Introduction: Navigating the Global Market for cnc machine files

In the rapidly evolving landscape of manufacturing, sourcing high-quality CNC machine files presents a significant challenge for international B2B buyers. Whether you’re looking to produce intricate designs for custom furniture or streamline production processes in metalworking, the need for reliable and compatible CNC files is crucial. This guide serves as a comprehensive resource that addresses the complexities of sourcing CNC machine files, covering various file types such as DXF, SVG, and CRV, along with their specific applications in different industries.

Throughout this guide, buyers will gain insights into the nuances of selecting the right CNC files, understanding the compatibility with various machines, and evaluating supplier credibility. We delve into critical factors such as cost considerations, file quality, and the importance of tested designs to ensure optimal results. Additionally, the guide highlights the diverse applications of CNC files across different sectors, providing practical examples relevant to markets in Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Brazil.

By empowering B2B buyers with actionable knowledge, this guide aims to facilitate informed purchasing decisions, ultimately enhancing production efficiency and product quality. Whether you are a seasoned manufacturer or a newcomer to the CNC world, navigating the global market for CNC machine files has never been more accessible.

Understanding cnc machine files Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DXF Files | Vector-based format, widely compatible, supports 2D designs | Sign making, furniture design, prototyping | Pros: Easy to use; Cons: Limited to 2D designs |

| SVG Files | Scalable vector graphics, ideal for web and print, supports animation | Graphic design, custom signage, logos | Pros: High quality; Cons: Less common in CNC |

| G-code Files | Machine-specific, instructions for CNC machines, varies by machine type | Manufacturing, complex machining operations | Pros: Direct machine control; Cons: Machine-specific |

| CRV Files | Proprietary format for Vectric software, includes tool paths | Woodworking, detailed inlays, engraving | Pros: Optimized for Vectric; Cons: Software dependency |

| AI Files | Adobe Illustrator format, supports complex graphics and designs | Artistic projects, custom designs | Pros: Versatile; Cons: Requires Adobe software |

What Are DXF Files and Their Key Characteristics for B2B Buyers?

DXF (Drawing eXchange Format) files are vector-based files that facilitate the exchange of CAD data. They are universally compatible with most CNC machines and CAD/CAM software, making them a popular choice for businesses needing to create precise designs. The primary applications include sign making, furniture design, and prototyping. When considering DXF files, buyers should note their ease of use and the limitation of being primarily 2D, which may not suit all project needs.

How Do SVG Files Differ and What Are Their B2B Uses?

SVG (Scalable Vector Graphics) files are vector images that can be scaled without losing quality, making them ideal for both print and digital applications. They are commonly used in graphic design, custom signage, and logo creation. For B2B buyers, the advantage of SVG files lies in their high quality and versatility. However, their use in CNC applications is less common compared to other formats, which may necessitate additional software for conversion or editing.

What Role Do G-code Files Play in CNC Machining?

G-code files are essential for CNC operations as they provide machine-specific instructions for cutting and shaping materials. These files are crucial in manufacturing and complex machining operations, allowing precise control over the machining process. Buyers should appreciate the direct control G-code offers but must also consider that these files are tailored to specific machines, limiting their versatility across different equipment.

Why Are CRV Files Important for Woodworking Projects?

CRV files are proprietary to Vectric software and include detailed tool paths, making them particularly useful for woodworking projects, such as intricate inlays and engravings. For businesses focused on wood products, CRV files provide optimized designs that enhance production efficiency. However, buyers should be aware of the software dependency, as these files can only be utilized within Vectric-compatible programs.

How Can AI Files Enhance Artistic CNC Projects?

AI (Adobe Illustrator) files are versatile and support complex graphics suitable for artistic CNC projects. They are commonly used in custom designs, allowing for intricate detailing. For B2B buyers, the advantage of AI files lies in their adaptability and high-quality output. However, the requirement for Adobe software may pose a limitation for some businesses, making it essential to evaluate software capabilities before purchase.

Key Industrial Applications of cnc machine files

| Industry/Sector | Specific Application of CNC Machine Files | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture components and intricate designs | Enables mass customization, reducing lead times and costs | Compatibility with existing CNC machinery and software |

| Automotive | Production of precision parts and prototypes | Enhances production efficiency and accuracy | Supplier reliability and availability of technical support |

| Aerospace | Manufacturing of complex components and parts | Meets stringent safety and quality standards | Certifications and adherence to industry regulations |

| Electronics | Fabrication of circuit boards and enclosures | Improves product design flexibility and speed to market | Material specifications and file format compatibility |

| Signage and Advertising | Creation of intricate signage and displays | Boosts brand visibility and customer engagement | Design complexity and production scalability |

How are CNC Machine Files Used in Furniture Manufacturing?

In the furniture manufacturing sector, CNC machine files are pivotal for creating custom components and intricate designs. These files allow manufacturers to automate the cutting and shaping of materials like wood, metal, and plastic, ensuring precision and uniformity. This automation reduces lead times and costs associated with traditional manufacturing methods. For international buyers, especially from regions like Africa and South America, it’s essential to ensure compatibility with existing CNC machinery and software to maximize efficiency and minimize downtime.

What Role Do CNC Machine Files Play in Automotive Production?

The automotive industry relies heavily on CNC machine files for the production of precision parts and prototypes. These files facilitate the manufacture of complex components, ensuring high accuracy and consistency, which is critical for vehicle safety and performance. By utilizing CNC technology, automotive manufacturers can significantly enhance their production efficiency, allowing for quicker turnaround times on new models. Buyers in this sector should prioritize suppliers with a proven track record of reliability and robust technical support to navigate the complexities of automotive production.

How are CNC Machine Files Essential in Aerospace Manufacturing?

CNC machine files are crucial in the aerospace industry for manufacturing complex components that require adherence to stringent safety and quality standards. These files enable the precise machining of materials such as titanium and aluminum, which are commonly used in aircraft production. The ability to produce intricate parts with high accuracy directly impacts the safety and performance of aerospace products. Buyers in this sector must consider suppliers’ certifications and their adherence to industry regulations to ensure compliance and quality assurance.

What Benefits Do CNC Machine Files Provide in Electronics Fabrication?

In the electronics industry, CNC machine files are used for fabricating circuit boards and enclosures, allowing for greater design flexibility and speed to market. These files support the production of intricate designs that are essential for modern electronic devices, enabling manufacturers to stay competitive in a fast-paced market. International buyers should pay attention to material specifications and ensure that the CNC files are compatible with their existing production processes to facilitate seamless integration.

How Do CNC Machine Files Enhance Signage and Advertising?

CNC machine files play a significant role in the signage and advertising sector by enabling the creation of intricate signage and displays. These files allow businesses to produce customized signs that enhance brand visibility and customer engagement. The precision and versatility of CNC machining ensure that even complex designs can be executed efficiently. Buyers in this sector should consider the design complexity and the scalability of production when sourcing CNC files to meet varying demand levels effectively.

3 Common User Pain Points for ‘cnc machine files’ & Their Solutions

Scenario 1: Difficulty in File Compatibility with CNC Machines

The Problem: One of the most pressing challenges for B2B buyers of CNC machine files is ensuring that the files they purchase are compatible with their specific CNC machines and software. With a variety of file formats available (such as DXF, SVG, AI, and proprietary formats like VCarve), users often find themselves with files that cannot be opened or properly utilized in their systems. This leads to wasted time, additional costs, and project delays, especially when the buyer is under pressure to meet tight deadlines.

The Solution: To mitigate compatibility issues, buyers should conduct thorough research on their CNC machine’s specifications and the file formats it supports before making any purchases. It’s advisable to select vendors that provide clear details about file compatibility and to prioritize those that offer multiple formats. When possible, request samples or trial versions of files to test compatibility before committing to a purchase. Additionally, utilizing conversion software can help bridge gaps between different file formats, ensuring that even if a file isn’t natively supported, it can be adapted for use.

Scenario 2: Inadequate File Specifications Leading to Production Errors

The Problem: Another significant pain point arises when CNC machine files lack detailed specifications for toolpaths, feed rates, or material settings. Inadequate information can result in production errors, such as incorrect cutting depths or speeds, leading to wasted materials and increased operational costs. For businesses that rely on precision, such errors can compromise the quality of their final products and damage their reputation with clients.

The Solution: Buyers should prioritize sourcing CNC machine files from reputable suppliers that provide comprehensive specifications alongside their files. This includes detailed notes on feed rates, spindle speeds, and material compatibility. When purchasing, look for files that have been tested and verified for performance on specific materials and machine types. Additionally, investing in training for staff on how to interpret and adapt these specifications can further reduce the risk of errors. Implementing a standardized checklist for file verification before production can also help catch potential issues early in the process.

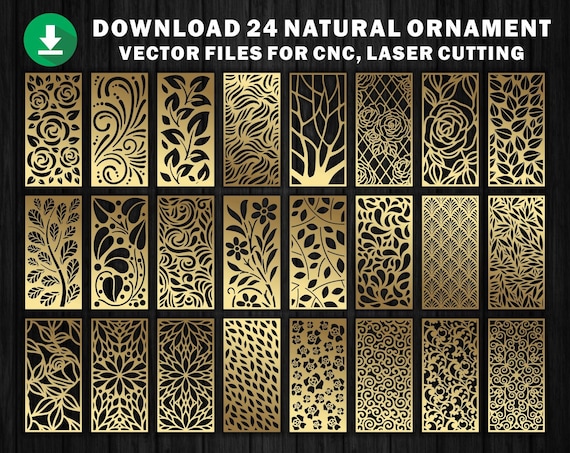

Scenario 3: Lack of Design Inspiration and Customization Options

The Problem: Many B2B buyers struggle with a limited selection of CNC machine files that fail to inspire creativity or meet specific design needs. This can be particularly frustrating for companies looking to differentiate their products in competitive markets. A lack of unique designs may lead to stagnation in product offerings, ultimately affecting sales and market presence.

The Solution: To overcome this challenge, buyers should actively seek suppliers that offer a diverse range of designs and customization options. This can include companies that provide both ready-to-use files and customizable templates. Engaging with online communities, forums, and social media groups dedicated to CNC machining can also provide inspiration and access to unique designs shared by other professionals. Moreover, investing in design software that allows for easy modification of existing files can empower businesses to create tailored solutions that align with their branding and customer preferences. Regularly reviewing industry trends and competitor offerings can also help identify gaps in the market that can be filled with innovative designs.

Strategic Material Selection Guide for cnc machine files

What are the Key Properties of Common Materials Used in CNC Machine Files?

When selecting materials for CNC machine files, it is essential to consider their properties, manufacturing complexity, and end-use applications. Below, we analyze four common materials: wood, acrylic, aluminum, and steel. Each material has unique characteristics that affect its performance, durability, and suitability for various applications.

Wood: A Versatile Choice for CNC Applications

Wood is a popular choice for CNC machining due to its availability, ease of cutting, and aesthetic appeal. Key properties include a moderate temperature rating and natural resistance to corrosion. However, wood can be susceptible to warping and moisture absorption, which may affect the final product’s durability.

Pros: Wood is generally cost-effective, easy to work with, and provides a warm, natural finish, making it suitable for decorative items and furniture.

Cons: Its susceptibility to environmental factors can limit its use in outdoor applications or in areas with high humidity.

For international buyers, especially in regions like Africa and South America, sourcing sustainably harvested wood can align with environmental regulations and consumer preferences.

Acrylic: A Clear Contender in CNC Machining

Acrylic is known for its clarity and versatility, making it suitable for applications requiring transparency, such as displays and signage. It has a high impact resistance and can withstand moderate temperatures, but it can be prone to scratching.

Pros: Acrylic is lightweight, easy to fabricate, and available in various colors, enhancing design flexibility.

Cons: The material can be more expensive than wood and may require special handling to avoid damage during machining.

International buyers should consider the availability of acrylic in their regions and any compliance with local regulations regarding plastic materials.

Aluminum: A Strong and Durable Option

Aluminum is a lightweight yet strong material that is frequently used in CNC machining for parts requiring high durability and resistance to corrosion. Its temperature rating allows it to perform well in various environments, making it suitable for automotive and aerospace applications.

Pros: Aluminum is highly durable, offers excellent machinability, and can be anodized for additional protection.

Cons: The initial cost of aluminum can be higher than that of wood or acrylic, and machining it requires specialized tools and techniques.

For B2B buyers in the Middle East and Europe, understanding local standards for aluminum products (such as ASTM or DIN) is crucial for ensuring compliance with industry regulations.

Steel: The Heavyweight Champion of Materials

Steel is renowned for its strength and durability, making it the go-to material for heavy-duty applications. It can withstand high temperatures and pressures, which is essential for components in industrial machinery.

Pros: Steel’s robustness makes it ideal for structural applications, and it can be treated for enhanced corrosion resistance.

Cons: The material is heavier and more challenging to machine compared to other options, which may increase production costs and time.

International buyers, particularly in regions with stringent safety standards, must ensure that the steel used meets relevant compliance requirements, such as JIS or ASTM standards.

Summary Table of Material Selection for CNC Machine Files

| Material | Typical Use Case for CNC Machine Files | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, decorative items | Cost-effective and aesthetically pleasing | Susceptible to warping and moisture | Low |

| Acrylic | Displays, signage | Lightweight and versatile | Prone to scratching, higher cost | Medium |

| Aluminum | Automotive, aerospace components | High durability and corrosion resistance | Higher initial cost, requires special tools | High |

| Steel | Heavy-duty structural applications | Exceptional strength and durability | Heavier, more complex machining | Medium to High |

This analysis provides a clear overview of the materials commonly used in CNC machine files, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc machine files

What Are the Typical Manufacturing Processes for CNC Machine Files?

The manufacturing of CNC machine files involves several critical stages, each ensuring that the end product is precise and meets the specific requirements of the buyer. Understanding these processes is essential for B2B buyers looking to source high-quality CNC files.

How Is Material Prepared for CNC Machine Files?

Material preparation is the foundational step in the manufacturing process of CNC machine files. This stage involves the selection and setup of digital design files, typically created using CAD software. The designs must be optimized for the specific CNC machine being used, taking into consideration factors such as machine capabilities, material type, and desired final product specifications.

In this phase, key techniques include:

- File Conversion: Converting designs into formats compatible with CNC software, such as DXF, SVG, or proprietary formats like Vectric CRV.

- Parameter Settings: Adjusting parameters such as feed rates, spindle speeds, and plunge rates to align with the material properties and desired cutting precision.

What Are the Forming Techniques Used in CNC Manufacturing?

Once the files are prepared, the next stage is the actual forming process, where the CNC machine executes the designs. This involves several techniques:

- Cutting: CNC machines use various cutting tools to remove material from a workpiece. The choice of tool and technique (e.g., milling, engraving, laser cutting) depends on the complexity of the design and the material being used.

- Inlay Work: For designs that involve inlays, special care is required to ensure that the inlay fits perfectly into the designated spaces, maintaining aesthetic and functional quality.

- 3D Modeling: Advanced CNC operations may involve 3D modeling techniques, which require intricate programming and setup to achieve the desired depth and detail.

How Is the Assembly Process Handled for CNC Machine Files?

The assembly process for CNC machine files is less about physical assembly and more about ensuring that all components of the digital design are correctly integrated. This includes:

- Layering: For designs that involve multiple layers (e.g., inlays), it’s crucial to verify that each layer aligns perfectly during the CNC machining process.

- Simulation Testing: Before actual cutting, many manufacturers utilize simulation software to visualize the cutting process, ensuring that there are no unforeseen issues in the design.

What Finishing Techniques Are Commonly Used in CNC Manufacturing?

The finishing stage enhances the aesthetic and functional qualities of the CNC machined product. This might include:

- Sanding and Polishing: Depending on the material, post-machining processes like sanding and polishing are essential to achieve a smooth surface finish.

- Coating: Applying protective coatings or finishes can enhance durability and resistance to wear, especially for products meant for commercial use.

What Quality Assurance Measures Are Essential for CNC Machine Files?

Quality assurance (QA) is critical in ensuring that CNC machine files meet international standards and customer expectations. Various measures are put in place throughout the manufacturing process.

Which International Standards Are Relevant for CNC Machine File Quality?

B2B buyers should be aware of relevant international standards that govern the quality of CNC machine files. The ISO 9001 standard is the most widely recognized for quality management systems, focusing on meeting customer and regulatory requirements. Other industry-specific standards include:

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: Relevant for files used in the oil and gas sector, ensuring quality and safety in the manufacturing process.

What Are the Key Quality Control Checkpoints in CNC Manufacturing?

Quality control (QC) is integrated at various stages of the CNC file manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial stage checks the incoming raw materials and components against specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify any deviations from the required standards.

- Final Quality Control (FQC): A thorough inspection of the finished product before it is delivered to the buyer, ensuring it meets all specifications and quality standards.

What Common Testing Methods Are Employed in CNC File Quality Assurance?

To ensure the quality of CNC machine files, several testing methods are commonly employed:

- Dimensional Inspection: Verifying that the finished product adheres to the specified dimensions using precision measurement tools.

- Performance Testing: For files intended for specific applications, performance testing ensures that the final output meets operational requirements.

- Visual Inspection: A final visual check to identify any aesthetic defects or issues that could affect the end-user experience.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be proactive in verifying the quality control measures of their CNC file suppliers. Several strategies can be employed:

- Supplier Audits: Conducting regular audits of suppliers to assess their quality management systems and adherence to industry standards.

- Quality Assurance Reports: Requesting detailed QC reports that outline the procedures and outcomes of quality checks performed throughout the manufacturing process.

- Third-Party Inspections: Engaging independent inspectors to evaluate the quality of the CNC files before they are shipped can provide an additional layer of assurance.

What Nuances Should International B2B Buyers Consider Regarding QC?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. These may include:

- Regulatory Differences: Understanding the regulatory landscape in their respective countries and how it affects the import of CNC files.

- Cultural Expectations: Recognizing that expectations regarding quality and service may vary by region, influencing how QC measures are perceived.

- Communication Barriers: Ensuring clear communication with suppliers regarding quality expectations and standards to avoid misunderstandings that could impact the final product.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing CNC machine files, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc machine files’

Introduction

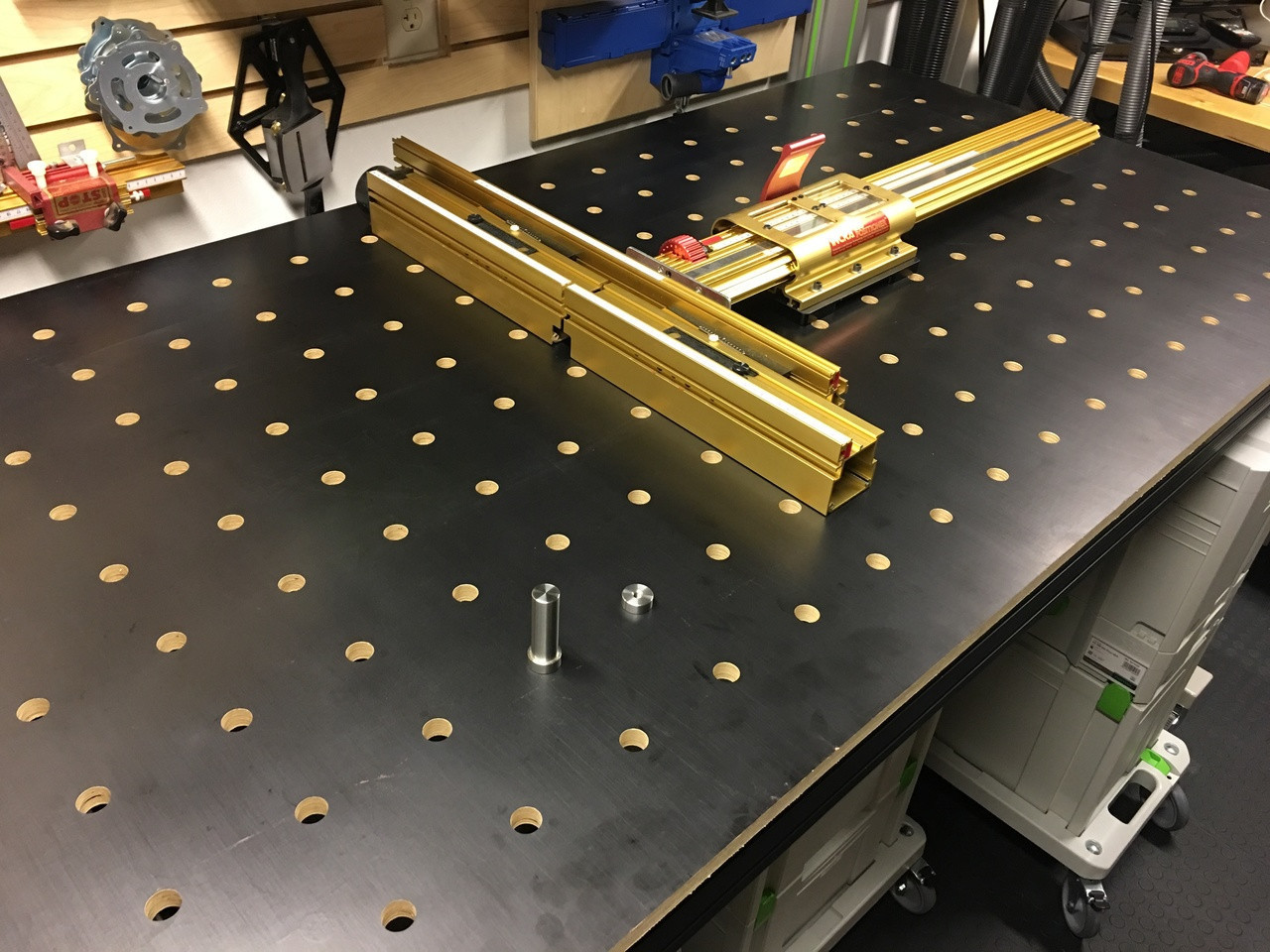

When sourcing CNC machine files, it is essential to follow a structured approach to ensure you obtain high-quality, compatible designs that meet your specific production needs. This checklist will guide you through the critical steps to efficiently procure CNC files, whether for custom projects or standard production runs, ensuring you make informed decisions that align with your business objectives.

Step 1: Define Your Technical Specifications

Clearly outline the requirements for your CNC projects, including material types, dimensions, and desired functionalities. Understanding these specifications will help you communicate effectively with suppliers and ensure that the files you procure will work seamlessly with your machines. Additionally, consider the file formats you require (e.g., DXF, SVG, AI) to avoid compatibility issues later.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers who specialize in CNC machine files. Look for suppliers with a proven track record and positive reviews from other businesses in your industry. Utilize platforms like industry forums, trade shows, and online marketplaces to discover reputable sources that align with your sourcing goals.

Step 3: Evaluate Supplier Credentials

Before entering into any agreements, it is crucial to vet suppliers comprehensively. Request documentation such as company profiles, certifications, and examples of past work to assess their credibility. Additionally, seek out case studies or testimonials from similar businesses to understand the supplier’s reliability and customer service quality.

Step 4: Request Sample Files

Always ask for sample files or trial versions before making a bulk purchase. This will allow you to test the files on your CNC machines to verify compatibility and quality. Pay attention to the level of detail and accuracy in the designs, as well as the provided specifications such as feed rates and spindle speeds, which are vital for successful execution.

Step 5: Verify File Format Compatibility

Ensure that the CNC files you are interested in are compatible with your existing software and machinery. Check the file formats offered by the supplier and confirm that they can be opened and processed by your CAD/CAM systems. Misalignment in file formats can lead to delays and increased costs during production.

Step 6: Assess Support and After-Sales Service

Evaluate the level of support and after-sales service offered by the supplier. Reliable suppliers should provide technical assistance, updates on file improvements, and access to a knowledge base for troubleshooting. This support can be crucial for optimizing your CNC operations and minimizing downtime.

Step 7: Negotiate Terms and Finalize Purchase

Once you have selected a supplier, negotiate the terms of purchase, including price, delivery timelines, and payment methods. Ensure that you clarify any licensing agreements related to the CNC files, especially if you plan to modify or resell the designs. A clear contract will protect both parties and foster a successful business relationship.

Comprehensive Cost and Pricing Analysis for cnc machine files Sourcing

What Are the Key Cost Components in Sourcing CNC Machine Files?

When sourcing CNC machine files, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: This refers to the software and resources needed to create the CNC files. High-quality design software, such as VCarve Pro, often requires licensing fees, which can affect the overall cost of the files. Furthermore, the complexity of the designs can necessitate more advanced materials, influencing pricing.

-

Labor: The expertise required to create and refine CNC files is significant. Skilled designers and engineers contribute to the labor costs, especially when custom designs are requested. This is particularly relevant for intricate projects that demand a high level of precision.

-

Manufacturing Overhead: Overhead costs encompass everything from utilities to office space. For companies producing CNC files, these costs are allocated across all projects and can vary depending on the operational scale.

-

Tooling: The tools and equipment used in the creation of CNC files, such as computers and design software, contribute to the tooling costs. Continuous updates and maintenance of these tools can also add to the expenses.

-

Quality Control (QC): Ensuring the accuracy and reliability of CNC files is crucial. QC processes may involve testing the files on actual machines, which can increase costs but ultimately ensures higher quality outcomes for buyers.

-

Logistics: While CNC files are digital products, logistics can still play a role, particularly if physical samples or documentation are involved. International shipping and handling of these materials can incur additional costs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin varies based on the supplier’s market positioning and the perceived value of their offerings.

How Do Price Influencers Impact CNC Machine File Costs?

Several factors can influence the pricing of CNC machine files, particularly in international markets:

-

Volume/MOQ (Minimum Order Quantity): Higher volumes typically lead to lower per-unit costs. Buyers should negotiate for bulk pricing to maximize savings.

-

Specifications and Customization: Customized files tailored to specific project needs can significantly increase costs. The more intricate the design, the higher the associated labor and software costs.

-

Materials Quality and Certifications: Files made from premium materials or those that comply with specific industry certifications may command higher prices. Buyers should assess whether these certifications are necessary for their projects.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their expertise and proven quality, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: Understanding the terms of shipping and handling is vital for international transactions. Incoterms can affect the total cost, including shipping responsibilities, insurance, and tariffs.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Effectively: Leverage your purchasing power by negotiating prices, especially when ordering in bulk or establishing long-term relationships with suppliers.

-

Consider Total Cost of Ownership (TCO): Assess not just the upfront costs but also the long-term implications of using the CNC files, including potential maintenance and operational costs.

-

Understand Pricing Nuances: Familiarize yourself with the pricing structures prevalent in different regions. For instance, suppliers in Europe may have different cost bases compared to those in South America or Africa.

-

Evaluate Multiple Suppliers: Don’t settle for the first supplier. Gather quotes from multiple sources to ensure competitive pricing and better service offerings.

-

Stay Informed on Market Trends: Keep abreast of trends in CNC technology and file sourcing to make informed decisions that can lead to cost savings.

What Disclaimers Should Buyers Keep in Mind Regarding Pricing?

Prices for CNC machine files can vary widely based on the factors discussed above. It’s important for buyers to recognize that indicative prices may not represent the final costs due to fluctuations in market conditions, supplier pricing strategies, and changes in demand. Always request detailed quotes and clarify what each component of the cost entails to avoid unexpected expenses.

Alternatives Analysis: Comparing cnc machine files With Other Solutions

Introduction: Exploring Alternatives to CNC Machine Files

In the ever-evolving landscape of manufacturing and design, businesses frequently seek efficient solutions to meet their production needs. While CNC machine files are a popular choice for guiding CNC machinery, several alternatives also exist that can accomplish similar goals. Understanding these options is crucial for B2B buyers looking to optimize their operations, particularly in diverse markets across Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | CNC Machine Files | Free DXF Files | CAD Software Solutions |

|---|---|---|---|

| Performance | High precision and customizability | Moderate precision; may vary by source | Very high precision; fully customizable |

| Cost | Moderate (varies by design complexity) | Free | High (software licensing fees) |

| Ease of Implementation | Requires compatible CNC software | Simple download and use | Steeper learning curve; requires training |

| Maintenance | Low (once files are created) | None (static files) | Ongoing updates and support needed |

| Best Use Case | Custom production runs and unique designs | Quick prototyping and general tasks | Complex designs and detailed engineering |

Detailed Breakdown of Alternatives

Free DXF Files

Free DXF files serve as an accessible alternative for businesses that require simple designs without incurring costs. They are particularly beneficial for small projects or prototyping, as they allow for quick downloads and immediate use. However, the precision and quality of these files can vary significantly based on the source, potentially leading to inconsistencies in production quality. Additionally, while they are useful for straightforward tasks, their lack of customization limits their effectiveness for more intricate projects.

CAD Software Solutions

CAD (Computer-Aided Design) software offers a robust alternative to CNC machine files, providing users with comprehensive tools for creating detailed and complex designs. This approach allows for complete customization, enabling businesses to develop unique solutions tailored to their specific needs. However, CAD software often comes with high licensing fees and requires a significant investment in training and time to master. As a result, while it provides superior precision and versatility, it may not be the best fit for companies seeking quick, cost-effective solutions.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right solution between CNC machine files and alternatives like free DXF files or CAD software depends on the specific requirements of your business. If your operations require high precision and unique designs, investing in CNC machine files is likely the best choice. However, for quick prototypes or simpler tasks, free DXF files can save time and money. On the other hand, if your projects demand intricate designs and detailed engineering, CAD software could be the most effective solution, albeit at a higher cost and complexity. By assessing your production needs, budget, and available resources, you can make an informed decision that aligns with your operational goals.

Essential Technical Properties and Trade Terminology for cnc machine files

What Are the Key Technical Properties of CNC Machine Files?

When dealing with CNC machine files, several critical specifications are essential for ensuring optimal performance and compatibility across various projects. Understanding these properties is crucial for B2B buyers looking to make informed purchasing decisions.

1. File Format

CNC files can come in various formats, including DXF, SVG, AI, and proprietary formats like Vectric CRV. Each format serves specific purposes and is compatible with different software. For example, DXF files are widely used for 2D designs and are compatible with most CAD applications. Knowing the required file format helps buyers select appropriate designs that fit their machine capabilities and software.

2. Feed Rate

Feed rate refers to the speed at which the CNC machine moves the tool through the material. It is typically measured in units like inches per minute (IPM) or millimeters per minute (MPM). Selecting the right feed rate is crucial for achieving precision and preventing material damage. Buyers must consider the material type and thickness to determine the optimal feed rate for their projects.

3. Spindle Speed

Spindle speed indicates how fast the CNC machine’s spindle rotates, measured in revolutions per minute (RPM). The spindle speed affects the quality of the cut and the type of material being machined. For instance, harder materials require higher spindle speeds to achieve a clean cut. Buyers should ensure that the spindle speed aligns with the specifications of the CNC files they intend to use.

4. Tolerance

Tolerance defines the acceptable limits of variation in a manufactured part’s dimensions. In CNC machining, tighter tolerances result in higher precision but may increase production costs. Understanding tolerance levels is vital for buyers, especially when producing components that must fit together or adhere to strict quality standards.

5. Material Compatibility

Different CNC files are optimized for specific materials, such as wood, metal, or plastic. Buyers must ensure that the CNC files they select are compatible with the materials they plan to use. This compatibility affects the quality of the final product and the efficiency of the machining process.

6. Layer Specifications

For complex designs, CNC files may include multiple layers, each with its own parameters such as depth and cutting order. Understanding these layer specifications allows buyers to anticipate the complexity of the machining process and prepare accordingly. This knowledge is particularly important when working with intricate designs that require precision.

What Are Common Trade Terms Related to CNC Machine Files?

Familiarity with industry terminology can significantly enhance communication and negotiation processes in B2B transactions involving CNC machine files.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers when sourcing CNC files, as it can impact quality assurance and compatibility with existing machinery.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Buyers should pay attention to MOQ requirements when purchasing CNC files, as it may affect their project budgets and timelines. Knowing the MOQ helps buyers plan their orders effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal request for a price quote from suppliers. This document outlines the specifications of the CNC files needed, allowing buyers to compare offers from multiple vendors. Using RFQs streamlines the procurement process and ensures that buyers receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities when sourcing CNC files globally.

5. CAM (Computer-Aided Manufacturing)

CAM refers to the use of software to control machine tools in the manufacturing process. Understanding CAM is essential for buyers, as it relates directly to how CNC files are utilized in production. Buyers should ensure that their CAM software is compatible with the CNC files they intend to purchase.

By grasping these essential technical properties and trade terminologies, B2B buyers can make more informed decisions when navigating the complex landscape of CNC machine files.

Navigating Market Dynamics and Sourcing Trends in the cnc machine files Sector

What are the Key Drivers and Trends in the CNC Machine Files Market?

The CNC machine files market is experiencing significant growth due to the increasing demand for precision engineering and automation across various industries, including manufacturing, woodworking, and metalworking. Key drivers include the rise of digital fabrication technologies, which enable businesses to streamline production processes and improve product quality. Additionally, the expansion of e-commerce has made it easier for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, to access a diverse range of CNC files and designs.

Emerging trends in the sector point towards a heightened focus on customization and flexibility. Buyers are increasingly seeking tailored solutions that meet specific project requirements, leading to a surge in demand for customizable CNC file designs. Furthermore, advancements in software compatibility, such as the support for multiple file formats (e.g., DXF, SVG, AI), enhance the usability of CNC files across various machines, thus attracting a broader customer base.

International buyers are also becoming more discerning about the sources of their CNC files, emphasizing the need for reliable vendors who provide tested and proven designs. This demand for quality assurance is crucial in fostering long-term partnerships and ensuring that projects are completed efficiently and effectively.

How is Sustainability Influencing Sourcing Decisions in the CNC Machine Files Sector?

Sustainability is becoming an essential consideration in the sourcing of CNC machine files, as businesses strive to minimize their environmental impact. The CNC machining process can generate waste and consume significant energy, prompting buyers to seek out designs and materials that promote sustainability. This includes utilizing files that are optimized for material usage, thereby reducing offcuts and minimizing waste.

Moreover, ethical sourcing is gaining traction among international B2B buyers, who are increasingly concerned about the environmental and social implications of their supply chains. Suppliers that offer ‘green’ certifications or use environmentally friendly materials in their CNC file designs are likely to stand out in a competitive marketplace. This trend is particularly relevant for buyers in regions like Europe, where stringent regulations and consumer preferences are driving demand for sustainable practices.

Implementing sustainable sourcing strategies not only enhances a company’s reputation but can also lead to cost savings in the long run. By prioritizing eco-friendly materials and processes, businesses can improve operational efficiency and reduce their overall carbon footprint.

What is the Historical Context of CNC Machine Files in B2B?

The evolution of CNC machine files can be traced back to the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies in the late 20th century. Initially, CNC files were primarily used in industrial settings for mass production. However, with the rise of digital fabrication and the democratization of technology, the accessibility of CNC files has significantly expanded.

Today, CNC machine files cater to a diverse audience, from hobbyists to large-scale manufacturers, reflecting the growing versatility and importance of CNC technology in various sectors. This evolution underscores the shift towards a more integrated and technology-driven approach in manufacturing, where precision and efficiency are paramount for B2B buyers globally. As the market continues to evolve, the demand for high-quality, customizable CNC files will likely remain a key focus for international buyers seeking to leverage the benefits of CNC machining in their operations.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc machine files

-

How do I ensure the CNC machine files I purchase are of high quality?

To ensure high-quality CNC machine files, start by sourcing from reputable suppliers with positive reviews and a proven track record. Look for files that have been tested on actual CNC machines, as indicated by the seller. Additionally, verify that the files come with detailed specifications, including feed rates, spindle speeds, and plunge rates, which are crucial for achieving optimal results. Request samples or demo files if available, and consider suppliers that offer customer support to assist you in case of any issues. -

What file formats should I look for when purchasing CNC machine files?

When purchasing CNC machine files, it’s essential to look for compatibility with your software and CNC machine. Common file formats include DXF, SVG, AI, and Vectric CRV. Each format serves different purposes; for example, DXF files are ideal for CAD applications, while SVG files are often used for laser cutting. Ensure that the supplier provides multiple formats to give you flexibility in your projects, and check that your software can open the specific formats offered. -

How can I customize CNC machine files to fit my specific needs?

Customization of CNC machine files can often be achieved through CAD/CAM software. Many suppliers provide files that are editable, allowing you to adjust dimensions, design elements, or other parameters to suit your project requirements. If you need significant alterations, consider working with a supplier that offers custom design services. Always communicate your specific needs clearly and inquire about any additional costs associated with customization. -

What are the typical minimum order quantities (MOQs) for CNC machine files?

Minimum order quantities (MOQs) for CNC machine files can vary significantly between suppliers. Some may offer files on a per-piece basis, while others might require bulk purchases to achieve better pricing. When sourcing, clarify the MOQ with the supplier and assess whether it aligns with your project needs. It’s beneficial to find suppliers who offer flexibility in order sizes, especially if you are testing new designs or working on smaller projects. -

What payment terms are commonly offered by suppliers of CNC machine files?

Payment terms can vary widely among suppliers of CNC machine files. Many suppliers accept credit cards, bank transfers, or digital payment platforms like PayPal. It’s advisable to look for suppliers who offer secure payment options and clear return policies. Additionally, inquire about any available credit terms, especially if you plan to make frequent purchases, as this can help manage cash flow and facilitate smoother transactions. -

How do I vet suppliers for CNC machine files in international trade?

Vetting suppliers for CNC machine files in international trade involves a thorough due diligence process. Start by researching their reputation through online reviews, industry forums, and references from other businesses. Check for certifications and memberships in trade organizations, which can indicate a commitment to quality and professionalism. Additionally, consider requesting samples of their work and engaging in direct communication to assess their responsiveness and willingness to collaborate. -

What quality assurance measures should be in place when sourcing CNC machine files?

Quality assurance measures are crucial when sourcing CNC machine files. Look for suppliers who provide documentation of their design process, testing results, and any quality certifications. Establish clear communication regarding your quality expectations and request a trial run of the files before full-scale production. Implementing a feedback loop can also be beneficial; encourage open dialogue with the supplier to address any issues and ensure continuous improvement in file quality. -

How can I handle logistics and delivery for CNC machine files purchased internationally?

Handling logistics and delivery for internationally purchased CNC machine files requires clear communication with your supplier. Ensure they provide a reliable method for file delivery, whether through secure download links or email. Discuss the expected delivery timelines, especially if you have tight project deadlines. Additionally, familiarize yourself with any import regulations or tariffs that may apply to digital goods in your region to avoid unexpected delays or costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Machine Files Manufacturers & Suppliers List

1. AribaBox – Free DXF Files for CNC

2. Vectric – Aspire, VCarve, Cut2D

Domain: vectric.com

Registered: 2005 (20 years)

Introduction: Vectric offers over 300 free CNC projects available for download, each accompanied by a step-by-step training video. The projects are designed to inspire users and provide training for Vectric software. The products mentioned include Aspire, VCarve, Cut2D, Makerspace Edition, Laser Module, EasyCarve, Cut3D, and PhotoVCarve.

3. Etsy – CNC File Selection

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – CNC File Selection, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. CNC Cookbook – Free DXF Files & Patterns

Domain: cnccookbook.com

Registered: 2007 (18 years)

Introduction: Free DXF Files and CNC Patterns available for download. Categories include Animals, Vehicles, Nature, Maps, Music, Symbols, Holiday, Toys, Signs, Sports, Food, Religion, Western. DXF files are vector CAD files used for CNC cutting, created by Autodesk for AutoCAD. They contain objects like lines, polygons, circles, arcs, Bezier curves, and text. The files come in a Zip format, with both .dxf (for …

5. Langmuir Systems – FireShare Beta

Domain: langmuirsystems.com

Registered: 2017 (8 years)

Introduction: FireShare Beta allows users to download free cut-ready CNC project files. It supports uploading G-Code files for FireControl and Mach3. Users can explore and download user-uploaded projects, including categories like Home & Garden and Tabs & Brackets. Popular projects include various sizes of 1/4″ Hole Flat Weld Tabs with different standoff options. Langmuir Systems also offers products like Cross…

6. CNC Design Shop – Free DXF Files for CNC Cutting

Domain: cncdesignshop.com

Registered: 2018 (7 years)

Introduction: Free DXF files for CNC machines designed for plasma, laser, and waterjet cutting. Categories include Home Decor, Outdoor & Garden, Retail Signs, Stock Art, and more. Specific products include clocks, wall art, privacy screens, garden art, and various themed signs. Membership options available for access to hundreds of free DXF files and custom design services.

7. CNCgcode – Free DXF Shape Files

Domain: cncgcode.weebly.com

Registered: 2006 (19 years)

Introduction: CNCgcode offers free DXF shape files for CNC cutting, including 2D outlines for various designs. Key products include: 1. Wolf Howling Over a Blue Moon – DXF and Gcode available for download. 2. Gingerbread Man Super Pack – Contains individual DXF and Gcode for 5 gingerbread boys. 3. Butterfly Designs – Two intricate butterfly shapes with DXF and Gcode included. 4. Playing Card Suits – Hearts, Clu…

Strategic Sourcing Conclusion and Outlook for cnc machine files

In the ever-evolving landscape of CNC machining, strategic sourcing of CNC machine files has become a pivotal factor for businesses aiming to optimize their production processes. By prioritizing high-quality, tested designs, buyers can significantly reduce errors and enhance their operational efficiency. The availability of diverse file formats such as DXF, SVG, and AI ensures compatibility with various CNC machines, catering to a wide range of project requirements.

Moreover, leveraging free resources and community-driven platforms can provide additional value, enabling companies to innovate without excessive investment. As international markets, particularly in Africa, South America, the Middle East, and Europe, continue to expand, the demand for reliable and versatile CNC files will only grow.

Looking ahead, businesses are encouraged to adopt a proactive approach to sourcing CNC files, staying attuned to emerging trends and technologies. Embracing continuous learning and collaboration will empower companies to remain competitive in this dynamic industry. Seize the opportunity to explore new designs, enhance your capabilities, and drive your business forward by integrating strategic sourcing practices today.