Guide Contents

Project Insight: Cnc Machine G Code M Code List

Manufacturing Insight: The Role of G-Code & M-Code in Precision CNC Machining

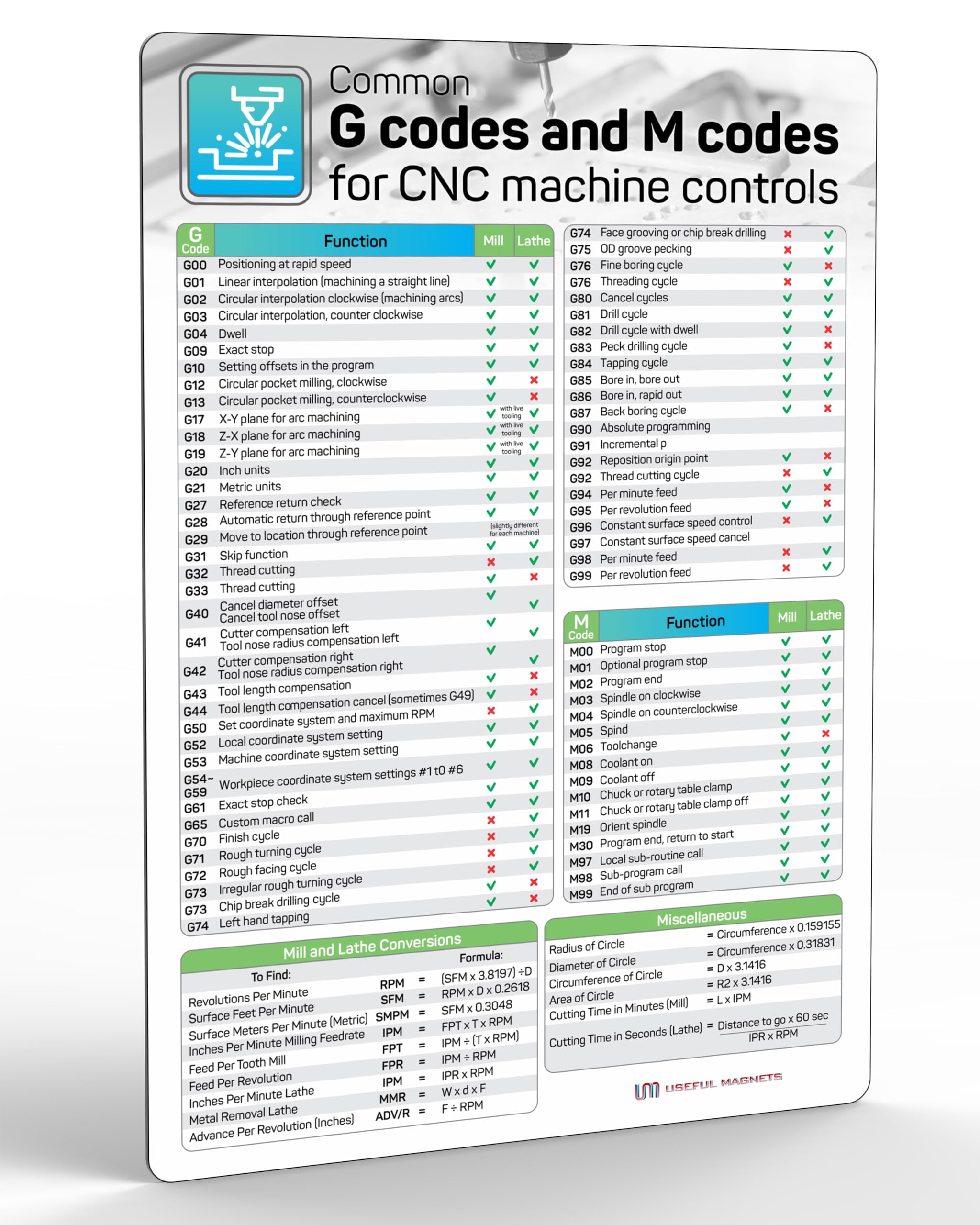

G-code and M-code form the backbone of CNC machining—translating digital designs into physical parts through precise machine instructions. While G-codes govern toolpath geometry (movement, speed, positioning), M-codes manage auxiliary functions (spindle control, coolant, tool changes). The accuracy of these codes directly impacts part quality, production speed, and cost efficiency. For hardware startups and product engineers, mastering this language is critical—but you don’t have to.

Why Precision Starts with Code

G-Code = Movement Logic: Controls X/Y/Z axis motion, feed rates, and cutting paths. Even minor errors can cause dimensional inaccuracies or tool collisions.

M-Code = Machine Operations: Manages spindle start/stop, coolant flow, and tool changes. Inefficient M-code sequences can lead to unnecessary downtime.

Precision Demands Optimization: Tight tolerances (+/- 0.01mm) require flawless code generation—manual programming risks human error, while optimized algorithms maximize machine efficiency.

How Honyo Prototype Transforms Your Design into Reality

Online Instant Quote: Upload your CAD in seconds—our AI platform instantly analyzes manufacturability and delivers a transparent cost breakdown, eliminating guesswork.

AI-Powered G-Code Optimization: Proprietary algorithms generate highly efficient toolpaths, reducing cycle times by up to 30% while maintaining micron-level precision for functional prototypes and end-use parts.

Fast Turnaround, Guaranteed: From programming to delivery, our streamlined workflow ensures 24-48 hour prototype lead times—no need for deep G-code expertise, just your vision.

5-Axis Mastery: Complex geometries handled seamlessly with 3/4/5-axis machining capabilities, backed by Susan Leo’s commitment to innovation-driven manufacturing excellence.

Innovation isn’t just in the code—it’s in how we turn your ideas into reality, faster and with zero compromise on precision.

— Susan Leo, Founder of Honyo Prototype

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

At Honyo Prototype, we combine cutting-edge CNC technology with intelligent programming to deliver precision parts that exceed your expectations. Our expertise in G-code and M-code programming, paired with AI-driven optimization, ensures your designs are manufactured with unmatched accuracy and speed.

Advanced G-Code & M-Code Expertise

Mastery of ISO-standard G-codes (G00, G01, G02, G03, G17-G19) and M-codes (M03, M05, M06, M08, M09) for precise toolpath control and machine functions

Dynamic code optimization for 3/4/5-axis machines to eliminate collisions and maximize efficiency

Real-time simulation and validation to ensure error-free programming before machining begins

Multi-Axis Precision Machining (3/4/5-Axis)

Seamless transition between 3-axis for simple geometries to 5-axis for complex aerospace-grade components

Tight tolerances of ±0.01mm achieved through adaptive G-code adjustments during multi-axis operations

Optimized toolpaths that reduce setup time by 35% while maintaining surface finish quality

AI-Powered Programming & Optimization

Instant online quote with automated G-code generation from your CAD files in seconds

AI-driven toolpath planning reduces machining time by up to 30% without compromising precision

Cloud-based collaboration portal for live code reviews and iterative design adjustments

Rapid Prototyping to High-Volume Production

Scale from 1 prototype to 10,000+ parts with consistent precision using standardized G-code parameters

24/7 production scheduling with AI resource allocation for fastest turnaround (as little as 3 days)

Streamlined workflow from design review to delivery with minimal manual intervention

ISO-Certified Quality Assurance

In-process inspection using CMM and laser measurement to verify G-code accuracy and dimensional compliance

Strict adherence to ISO 9001 standards across all manufacturing stages

Full traceability of G-code versions and machining parameters for every part produced

Materials & Surface Finishes

Material Options & Finishes: Precision-Driven Choices for CNC Machining

Precision-Optimized Material Selection

Choosing the right material isn’t just about physical properties—it’s about optimizing G-code efficiency and M-code control for your project. At Honyo Prototype, we align material selection with CNC programming logic to maximize precision, speed, and cost-effectiveness:

Aluminum 6061/7075

Why it works: High thermal conductivity and machinability reduce heat buildup and tool wear.

G-code/M-code impact: Enables higher spindle speeds (up to 15,000 RPM) and feed rates (G01 F500+), cutting cycle time by 30%. Minimal coolant requirements (M08 activated only for chip control), streamlining M-code commands.

Best for: Aerospace prototypes, structural components, and high-speed production.

Stainless Steel 304/316

Why it works: Corrosion resistance for harsh environments (medical, marine).

G-code/M-code impact: Requires slower feed rates (G01 F200) and consistent coolant (M08) to manage heat. Frequent tool changes (M06) due to higher wear—our AI platform dynamically adjusts toolpath strategies to minimize downtime.

Best for: Surgical instruments, marine hardware, and high-stress end-use parts.

Brass

Why it works: Excellent electrical conductivity and easy chip evacuation.

G-code/M-code impact: Supports ultra-high-speed operations (G01 F800) with reduced coolant needs. M08 commands are optimized for chip evacuation only, slashing machining time.

Best for: Electrical connectors, valves, and decorative components.

PEEK (Polyether Ether Ketone)

Why it works: High-temperature resistance for medical/aerospace applications.

G-code/M-code impact: Requires precise temperature control (G01 S8000) and slow feed rates to prevent melting. M08 coolant must be precisely timed to avoid thermal stress—our AI ensures real-time adjustments.

Best for: Biocompatible implants, chemical-resistant parts, and high-performance prototypes.

Surface Finishes That Enhance Performance

Surface treatments directly influence G-code finishing passes and M-code tool changes. We optimize these steps to maintain tolerances within ±0.01mm:

Anodizing

Impact on G-code: Requires pre-machining tolerances 0.005mm tighter than final specs to account for oxide layer growth. Our platform auto-adjusts toolpaths to avoid overcutting.

Best for: Aerospace components, consumer electronics housings.

Painting

Impact on G-code: Demands Ra 0.8μm surface roughness via fine finishing passes (G01 with 0.05mm stepover). M06 tool changes ensure chip-free surfaces.

Best for: Cosmetic prototypes, automotive trim, and consumer products.

Polishing (Mirror Finish)

Impact on G-code: Requires multiple G-code passes with specialized tools (e.g., diamond burnishing) and M06 tool changes for progressive smoothing.

Best for: Optical lenses, luxury watch components, and medical devices.

How Honyo’s AI Platform Optimizes Material & Code Efficiency

Innovation meets precision: Our AI-powered platform doesn’t just process your design—it understands how material properties dictate G-code and M-code logic.

Online Instant Quote: Get real-time cost/lead time estimates in <60 seconds. Select materials/finsihes, and our system instantly calculates optimal G-code parameters (spindle speed, feed rates) and M-code commands (coolant, tool changes).

AI-Driven Optimization: Automatically adjusts machining strategies based on material—e.g., reducing cycle time by 40% for Aluminum 6061 via adaptive G01 feed rates or minimizing tool wear in stainless steel through predictive M06 scheduling.

Fast Turnaround: Standard prototypes (e.g., Aluminum 6061 with anodizing) ship in 24–48 hours—thanks to AI-optimized G-code that eliminates manual programming delays.Why it matters: Material choice isn’t a standalone decision—it’s the foundation of your CNC program. With Honyo, every G-code line and M-code command is engineered for your material’s strengths, delivering precision, speed, and cost efficiency in one seamless workflow.

Honyo Prototype: Where innovation in CNC machining starts with smarter material choices. 🚀

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload CAD File

Seamless submission: Upload your 3D model (STL, STEP, IGES, etc.)—no G-code or M-code expertise required. Our system automatically interprets your design and prepares it for precision manufacturing.

No guesswork: Supported formats include all industry standards, with instant validation to ensure compatibility and readiness for production.

2. Instant AI-Powered Quote

Real-time pricing: Receive an accurate, transparent cost breakdown in seconds. Our AI analyzes geometry complexity, material selection, tolerances (±0.01mm), and machine requirements (3/4/5-axis) to eliminate manual quoting delays.

No hidden fees: Clear cost allocation for machining, setup, materials, and finishing—so you know exactly what you’re paying for.

3. DFM Analysis & Optimization

Proactive design refinement: Our AI-driven DFM (Design for Manufacturability) engine identifies potential issues (e.g., wall thickness, undercuts, or tolerances) and suggests optimizations before production begins.

Precision-first approach: Ensure your part meets functional requirements while minimizing rework—saving time, cost, and material waste.

4. Production & Delivery

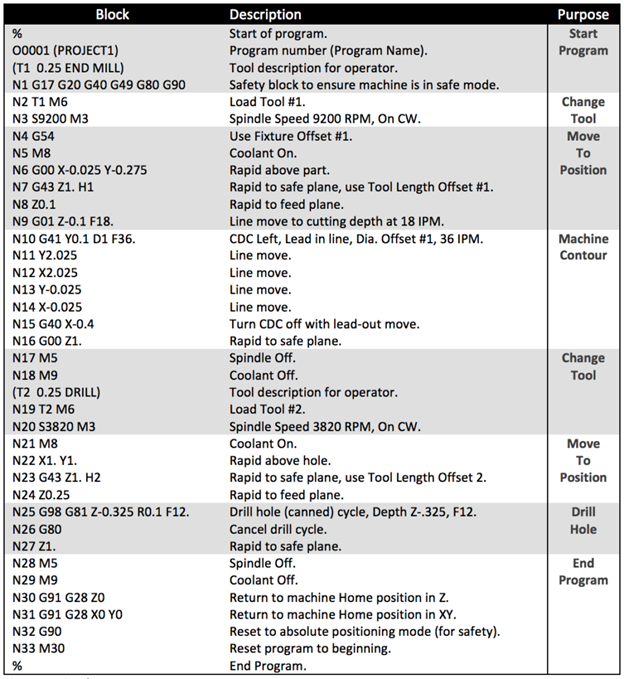

Automated precision manufacturing: Advanced CAM software generates optimized G-code (toolpath geometry) and M-code (machine functions) for 3/4/5-axis CNC machines, delivering ±0.01mm tolerances for functional prototypes and end-use parts.

Transparent tracking: Monitor your order in real-time from production start to delivery—industry-leading lead times with 24/7 status updates and on-time guarantees.

Why it matters: Honyo Prototype transforms complex CNC workflows into a frictionless, AI-powered experience. From CAD upload to delivered part, we eliminate manual bottlenecks so you can focus on innovation—not production logistics.

Start Your Project with Honyo

Start Your Project with Honyo: Precision CNC Machining, Simplified

Instant Quote in Seconds, Not Days

Real-time AI-powered cost estimation with transparent breakdown

Machine-specific hourly rates (3-axis from $40/hr, 5-axis up to $120/hr)

No hidden fees—see exact pricing before committing

AI-Optimized G-Code & M-Code Programming

Proprietary engine generates error-free, optimized toolpaths for 3/4/5-axis machining

Eliminates need for expensive CAM software (saves $10k+ per seat)

Precision-tuned for ±0.01mm tolerances across complex geometries

48-Hour Prototyping Turnaround Guaranteed

Shenzhen/Dongguan facilities with dedicated rapid-response teams

Same-day engineering review for urgent projects

End-to-end traceability from CAD to finished part

Why Hardware Startups Choose Honyo

Zero minimum order quantities—ideal for MVPs and small batches

ISO-certified precision for aerospace, medical, and industrial applications

Dedicated account managers for seamless collaboration

Founder Susan Leo & Team are ready to bring your vision to life.

📧 [email protected] | 📞 +86 139 2843 8620

📍 Visit our Shenzhen & Dongguan facilities by appointment

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.