Contents

Manufacturing Insight: Cnc Machine Definition

Defining Precision Manufacturing with Honyo CNC Machining

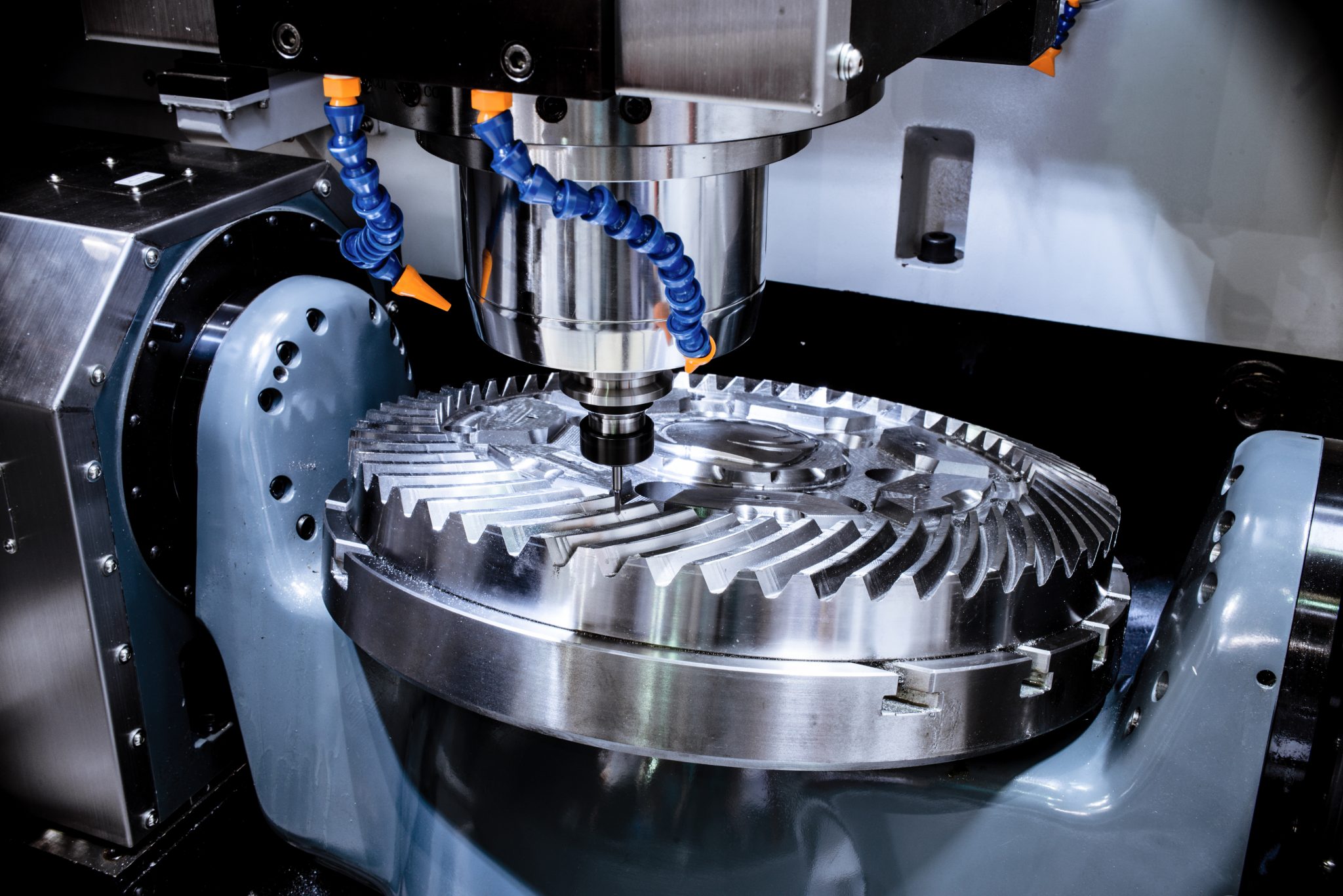

Computer Numerical Control (CNC) machining represents the cornerstone of modern precision manufacturing, utilizing computerized systems to automate the operation of machine tools such as mills, lathes, and routers. This technology executes complex, multi-axis movements with micron-level accuracy based on precise digital design files, transforming raw materials like aluminum, steel, titanium, plastics, and composites into functional components. At Honyo Prototype, we leverage advanced CNC machining capabilities to deliver exceptional prototyping and low-to-medium volume production services for demanding industrial applications.

Our comprehensive CNC machining services encompass 3-axis, 4-axis, and 5-axis milling, precision turning, and multi-tasking operations, ensuring optimal solutions for intricate geometries and tight tolerances. Honyo’s engineering expertise and state-of-the-art equipment guarantee consistent part quality, rapid turnaround times, and material efficiency across diverse sectors including aerospace, medical devices, automotive, and industrial equipment. We prioritize process optimization to meet stringent technical specifications while maintaining cost-effectiveness for your project lifecycle.

Accelerate your development cycle with Honyo’s Online Instant Quote system. This proprietary platform provides transparent, real-time pricing and lead time estimates within seconds, directly from your uploaded CAD files. Eliminate traditional quoting delays and gain immediate insight into manufacturability and cost, empowering faster decision-making for your critical prototyping and production needs. Experience the efficiency of precision CNC machining, backed by Honyo Prototype’s engineering excellence and commitment to on-time delivery.

Technical Capabilities

CNC machine definition refers to computer numerical control systems that automate the operation of machine tools through programmed sequences of machining commands. These machines are widely used in precision manufacturing for their ability to produce complex geometries with high repeatability and tight tolerances. Below is a technical specification summary focusing on 3-axis, 4-axis, and 5-axis milling, CNC turning, and capabilities related to tight tolerance machining across common engineering materials.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability |

|---|---|---|---|---|---|

| Degrees of Freedom | X, Y, Z linear axes | X, Y, Z + rotary A-axis (rotation around X) | X, Y, Z + two rotary axes (e.g., A & B or B & C) | X, Z linear axes + C-axis (rotary spindle) | Achievable across all configurations with proper setup |

| Typical Spindle Speed Range | 8,000 – 24,000 RPM | 8,000 – 20,000 RPM | 10,000 – 20,000 RPM (high-speed variants up to 30,000 RPM) | 1,500 – 6,000 RPM (varies by workpiece size) | Optimized with high-precision spindles (≤ 3 µm runout) |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm to ±0.003 mm | ±0.005 mm | Up to ±0.001 mm with laser calibration and thermal compensation |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.003 mm | ±0.001 mm achievable under controlled conditions |

| Typical Feed Rates | 1,000 – 10,000 mm/min | 1,000 – 8,000 mm/min | 1,000 – 8,000 mm/min (simultaneous motion reduces effective speed) | 500 – 5,000 mm/min | Maintained consistently via adaptive feed control |

| Work Envelope (Typical Max) | 700 x 400 x 400 mm | 700 x 400 x 400 mm + rotational range | 600 x 500 x 400 mm (varies significantly by machine type) | Diameter: up to 500 mm, Length: up to 1,000 mm | Depends on machine class; precision lathes support smaller, controlled envelopes |

| Materials Processed | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon (also titanium, Inconel for high-end models) | Aluminum, Steel, ABS (Nylon with proper chip control) | All above materials with process optimization |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm | Ra 0.8 – 1.6 µm | Ra 0.4 – 1.6 µm (down to Ra 0.2 µm with polishing passes) | Ra 0.8 – 1.6 µm (down to Ra 0.4 µm with fine turning) | Ra ≤ 0.4 µm achievable with diamond turning or grinding |

| Tight Tolerance Range | ±0.010 mm standard, ±0.005 mm with fine tuning | ±0.010 mm standard | ±0.005 mm standard, ±0.002 mm with precision calibration | ±0.010 mm diameter control, ±0.005 mm with gauging | ±0.001 mm to ±0.005 mm using statistical process control and CMM verification |

| Coolant & Lubrication | Flood coolant, mist, or minimum quantity lubrication (MQL) | Flood or MQL | High-pressure through-spindle coolant | Flood or MQL | Precision nozzles and temperature-stabilized coolant |

| Control System | Fanuc, Siemens, Heidenhain, or proprietary (e.g., Mitsubishi) | Same as 3-axis with rotary coordination | Advanced 5-axis interpolation with collision avoidance | Fanuc or Siemens with live tooling support | Full closed-loop feedback with thermal drift compensation |

Material Notes

Aluminum: Easily machined across all CNC platforms; high material removal rates. Ideal for prototypes and lightweight components.

Steel (mild, stainless, tool): Requires rigid setups and proper tooling. 5-axis and high-torque turning machines preferred for hardened grades.

ABS: Low melting point; requires sharp tools and low heat input. Best suited for 3-axis and 4-axis milling with optimized feeds.

Nylon: Prone to deformation; needs secure fixturing and controlled cutting forces. Machinable on milling and turning centers with attention to chip evacuation.

Summary

3-axis machines offer cost-effective solutions for prismatic parts, while 4-axis adds indexing or continuous rotary capability for features like drilled holes on the side of a part. 5-axis milling enables full contouring of complex geometries such as impellers, aerospace components, and molds. CNC turning excels at high-volume, symmetric parts. Tight tolerance production across all configurations demands machine rigidity, thermal stability, high-resolution feedback systems, and skilled process validation.

From CAD to Part: The Process

Honyo Prototype defines the CNC machine process as a closed-loop digital workflow transforming client CAD data into certified physical parts. This integrated sequence ensures manufacturability, cost transparency, and on-time delivery while minimizing manual intervention points.

CAD Upload and Initial Processing

Clients submit native or neutral format CAD files (STEP, IGES, Parasolid) via our secure portal. Our system immediately performs geometric validation, checking for non-manifold edges, gaps, and unit inconsistencies. Validated models trigger automatic material library cross-referencing based on part geometry and client-specified requirements, generating a preliminary process roadmap before human review.

AI-Powered Quoting Engine

The validated CAD model enters our proprietary AI quoting system which analyzes 127+ geometric and logistical parameters including volume, feature density, axis complexity, and surface finish requirements. Unlike basic volume-based quoting, our AI correlates historical machine utilization data, real-time shop floor capacity, and material scrap rates to generate a technically validated price within 90 seconds. Critical tolerances beyond ±0.025mm automatically flag for engineering review to prevent under-quoting.

Engineer-Validated DFM Analysis

All quotes undergo mandatory Design for Manufacturing review by our AS9100-certified engineering team. We identify three critical manufacturability tiers:

Standard features requiring no modification

Advisory items where minor geometry adjustments (e.g., internal radii optimization) reduce cost by 15-30%

Non-Production elements necessitating client redesign (e.g., impossible undercuts)

Our DFM report includes annotated 3D visualizations and tolerance stack-up simulations, not generic checklists. Typical DFM resolution occurs within 4 business hours for 92% of projects.

Integrated Production Execution

Approved designs move to our centralized production module where:

Machine allocation occurs based on real-time spindle load balancing across 87 CNC assets (3/4/5-axis mills, lathes)

CAM programming uses hyperMILL with collision-avoidance verification against actual machine kinematics

In-process inspection plans auto-generate from client’s GD&T callouts

Material traceability begins at billet level with laser-etched part IDs linking to heat treatment certs and CMM reports.

Certified Delivery Protocol

All shipments include:

First Article Inspection report per AS9102 format

Material certification with full chemical/mechanical properties

Dimensional results mapped to original CAD via 3D deviation color plots

Vacuum-sealed packaging with humidity indicators for precision components

Our delivery tracker provides GPS-enabled logistics with customs clearance documentation auto-generated for international shipments. Average lead time from CAD upload to certified delivery is 72 hours for standard aluminum prototypes.

This workflow eliminates traditional handoffs between quoting, engineering, and production teams. The AI quote accuracy rate exceeds 95% against final invoice values due to our closed-loop data system where actual machine cycle times continuously refine the quoting algorithm. Clients receive technical ownership of all process documentation through our client portal, ensuring full transparency from design intent to certified part.

Start Your Project

For a detailed CNC machine definition and technical specifications, contact Susan Leo at [email protected]. Honyo Prototype operates a precision manufacturing facility in Shenzhen, providing high-accuracy CNC machining services for rapid prototyping and low-volume production. Reach out to discuss your project requirements and learn how our advanced CNC capabilities can support your engineering and product development needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.