Contents

Manufacturing Insight: Cnc Machine G Code

Precision Engineering Through Optimized G Code Execution

At Honyo Prototype, our CNC machining services transform complex engineering designs into high-integrity components by leveraging deep expertise in G code generation and optimization. G code—the fundamental language driving CNC machinery—is not merely interpreted at Honyo; it is meticulously engineered to maximize precision, efficiency, and repeatability across every project. Our senior manufacturing engineers apply advanced parametric programming techniques, rigorous validation protocols, and real-time machine calibration to ensure each line of G code delivers uncompromised part accuracy, even for geometries demanding sub-micron tolerances or challenging multi-axis operations.

This technical mastery extends across our full-spectrum CNC capabilities, including 3-axis, 5-axis milling, precision turning, and multi-tasking platforms, all supported by material-agnostic expertise in aerospace alloys, medical-grade polymers, and exotic composites. By controlling the entire G code workflow in-house—from CAM simulation to spindle-load-optimized toolpaths—we eliminate third-party translation errors and accelerate time-to-part without sacrificing quality.

Accelerate your prototyping or low-volume production timeline with Honyo’s Online Instant Quote system. Input your part specifications and receive a validated manufacturing assessment with lead time and pricing transparency within minutes—no manual RFQ delays. Our G code-driven precision starts with your first upload.

Request Your Quote Today at honyoprototype.com/quote.

Technical Capabilities

CNC Machine G-Code Technical Specifications for 3/4/5-Axis Milling and Turning – Focus on Tight Tolerance Applications

G-code is the standardized programming language used to control CNC (Computer Numerical Control) machines. It dictates tool paths, spindle speeds, feed rates, coolant activation, and axis movements. The complexity and precision of G-code vary significantly depending on the machine configuration (3, 4, or 5-axis), operation type (milling or turning), and required tolerances. The following table outlines key technical parameters relevant to high-precision machining of common engineering materials.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Axis Configuration | X, Y, Z | X, Y, Z + Rotary (A or B) | X, Y, Z + Two Rotary (A/B or B/C) | X, Z (primary), sometimes C-axis | 5-axis allows simultaneous movement in all five axes for complex contours |

| Typical Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | High-end machines achieve ±0.001 mm with laser calibration |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm | Critical for tight-tolerance batch production |

| Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 20,000 RPM | 10,000 – 30,000 RPM | 1,500 – 6,000 RPM (aluminum) | Higher speeds for aluminum and plastics; lower for steel |

| Feed Rate (Max) | 10,000 mm/min | 8,000 mm/min | 6,000 mm/min (simultaneous) | 5,000 mm/min | 5-axis feed rates depend on tool engagement and interpolation |

| Tolerance Capability | ±0.01 mm (standard) to ±0.005 mm | ±0.01 mm to ±0.005 mm | ±0.005 mm to ±0.002 mm | ±0.005 mm (diameter) | Achievable with proper fixturing, tooling, and thermal stability |

| Surface Finish (Typical) | 0.8 – 3.2 µm Ra | 0.8 – 1.6 µm Ra | 0.4 – 1.6 µm Ra | 0.8 – 1.6 µm Ra | Finishing passes in 5-axis improve surface quality |

| Common G-Codes | G00, G01, G02/G03, G17, G20/G21 | G00–G03, G43, G54–G59, G10 | G00–G03, G43.4, G68.2, G10 | G00, G01, G71, G76, G90, G94 | G68.2 enables 5-axis coordinate rotation; G71/G76 for turning cycles |

| Material – Aluminum (6061, 7075) | High feed, 12,000–18,000 RPM | Moderate feed, indexed rotation | High precision tool paths | 3,000–5,000 RPM, sharp carbide | Low cutting forces; requires chip evacuation control |

| Material – Steel (4140, 1045) | Lower feed, 6,000–10,000 RPM | High rigidity, reduced overhang | High-torque spindles, pecking | 600–1,200 RPM, coolant essential | Tight tolerances require tool wear compensation |

| Material – ABS | High-speed, low engagement | Limited heat buildup | Shallow depth cuts, cooling | Not typically turned | Tolerances ±0.05 mm typical; sensitive to melting |

| Material – Nylon (PA6, PA66) | Low RPM, sharp tools, no coolant | Minimal clamping pressure | Smooth tool paths | Feasible with chip control | Hygroscopic; pre-dry recommended; tolerances ±0.05 mm achievable |

| Thermal Compensation | Recommended | Required | Essential | Required | Critical for sub-±0.005 mm tolerances over long cycles |

| Tooling Requirements | Carbide end mills, HSS optional | Indexed rotary-compatible tools | High-precision ball/square end | Carbide inserts, wipers | Tool length offset (G43) and wear compensation (G10) essential |

Notes on Tight Tolerance Machining:

Machine calibration, vibration damping, and environmental control (temperature/humidity) are critical for tolerances below ±0.005 mm.

5-axis CNC systems reduce setup次数 and improve accuracy by minimizing re-fixturing.

In turning, sub-micron tolerances on concentricity and runout require live tooling and C-axis control for milling operations.

Materials like nylon and ABS require specialized toolpaths to avoid deformation; G-code should include reduced feed and no dwell times.

This specification guide supports precision manufacturing workflows at Honyo Prototype for aerospace, medical, and industrial clients requiring high repeatability and tight geometric tolerances.

From CAD to Part: The Process

Honyo Prototype CNC Manufacturing Process: From CAD to Delivery

Honyo Prototype employs a streamlined, technology-driven workflow for CNC machining projects, ensuring precision, efficiency, and rapid turnaround. The process begins with secure CAD file submission and culminates in certified part delivery, with integrated quality checks at every phase. Below is a technical overview of each stage.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) via Honyo’s encrypted online portal. Our system automatically validates file integrity, units, and geometry completeness. Critical dimensions, tolerances, and material specifications defined in the CAD model are parsed for downstream processing. Unsupported formats or incomplete metadata trigger immediate client notification for correction, preventing downstream delays.

AI-Powered Quoting

Uploaded CAD data feeds into Honyo’s proprietary AI quoting engine, which performs real-time manufacturability analysis and cost estimation. The AI evaluates geometric complexity, feature density, material utilization, and machine time requirements against our live database of machine capabilities, material costs, and labor rates. Within minutes, clients receive a detailed quote including:

Estimated machining hours

Material cost breakdown

Secondary operation recommendations (e.g., tapping, deburring)

Risk flags for challenging geometries

This stage reduces quoting time by 90% compared to manual methods while maintaining >95% accuracy through continuous AI training on historical production data. Human engineers review high-risk or complex projects before final quote approval.

DFM Analysis and Optimization

All projects undergo rigorous Design for Manufacturability (DFM) review by Honyo’s engineering team. Using CAM-integrated simulation tools (Mastercam, Fusion 360), we analyze:

Tool accessibility and collision risks

Optimal stock size and fixturing requirements

Wall thicknesses below 0.5mm or aspect ratios exceeding 10:1

Surface finish inconsistencies relative to specified tolerances

Clients receive a formal DFM report within 4 business hours, highlighting actionable modifications to reduce cost or lead time. Common recommendations include adjusting radii for standard tooling, consolidating features to minimize setups, or material substitutions. Client approval of DFM suggestions is required before G-code generation.

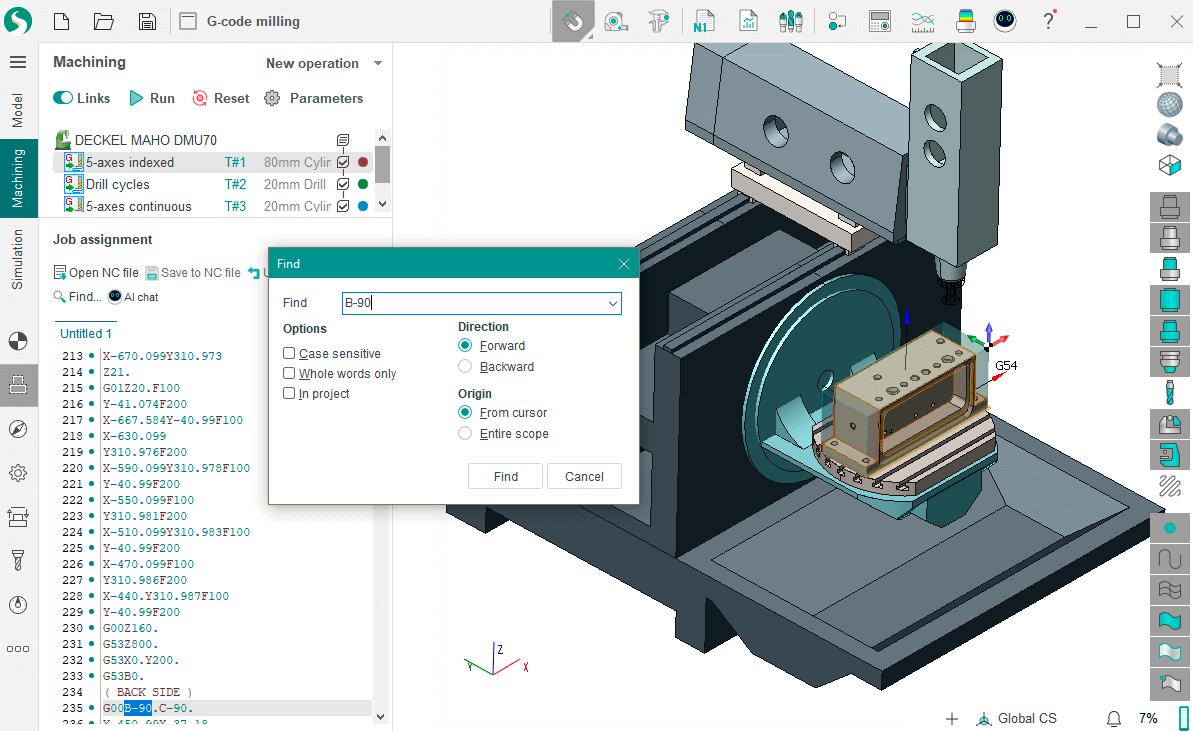

Production: G-Code Generation and Machining

Upon DFM sign-off, our CAM team generates optimized G-code using machine-specific post-processors calibrated for Honyo’s CNC inventory (DMG MORI, Haas, Makino). Critical steps include:

Toolpath simulation in Vericut to eliminate collisions and verify tolerances

Adaptive clearing strategies to maximize material removal rates

In-process probing routines for automated work offset verification

Integration of custom macros for recurring features (e.g., threaded inserts)

G-code is validated against the original CAD model using deviation analysis software, ensuring positional accuracy within ±0.005mm. Production occurs in climate-controlled cells with real-time machine monitoring; first-article inspection data is shared before full batch execution.

Delivery and Documentation

Finished parts undergo final CMM inspection per AS9100 standards, with full traceability to material certs and process parameters. Clients receive:

Dimensional inspection report (PDF/Excel)

Material certification (e.g., EN AW-6082 T6)

Digital twin of the as-machined part (optional)

Shipping documentation with real-time logistics tracking

Standard lead times range from 5–15 business days depending on complexity, with expedited options available. All deliverables are accessible via Honyo’s client portal, including archived G-code and tooling records for future revisions.

Material and Tolerance Capabilities

Honyo supports the following common materials and tolerances in CNC production:

| Material Category | Examples | Standard Tolerance (mm) | Max Feature Size (mm) |

|---|---|---|---|

| Aluminum Alloys | 6061-T6, 7075-T6 | ±0.025 | 1200 x 800 x 500 |

| Engineering Plastics | POM, PEEK, Nylon | ±0.05 | 1000 x 600 x 400 |

| Stainless Steel | 304, 316, 17-4PH | ±0.025 | 900 x 600 x 400 |

| Titanium | Grade 5 (Ti-6Al-4V) | ±0.05 | 700 x 500 x 300 |

This integrated process ensures Honyo delivers production-ready CNC components with minimized non-conformities and full technical transparency, directly supporting clients’ prototyping and low-volume production timelines.

Start Your Project

For expert CNC machining services with precision G code programming, contact Susan Leo at [email protected]. Our advanced manufacturing facility in Shenzhen ensures high-quality, efficient production for your prototyping and low-volume manufacturing needs. Reach out today to streamline your CNC machining requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.