Contents

Manufacturing Insight: Cnc Machine Light

Precision CNC Machining Engineered for Your Next Breakthrough

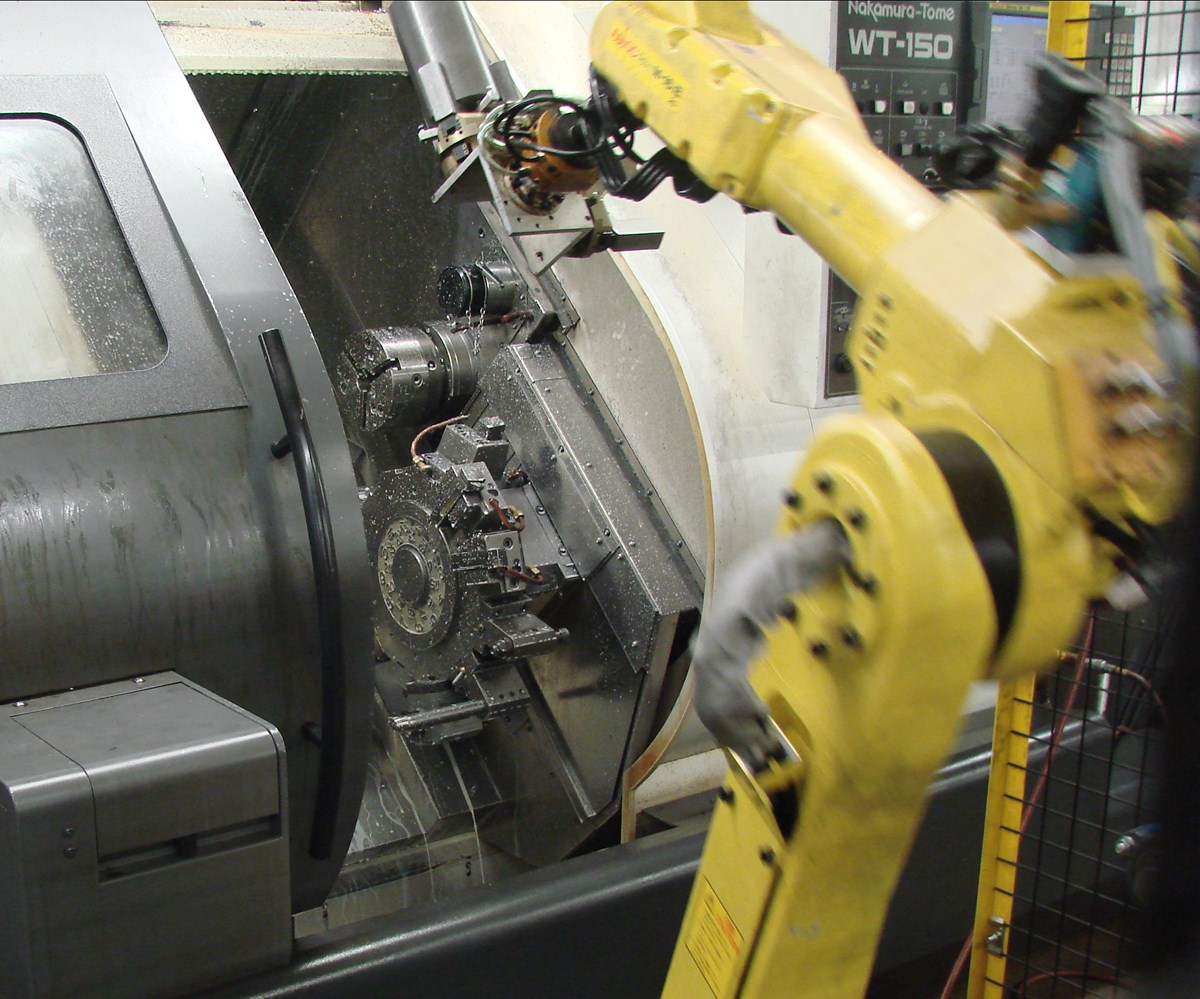

At Honyo Prototype, we transform complex designs into high-accuracy components through advanced CNC machining capabilities tailored for demanding industrial applications. Our facility leverages state-of-the-art 3-axis, 4-axis, and 5-axis milling and turning centers to deliver parts with tight tolerances down to ±0.0002 inches, across aerospace-grade aluminum, medical stainless steel, titanium, and engineering plastics. Every process is rigorously controlled under ISO 9001 standards, ensuring repeatability and material integrity from prototype to low-volume production.

Our technical expertise spans intricate geometries, thin-wall features, and multi-part assemblies where precision directly impacts performance. Whether you require rapid functional prototypes or certified production runs, Honyo’s engineering team collaborates early to optimize manufacturability—reducing lead times without compromising quality. This proactive approach minimizes costly revisions and accelerates time-to-market for sectors including aerospace, medical devices, and robotics.

Online Instant Quote: Accelerate Your Project Timeline

Eliminate quoting delays with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file, specify materials and quantities, and receive a detailed manufacturing assessment within minutes—not days. The system evaluates geometric complexity, material utilization, and machine time to provide transparent, competitive pricing with clear lead time estimates. This digital workflow empowers engineering teams to iterate faster during design validation while maintaining full visibility into cost drivers.

Partner with Honyo Prototype to leverage CNC machining precision that meets the highest industry demands. Begin your project with confidence using our Online Instant Quote tool at honyoprototype.com/quote, where technical excellence and operational efficiency converge.

Technical Capabilities

Technical specifications for CNC machine lights are critical in precision machining environments where visibility directly impacts accuracy, especially in 3-axis, 4-axis, and 5-axis milling, turning operations, and tight-tolerance work. These lights are designed to illuminate the cutting zone under challenging conditions involving coolant, metal shavings, and confined spaces. They are essential for inspecting tool engagement, workpiece alignment, and surface finish during high-precision machining of materials such as aluminum, steel, ABS, and nylon.

The following table outlines key technical specifications for industrial-grade CNC machine lights tailored for high-accuracy applications:

| Specification | Detail |

|---|---|

| Light Source | High-intensity LED (typically 5000K–6500K color temperature) |

| Luminous Output | 2,000–5,000 lux at 100 mm distance |

| Power Supply | 12–24 VDC (regulated), compatible with standard CNC control systems |

| Voltage Tolerance | ±10% |

| Protection Rating (IP) | IP67 or higher (dust-tight and protected against water immersion) |

| Housing Material | Anodized aluminum or stainless steel (corrosion and impact resistant) |

| Operating Temperature | -20°C to +60°C |

| Mounting Options | Magnetic base, articulated arm, or fixed bracket for flexible positioning |

| Coolant Resistance | Fully sealed optics and housing to withstand oil, coolant, and debris |

| Vibration Resistance | Designed for high-vibration environments (tested up to 10G) |

| Lifespan (L70) | 50,000 hours minimum |

| Adjustability | 360° rotational and multi-joint articulation for precise beam aiming |

| Beam Angle | 30°–60° (adjustable or interchangeable lenses) |

| Compliance Standards | CE, RoHS, UL/CSA (depending on region) |

| Compatible Machines | 3-axis, 4-axis, and 5-axis CNC mills, CNC lathes (turning centers) |

| Material Suitability | Optimized for use with aluminum, steel, ABS, nylon, and other engineering materials |

| Application Focus | Tight-tolerance machining (< ±0.005 mm), tool monitoring, burr inspection |

These lighting systems are engineered to support precision operations across a range of materials. For instance, when machining reflective aluminum or dark nylon, consistent color temperature and high CRI (>80) ensure accurate visual assessment of tool paths and surface quality. In steel turning or 5-axis milling of complex geometries, the ability to direct light into deep cavities or undercuts is critical. Lights with magnetic or modular mounting allow integration into confined spaces typical of multi-axis setups.

Reliability under continuous operation and resistance to harsh shop floor conditions make these lights indispensable for maintaining quality and efficiency in prototype and production environments.

From CAD to Part: The Process

Honyo Prototype’s CNC Machine Light service delivers rapid, high-precision prototyping and low-volume production for machined components through a streamlined digital workflow. This process minimizes lead times while ensuring manufacturability and quality, specifically optimized for straightforward CNC projects requiring expedited turnaround. The end-to-end sequence operates as follows.

CAD Upload

Customers initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) via Honyo’s secure customer portal. The system validates file integrity and geometry completeness, confirming the design meets minimum feature size requirements for CNC machining. Supported materials are pre-filtered based on the geometry analysis during this stage.

AI-Powered Quoting

Uploaded designs are processed through Honyo’s proprietary AI quoting engine, which analyzes geometric complexity, material selection, required tolerances, and surface finish specifications. The engine cross-references real-time machine availability, material inventory costs, and historical production data to generate an instant preliminary quote within minutes. Crucially, this AI output undergoes immediate human validation by our manufacturing engineering team to verify feasibility and adjust parameters where the AI model requires contextual oversight, ensuring quote accuracy before customer presentation.

Engineer-Validated DFM Analysis

Upon quote acceptance, the project enters our mandatory Design for Manufacturability (DFM) phase. A dedicated manufacturing engineer performs a rigorous review against CNC-specific constraints. Key focus areas include:

| DFM Checkpoint | Critical Parameters Verified | Outcome Resolution |

|---|---|---|

| Feature Feasibility | Minimum wall thickness, hole depth-to-diameter ratios, undercuts, internal radii | Redesign recommendation or process adaptation |

| Tolerance Validation | Geometric Dimensioning & Tolerancing (GD&T) alignment with CNC capabilities, stack-up analysis | Tolerance relaxation or secondary operation plan |

| Material Utilization | Blank size optimization, nesting efficiency, scrap reduction | Material specification adjustment |

| Fixture & Setup Planning | Workholding strategy, datum scheme, number of operations required | Setup reduction or custom fixture proposal |

This phase typically completes within 4 business hours. The engineer provides a formal DFM report with actionable feedback, requiring customer sign-off before production release.

Precision Production Execution

Approved designs move to Honyo’s climate-controlled machine floor. Each job receives:

Dedicated machine assignment (3-axis or 5-axis mills, lathes) based on part complexity

Real-time in-process inspection using integrated Renishaw probes for critical dimensions

Material certification and traceability documentation for aerospace/medical builds

Automated production logging with timestamped milestone tracking accessible via customer portal

First-article inspection reports (FAIR) are generated per AS9102 standards for qualifying runs, with full batch traceability maintained throughout machining, deburring, and finishing.

Quality-Controlled Delivery

Completed parts undergo final verification against the original CAD model using calibrated CMM equipment or optical comparators. All shipments include:

Dimensional inspection report with actual vs. nominal measurements

Material certification (if applicable)

Protective packaging meeting ISTA 1A standards for transit security

Standard delivery is 5-7 business days from DFM sign-off for 1-10 part quantities, with expedited 72-hour options available. Logistics partners provide trackable shipments with delivery confirmation, and our portal updates customers at each fulfillment milestone. This integrated approach ensures technical rigor while maintaining the speed expected in modern rapid manufacturing engagements.

Start Your Project

Upgrade your CNC operations with high-performance machine lighting solutions designed for precision and durability. Engineered for optimal visibility in demanding manufacturing environments, our CNC machine lights enhance accuracy and safety on the shop floor.

Contact Susan Leo for product specifications, pricing, and bulk order options. As a trusted manufacturer based in Shenzhen, Honyo Prototype delivers reliable, industrial-grade components with fast lead times and OEM support.

Email: [email protected]

Let’s illuminate your production efficiency—reach out today to request samples or a technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.