Contents

Manufacturing Insight: Cnc Machine Coolant Nozzles

Optimizing CNC Performance Through Precision Coolant Delivery

Effective thermal management remains a critical factor in maximizing CNC machining productivity and part quality. Honyo Prototype understands that precision coolant nozzles are not merely accessories but engineered components essential for chip evacuation, tool life extension, and dimensional stability during high-speed operations. Substandard nozzles lead to inconsistent coolant flow, accelerated tool wear, and compromised surface finishes—directly impacting your production efficiency and scrap rates.

At Honyo Prototype, our CNC machining services integrate rigorous component design with advanced manufacturing capabilities to deliver coolant delivery systems engineered for reliability. We leverage multi-axis milling and turning centers with tight tolerance control to produce nozzles that ensure optimal coolant pressure distribution and targeted application, whether for complex aerospace alloys or high-volume automotive components. Our engineering team collaborates with clients to validate nozzle geometry, material selection, and interface compatibility within your specific machine environment, eliminating trial-and-error downtime.

This commitment to precision extends across our entire CNC machining portfolio, from rapid prototyping to low-volume production runs. To accelerate your project timeline, utilize our Online Instant Quote platform for immediate pricing on custom nozzle fabrication or full-part machining services. Submit your CAD file and receive a detailed quote within hours—enabling faster validation of thermal management solutions that protect your tooling investment and uphold stringent quality standards.

Technical Capabilities

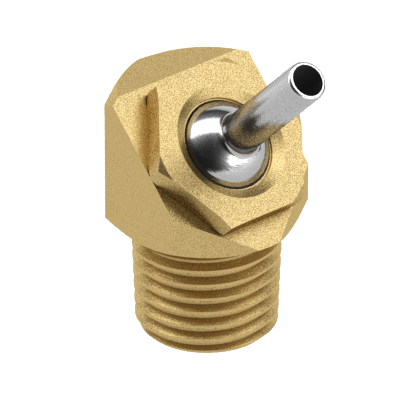

CNC machine coolant nozzles are critical components in precision machining environments, especially in 3-, 4-, and 5-axis milling and turning operations where tight tolerances demand optimal chip evacuation and thermal control. These nozzles deliver high-velocity streams of coolant directly to the cutting zone, minimizing thermal deformation, extending tool life, and improving surface finish. The design and material selection of the nozzle must accommodate complex tool paths, multi-angle access, and compatibility with various workpiece materials such as aluminum, steel, ABS, and nylon.

| Specification | Detail |

|---|---|

| Application | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning; high-precision machining with tight tolerances (±0.005 mm or better) |

| Coolant Delivery Type | High-pressure (up to 1,000 psi), high-velocity through-spindle or external nozzles; adjustable flow and directional control |

| Nozzle Orientation | Multi-axis articulating or swiveling heads for 5-axis reach; fixed and flexible gooseneck variants for 3- and 4-axis systems |

| Flow Rate Range | 5–50 liters per minute (dependent on pressure and nozzle orifice size) |

| Orifice Diameter | 1.0 mm to 3.0 mm (interchangeable tips for different flow patterns and pressures) |

| Mounting Interface | ISO, DIN, or custom mounts compatible with machine tool turrets, spindle housings, or robotic arms |

| Adjustability | 360° radial rotation; ±90° angular tilt; lockable positions for repeatability |

| Materials – Nozzle Body | Stainless steel (304/316) for corrosion resistance and durability; aluminum alloy (6061-T6) for lightweight articulating arms; engineered plastics (ABS, Nylon 6/6 or PEEK) for non-marring applications on soft materials |

| Material Compatibility Notes | • Aluminum: Use high-flow coolant to prevent built-up edge; nylon or stainless steel nozzles avoid contamination • Steel (alloy/tool): High-pressure coolant (700+ psi) with stainless steel nozzles to manage heat and chip removal • ABS & Nylon (plastics): Low to medium pressure; nylon or ABS nozzles recommended to prevent scratching or static buildup; avoid excessive coolant force to prevent part deformation |

| Thermal Management | Designed to minimize thermal drift in high-precision operations; consistent coolant targeting ensures dimensional stability |

| Integration | Compatible with CNC-controlled positioning; optional servo-driven or pneumatically actuated adjustment for dynamic alignment during multi-axis toolpaths |

| Maintenance | Self-cleaning orifice designs; filter integration to prevent clogging from particulates in recycled coolant |

Advanced CNC coolant nozzles used in tight-tolerance environments often feature modular tip systems, allowing quick changeover between fan, solid stream, and atomized mist patterns based on the material and operation. In 5-axis milling, spatial constraints require compact, rotatable nozzle bodies made from lightweight aluminum or high-strength nylon composites. For turning applications, rigid stainless steel nozzles ensure stable positioning near the insert. Material selection for the nozzle itself is crucial—non-metallic options like ABS and nylon are preferred when machining soft or non-ferrous materials to avoid accidental contact damage.

From CAD to Part: The Process

Honyo Prototype executes a streamlined, quality-focused workflow for CNC machine coolant nozzle production designed to minimize lead times while ensuring functional reliability in demanding machining environments. Our process integrates digital efficiency with engineering rigor at every stage.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via our secure customer portal. Our system automatically validates file integrity and geometry completeness, flagging common issues like missing fillets or underspecified threads specific to coolant nozzle interfaces. For legacy 2D drawings, our engineering team performs rapid 3D reconstruction with client confirmation prior to quoting, ensuring dimensional accuracy for critical features such as nozzle orifice diameters and mounting threads.

AI-Powered Quoting with Engineering Validation

Uploaded designs enter our AI-driven quoting engine, which analyzes geometric complexity, feature tolerances (e.g., ±0.05mm for concentricity), and material requirements against real-time machine capacity and material costs. Crucially, this is not a fully automated system; a Senior Manufacturing Engineer reviews the AI output within 4 business hours. This human-in-the-loop step verifies feasibility of internal coolant channels, assesses potential for turbulent flow due to sharp bends, and confirms material suitability (e.g., 303 stainless steel vs. brass for corrosion resistance in alkaline coolants). Clients receive a formal quote with explicit lead time commitments and cost breakdowns.

Engineering-Centric DFM Analysis

Upon quote acceptance, our DFM phase begins with dedicated focus on coolant nozzle performance criteria. Engineers perform fluid dynamics simulations to identify pressure drop risks in complex internal passages and verify spray pattern integrity. We proactively address common failure points:

Recommending chamfers on inlet/outlet edges to prevent burr-induced flow disruption

Optimizing wall thickness around thin sections (e.g., tapered tips) to avoid deflection during clamping

Validating thread engagement depth to withstand vibration in high-RPM spindles

This phase includes a client-facing report with actionable suggestions, typically completed within 72 hours. For urgent orders, we offer a 24-hour expedited DFM path with priority engineering allocation.

Precision Production and Validation

Approved designs move to production on our Swiss-type CNC lathes and 5-axis milling centers equipped with high-pressure coolant systems mirroring end-use conditions. Key production controls include:

| Material Option | Typical Application | Critical Process Control |

|---|---|---|

| 303 Stainless Steel | Corrosive coolant environments | Passivation post-machining; 100% pressure test at 1.5x operating pressure |

| Free-Machining Brass (C36000) | General purpose; cost-sensitive | Deburring verification via borescope; dimensional audit of thread pitch |

| PEEK Polymer | Non-marring applications; chemical resistance | In-process thermal monitoring to prevent crystallization defects |

All nozzles undergo flow testing at specified pressure/flow rate parameters, with results documented in the shipment package. Dimensional verification uses calibrated CMMs for critical interfaces like O-ring grooves and mounting faces.

Traceable Delivery and Performance Assurance

Finished nozzles ship with comprehensive documentation including first-article inspection reports, material certifications, and flow test data. We implement serialized part tracking enabling full process traceability from raw material lot to final inspection. For critical path clients, we offer direct integration with their maintenance systems via API, providing real-time delivery status and historical performance analytics to forecast replacement needs. Standard delivery is 5-7 business days from DFM approval, with emergency 72-hour turnaround available for qualifying orders. This end-to-end process ensures coolant nozzles deliver consistent performance, minimizing machine downtime through precision engineering and operational transparency.

Start Your Project

Upgrade your CNC machining performance with precision-engineered coolant nozzles designed for optimal chip removal and tool cooling. Manufactured in our Shenzhen factory, our nozzles ensure consistent flow accuracy and long-term durability under high-pressure coolant systems.

Contact Susan Leo today at [email protected] to request specifications, samples, or volume pricing. Enhance your CNC efficiency with reliable, custom-fit nozzle solutions built to meet the demands of modern precision manufacturing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.