Contents

Manufacturing Insight: Cnc Machine For Automotive Industry

Precision CNC Machining Solutions Engineered for Automotive Excellence

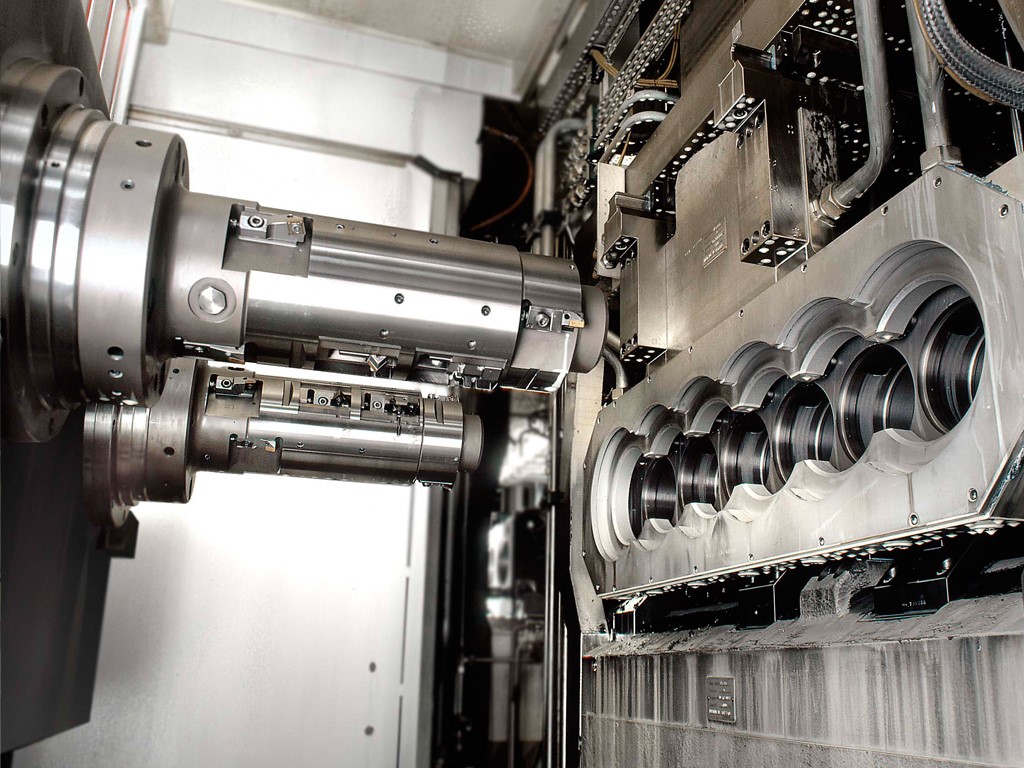

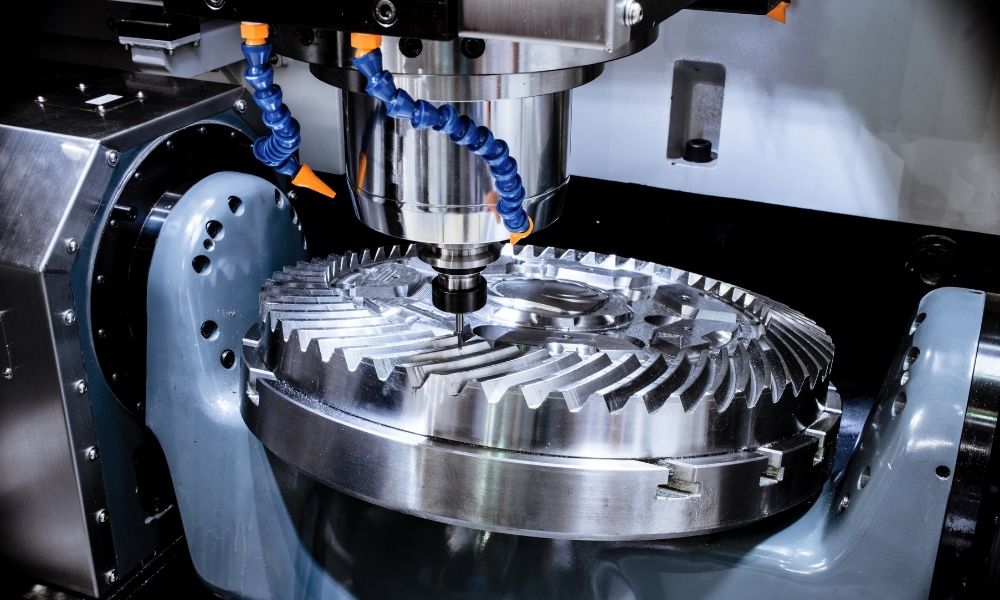

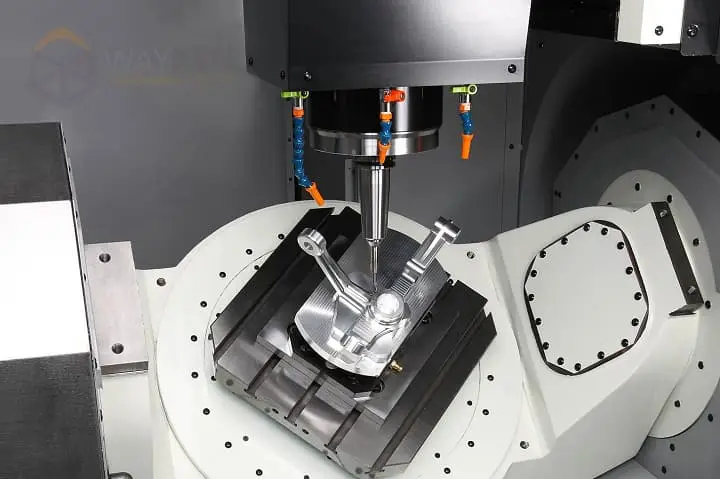

Honyo Prototype delivers mission-critical CNC machining services tailored to the rigorous demands of the automotive industry. Modern vehicle manufacturing requires components that adhere to exacting geometric tolerances, material specifications, and production scalability—whether for prototyping next-generation powertrain systems, producing low-volume specialty parts, or supporting high-mix production runs. Our advanced 3-, 4-, and 5-axis CNC machining centers, coupled with stringent quality control protocols, ensure consistent repeatability down to ±0.005 mm. This precision is non-negotiable for safety-critical applications such as engine blocks, transmission housings, suspension components, and EV battery enclosures, where dimensional integrity directly impacts vehicle performance and regulatory compliance.

We understand automotive suppliers operate under compressed timelines and complex supply chain pressures. Honyo’s integrated manufacturing ecosystem addresses this through rapid prototyping capabilities, in-house first-article inspection (FAI), and full PPAP documentation support. Our engineering team collaborates directly with OEMs and Tier 1–2 partners to optimize part designs for manufacturability, reducing lead times without compromising on the metallurgical or surface-finish requirements essential for automotive applications. Material expertise spans aerospace-grade aluminum alloys, hardened steels, titanium, and composite blends, all processed under ISO 9001-certified workflows with real-time SPC monitoring.

For immediate project assessment, leverage Honyo’s Online Instant Quote platform. Upload CAD files (STEP, IGES, SolidWorks) to receive a detailed, no-obligation cost analysis within hours—not days—including DFM feedback, material sourcing options, and accelerated lead-time pathways. This digital workflow eliminates procurement bottlenecks, allowing engineering teams to validate budgets and schedules during the earliest design phases.

Typical Automotive Applications and Capabilities

| Component Category | Tolerance Range | Common Materials | Key Processes |

|---|---|---|---|

| Powertrain Systems | ±0.005 mm – ±0.02 mm | 4140 Steel, 7075-T6 Aluminum | 5-axis milling, Boring |

| Chassis & Suspension | ±0.01 mm – ±0.05 mm | Forged 4340, Magnesium Alloys | Precision turning, Milling |

| EV Battery Components | ±0.008 mm – ±0.03 mm | 6061-T6, 5052 Aluminum | High-speed milling, Deburring |

| Transmission Assemblies | ±0.003 mm – ±0.01 mm | 8620 Steel, Brass | Multi-axis machining, Honing |

Accelerate your automotive development cycle with Honyo’s blend of technical precision, material science proficiency, and digital procurement efficiency. Initiate your project with confidence using our Online Instant Quote system—designed for engineers who demand speed without sacrificing accuracy.

Technical Capabilities

CNC Machine Technical Specifications for Automotive Industry Applications

The following table outlines the key technical specifications for CNC machines tailored to the automotive industry, with emphasis on high-precision 3-axis, 4-axis, and 5-axis milling, turning operations, and the capability to maintain tight tolerances. These machines are optimized for processing common automotive materials such as aluminum, steel, ABS, and nylon.

| Parameter | Specification Description |

|---|---|

| Machine Type | 3-Axis, 4-Axis, and 5-Axis CNC Milling Centers; CNC Turning Centers (Swiss and Mill-Turn) |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Tolerance Capability | ±0.01 mm (±0.0004 in) for standard features; up to ±0.005 mm with fine finishing cycles |

| Spindle Speed Range | 8,000 – 42,000 RPM (high-speed spindles for aluminum and plastics); 6,000 – 12,000 RPM for steel |

| Spindle Power | 15 – 50 kW depending on machine class and material requirements |

| Axis Travel (Typical) | X: 500–1200 mm, Y: 400–900 mm, Z: 350–600 mm; 4th/5th axis rotary range: ±360° (A/C axes) |

| Tool Changer Capacity | 24 – 60 tools (ATC – Automatic Tool Changer) with tool length measurement |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7xx with 5-axis interpolation and look-ahead |

| Materials Processed | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 303/316), ABS, Nylon (PA6, PA66) |

| Coolant System | High-pressure through-spindle coolant (up to 70 bar) for steel; mist cooling for plastics |

| Work Envelope Flexibility | Pallet pooling systems (2–6 pallets) with automation interface for high-volume production |

| Surface Finish Capability | Ra < 0.8 µm (32 µin) achievable with fine milling; < 1.6 µm for turned steel components |

| Dynamic Performance | Rapid traverse rates up to 60 m/min; acceleration up to 1.0 g for high-efficiency machining |

| Thermal Compensation | Standard with real-time spindle and ambient temperature monitoring |

| Probing Systems | On-machine touch probes for in-process inspection and tool setting |

These CNC systems are engineered for automotive applications requiring complex geometries (e.g., engine blocks, transmission cases, suspension components, and prototype molds), where multi-axis capability and micron-level precision are critical. The machines support both high-volume production and low-volume prototyping, with optimized parameters for lightweight materials like aluminum and engineering plastics (ABS, nylon), as well as high-strength steels.

From CAD to Part: The Process

Honyo Prototype Automotive CNC Machining Process Overview

Honyo Prototype delivers precision CNC-machined components for the automotive industry through a rigorously defined workflow designed to ensure quality, compliance, and rapid turnaround. Our process integrates advanced digital tools with deep manufacturing expertise to meet stringent automotive standards including ISO/TS 16949, PPAP, and GD&T requirements.

CAD Upload & Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. Automotive-specific validation checks immediately verify geometric integrity, material specifications, and tolerance alignment with common automotive alloys (e.g., 6061-T6, 7075-T7351, EN AC-43000). Critical parameters such as draft angles for cast-to-machined transitions and weld prep geometries are flagged for early review.

AI-Powered Quoting Engine

Our proprietary AI engine analyzes the validated CAD model to generate an instant technical and commercial quote within 4 hours. The system cross-references real-time data on material availability (including certified mill test reports), machine capacity, and automotive-specific secondary operations like anodizing per AMS 2471 or passivation per ASTM A967. Quotes explicitly detail compliance adherence (e.g., “RoHS 3 compliant,” “PPAP Level 3 documentation included”) and highlight potential cost drivers such as tight tolerances below ±0.025mm.

Automotive-Optimized DFM Analysis

Engineers conduct a dual-phase Design for Manufacturability review:

First, automated analysis identifies geometric risks specific to automotive applications—undercuts in transmission housings, thin-wall distortion in EV battery brackets, or coolant channel accessibility. Second, our senior team performs a manual review focusing on assembly implications, including weld seam accessibility for subassemblies and thermal expansion compensation in multi-material systems. Clients receive an interactive DFM report with actionable alternatives, such as suggesting consolidated features to reduce fixture changes for high-volume runs.

Precision Production Execution

Approved designs move to dedicated automotive production cells featuring:

Multi-axis CNC machining centers (5-axis DMG MORI, Makino) with in-process probing for closed-loop tolerance control

Real-time SPC monitoring of critical dimensions (e.g., brake caliper bore concentricity)

Material traceability via laser-etched batch numbers linked to MTRs

Mandatory first-article inspection (FAI) per AS9102 with full CMM reports in PDF and XML formats

All processes follow documented work instructions aligned with customer-specific requirements (e.g., Ford Q1, VW Formel Q).

Traceable Delivery & Documentation

Components ship with complete traceability packages including:

Material certifications with full chemical and mechanical properties

Dimensional reports showing actual vs. nominal values for all critical characteristics

PPAP documentation (where specified) including MSA and capability studies

ASNs with serialized barcodes matching internal lot numbers

Standard lead time for prototype to low-volume production is 10–15 business days, with expedited options for urgent automotive program support.

Process Performance Metrics

| Phase | Typical Duration | Key Automotive Compliance Focus |

|——-|——————|——————————–|

| CAD Upload to Quote | <4 hours | Material certification validation |

| DFM Review | 1–2 business days | GD&T alignment with assembly intent |

| Production | 8–12 business days | SPC control of critical-to-quality dimensions |

| Delivery Documentation | Included in shipment | Full traceability to raw material MTR |

This integrated approach ensures Honyo Prototype consistently delivers automotive CNC components that meet functional performance requirements while reducing time-to-market through digital continuity from design to delivery.

Start Your Project

Looking for precision CNC machining solutions tailored to the automotive industry? Honyo Prototype offers high-accuracy, high-efficiency CNC services from our state-of-the-art factory in Shenzhen. Specializing in automotive prototyping and production components, we deliver tight-tolerance parts with fast turnaround and consistent quality.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our expertise in automotive CNC machining for reliable, scalable manufacturing support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.