Contents

Manufacturing Insight: Cnc Machine Files

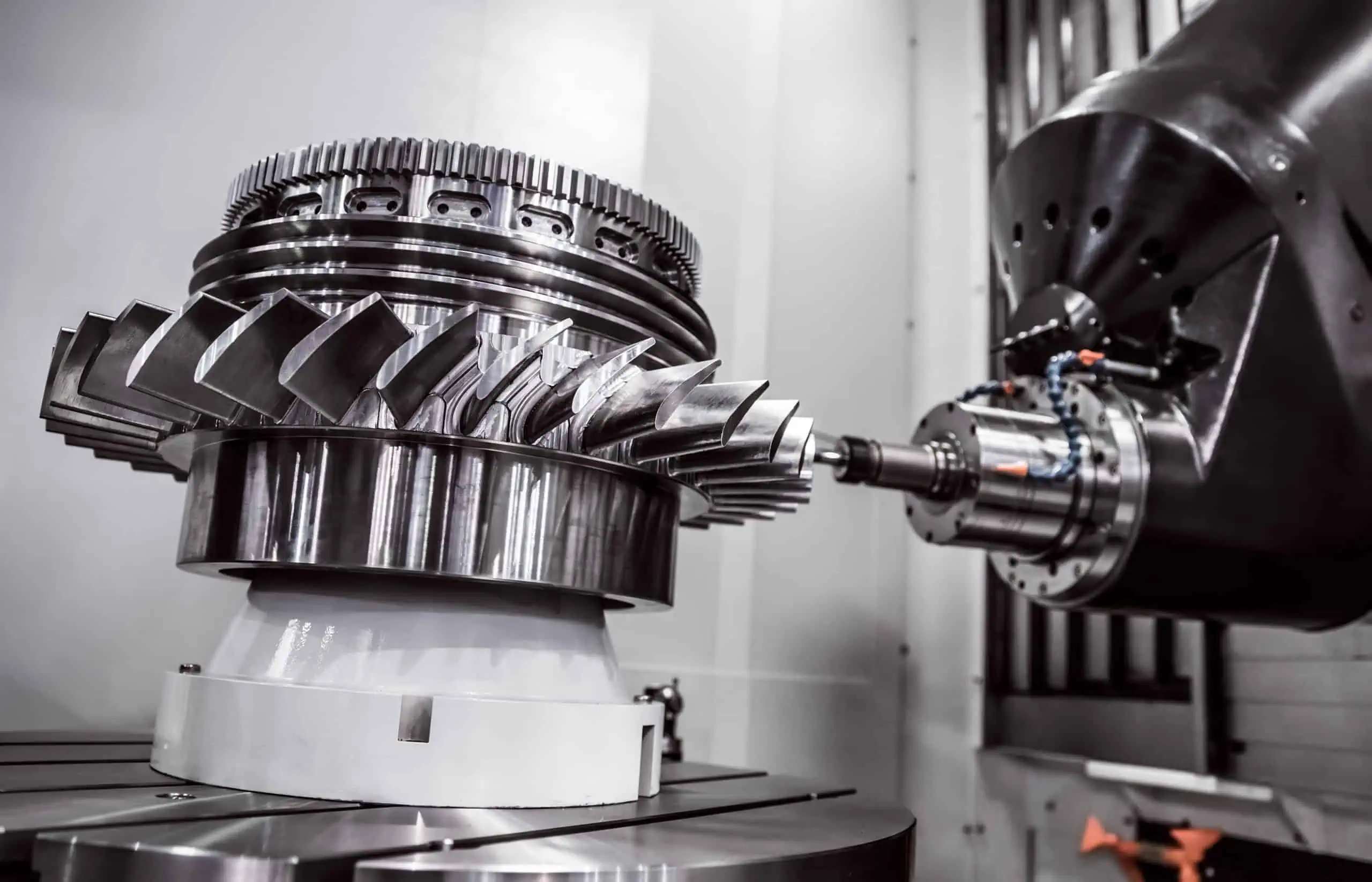

Precision CNC Machining Services: Transforming Your Digital Designs into High-Fidelity Prototypes and Production Parts

At Honyo Prototype, we engineer excellence from concept to physical reality through advanced CNC machining capabilities. Our end-to-end manufacturing process begins with your precise CAD/CAM data, where we rigorously validate CNC machine files—ensuring optimal toolpaths, material utilization, and geometric accuracy before a single chip is cut. We specialize in producing complex, tight-tolerance components across aerospace alloys, medical-grade polymers, and engineering composites, leveraging 3-axis, 4-axis, and 5-axis milling and turning centers with ±0.005mm repeatability. Every program undergoes our proprietary simulation protocol to eliminate collisions, minimize cycle times, and guarantee first-article success, directly translating your digital specifications into mission-critical hardware.

Honyo’s technical team collaborates closely with clients to optimize part geometry for manufacturability, reducing cost drivers without compromising functional integrity. Whether you require rapid prototype iterations or low-volume production runs, our integrated workflow—from file review to finishing—delivers consistent quality certified to ISO 9001:2015 standards. Material versatility is core to our value proposition, as demonstrated below:

| Material Category | Common Grades | Typical Applications |

|---|---|---|

| Aluminum Alloys | 6061-T6, 7075-T6 | Aerospace brackets, heat sinks |

| Engineering Plastics | PEEK, Ultem, Acetal | Medical instruments, fluid systems |

| Stainless Steel | 303, 304, 17-4PH | Hydraulic components, surgical tools |

| Titanium | Grade 5 (Ti-6Al-4V) | Implants, defense hardware |

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload your STEP, IGES, or native CAD file alongside technical requirements to receive a detailed manufacturing assessment and competitive pricing within minutes—not days. This seamless digital interface provides transparency into lead times, material costs, and critical process notes, empowering procurement and engineering teams to make data-driven decisions without traditional quotation delays. Experience how our CNC expertise and digital-first engagement model reduce time-to-market while upholding uncompromising quality benchmarks.

Technical Capabilities

Technical specifications for CNC machine files are critical to ensure precision, repeatability, and compatibility across 3-axis, 4-axis, and 5-axis milling systems, as well as CNC turning centers. These files—typically in formats such as G-code, STEP, or native CAD/CAM outputs—must reflect detailed geometric, dimensional, and process parameters, especially when producing parts with tight tolerances (±0.001″ to ±0.0002″). Below is a summary of key technical specifications categorized by machine type, operation, material, and tolerance capability.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes |

|---|---|---|---|---|---|

| Axis Configuration | X, Y, Z | X, Y, Z + Rotary (A or B) | X, Y, Z + Two Rotaries (A/B or B/C) | X, Z + Spindle Rotation | 4-axis enables indexing or continuous rotary motion. 5-axis allows complex compound angles. |

| Typical File Format | G-code, STEP, .NC, .CNC | G-code, STEP, .NC, .CNC | G-code, STEP, .CNC, native CAM (e.g., .CLSF) | G-code, .NC, CAM-generated programs | STEP for geometry transfer; G-code for machine execution. |

| Tolerance Capability | ±0.001″ (standard), ±0.0005″ (tight) | ±0.001″, up to ±0.0002″ with calibration | ±0.0005″, down to ±0.0002″ with high-end CNC | ±0.0005″ on diameter, ±0.001″ on length | Tight tolerance machining requires thermal stability, high-precision tooling, and metrology. |

| Surface Finish (Ra) | 32–125 μin (standard), 16–32 μin (fine) | 32–63 μin, down to 16 μin with finishing passes | 16–32 μin, down to 8 μin with high-speed machining | 16–63 μin, down to 8 μin with fine turning | Finish depends on tool path, feed rate, and material. |

| Aluminum (e.g., 6061-T6) | High MRR, sharp tools, coolant recommended | Compatible, especially for impeller/vane geometries | Ideal for complex aerospace components | Excellent machinability, high RPM | Use carbide tools; avoid built-up edge. |

| Steel (e.g., 4140, 17-4 PH) | Moderate MRR, rigid setup, coated inserts | Possible with proper fixturing and power | Suitable for high-strength parts with undercuts | Good for shafts, pins; slower speeds | Requires rigid tooling and peck drilling for deep holes. |

| ABS | Low melting point, sharp tools, low RPM | Suitable for prototypes and enclosures | Used in mold and fixture applications | Less common; possible for jigs | Minimize heat; use air blast or light coolant. |

| Nylon (e.g., PA6, PA66) | Can deform; sharp tools, low feed, support structures | Possible with vacuum fixturing | Limited use; requires low thermal load | Feasible for bushings, gears | Avoid excessive clamping force; prone to moisture absorption. |

| Tooling Requirements | End mills, drills, chamfer tools | Same as 3-axis + rotary-compatible tooling | High-precision ball/nose end mills, tilting tools | Turning inserts, boring bars, parting tools | Use PCD or carbide for non-ferrous; CBN for hardened steel. |

| Fixturing | Vise, clamps, custom fixtures | Rotary table integration required | Multi-sided access; minimal re-fixturing | Collet chucks, 3-jaw/4-jaw chucks | 5-axis reduces need for multiple setups. |

| Applications | Flat parts, pockets, holes | Impellers, turbine blades, indexed features | Aerospace components, molds, medical implants | Shafts, bushings, threaded components | Tight tolerance applications common in aerospace, medical, and optics. |

Note: Achieving tight tolerances consistently requires machine calibration, tool pre-setting, in-process probing, and environmental control (e.g., temperature-stable facilities). Material selection impacts tool life, cycle time, and achievable precision.

From CAD to Part: The Process

Honyo Prototype CNC Machine File Processing Workflow

Honyo Prototype employs a rigorously structured workflow for CNC machining projects to ensure precision, efficiency, and alignment with client specifications. This integrated process begins with CAD file submission and concludes with certified part delivery, minimizing errors and accelerating time-to-market. Below is a technical breakdown of each phase.

CAD File Upload and Validation

Clients initiate the process by uploading native or neutral CAD formats via Honyo’s secure customer portal. Supported formats include STEP AP203/AP214, IGES, Parasolid (.x_t), and native SOLIDWORKS/Autodesk Inventor files. Our system automatically validates geometric integrity, unit consistency, and feature completeness. Files failing validation—such as those with open surfaces, unsealed volumes, or incompatible units—are flagged immediately, and clients receive detailed correction guidance within 2 business hours. This step ensures downstream processes operate on error-free geometry, eliminating rework from ambiguous or defective models.

| CAD Format | Validation Criteria | Typical Resolution Time |

|---|---|---|

| STEP AP203/AP214 | Surface continuity, manifold validation | < 2 hours |

| IGES | Curve/surface tolerance, layer integrity | < 4 hours |

| Native (e.g., SLDPRT) | Feature tree consistency, material properties | < 1 business day |

AI-Powered Quoting Engine

Validated CAD files enter Honyo’s proprietary AI quoting system, which analyzes 200+ geometric and manufacturing parameters. The algorithm cross-references real-time data from our machine shop—including spindle utilization rates, tooling availability, and material costs—to generate accurate cost and lead-time estimates. Unlike manual quoting, this system identifies complex features (e.g., deep cavities, thin walls, or tight tolerances) that impact machining strategy, applying dynamic cost multipliers. Quotes include material waste calculations, fixture requirements, and secondary operation recommendations, typically delivered within 4 business hours for standard parts.

DFM Analysis and Client Collaboration

All projects undergo mandatory Design for Manufacturability (DFM) review by Honyo’s engineering team. This phase converts CAD geometry into optimized machining sequences using Mastercam and Fusion 360. Engineers evaluate:

Tool access constraints and undercuts requiring 5-axis solutions

Tolerance stack-up analysis against GD&T callouts

Material removal rates to prevent chatter or deflection

Cost-saving opportunities (e.g., standardizing hole sizes)

Clients receive an interactive DFM report with annotated suggestions. Critical deviations—such as non-machinable radii or unachievable surface finishes—trigger a collaborative revision loop. Only after client approval of the DFM report do we proceed to CAM programming, ensuring alignment with both design intent and process capabilities.

Production Execution and Traceability

Approved CAM files (G-code) are transmitted to our CNC network via ShopBot, with real-time monitoring of machine parameters (RPM, feed rate, tool wear). Each work order includes:

Digital twin verification against original CAD using Verisurf

In-process inspections at critical stages via Renishaw probes

Material lot traceability from certified suppliers (e.g., SAE 6061-T6 aluminum)

High-risk features undergo first-article inspection (FAI) per AS9102 standards. All machining data—including toolpath simulations and metrology reports—is logged in our QMS for full auditability.

Quality-Controlled Delivery

Final parts undergo comprehensive validation:

CMM inspection for dimensional compliance (reporting to ±0.005mm)

Surface roughness testing (Ra values per ISO 21920)

Material certification cross-verification

Completed orders include a digital package: as-machined 3D model, inspection reports, and material certs. Physical shipments are vacuum-sealed with humidity indicators and dispatched via tracked logistics, accompanied by a delivery confirmation email containing shipment ID and ETA.

This closed-loop workflow ensures Honyo delivers CNC-machined prototypes and production parts with 99.2% first-pass yield, reducing client rework costs by up to 35% compared to industry benchmarks. All process data feeds into continuous improvement cycles for our AI quoting and DFM systems.

Start Your Project

Need precision CNC machine files for your next project? Contact Susan Leo at [email protected] to discuss your requirements.

Our manufacturing facility is located in Shenzhen, ensuring fast turnaround and high-quality production.

Let Honyo Prototype deliver accurate, reliable CNC machining solutions tailored to your specifications. Reach out today to get started.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.