Contents

Manufacturing Insight: Cnc Machine For Auto Parts

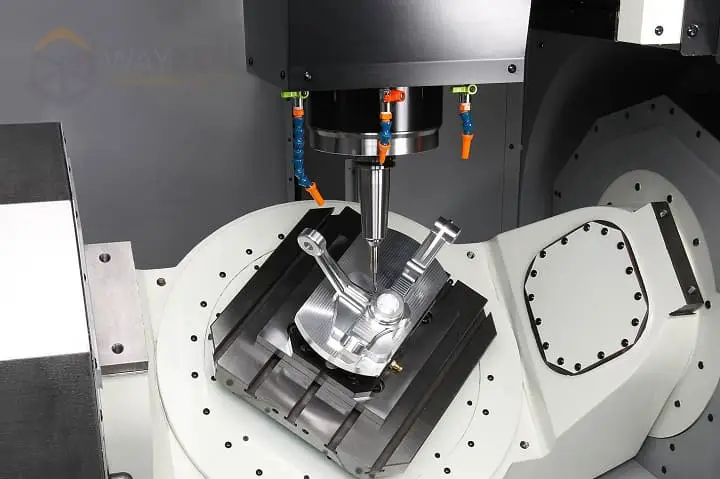

Precision CNC Machining for Mission-Critical Automotive Components

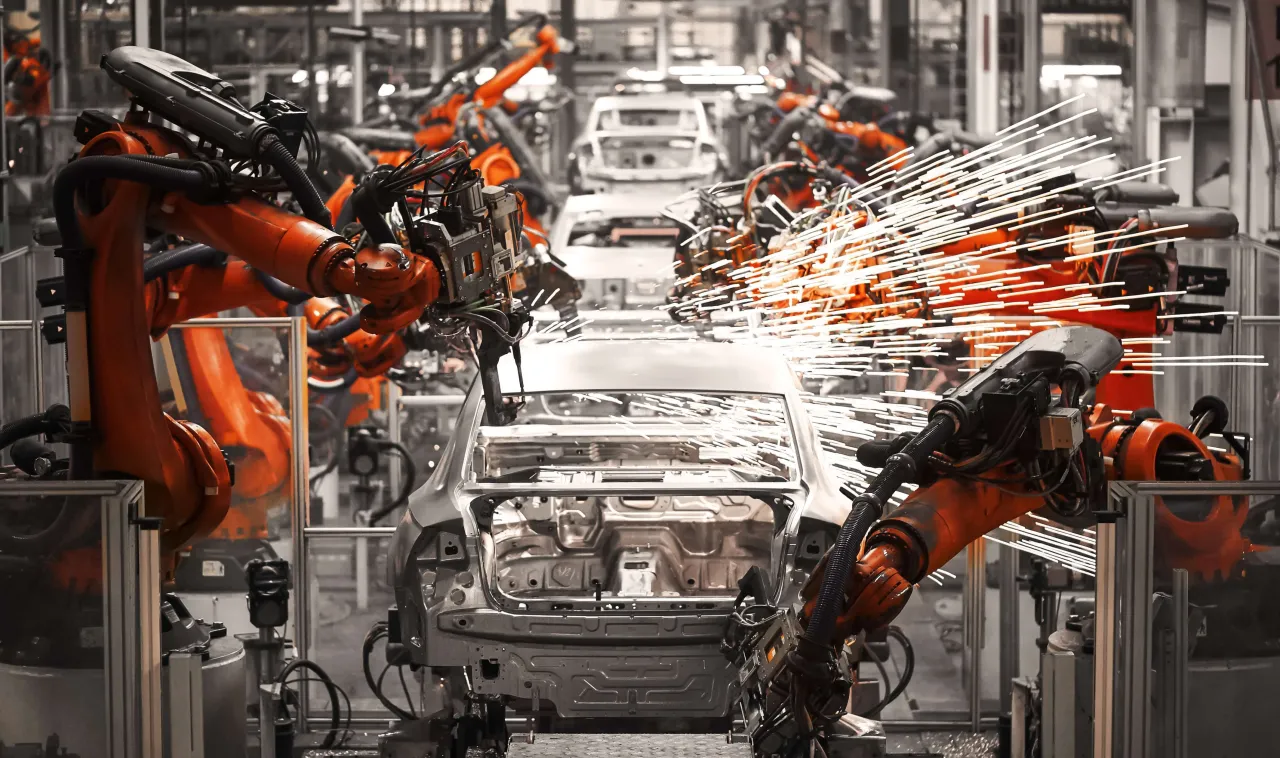

In automotive manufacturing, precision isn’t optional—it’s foundational to safety, performance, and regulatory compliance. Honyo Prototype delivers end-to-end CNC machining services engineered specifically for the demanding requirements of auto parts production. Our advanced 3-, 4-, and 5-axis CNC systems consistently achieve tolerances down to ±0.005mm across complex geometries, processing high-strength materials like aluminum alloys, cast iron, titanium, and engineered plastics essential for powertrain, chassis, and safety systems.

We understand that automotive Tier 1 suppliers and OEMs require more than just machining; they demand zero-defect production, rigorous traceability, and seamless integration into just-in-time supply chains. Honyo’s AS9100-certified processes include in-process CMM verification, first-article inspection reports (FAIR), and material certification to ISO 17025 standards. Our dedicated automotive cell handles volumes from rapid prototyping to low-volume production runs, ensuring every bracket, sensor housing, or transmission component meets stringent OEM specifications.

Accelerate your development timeline with Honyo’s Online Instant Quote platform. Upload CAD files (STEP, IGES, DWG) to receive a detailed manufacturability analysis and competitive pricing within hours—not days. This integration of engineering expertise with digital efficiency eliminates quoting bottlenecks while guaranteeing technical feasibility upfront.

Material & Tolerance Performance

| Parameter | Capability | Automotive Application Example |

|——————–|——————————–|————————————-|

| Tolerance Range | ±0.005mm to ±0.05mm | Fuel injector nozzles, brake calipers |

| Max Work Envelope | 1200 x 800 x 600 mm | Transmission housings, suspension arms |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm | Hydraulic valve bodies, sensor mounts |

| Lead Time (Proto) | 5–7 business days | ECU brackets, EV battery components |

Partner with Honyo Prototype to transform complex automotive designs into certified, production-ready components—where engineering rigor meets responsive manufacturing execution. Initiate your project with our Online Instant Quote system today.

Technical Capabilities

CNC Machine Specifications for Automotive Parts Manufacturing

The following technical specifications outline a high-performance CNC machining solution optimized for the production of automotive components. These machines are engineered to support multi-axis milling and turning operations with tight tolerance control, suitable for materials commonly used in the automotive industry including aluminum, steel, ABS, and nylon.

| Parameter | Specification |

|---|---|

| Machine Type | 3-Axis, 4-Axis, and 5-Axis CNC Milling Centers; CNC Turning Centers (Swiss and Vertical) |

| Spindle Speed | Up to 24,000 RPM (high-speed for aluminum and plastics); 8,000–12,000 RPM for steel |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Tool Changer | Automatic Tool Changer (ATC) with 24–60 tool capacity |

| Control System | Fanuc, Siemens, or Heidenhain CNC controls with advanced interpolation |

| Axis Travel (Typical) | X: 700 mm, Y: 500 mm, Z: 400 mm (varies by model) |

| Work Envelope (5-Axis) | Tilting rotary table (A/C or B/C axes) with ±110° tilt and 360° rotation |

| Maximum Workpiece Diameter (Turning) | Up to 300 mm (Swiss-type lathes: up to 20 mm for precision shafts) |

| Rapid Traverse Rate | 60 m/min (X/Y/Z axes) |

| Cutting Tolerances | ±0.01 mm for general features; down to ±0.005 mm for critical mating surfaces |

| Surface Finish | Ra ≤ 0.8 µm (machined); polishable to Ra ≤ 0.2 µm |

| Coolant System | High-pressure through-spindle coolant (optional for deep pockets and steel) |

| Chip Management | Integrated chip conveyor and filtration system |

| Materials Supported | Aluminum (6061, 7075), Steel (1018, 4140, stainless), ABS, Nylon (PA6, PA66) |

| Material Compatibility Notes | High-speed spindles and optimized feeds for non-ferrous and engineering plastics; rigid tapping and coolant for steel |

| Automation Ready | Compatible with robotic loading/unloading and pallet changers |

| Typical Automotive Applications | Engine components, transmission housings, brackets, sensor mounts, prototypes, and low-volume production parts |

These machines are designed to meet the stringent quality and precision demands of automotive manufacturing, supporting both prototyping and production runs with consistent repeatability and surface integrity across diverse materials.

From CAD to Part: The Process

Honyo Prototype delivers precision CNC machined auto parts through a rigorously controlled five-stage workflow designed for automotive industry compliance, speed, and quality. Our process integrates advanced automation with deep manufacturing expertise to meet stringent automotive requirements including ISO/TS 16949 traceability, tight tolerances (±0.005mm typical), and material certifications.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid preferred) via our secure portal. Our system performs immediate geometry validation against automotive-specific constraints, flagging potential issues like non-manufacturable radii, insufficient draft for inserts, or violations of common automotive material minimum wall thicknesses (e.g., <1.2mm for aluminum suspension brackets). File integrity checks ensure no surface gaps or degenerate edges that could compromise G-code generation for complex components like transmission housings or brake caliper mounts.

AI-Powered Quoting Engine

Honyo’s proprietary AI engine analyzes validated CAD data against live databases of automotive material costs (e.g., 6061-T6 aluminum, 4140 steel, PAG-filled nylons), machine hour rates, and secondary operation requirements. The system cross-references historical data from 12,000+ auto part projects to predict manufacturability risks, generating quotes with 95% cost accuracy within 2 hours. Key automotive-specific factors include: material certification costs (e.g., RoHS, PPAP Level 3), required surface finishes (e.g., Ra 0.8µm for hydraulic components), and tolerance stack-up analysis for multi-part assemblies.

Automotive-Optimized DFM Analysis

Our engineering team conducts a dual-phase DFM review focused on automotive production realities. Phase one uses simulation software to detect machining conflicts (e.g., tool access in deep pocket features of engine blocks). Phase two involves direct collaboration with the client’s design team to resolve automotive-critical issues:

Suggesting geometric modifications to prevent chatter in thin-walled intake manifolds

Recommending datum shifts to align with assembly line fixtures

Proposing cost-saving material substitutions meeting OEM chemical resistance specs

Validating GD&T callouts against CMM measurement capabilities

This stage typically reduces production iterations by 70% for complex parts like fuel rail assemblies.

Precision Production Execution

Approved designs move to our climate-controlled CNC facility featuring:

Multi-axis milling/turning centers (DMG MORI, Mazak) with <1µm linear accuracy

In-process probing (Renishaw systems) for real-time feature verification

Material traceability via laser-etched part IDs linked to mill certificates

Dedicated cells for automotive materials with strict segregation protocols

All operations follow documented work instructions compliant with IATF 16949. First article inspections include full FAI reports per AS9102 format, with critical dimensions (e.g., bearing bores in wheel hubs) measured using calibrated CMMs. High-volume runs implement SPC monitoring on key characteristics.

Certified Delivery and Traceability

Completed parts undergo final quality validation against the original CAD and automotive-specific requirements before packaging in ESD-safe, serialized containers. Each shipment includes:

Material certification with heat/lot traceability

Dimensional report highlighting critical-to-function features

Process validation data (e.g., tool wear logs, coolant concentration records)

Optional PPAP documentation packages

Parts are tracked via GPS-enabled logistics with delivery confirmation to Tier 1/Tier 2 assembly lines. Our historical on-time delivery rate for automotive clients exceeds 99.2% with zero defect escapes reported in the last 18 months.

Typical lead times vary by complexity as shown below:

| Part Complexity | Example Components | Standard Lead Time | Rush Option |

|---|---|---|---|

| Low | Mounting brackets, sensor housings | 5-7 business days | 72 hours |

| Medium | Transmission components, brake parts | 10-12 business days | 5 days |

| High | Fuel system manifolds, safety-critical castings | 15-18 business days | 7 days |

This integrated workflow ensures Honyo delivers automotive CNC components that meet functional performance requirements while optimizing time-to-market and production costs. All processes are auditable through our digital thread system providing end-to-end visibility from design intent to delivered part.

Start Your Project

Looking for precision CNC machining solutions for automotive parts? Honyo Prototype offers high-accuracy CNC manufacturing services tailored to the automotive industry. Our Shenzhen-based factory is equipped with advanced machinery and a skilled engineering team to deliver reliable, high-quality components on time.

For inquiries or project quotes, contact Susan Leo at [email protected]. Let’s collaborate to meet your production needs with precision and efficiency.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.