Guide Contents

Project Insight: Cnc Machine G Code

Mastering Speed & Precision: The Critical Role of G-Code in Modern Manufacturing

Why G-Code is the Backbone of Precision Manufacturing

Precision starts with code: G-code directly dictates toolpath accuracy, surface finish, and dimensional tolerance. A single misplaced command can compromise the entire part.

Speed isn’t just about RPM—it’s about optimized motion planning: Inefficient G-code inflates cycle times, turning even high-end machines into cost drains.

Honyo’s AI-driven G-code generation eliminates manual errors and optimizes feed rates, spindle speeds, and toolpaths for maximum throughput—without sacrificing tight tolerances (±0.01mm).

How Honyo Prototype Accelerates Your Product Development

Online Instant Quote: Get real-time pricing in seconds—no manual estimates or delays. Our platform instantly analyzes your CAD file, factoring in material, tolerances, and machine requirements to deliver transparent, no-hidden-fee quotes.

AI-Powered Platform: Proprietary algorithms generate and simulate G-code with predictive error detection, reducing scrap rates by up to 40% and ensuring first-time-right production.

Fast Turnaround: From quote to delivery in 3–5 days for prototypes. Our automated workflow cuts traditional lead times by 50% through seamless digital integration—from design to finished part.

Why Precision & Speed Matter More Than You Think

For hardware startups: Faster iterations mean quicker market validation. A 24-hour quote and 3-day delivery can accelerate your MVP testing cycle by weeks—critical for securing funding or catching market trends.

For product engineers: Tight tolerances (+/- 0.01mm) with optimized G-code ensure functional prototypes behave exactly like final parts—no guesswork in assembly or performance testing.

For procurement managers: Lower total cost of ownership. Even with premium 5-axis rates ($75–$120/hr), our optimization reduces actual machine time by 25–30%, delivering true value without compromising quality.

At Honyo Prototype, we don’t just machine parts—we engineer solutions.

Let our digital manufacturing platform turn your vision into reality, faster and with unmatched precision.

Powered by Susan Leo’s vision for innovation-driven manufacturing.

Honyo Capabilities & Technology

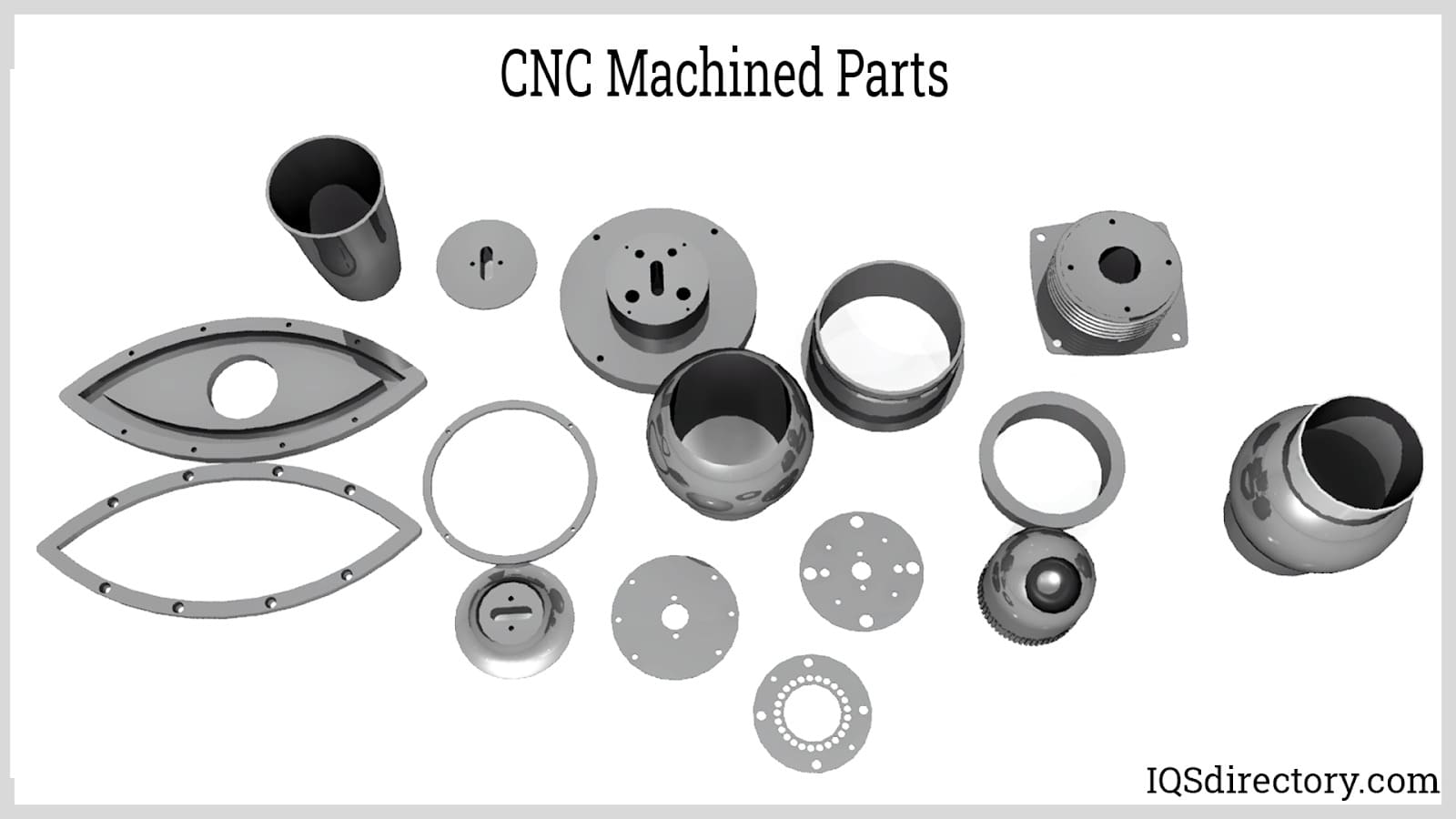

Precision CNC Machining Capabilities

Multi-Axis Precision Engineering

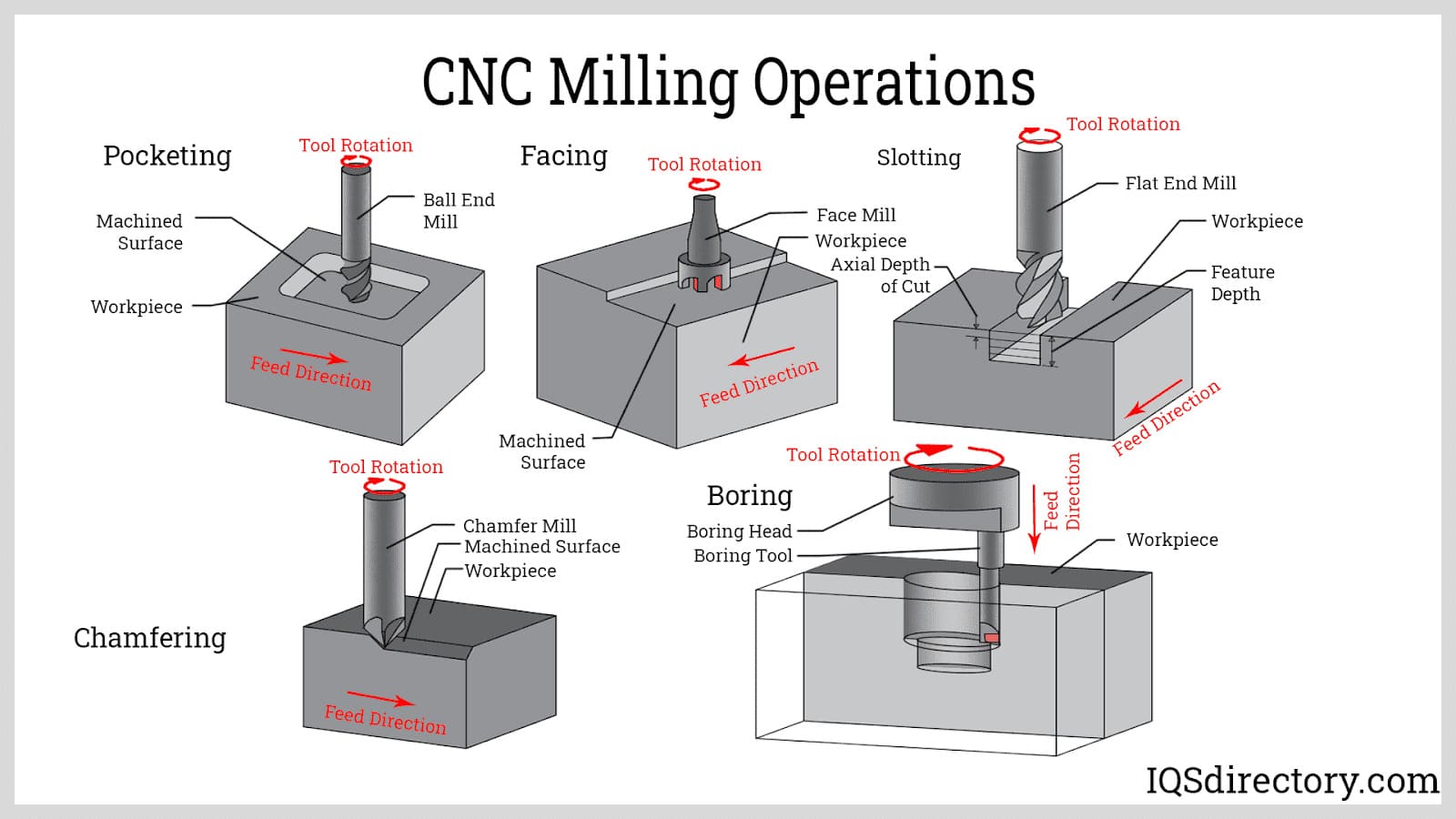

Advanced 3/4/5-axis machining for complex geometries with single-setup precision, eliminating secondary operations and cumulative errors.

Consistent ±0.01mm tolerances across all axes, critical for functional prototypes and end-use parts in aerospace, medical, and industrial applications.

Capability to machine intricate features like undercuts, angled surfaces, and complex contours in a single operation—no compromise on complexity or accuracy.

Rigorous Quality Assurance

ISO 9001-certified processes with in-process inspections and final QA reports for full traceability.

Advanced metrology tools (CMM, optical scanners) verify ±0.01mm tolerances on every part, ensuring functionality for mission-critical applications.

Statistical process control (SPC) and first-article inspections (FAI) maintain consistency at scale—quality you can trust from prototype to production.

Smart Manufacturing Ecosystem

Online Instant Quote Platform: Get precise cost estimates in seconds via our web-based portal, with transparent breakdowns for materials, machining time, and finishing options.

AI-Powered G-Code Optimization: Proprietary algorithms generate highly efficient toolpaths, reducing cycle times by up to 30% while maintaining ±0.01mm tolerances—no wasted material, no rework.

Fast Turnaround Guarantee: Expedited production schedules with 24-72 hour prototype delivery, supported by ISO-certified quality control and real-time progress tracking.

Scalable Production from Prototype to Volume

Seamlessly transition from 1 prototype to 10,000+ production parts without retooling or setup changes—scale with your innovation.

Dedicated production lines for high-volume orders, ensuring consistent quality and timely delivery even for complex geometries.

Rapid iteration support for design changes, enabling startups to refine products quickly without delays—agile manufacturing for fast-moving innovation.

“At Honyo Prototype, we don’t just machine parts—we engineer solutions that accelerate your product development cycle. Our AI-driven platform turns complexity into simplicity, so you can focus on innovation, not logistics.”

— Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes for Precision CNC Machining

At Honyo Prototype, we know that material selection is the foundation of precision CNC machining. Your choice directly impacts part functionality, manufacturability, and cost—especially when translating designs into optimized G-code. With our 3/4/5-axis capabilities and ±0.01mm tolerances, we help you navigate material options to achieve flawless results every time.

Key Material Choices for CNC Machining

Aluminum 6061: Optimal balance of strength, weight, and machinability. Ideal for functional prototypes and structural components. Excellent corrosion resistance and compatibility with anodizing for quick turnaround.

Aluminum 7075: Aerospace-grade strength with high stress tolerance. Requires slower feed rates but our AI-optimized G-code minimizes cycle time and tool wear.

Stainless Steel 304: Reliable corrosion resistance for medical and food industry parts. Our 5-axis machining ensures precision despite higher hardness.

Stainless Steel 316: Superior marine/chemical resistance. Automatically adjusted parameters maintain ±0.01mm tolerances in aggressive environments.

Brass: High electrical conductivity and aesthetic appeal. Minimal tool wear enables fast, cost-effective production for connectors and decorative parts.

PEEK: Exceptional thermal stability and biocompatibility. AI-monitored thermal control prevents warping during machining for aerospace/medical applications.

Surface Finish Options & Benefits

Anodizing (Type II/III): Enhances aluminum corrosion resistance and aesthetics with color options. Perfect for visible prototypes requiring durability.

Passivation: Removes surface contaminants from stainless steel, boosting corrosion resistance without dimensional changes—critical for medical devices.

Powder Coating: Durable, scratch-resistant finish for aluminum/steel. Wide color range for consumer products needing both protection and style.

Bead Blasting: Uniform matte texture to hide machining marks. Ideal for professional-looking aluminum and stainless steel components.

Electropolishing: Electrochemical smoothing for stainless steel. Enhances corrosion resistance and surface finish for surgical instruments and cleanroom applications.

How to Choose the Right Material for Your CNC G-Code Project

Mechanical Requirements: Match material properties to functional needs—e.g., 7075 aluminum for high-stress aerospace parts, 316 SS for marine exposure.

Machinability & Cost Efficiency: Softer materials like 6061 aluminum reduce machining time and tooling costs. Harder alloys require AI-optimized G-code for efficiency.

Surface Finish Compatibility: Anodizing works only on aluminum; stainless steel needs passivation or electropolishing for optimal performance.

Environmental Factors: PEEK’s thermal stability is essential for high-heat applications, but requires precise temperature control during machining—our AI handles this automatically.

Accelerate Your Project with Honyo’s Smart Manufacturing Platform

✅ Online Instant Quote: Get real-time pricing for any material or finish combination in seconds—no waiting, no guesswork.

🚀 AI-Powered Optimization: Our machine learning algorithms analyze your design files to recommend the most efficient material and surface finish, reducing machining time and costs by up to 25%.

⏱️ Fast Turnaround: Leverage our Shenzhen-based facility with 24/7 production scheduling for prototypes in 3-5 days and production runs in 7-10 days.

Ready to optimize your design for precision manufacturing? Upload your CAD file today and receive an AI-generated cost breakdown within 60 seconds.

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve reimagined CNC machining through an AI-powered workflow that turns your design into a precision part in record time. No more waiting for quotes or guessing about manufacturability — our platform delivers instant insights, transparent pricing, and accelerated production cycles. Here’s how it works:

Upload Your CAD File: Simple, Secure, Instant

Seamless cloud-based submission for any standard format (STEP, STL, IGES, DWG) — no file size limits or technical hurdles.

Military-grade encryption ensures your intellectual property stays protected from upload to delivery.

Zero setup time — start your project in seconds, not days.

AI-Powered Instant Quote: Transparency in Seconds

60-second pricing breakdown with zero hidden fees — see exactly what you’re paying for (material, machine hours, setup, finishing).

Dynamic cost optimization: Our AI calculates optimal toolpaths and machining strategies for your design’s complexity, leveraging our 3/4/5-axis capabilities and ±0.01mm tolerances.

Real-time adjustments for material choices, tolerances, and geometry — no manual calculations, no delays.

DFM Analysis: Design for Precision from the Start

Automated manufacturability checks identify potential issues (e.g., thin walls, undercuts, draft angles) before production begins.

Smart design suggestions to reduce costs, improve tolerances, and accelerate time-to-market — all integrated directly into your quote.

Eliminate redesign cycles with proactive engineering feedback from Honyo’s precision-focused algorithms.

Precision Production & Delivery: Fast, Reliable, Traceable

Shenzhen-based 3/4/5-axis CNC facilities with ±0.01mm tolerances — perfect for functional prototypes and end-use parts.

Rapid turnaround: Prototypes in as little as 24 hours, with scalable production for volume orders.

End-to-end tracking: Real-time production updates and delivery ETA via your Honyo dashboard — from machine to your doorstep.

Rigorous quality control at every stage, backed by Susan Leo’s commitment to excellence.

Why it matters: Traditional CNC quoting takes days. Ours is instant. Traditional DFM requires manual reviews. Ours is automated. Traditional production waits weeks. Ours is accelerated. At Honyo, we turn complexity into clarity — so you ship faster, spend smarter, and build better.

Start Your Project with Honyo

Start Your Project with Honyo

Precision CNC Machining, Engineered for Innovation

AI-Powered Instant Quote: Upload your CAD file and receive real-time pricing and lead times in seconds—no more manual quotes or waiting days for estimates. Our platform optimizes costs while maintaining ±0.01mm tolerances for functional prototypes and end-use parts.

Fast Turnaround, Guaranteed: From design to delivery in as little as 3 days. Our Shenzhen facility ensures seamless global shipping with minimal delays—perfect for agile hardware startups and urgent prototyping needs.

3/4/5-Axis Expertise: Complex geometries? No problem. Our advanced machining capabilities handle intricate designs with unmatched precision, delivering parts that meet exact specifications for aerospace, medical, and consumer tech applications.

Why Partner with Honyo?

Founder-Led Precision: Susan Leo and our engineering team bring decades of hands-on experience to every project, ensuring innovative solutions and meticulous attention to detail from concept to completion.

Transparent, Scalable Pricing: No hidden fees. Our platform provides clear, itemized costs upfront—so you can budget confidently for prototypes or high-volume production runs without compromise.

Global Support, Local Expertise: With facilities in Shenzhen and Dongguan, we offer on-site collaboration, rapid response times, and end-to-end support for clients worldwide.

Ready to Build the Future?

Contact us today to start your project:

📧 Email: [email protected]

📞 Phone: +86 139 2843 8620

🏭 Visit us: Explore our state-of-the-art Shenzhen and Dongguan facilities by appointment.

Let’s turn your ideas into reality—precision-engineered, on time, and within budget.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.