Contents

Manufacturing Insight: Cnc Machine Desktop

Honyo Prototype CNC Machining Services

For engineering teams requiring precision prototyping and low-volume production, Honyo Prototype delivers advanced CNC machining capabilities engineered for speed and accuracy. Our state-of-the-art 3-, 4-, and 5-axis CNC milling and turning centers handle complex geometries in materials ranging from aluminum and stainless steel to engineering plastics and titanium, consistently achieving tight tolerances down to ±0.005mm. This desktop-scale machining solution accelerates your design-to-prototype workflow without compromising on industrial-grade quality, enabling rapid iteration for functional validation and pre-production testing.

Integrated directly into our streamlined process is the Honyo Online Instant Quote platform, eliminating traditional quoting delays. Upload your CAD file, specify materials and finishes, and receive a detailed, transparent cost estimate within minutes—no manual back-and-forth required. This real-time pricing system ensures your project moves from concept to machined part faster, supporting agile development cycles while maintaining rigorous quality control standards. Trust Honyo to transform your digital designs into high-fidelity physical prototypes with unmatched efficiency.

Technical Capabilities

Desktop CNC Machine Technical Specifications

The following table outlines key technical specifications for a high-precision desktop CNC machine designed for 3, 4, and 5-axis milling as well as turning operations. This machine is engineered for tight-tolerance applications across a range of materials including aluminum, steel, ABS, and nylon.

| Specification | Detail |

|---|---|

| Machine Type | Multi-axis CNC (3-axis standard, 4/5-axis optional with rotary indexing) Integrated turning capability |

| Work Envelope (XYZ) | 300 mm × 250 mm × 200 mm (11.8 in × 9.8 in × 7.9 in) |

| Spindle Speed Range | 8,000 – 24,000 RPM (air-cooled or liquid-cooled options) |

| Spindle Power | 1.5 kW – 2.2 kW |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.002 mm (±0.0001 in) |

| Axis Resolution | 0.001 mm (0.00004 in) |

| Control System | Industrial-grade CNC controller with touchscreen HMI, compatible with G-code, supported by CAD/CAM software (e.g., Fusion 360, Mastercam) |

| Tool Changer | Automatic Tool Changer (ATC) with 8–12 tool capacity (optional) |

| Rotary Axis (4th/5th Axis) | Integrated dual-axis rotary table (A and B axes), ±360° rotation, indexing accuracy ±5 arc seconds |

| Turning Capability | Live tooling spindle for mill-turn operations; max turning diameter: 80 mm |

| Materials Supported | Aluminum (6061, 7075), Mild and Stainless Steel (1018, 303, 304), Engineering Plastics (ABS, Nylon, PEEK, Delrin) |

| Coolant System | Mist coolant or flood coolant option; air blast for non-metallic materials |

| Maximum Material Hardness | Up to 60 HRC (with appropriate tooling and parameters) |

| Tolerance Range | ±0.01 mm (±0.0004 in) typical; tight-tolerance features achievable down to ±0.005 mm with process optimization |

| Linear Guideways | High-precision linear rails with preloaded bearings |

| Drive System | Servo motors with ball screw drive (0.01 mm pitch) |

| Machine Frame | Rigid cast aluminum or steel composite construction with vibration damping |

| Power Requirement | 200–240 VAC, 3-phase, 10 A |

| Dimensions (L×W×H) | 900 mm × 750 mm × 950 mm (35.4 in × 29.5 in × 37.4 in) |

| Weight | Approx. 280 kg (617 lbs) |

| Safety Features | Full enclosure with interlocks, emergency stop, dust/chip extraction port, CE and ISO compliance |

This desktop CNC platform is ideal for precision prototyping, small-batch production, and R&D environments where space efficiency and high accuracy are critical. The system supports multi-material machining, enabling seamless transitions between metals and engineering plastics with optimized tool paths and spindle settings.

From CAD to Part: The Process

Honyo Prototype delivers precision CNC machined desktop-scale components through a rigorously controlled digital workflow designed for speed, accuracy, and manufacturability. Our process eliminates traditional quoting bottlenecks while ensuring engineering integrity from initial upload to final shipment.

CAD File Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid) or 3D PDFs via our secure customer portal. Our system immediately performs automated validation checks for file integrity, unit consistency, and geometric completeness. Critical parameters including material specifications, surface finish requirements, and geometric dimensioning and tolerancing (GD&T) are extracted. Unresolved ambiguities trigger an immediate notification to the client for clarification before progression.

AI-Powered Instant Quoting

Validated CAD data feeds into Honyo’s proprietary AI quoting engine, trained on 12,000+ historical CNC machining projects. The system analyzes part geometry, material density, feature complexity, and tolerance stringency to generate accurate cost and lead time estimates within 90 seconds. Unlike basic calculators, our AI factors in machine-specific capabilities, toolpath complexity, and secondary operation requirements. Clients receive a transparent breakdown of machining hours, material costs, and finishing operations before formal commitment.

Engineering-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability review by our senior CNC engineering team. This phase identifies and resolves potential production issues through collaborative client engagement. Key focus areas include:

| DFM Parameter | Typical Issue Identified | Honyo Resolution Approach |

|---|---|---|

| Wall Thickness | < 0.5mm features in aluminum | Recommend geometry modification or alternative material |

| Tolerance Stack-Ups | Conflicting GD&T callouts | Propose revised tolerance scheme meeting functional requirements |

| Tool Access | Deep cavities with narrow radii | Suggest chamfers or alternative machining sequence |

| Material Utilization | Excessive raw stock waste | Optimize part orientation and nesting |

The DFM report includes annotated 3D models highlighting suggested modifications with engineering rationale. Clients approve revisions digitally before production release.

Precision CNC Production

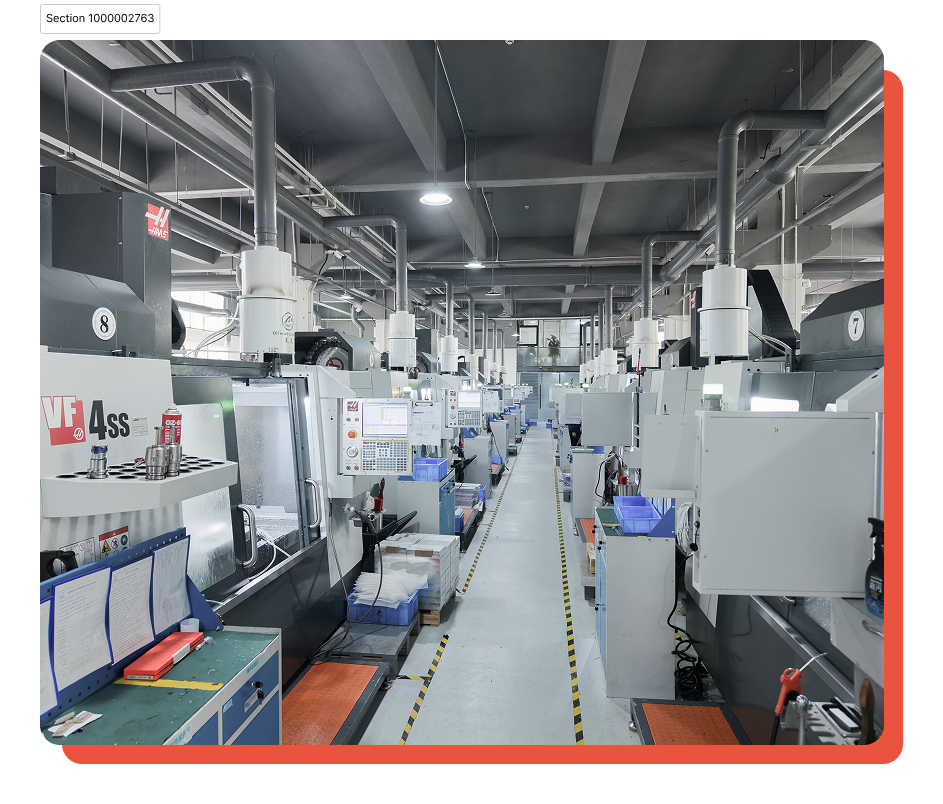

Approved designs move to our climate-controlled machine shop featuring 28 Haas and DMG MORI centers. Desktop components typically utilize our:

5-axis vertical machining centers for complex organic shapes

High-speed CNC lathes with live tooling for turned/milled hybrids

Dedicated deburring and finishing cells

All operations follow documented work instructions with in-process inspections at critical stages. First-article inspection reports (FAIR) using Zeiss coordinate measuring machines are provided for quantities exceeding 10 units. Material traceability is maintained via serialized barcoding from raw stock to finished part.

Quality-Controlled Delivery

Completed orders undergo final validation against original specifications including:

Dimensional verification per ASME Y14.5

Surface roughness testing (Ra/Rz)

Visual inspection for burrs or handling damage

Parts are packaged in anti-static ESD-safe containers with custom foam inserts for fragile desktop components. Shipping includes real-time logistics tracking and full documentation package (certificates of conformance, material test reports, FAIRs). Standard lead time for desktop-scale CNC projects is 5-7 business days from DFM approval, with expedited 72-hour options available for qualifying geometries.

Start Your Project

Looking for a precision CNC machine designed for desktop use? Contact Susan Leo at [email protected] to learn more about our compact, high-performance CNC solutions engineered for prototyping and small-scale manufacturing.

Our facility is based in Shenzhen, a global hub for advanced manufacturing, ensuring rapid production cycles and strict quality control. Whether you’re a product designer, engineer, or R&D team, our desktop CNC machines deliver accuracy, reliability, and ease of integration into your workflow.

Reach out today to request specifications, pricing, or arrange a technical consultation. Let Honyo Prototype support your innovation with made-to-precision engineering from our Shenzhen factory.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.