Contents

Manufacturing Insight: Cnc Machine Chuck

Precision Workholding Starts Here: Honyo’s CNC Machining Excellence

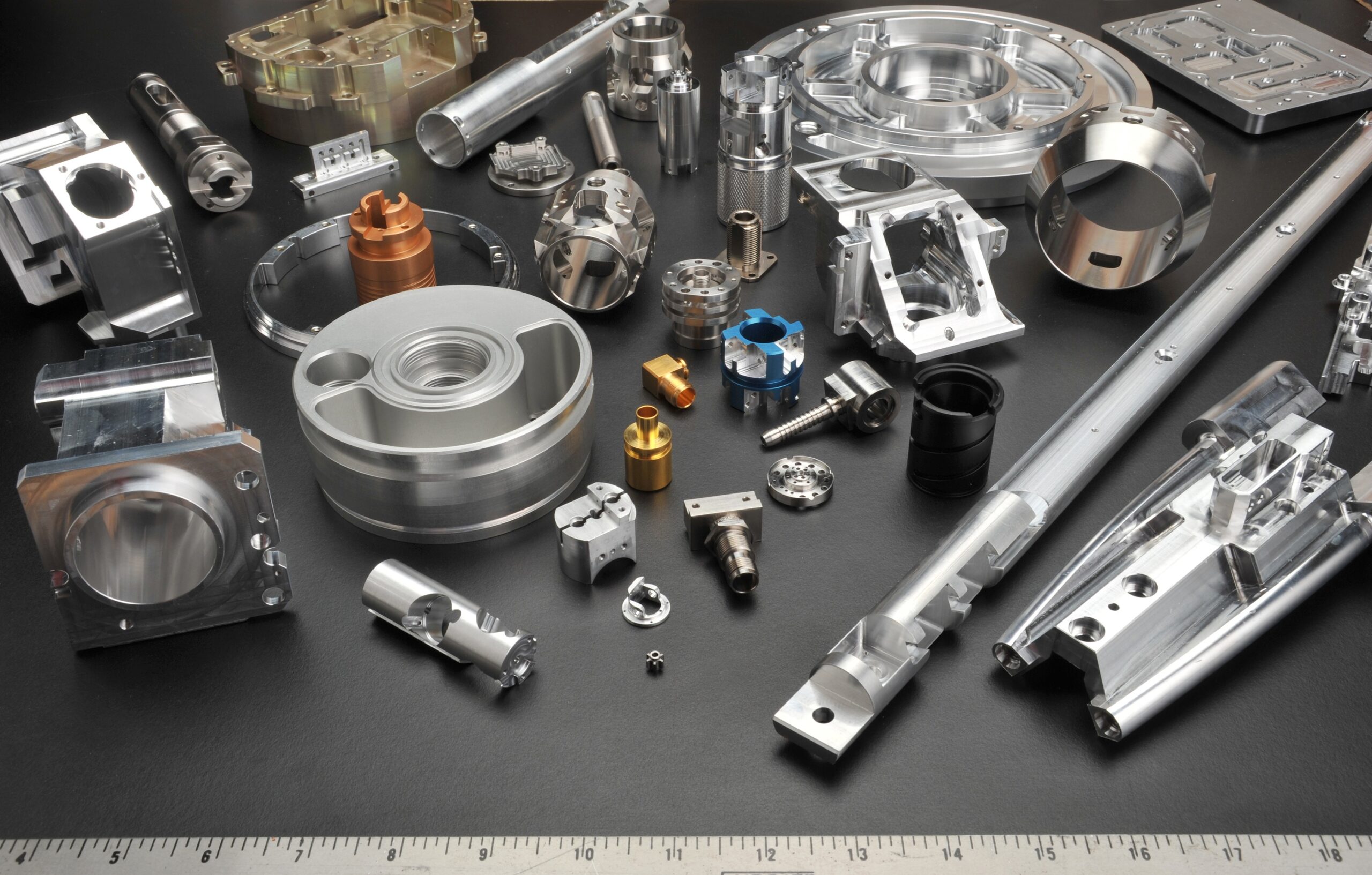

The CNC machine chuck is far more than a simple clamping device; it is the critical foundation for achieving micron-level tolerances, exceptional surface finishes, and unwavering repeatability in high-precision manufacturing. At Honyo Prototype, we engineer every chuck interface and machining process to eliminate runout, vibration, and thermal drift—ensuring your complex components meet the most stringent aerospace, medical, and industrial specifications. Our advanced CNC machining services leverage state-of-the-art 3-, 4-, and 5-axis centers with dynamic tool monitoring and automated pallet systems, enabling rapid prototyping and low-volume production without compromising accuracy or material integrity.

Honyo’s commitment to operational agility extends to our customer experience. We eliminate traditional quoting bottlenecks with our Online Instant Quote platform, providing transparent, real-time pricing and lead time estimates for CNC milling, turning, and multi-axis operations within minutes. Upload your STEP or IGES files, specify materials and tolerances, and receive actionable data to accelerate your project timeline—no callbacks, no delays. Partner with Honyo Prototype where precision engineering meets seamless procurement efficiency. Request your quote today to experience manufacturing without compromise.

Technical Capabilities

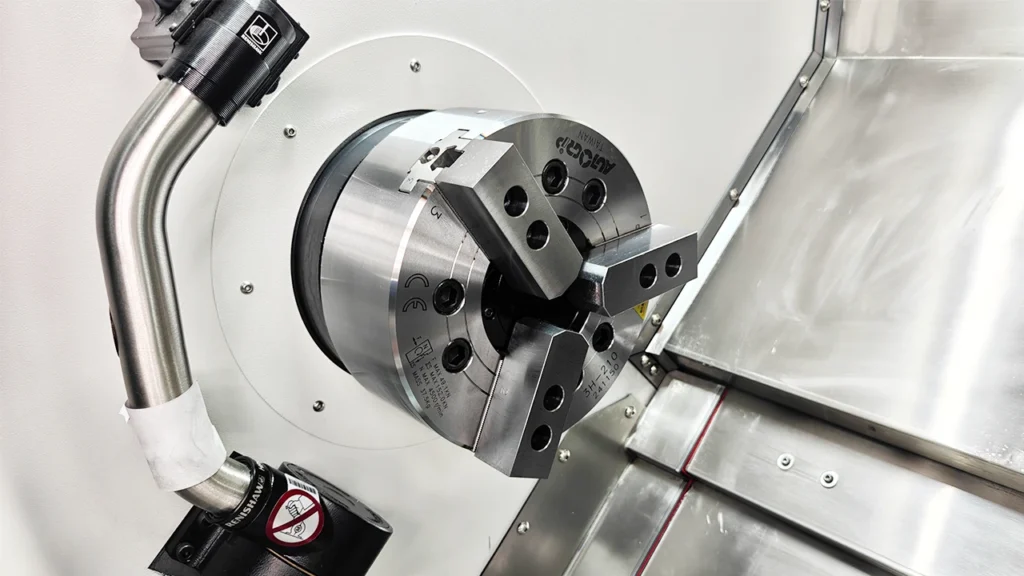

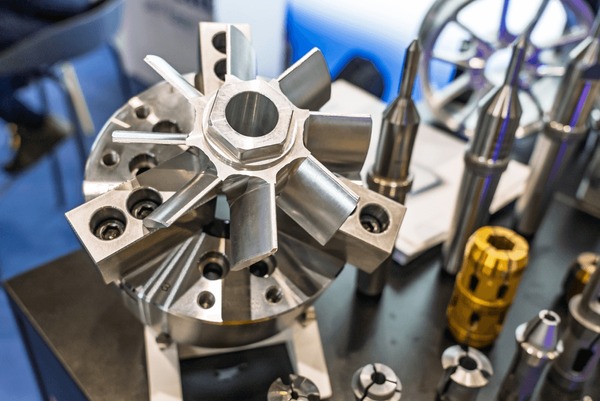

CNC machine chucks are critical workholding devices used to secure raw material or workpieces during machining operations such as 3/4/5-axis milling and turning. High-performance chucks are engineered for rigidity, precision, and repeatability, especially when tight tolerances (±0.0005″ or better) are required. The chuck must maintain concentricity, minimize runout, and provide consistent clamping force across various materials including aluminum, steel, ABS, and nylon. Below is a technical specification table outlining key performance and compatibility parameters.

| Parameter | Specification |

|---|---|

| Chuck Type | Hydraulic, Pneumatic, or Mechanical Power Chucks; Collet Chucks (e.g., ER, TG, R8) |

| Compatible Machines | 3-Axis, 4-Axis, 5-Axis CNC Mills, CNC Lathes (Turning Centers) |

| Maximum RPM | Up to 12,000 RPM (dependent on chuck size, balance, and clamping method) |

| Repeatability (Total Indicated Runout) | ≤ 0.0002″ (5 µm) for precision collet and hydraulic chucks |

| Clamping Force | 1,000 – 15,000 lbs (hydraulic); 500 – 5,000 lbs (pneumatic) |

| Jaw Options | Soft Jaws (machinable), Hard Jaws, Custom Formed Jaws |

| Jaw T-slot Size | Standard: 5mm, 8mm, 10mm; Custom options available |

| Chuck Face Runout | ≤ 0.0004″ (10 µm) at full diameter |

| Balancing Standard | ISO 1940/1 Grade G2.5 (high-speed applications) |

| Interface Standard | A, D, DA, or HSK-C; Custom flange plates per machine spindle |

| Material Compatibility – Metals | Aluminum (6061, 7075), Steel (1018, 4140, Stainless), Titanium, Brass |

| Material Compatibility – Plastics | ABS, Nylon (6/66), PEEK, Delrin, HDPE, Polycarbonate |

| Minimum Feature Size (Milling) | Capable of holding parts ≥0.125″ diameter with soft jaws or collets |

| Thermal Stability | Designed for minimal thermal drift; suitable for ±0.0005″ tolerance machining |

| Sensor Integration | Optional: Force monitoring, proximity sensors for part detection |

| Surface Finish Protection | Replaceable jaw inserts, non-marring coatings (e.g., anodized, rubber-clad) |

| Maintenance Interval | Lubrication and inspection every 500–1,000 hours of operation |

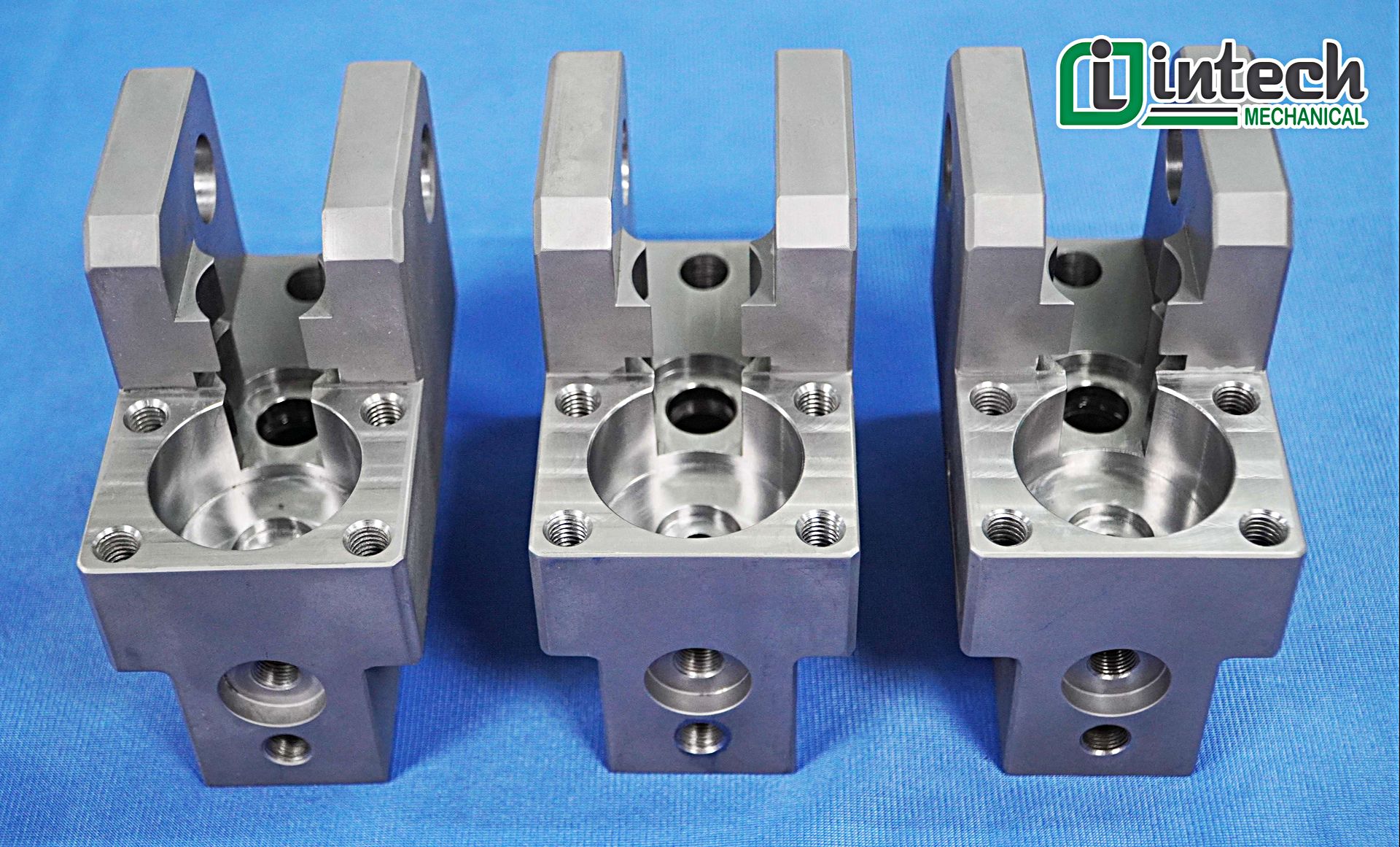

Chucks used in tight-tolerance applications must be regularly maintained and calibrated. For aluminum and plastics like ABS and nylon, soft jaws or custom gripping surfaces prevent deformation and surface damage. In steel turning and high-force milling, hardened jaws and hydraulic actuation ensure stability. Collet chucks (e.g., ER25, ER32) are preferred for small-diameter workpieces requiring high concentricity. For 5-axis operations, compact, low-profile chucks with high rigidity enable better tool access and multi-sided machining accuracy.

From CAD to Part: The Process

Honyo Prototype executes CNC machine chuck fabrication through a rigorously defined workflow designed for precision, efficiency, and client transparency. This integrated process ensures optimal manufacturability and delivery reliability for critical chuck components.

The engagement initiates when the client uploads their CAD model via our secure online portal. Our system accepts industry-standard formats including STEP AP203/214, IGES, Parasolid, and native formats from SOLIDWORKS, Creo, and Siemens NX. Upon validation of file integrity and geometric completeness, the data enters our proprietary AI-driven quoting engine. This system analyzes the 3D model against real-time parameters such as material availability, machine capacity, geometric complexity, surface finish requirements, and current production load. The AI generates a preliminary cost and lead time estimate within minutes, which is immediately presented to the client through the portal interface. Crucially, this AI output undergoes mandatory review by a Senior Manufacturing Engineer who validates assumptions, flags potential ambiguities, and ensures the quote reflects practical manufacturing constraints before final client acceptance.

Following quote approval, the project transitions to our mandatory Design for Manufacturability (DFM) phase. A dedicated Honyo engineer conducts a comprehensive review focused specifically on chuck functionality and CNC machining viability. Key analyses include jaw interface geometry validation against standard spindle noses, clamping force distribution modeling, thermal expansion compensation in critical bores, material grain flow orientation for structural integrity, achievable tolerance stack-ups for runout control, and fixture repeatability assessment. We proactively identify conflicts such as undercuts interfering with jaw travel or thin sections prone to chatter. The DFM report details specific, actionable recommendations with engineering rationale, often including revised geometry suggestions. This phase is critical for preventing costly rework and ensuring the chuck performs as intended under operational loads.

The following table illustrates common DFM findings specific to CNC chucks and their resolution impact:

| DFM Issue Category | Typical Example in Chuck Design | Honyo Resolution Approach | Impact on Production |

|---|---|---|---|

| Geometric Interference | Jaw pocket radius too small for standard jaw profile | Redesign pocket fillet radius to ISO standard | Prevents assembly failure, avoids scrap |

| Material Utilization | Excessive stock in non-critical flange areas | Optimize blank size and machining sequence | Reduces material cost by 15-25% |

| Tolerance Conflict | ±0.005mm runout spec on bore with rough surface finish | Collaborate to adjust spec or add finishing pass | Achieves functional requirement cost-effectively |

| Machinability Risk | Thin-walled collet section prone to deflection | Recommend support fixtures or adaptive toolpaths | Ensures dimensional accuracy, prevents part rejection |

Upon DFM sign-off, the project moves to production on our dedicated CNC turning and milling centers. Chuck components are typically manufactured on multi-axis lathes (DMG MORI NTX series, Okuma MULTUS) or vertical machining centers (Haas VF series) with sub-micron positioning accuracy. We implement strict process controls including pre-machined blank certification, in-process CMM verification of critical datums like mounting interface and bore concentricity, and final 100% inspection per AS9102 aerospace standards when required. Material traceability from mill certificate through heat treatment (if specified) is maintained. All chuck jaws undergo individual runout testing on precision arbors prior to assembly.

Final delivery encompasses more than physical shipment. We provide comprehensive documentation including certified material test reports, first-article inspection reports (FAIR) with GD&T verification, surface roughness measurements, and assembly instructions if applicable. Chucks are packaged with protective covers for critical sealing surfaces and shipped via tracked logistics with real-time visibility. Our standard lead time for complex chucks is 15-20 business days from DFM approval, with expedited options available. This end-to-end process, underpinned by engineering expertise at every transition point, guarantees chucks that meet stringent performance demands while minimizing time-to-assembly for our clients. Honyo maintains full NDA compliance and ITAR registration for defense-related chuck applications throughout this workflow.

Start Your Project

Need a reliable CNC machine chuck for your manufacturing operations? Contact Susan Leo today at [email protected] to discuss high-precision chucks engineered for performance and durability.

Honyo Prototype manufactures premium CNC chucks at our state-of-the-art facility in Shenzhen, ensuring tight tolerances, consistent quality, and fast lead times. Whether you require standard configurations or custom designs, our team delivers solutions tailored to your production needs.

Reach out to Susan Leo via email to request specifications, pricing, or technical support. Partner with a trusted Shenzhen-based manufacturer committed to excellence in precision engineering.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.