: Cnc Machine Michigan

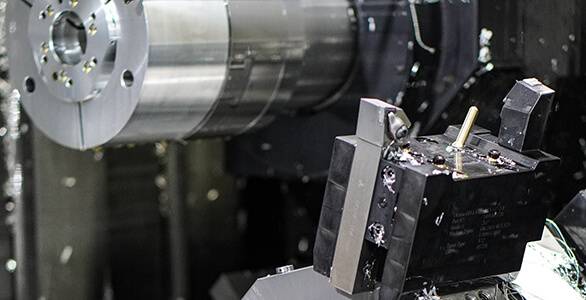

Precision CNC Machining Services for Michigan Manufacturers

Honyo Prototype delivers advanced CNC machining solutions engineered specifically for the demanding requirements of Michigan’s automotive, aerospace, and industrial sectors. Our Michigan-focused services provide rapid turnaround on complex, tight-tolerance components—from prototype development to high-volume production—using state-of-the-art 3-, 4-, and 5-axis milling and turning centers. All operations adhere to stringent AS9100 and ISO 9001 standards, ensuring repeatable accuracy down to ±0.0002 inches for critical applications.

Michigan-based clients benefit from localized support, streamlined logistics, and deep expertise in materials ranging from aerospace-grade aluminum and titanium to high-performance polymers. We eliminate traditional bottlenecks in the procurement cycle through our industry-leading Online Instant Quote platform. Upload CAD files directly to receive a detailed, no-obligation quote in under 60 seconds—accelerating your path from design to delivery without compromising on quality or technical validation.

For engineering teams prioritizing speed, precision, and supply chain resilience, Honyo Prototype integrates Michigan’s manufacturing legacy with next-generation digital workflows. Initiate your project immediately by accessing the Online Instant Quote system at honyoprototype.com.

Technical Capabilities

Honyo Prototype specializes in high-precision CNC machining services in Michigan, offering advanced 3-axis, 4-axis, and 5-axis milling alongside precision turning capabilities. Our CNC machining centers are engineered for tight tolerance production, typically holding ±0.0002″ (±0.005 mm) on critical dimensions, with process capability (Cp/Cpk) consistently above 1.67 under statistical process control (SPC). These systems support a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, enabling versatile prototyping and low-to-mid volume production.

Below is a summary of the technical specifications for our CNC machining services:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Spindle Speed | Up to 15,000 RPM | Up to 15,000 RPM | Up to 18,000 RPM | Up to 6,000 RPM (diameter-dependent) |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) | ±0.0001″ (±0.0025 mm) | ±0.0001″ (±0.0025 mm) | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.00005″ (±0.0013 mm) | ±0.00005″ (±0.0013 mm) | ±0.00005″ (±0.0013 mm) | ±0.00005″ (±0.0013 mm) |

| Typical Tolerance | ±0.0002″ (±0.005 mm) | ±0.0002″ (±0.005 mm) | ±0.0002″ (±0.005 mm) | ±0.0002″ (±0.005 mm) |

| Maximum Work Envelope | 24″ × 18″ × 12″ | 24″ × 18″ × 12″ + Rotary (360° indexing) | 20″ × 16″ × 12″ (5-axis simultaneous) | Ø16″ × 24″ length |

| Axis Resolution | 0.00001″ (0.00025 mm) | 0.00001″ (0.00025 mm) | 0.00001″ (0.00025 mm) | 0.00001″ (0.00025 mm) |

| Compatible Materials | Aluminum, Steel, ABS, Nylon, PEEK, Delrin, Titanium, Stainless Steel | Same as 3-axis with improved angular access | Full 5-axis capability for complex geometries in all materials | Bar stock up to Ø16″; supports Al, Steel, ABS, Nylon, brass |

| Tool Changer Capacity | 24-tool ATC | 24-tool ATC | 30-tool ATC (high-speed) | 12-station live tooling turret |

| Control System | Fanuc 31i-MB | Fanuc 31i-MB | Siemens 840D | Fanuc 32i-TB |

| Surface Finish (typical) | 32–64 μin (Ra) | 32–64 μin (Ra) | 16–32 μin (Ra) | 16–64 μin (Ra) |

Our Michigan-based facility maintains temperature-controlled environments and utilizes in-process probing with Renishaw systems to ensure dimensional accuracy across all material types. Aluminum and steel parts are machined with high-speed toolpaths and coolant-through spindles to minimize thermal drift. Engineering thermoplastics such as ABS and nylon are processed using sharp tooling, optimized feed rates, and non-contact fixturing to prevent deformation and maintain geometric integrity.

All CNC operations are supported by full CAD/CAM integration (SolidWorks, Fusion 360, Mastercam) and first-article inspection (FAI) reporting per AS9102 or customer-specific requirements.

From CAD to Part: The Process

Honyo Prototype executes CNC machining projects through a streamlined digital workflow designed for precision, speed, and client transparency. Our process begins when clients upload native CAD files (STEP, IGES, Parasolid, or native formats like SolidWorks) directly to our secure customer portal. This initiates our proprietary AI-powered quoting system, which analyzes geometric complexity, material requirements, tolerances, and feature density within minutes. Unlike manual quoting, our AI cross-references real-time machine availability, material stock levels, and historical production data to generate accurate cost and lead time estimates while flagging potential manufacturability concerns upfront.

Following client acceptance of the AI-generated quote, the project enters our mandatory Design for Manufacturability (DFM) phase. Our senior manufacturing engineers conduct a rigorous technical review, focusing on optimizing toolpaths, minimizing setups, identifying non-value-added operations, and suggesting geometric adjustments to reduce cost without compromising function. Clients receive a detailed DFM report with annotated recommendations and alternative solutions, enabling collaborative refinement before any metal is cut. This phase typically reduces production iterations by 40-60% based on historical project data.

Upon DFM sign-off, the job progresses to production in our climate-controlled Michigan facility. All CNC operations—milling, turning, multi-axis machining—occur on Haas, DMG MORI, and Makino equipment maintained to ISO 2768-mK standards. Each run employs in-process CMM verification at critical stages, with full First Article Inspection (FAI) reports per AS9102 format for aerospace/medical clients. Material certifications (CoC) and lot traceability are standard for all alloys, plastics, and composites.

Final inspection utilizes Zeiss CONTURA CMMs and optical comparators to validate conformance to print specifications, including surface finish and geometric tolerances. Approved parts undergo deburring, cleaning, and optional finishing (anodizing, plating, painting) before secure packaging. Delivery utilizes our integrated logistics platform, providing clients real-time shipment tracking with ETAs and customs documentation for international shipments. Typical lead times range from 3-15 business days depending on complexity, with expedited options available. All projects include digital delivery of inspection reports, process documentation, and as-built CAD models for client records.

Start Your Project

Looking for precision CNC machining services in Michigan? Partner with Honyo Prototype for high-quality, reliable manufacturing solutions. Although our advanced factory is located in Shenzhen, we provide seamless support and fast turnaround for clients across the U.S., including Michigan.

For project inquiries or quotes, contact Susan Leo directly at [email protected]. Let us bring your prototypes and production parts to life with precision CNC machining, strict quality control, and on-time delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.