Contents

Manufacturing Insight: Cnc Machine Meaning

Understanding CNC Machining: Precision Manufacturing Defined

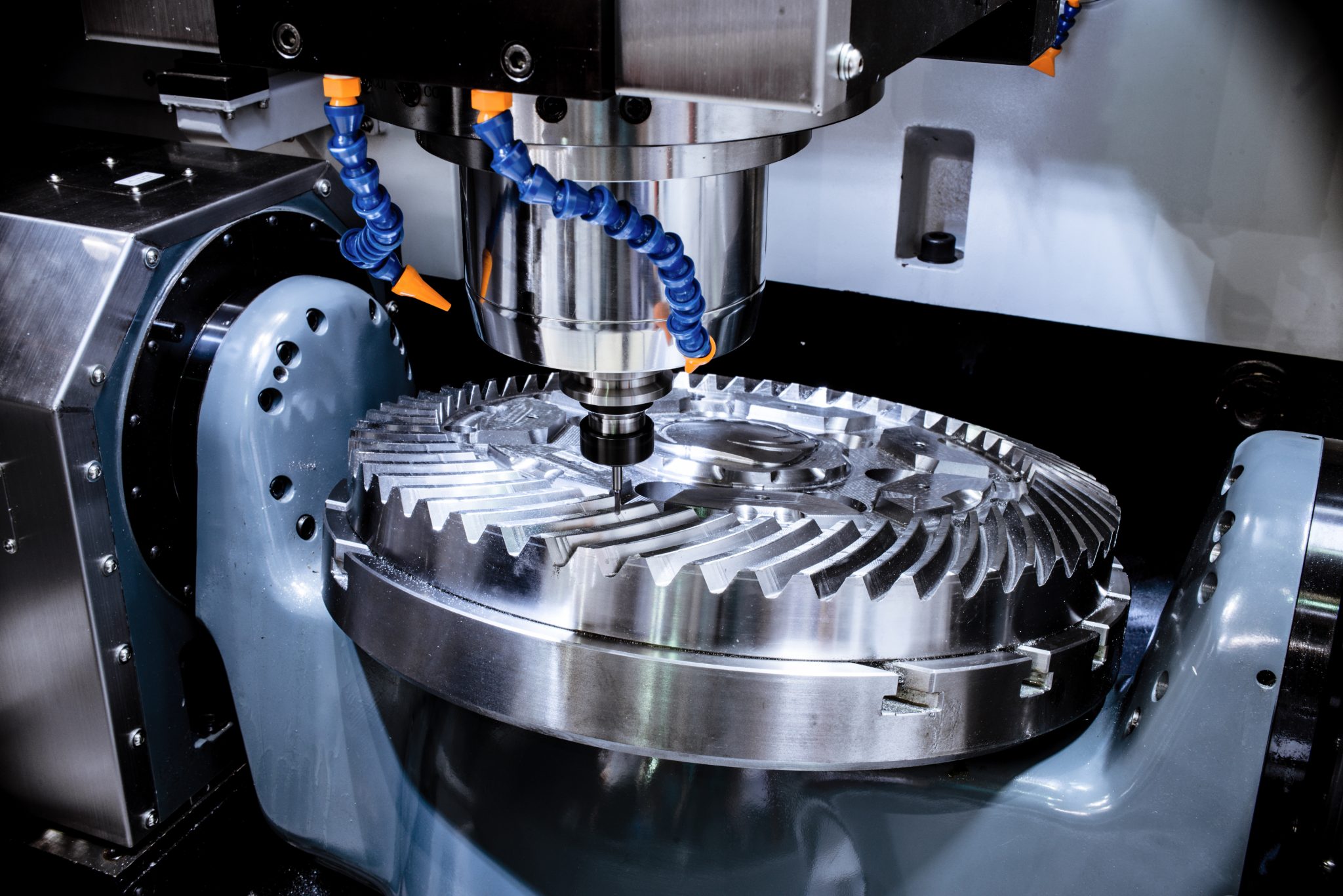

CNC machining refers to Computer Numerical Control manufacturing, a subtractive process where pre-programmed software directs multi-axis machine tools to remove material from a workpiece with micron-level accuracy. This automation enables the production of complex, high-tolerance components across metals, plastics, and composites—critical for aerospace, medical, and industrial applications where repeatability and dimensional integrity are non-negotiable. Unlike manual machining, CNC systems execute intricate geometries consistently, reducing human error while optimizing throughput for both prototyping and volume production.

At Honyo Prototype, we leverage advanced 3-, 4-, and 5-axis CNC milling and turning centers to transform engineering designs into mission-critical parts. Our AS9100-certified facility combines rigorous quality control—featuring in-process CMM validation and first-article inspection—with agile manufacturing workflows. Whether you require rapid functional prototypes or low-volume production runs, our engineering team collaborates closely to ensure material suitability, tolerance adherence, and on-time delivery.

Access Capabilities Instantly via Online Quote System

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload CAD files, specify materials and quantities, and receive a detailed cost and lead-time estimate within hours—no manual back-and-forth. This engineer-to-engineer digital workflow ensures transparency while maintaining the technical scrutiny your precision components demand.

Material & Process Capabilities Summary

| Category | Specifications |

|—————–|————————————————|

| Materials | Aluminum 6061/7075, Stainless Steel 303/316, Titanium, PEEK, Delrin, Brass |

| Tolerances | ±0.0002″ (5µm) standard; tighter upon engineering review |

| Max Work Envelope | 38″ x 20″ x 20″ (965 x 508 x 508 mm) |

| Lead Times | Prototypes: 3-5 days; Production: 7-12 days (varies by complexity) |

Technical Capabilities

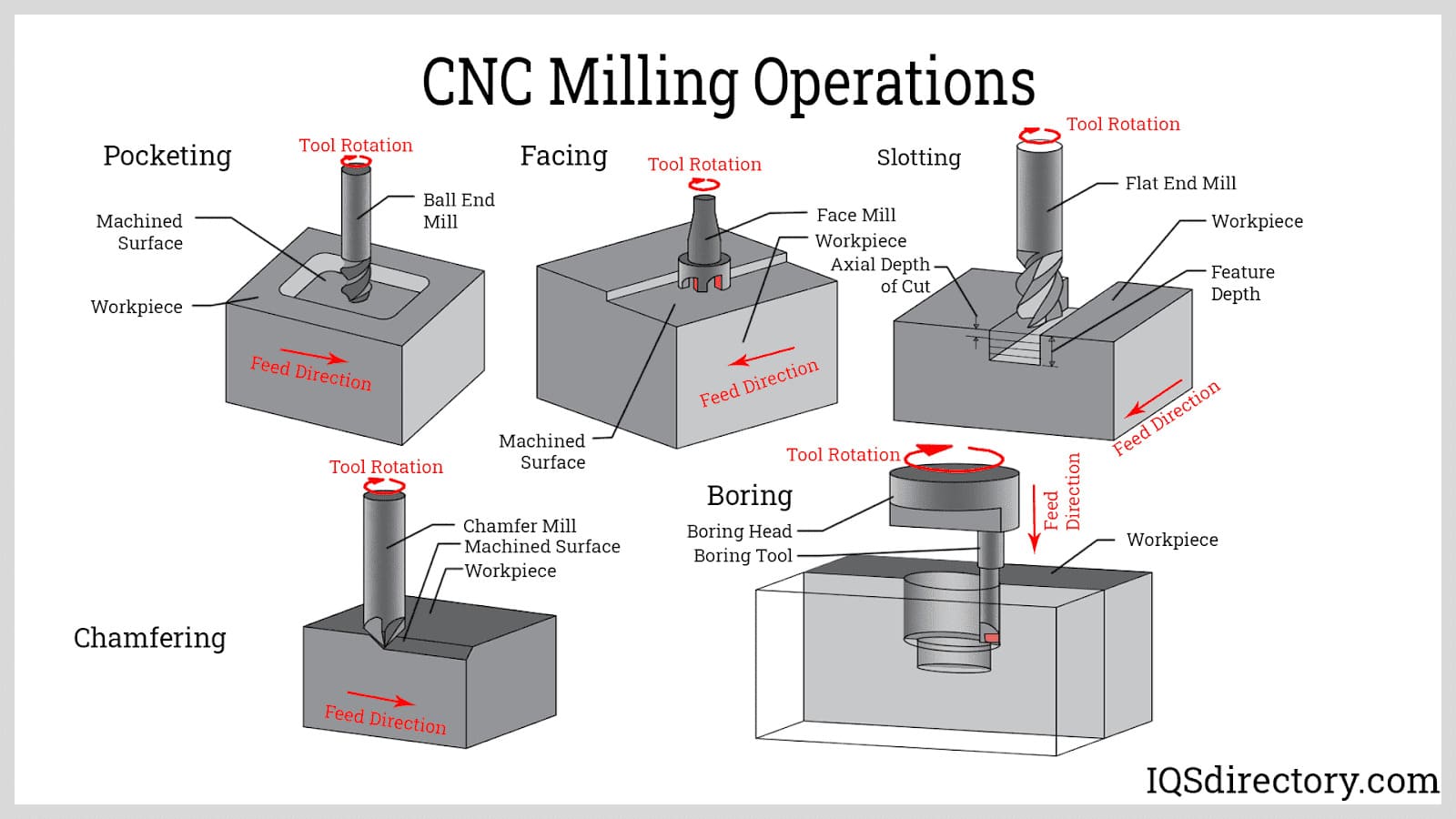

CNC machine meaning refers to Computer Numerical Control machinery that automates the operation of machine tools through programmed code. These systems precisely control movement along multiple axes to shape raw material into finished components with high repeatability and accuracy. In manufacturing, CNC machines are essential for producing complex geometries, especially in prototyping and low-to-mid volume production. Key types include 3-axis, 4-axis, and 5-axis milling machines, as well as CNC turning centers. These machines are capable of achieving tight tolerances, typically ranging from ±0.001″ to ±0.005″, depending on part geometry, material, and machine calibration.

The following table outlines the technical specifications relevant to 3/4/5-axis milling and turning processes, including achievable tolerances and compatible materials such as Aluminum, Steel, ABS, and Nylon.

| Specification | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Axis Movement | X, Y, Z linear axes | X, Y, Z + rotary A-axis (rotates around X) | X, Y, Z + two rotary axes (e.g., A & B or B & C) | X, Z linear + rotary spindle (C-axis optional) | 5-axis allows tool approach from complex angles |

| Typical Tolerance | ±0.002″ (±0.05 mm) | ±0.002″ (±0.05 mm) | ±0.001″ (±0.025 mm) | ±0.001″ (±0.025 mm) | Tight tolerances depend on machine rigidity, tooling, and environment |

| Surface Finish (Ra) | 32–125 μin | 32–125 μin | 16–63 μin | 16–63 μin | 5-axis and turning achieve finer finishes due to reduced setups |

| Spindle Speed Range | 8,000 – 20,000 RPM | 8,000 – 20,000 RPM | 10,000 – 30,000 RPM | 2,000 – 8,000 RPM | Higher speeds for milling; turning prioritizes torque |

| Feed Rate | Up to 1,500 IPM | Up to 1,500 IPM | Up to 1,200 IPM | Up to 500 IPM | Varies with toolpath complexity and material |

| Compatible Materials | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | All materials require appropriate tooling and speeds/feeds |

| Aluminum Machining | Excellent | Excellent | Excellent | Excellent | High material removal rates; low cutting forces |

| Steel Machining | Good | Good | Excellent | Excellent | Requires rigid setup and proper tooling (e.g., carbide) |

| ABS Machining | Good | Good | Good | Fair | Low melting point; requires coolants and sharp tools |

| Nylon Machining | Fair | Fair | Fair | Fair | Prone to deformation; needs precise clamping and slow feeds |

These specifications reflect standard industrial capabilities at precision manufacturing facilities such as Honyo Prototype, where tight tolerance requirements and diverse material processing are routine. 5-axis milling and CNC turning are particularly valuable for minimizing part handling and achieving complex, high-accuracy components in aerospace, medical, and industrial applications.

From CAD to Part: The Process

Honyo Prototype’s CNC machining process integrates digital efficiency with precision engineering to deliver rapid, high-quality prototypes and low-volume production parts. Our workflow begins with customer CAD submission and concludes with certified delivery, optimized for speed and manufacturability.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate geometric validation, checking for corrupt features, missing datums, or unsupported file formats. Validated files enter our production queue with automated version control, while invalid submissions trigger specific error reports to accelerate resubmission. This stage establishes the technical foundation for all subsequent steps, ensuring dimensional accuracy and feature completeness from the outset.

AI Quote

Honyo’s proprietary AI engine analyzes the CAD geometry against our 15+ years of machining cost databases, processing over 200 geometric parameters including feature complexity, material removal rate, and tolerance density. Unlike manual quoting, the system cross-references real-time machine availability, material costs from certified suppliers, and labor rates to generate a detailed cost breakdown within 24 hours. The output includes base machining cost, material surcharges, and optional finishing expenses, with transparent justification for complex feature pricing. This eliminates estimation guesswork while maintaining human oversight for exceptional cases.

DFM (Design for Manufacturability)

Our engineering team conducts a dual-path DFM review: automated software checks against Honyo’s 1,200+ rule library (e.g., minimum wall thickness, tool access angles) followed by senior engineer validation. Critical outputs include manufacturability scorecards highlighting high-risk features, suggested tolerance relaxations without functional impact, and alternative setup configurations to reduce machining time. Clients receive annotated CAD markups and a formal DFM report within 48 hours of quote acceptance, enabling informed design iterations before production commitment.

Production

Approved designs move to our climate-controlled CNC facility housing 37 HAAS and DMG MORI machines (3-axis to 5-axis mill-turn). Each job undergoes:

Material certification verification against MIL-STD-883

First Article Inspection (FAI) per AS9102 with full CMM reporting

In-process checks at 25%, 50%, and 75% completion milestones

Final inspection against original CAD with GD&T validation

All processes adhere to ISO 9001:2015 standards, with real-time machine monitoring ensuring ±0.005mm dimensional accuracy. Complex assemblies receive dedicated fixture documentation for repeatability.

Delivery

Completed parts undergo final cleaning, deburring verification, and packaging in ESD-safe containers with desiccant. Each shipment includes:

Dimensional inspection report (PDF and XML)

Material certification traceability

Process non-conformance log (if applicable)

Shipping manifest with barcode tracking

Honyo maintains 98.7% on-time delivery through our hub-and-spoke logistics network, with standard lead times varying by complexity as shown below:

| Complexity Tier | Typical Lead Time | Max Tolerance | Max Volume |

|---|---|---|---|

| Standard Geometry | 3-5 business days | ±0.05mm | 50 units |

| Moderate Features | 5-7 business days | ±0.025mm | 25 units |

| High Precision | 7-10 business days | ±0.005mm | 10 units |

This integrated workflow reduces time-to-part by 40% compared to industry averages while maintaining rigorous quality controls. Our closed-loop system feeds production data back into the AI quoting engine, continuously refining cost and lead time accuracy for future projects.

Start Your Project

For a deeper understanding of CNC machine meaning and how precision machining can elevate your prototyping or production needs, contact Susan Leo at [email protected]. As a Senior Manufacturing Engineer at Honyo Prototype, I can provide detailed technical insights into CNC machining processes, from 3-axis to 5-axis capabilities, material selection, tolerances, and design for manufacturability.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, China, specializing in high-accuracy CNC milling, turning, and rapid prototyping services for global clients across industries such as automotive, medical, and consumer electronics.

Let’s discuss your project requirements and how our CNC machining expertise can support your development timeline.

Contact:

Susan Leo

Email: [email protected]

Location: Shenzhen, China

Company: Honyo Prototype

| Service | Capability |

|---|---|

| CNC Milling | 3-axis, 4-axis, 5-axis |

| CNC Turning | Multi-axis, live tooling |

| Materials | Aluminum, Steel, Stainless, Plastics, etc. |

| Tolerances | As tight as ±0.005 mm |

| Lead Time | As fast as 3–5 days for prototypes |

| Finishes & Treatments | Anodizing, Plating, Bead Blasting, etc. |

Reach out today to align your design goals with precision manufacturing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.