Contents

Manufacturing Insight: Cnc Machine Grinding

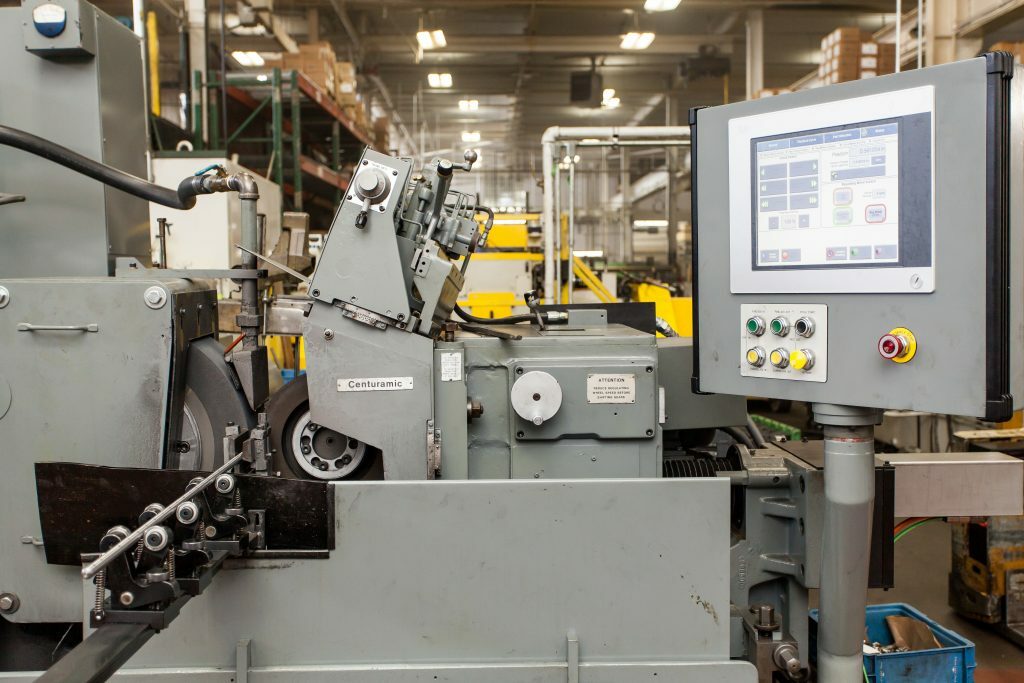

Precision CNC Grinding Solutions for Demanding Manufacturing Applications

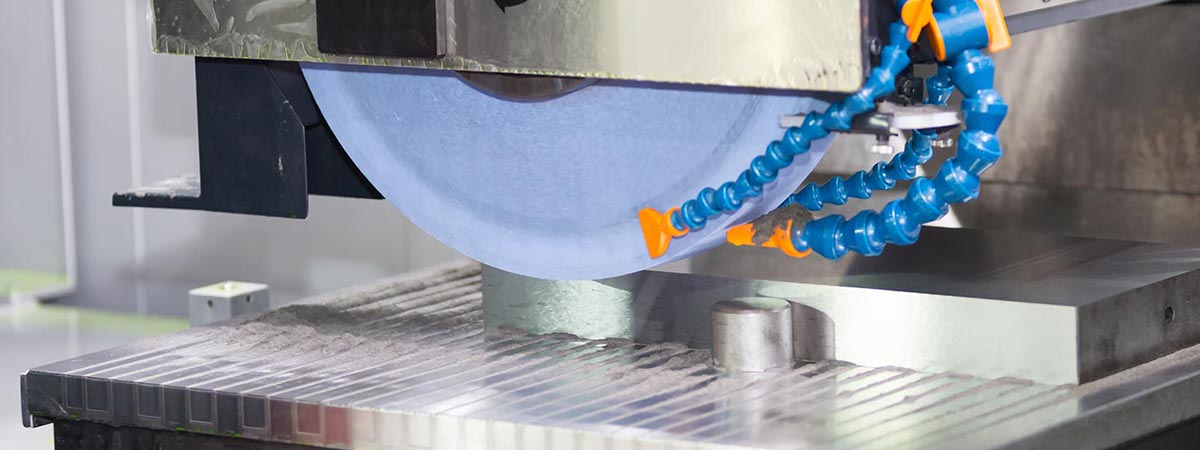

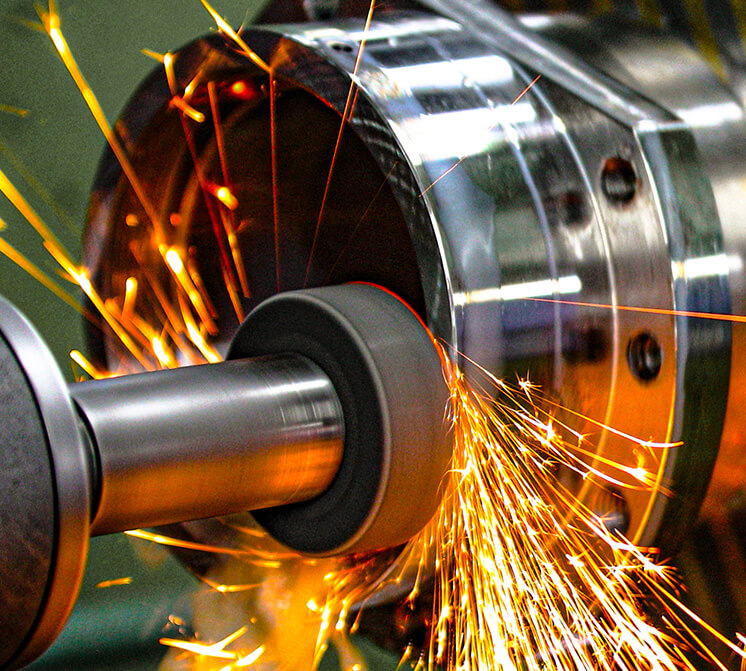

Honyo Prototype delivers advanced CNC grinding capabilities engineered to meet the stringent tolerances and surface finish requirements of aerospace, medical, and industrial components. Our multi-axis CNC grinding platforms utilize high-precision abrasive wheel technology to achieve sub-micron tolerances and Ra values as low as 0.05 μm, critical for functional surfaces in hydraulic systems, turbine blades, and surgical instruments. Unlike conventional milling, CNC grinding excels in hard materials like tool steels, Inconel, and ceramics where thermal stability and geometric accuracy are non-negotiable.

Our integrated manufacturing ecosystem combines state-of-the-art grinding centers with rigorous in-process metrology, ensuring first-article compliance to ISO 2768-mK and customer-specific GD&T callouts. Honyo’s engineering team collaborates directly with clients during DFM analysis to optimize grinding sequences, minimize cycle times, and eliminate secondary operations—reducing lead times by up to 30% without compromising repeatability. Material waste is systematically controlled through adaptive feed-rate algorithms and coolant management protocols, enhancing cost efficiency for low-volume, high-mix production.

Accelerate your prototyping and production timelines with Honyo’s Online Instant Quote system. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical and commercial assessment within 2 hours, including machine capability analysis, tolerance validation, and NRE cost breakdowns. This seamless digital workflow eliminates traditional RFQ bottlenecks while maintaining the engineering rigor expected from a Tier 1 supplier partner.

| Key Capability | Specification Range | Industry Application Example |

|---|---|---|

| Tolerance Control | ±0.0001″ (2.5 μm) | Aerospace fuel nozzles |

| Surface Finish (Ra) | 0.05–0.8 μm | Medical implant surfaces |

| Max Work Envelope | 24″ x 18″ x 12″ | Hydraulic valve bodies |

| Material Hardness Range | Up to 70 HRC | Mold and die components |

Honyo Prototype’s CNC grinding services merge metrology-grade precision with scalable production readiness, providing the technical foundation for mission-critical components where failure is not an option. Initiate your project with confidence through our validated quoting platform—engineered for engineers.

Technical Capabilities

Technical specifications for CNC machine grinding operations—particularly in the context of high-precision 3, 4, and 5-axis milling and turning—encompass a range of capabilities essential for achieving tight tolerances across diverse engineering materials such as aluminum, steel, ABS, and nylon. These machines are engineered for complex geometry machining with micron-level accuracy and fine surface finishes.

Key Technical Parameters for High-Precision CNC Milling and Turning (Including Grinding-Capable Systems)

| Parameter | Specification/Detail |

|---|---|

| Axes Configuration | 3-axis (X, Y, Z), 4-axis (includes A or B rotary), 5-axis (dual rotary: A-B or B-C) |

| Positioning Accuracy | ±0.002 mm (±0.00008″) |

| Repeatability | ±0.001 mm (±0.00004″) |

| Typical Tolerance Range | ±0.005 mm to ±0.025 mm (±0.0002″ to ±0.001″), depending on geometry and material |

| Surface Finish (Ra) | 0.4 μm to 1.6 μm (16 μin to 63 μin); grinding capable systems achieve <0.2 μm (8 μin) |

| Spindle Speed (Milling) | 8,000 – 40,000 RPM (high-speed spindles for precision finishing and grinding) |

| Spindle Taper | HSK-E25, HSK-F63, or BT30/BT40 for rigidity and precision |

| Tool Changer Capacity | 12 – 40 tools (ATC) with automatic tool length and diameter measurement |

| Control System | Fanuc, Siemens, or Heidenhain with 5-axis interpolation and adaptive control |

| Linear Axis Resolution | 0.001 mm (0.00004″) or finer |

| Coolant System | High-pressure through-spindle coolant; optional mist or cryogenic for plastics |

| Work Envelope (Typical) | 500 x 400 x 300 mm (20″ x 16″ x 12″), scalable to larger beds for 5-axis systems |

| Materials Processed | Aluminum (6061, 7075), Steel (4140, 17-4PH, tool steels), ABS, Nylon (6 & 66) |

| Material-Specific Notes | Aluminum: High feed rates, coolant critical. Steel: Lower speeds, rigid setup. ABS/Nylon: Sharp tools, reduced heat input, minimal clamping force to prevent deformation. |

| Grinding Capability | Optional integrated grinding spindle or hybrid milling-grinding head (up to 60,000 RPM), enabling fine finishes on hardened steels and precision molds |

| Applications | Aerospace components, medical implants, mold & die, precision fixtures, prototypes |

These specifications reflect the capabilities required at Honyo Prototype for delivering high-integrity parts under tight tolerance regimes. The integration of multi-axis motion with grinding functionality allows for finishing operations without part re-fixturing, ensuring geometric accuracy and surface quality across both metallic and engineering polymer substrates.

From CAD to Part: The Process

Honyo Prototype executes CNC machine grinding with a rigorously defined workflow optimized for precision components requiring tight tolerances and superior surface finishes. Our process begins when a client uploads a CAD model to our secure portal, initiating a structured sequence that ensures manufacturability and quality.

Upon CAD upload, our proprietary AI quoting engine analyzes geometric complexity, material specifications, and dimensional requirements. This system cross-references real-time machine availability, tooling costs, and historical production data to generate an accurate quote within 2 hours, including explicit tolerance validation against grinding capabilities. The AI specifically flags features requiring creep-feed grinding, centerless operations, or non-standard wheel specifications.

The Design for Manufacturability (DFM) phase follows quote acceptance, where our engineering team conducts a granular review focused on grinding-specific constraints. Key parameters evaluated include:

| DFM Parameter | Grinding-Specific Threshold | Action if Exceeded |

|---|---|---|

| Surface Roughness (Ra) | < 0.05 µm achievable | Recommends alternative finishing |

| Tolerance (±) | < 0.0002″ standard | Proposes tolerance relaxation |

| Feature Accessibility | Wheel clearance ≥ 1.5x depth | Suggests fixture redesign |

| Thermal Sensitivity | Material-specific limits | Adjusts feed rate strategy |

During production, grinding occurs on Makino G7 and Studer S41 machines with in-process gauging. Each setup includes laser-calibrated wheel truing, coolant filtration verification to 5-micron purity, and thermal drift compensation cycles. Critical dimensions undergo 100% inspection via Zeiss Coordinate Measuring Machines with surface profilometry, with data logged to our digital twin system.

Final delivery incorporates mil-spec packaging with desiccant and vibration monitoring labels. All grinding artifacts ship with a traceability dossier including as-built metrology reports, wheel specification logs, and coolant analysis certificates. Typical lead time from CAD upload to delivery is 7-10 business days for quantities under 50 pieces, with expedited 72-hour options for qualifying geometries. This integrated workflow consistently achieves ±0.0001″ geometric tolerances and Ra 0.025 µm surface finishes across materials from hardened tool steels to exotic alloys.

Start Your Project

For high-precision CNC machine grinding services, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen delivers tight-tolerance components with consistent quality and fast turnaround.

We specialize in CNC grinding for prototyping and low-volume production across aerospace, medical, and industrial sectors.

Reach out today to request a quote or discuss your project specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.