Introduction: Navigating the Global Market for cnc machine car parts

In today’s fast-paced automotive landscape, sourcing CNC machine car parts poses a significant challenge for B2B buyers, particularly those navigating the complexities of international trade. With the growing demand for precision-engineered components, businesses in Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia, require a reliable guide to streamline their procurement processes. This comprehensive resource addresses the pressing needs of global buyers by exploring various types of CNC machining processes, applications in automotive manufacturing, and essential considerations for supplier vetting.

This guide delves into the intricacies of CNC machining, highlighting the advantages of automated processes, such as increased production speed and repeatability, which are crucial for maintaining competitive edge in the automotive sector. Furthermore, it provides actionable insights on cost management, quality assurance, and compliance with international standards, empowering businesses to make informed purchasing decisions.

By equipping international buyers with the knowledge to navigate the global market effectively, this guide serves as a valuable tool for enhancing operational efficiency and driving innovation in automotive manufacturing. Whether you are looking to source high-quality components for prototyping or large-scale production, understanding the nuances of CNC machine car parts is essential for success in today’s dynamic marketplace.

Understanding cnc machine car parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Milled Parts | Precision-cut components, complex geometries | Engine components, chassis parts | Pros: High precision, versatile; Cons: Longer lead times for complex designs. |

| CNC Turned Parts | Rotationally symmetric components, high-speed machining | Shafts, axles, and fittings | Pros: Excellent surface finish, high accuracy; Cons: Limited to cylindrical shapes. |

| 5-Axis Machined Parts | Multi-axis machining capabilities for intricate designs | Aerospace and automotive custom parts | Pros: Complex shapes, reduced setup time; Cons: Higher cost and complexity. |

| CNC Sheet Metal Fabrication | Sheet metal cutting and forming, versatile material options | Body panels, brackets, and enclosures | Pros: Cost-effective for large runs; Cons: Less suitable for intricate designs. |

| CNC Plastic Parts | High-speed machining of plastic materials | Interior components, housing, and fixtures | Pros: Lightweight, rapid prototyping; Cons: Limited durability compared to metals. |

What Are CNC Milled Parts and Their B2B Significance?

CNC milled parts are characterized by their precision cutting capabilities, allowing for the creation of complex geometries that are essential in the automotive sector. These parts are commonly used for engine components and chassis parts, where accuracy is critical. When purchasing CNC milled parts, B2B buyers should consider the material specifications, tolerance levels, and the supplier’s capability to handle intricate designs. While these parts offer high precision and versatility, they may involve longer lead times for complex designs, which can impact production schedules.

How Do CNC Turned Parts Contribute to Automotive Manufacturing?

CNC turned parts are primarily used for producing rotationally symmetric components, such as shafts and axles. The high-speed machining process ensures an excellent surface finish and high accuracy, making them ideal for critical automotive applications. B2B buyers should focus on the specifications of the turning machines and the experience of the manufacturer in producing high-quality turned parts. Although these parts excel in accuracy, they are limited to cylindrical shapes, which may not fit all design requirements.

What Advantages Do 5-Axis Machined Parts Offer in Customization?

5-axis machined parts utilize advanced multi-axis machining capabilities, allowing for the creation of intricate designs that are often required in both the aerospace and automotive industries. These parts can be customized more easily than traditional machining methods, significantly reducing setup times and enhancing production efficiency. Buyers should evaluate the manufacturer’s technology and expertise in 5-axis machining to ensure high-quality outcomes. However, the complexity and cost of these parts may be higher, requiring careful budget considerations.

Why Choose CNC Sheet Metal Fabrication for Automotive Applications?

CNC sheet metal fabrication is essential for producing body panels, brackets, and enclosures in the automotive sector. This method provides versatility in material options and is cost-effective for large production runs. B2B buyers should assess the supplier’s capabilities in handling various sheet metal types and the technology used for cutting and forming. While it is an economical choice for high-volume production, CNC sheet metal may be less suitable for intricate designs that require more detailed machining.

What Role Do CNC Plastic Parts Play in Automotive Design?

CNC plastic parts are increasingly utilized for interior components and fixtures due to their lightweight nature and suitability for rapid prototyping. This technology allows manufacturers to quickly develop and test designs before full-scale production. Buyers should consider the durability and application of the plastic materials used, as they may not withstand the same stresses as metal components. Although they offer rapid prototyping advantages, the trade-off may involve reduced durability compared to metal parts, which is a critical consideration for automotive applications.

Key Industrial Applications of cnc machine car parts

| Industry/Sector | Specific Application of CNC Machine Car Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine Components Manufacturing | High precision and repeatability improve performance and reliability of vehicles. | Quality certifications, material specifications, and lead times. |

| Aerospace | Custom Brackets and Fixtures | Lightweight yet strong components enhance fuel efficiency and reduce overall weight. | Certification for aerospace standards and traceability of materials. |

| Electronics | Housing for Electronic Control Units | Precision machining ensures compatibility and performance in critical automotive electronics. | Compatibility with existing designs and rapid prototyping capabilities. |

| Medical Equipment | Specialized Automotive Medical Transport Parts | Custom parts improve functionality and safety for medical transport vehicles. | Compliance with medical standards and durability under varying conditions. |

| Renewable Energy | Parts for Electric Vehicles | Contributes to the production of sustainable vehicles, meeting rising market demand. | Availability of advanced materials and rapid scaling capabilities. |

How Are CNC Machine Car Parts Used in the Automotive Industry?

In the automotive sector, CNC machine parts are essential for producing engine components, such as cylinder heads and crankshafts. These parts require high precision and repeatability to ensure optimal engine performance and reliability. International buyers must focus on suppliers who can provide quality certifications and adhere to strict material specifications. Additionally, understanding lead times is crucial for maintaining production schedules, especially in regions like Africa and South America where supply chains may be less stable.

What Role Do CNC Machined Parts Play in Aerospace Applications?

CNC machining is vital in the aerospace industry for creating custom brackets and fixtures that are both lightweight and strong. These components are integral in reducing the overall weight of aircraft, thereby enhancing fuel efficiency. Buyers from the Middle East and Europe should prioritize suppliers with certifications for aerospace standards, ensuring that all materials used are traceable and compliant. This focus on quality not only improves safety but also aligns with regulatory requirements in the industry.

How Are CNC Machined Components Utilized in Electronics?

In the electronics sector, CNC machined parts are used to manufacture housings for electronic control units in vehicles. The precision achieved through CNC machining ensures that these components fit seamlessly with other electronic systems, enhancing overall vehicle performance. For B2B buyers, it is important to source from manufacturers who can provide rapid prototyping capabilities and demonstrate compatibility with existing designs. This is particularly relevant for buyers in Europe, where innovation cycles are fast-paced.

What Are the Applications of CNC Machining in Medical Equipment?

CNC machining finds its application in producing specialized parts for automotive medical transport vehicles, ensuring functionality and safety. These custom components are designed to withstand rigorous use while maintaining high standards of precision. Buyers in the medical field must ensure that their suppliers comply with medical standards and can provide durable parts that can endure varying conditions. This consideration is critical for maintaining the integrity of medical transport solutions in regions across Africa and South America.

How Does CNC Machining Support Renewable Energy Initiatives?

In the growing field of renewable energy, CNC machined parts are crucial for the production of electric vehicle components. As demand for sustainable transportation solutions rises, the ability to produce high-quality, lightweight parts becomes essential. International B2B buyers should seek suppliers with access to advanced materials and the capability to scale production quickly. This agility is particularly important in regions like the Middle East, where the renewable energy market is rapidly evolving.

3 Common User Pain Points for ‘cnc machine car parts’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Quality in CNC Machined Parts

The Problem: One of the primary challenges B2B buyers face when sourcing CNC machined car parts is ensuring consistent quality across multiple orders. Variability in material properties, machine calibration, and operator skill can lead to discrepancies in parts, which can affect assembly and vehicle performance. This inconsistency can result in increased production costs, delays, and even potential safety issues, making it crucial for buyers to find reliable suppliers who can deliver uniform quality.

The Solution: To overcome this challenge, buyers should prioritize suppliers with robust quality assurance processes. This includes looking for manufacturers who implement strict quality control measures such as ISO certifications and advanced inspection techniques. Buyers should request detailed documentation of quality checks performed during production, including material certifications and tolerance reports. Additionally, establishing a clear communication channel with suppliers to discuss specific quality requirements can help ensure that the produced parts meet exact specifications. Engaging in initial prototype testing before placing larger orders can also mitigate risks, allowing for adjustments to be made early in the process.

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem: Many B2B buyers in the automotive sector experience long lead times when ordering CNC machined parts, which can disrupt production schedules and delay product launches. Factors such as supplier capacity, machine breakdowns, and inefficiencies in the manufacturing process contribute to these delays, leading to increased costs and lost opportunities in a competitive market.

The Solution: To combat long lead times, buyers should consider partnering with suppliers who offer flexible manufacturing solutions and have the capacity to scale production as needed. Buyers can also benefit from implementing Just-In-Time (JIT) inventory strategies, which minimize inventory costs while ensuring that parts are available when required. Additionally, leveraging technology such as online platforms for real-time order tracking and communication can provide transparency and help buyers anticipate delays. Establishing long-term relationships with reliable suppliers can also lead to prioritized service and reduced lead times, as manufacturers may be more willing to accommodate repeat customers.

Scenario 3: Complexity in Customization and Prototyping

The Problem: As automotive designs become more sophisticated, B2B buyers often struggle with the complexity of customizing CNC machined parts to meet unique specifications. Traditional suppliers may lack the flexibility to accommodate rapid prototyping and customization needs, leading to longer development cycles and potential mismatches between design intent and final product.

The Solution: To streamline the customization process, buyers should seek out CNC machining suppliers that specialize in rapid prototyping and have advanced capabilities, such as 5-axis machining and additive manufacturing. Utilizing a supplier that can provide a range of materials and machining techniques allows for greater experimentation and design flexibility. Buyers should also engage in collaborative design processes with their suppliers, sharing 3D models and specifications early in the development phase. This can facilitate more effective communication and reduce the number of iterations needed to finalize designs. Furthermore, considering suppliers that utilize advanced software for simulations can help in visualizing the end product and identifying potential issues before production begins, thus expediting the overall process.

Strategic Material Selection Guide for cnc machine car parts

What Are the Key Materials for CNC Machined Car Parts?

When selecting materials for CNC machined car parts, it is crucial to consider the specific properties and performance requirements of each material. Here, we analyze four common materials used in the automotive industry: Aluminum, Steel, Titanium, and Plastics. Each material has distinct advantages and limitations that can impact the final product’s performance, cost, and suitability for various applications.

How Does Aluminum Perform in CNC Machining for Automotive Parts?

Aluminum is a popular choice for automotive components due to its lightweight nature and excellent corrosion resistance. Key properties include a high strength-to-weight ratio, thermal conductivity, and resistance to oxidation. These characteristics make aluminum suitable for parts that require both durability and reduced weight, such as engine components and structural elements.

Pros: Aluminum is relatively easy to machine, which can lead to lower manufacturing costs. Its lightweight nature contributes to improved fuel efficiency in vehicles, making it an attractive option for manufacturers focused on sustainability.

Cons: While aluminum has good tensile strength, it may not be as durable as steel under high-stress conditions. Additionally, it can be more expensive than some steel options, impacting overall production costs.

Impact on Application: Aluminum is compatible with various automotive fluids and environments, making it a versatile choice. However, buyers should ensure compliance with international standards such as ASTM and DIN for quality assurance.

What Are the Benefits of Using Steel for CNC Machined Car Parts?

Steel is another widely used material in the automotive sector, known for its high strength and toughness. Key properties include excellent wear resistance, high tensile strength, and the ability to withstand high temperatures and pressures.

Pros: Steel is durable and cost-effective, making it suitable for high-stress applications like chassis and suspension components. Its availability in various grades allows for tailored solutions based on specific performance requirements.

Cons: Steel is heavier than aluminum, which may negatively impact fuel efficiency in vehicles. Additionally, it is susceptible to corrosion, necessitating protective coatings or treatments.

Impact on Application: Steel’s compatibility with various automotive environments is generally strong, but international buyers should consider specific grades that meet regional standards for automotive applications.

Why Choose Titanium for High-Performance CNC Machined Parts?

Titanium is favored for high-performance automotive applications due to its exceptional strength-to-weight ratio and corrosion resistance. Key properties include high fatigue strength and the ability to withstand extreme temperatures.

Pros: Titanium is incredibly strong yet lightweight, making it ideal for high-performance parts like exhaust systems and engine components. Its resistance to corrosion extends the lifespan of components in harsh environments.

Cons: The primary drawback of titanium is its high cost and complexity in machining, which can lead to increased production times and expenses. This makes it less suitable for mass production compared to aluminum and steel.

Impact on Application: Titanium is compatible with various automotive fluids, but its cost may limit its use to premium applications. Buyers should verify compliance with standards such as ASTM and JIS to ensure quality.

When Should Plastics Be Considered for CNC Machined Car Parts?

Plastics, particularly engineering-grade polymers, are increasingly used in automotive applications due to their lightweight nature and versatility. Key properties include good chemical resistance, low density, and the ability to be molded into complex shapes.

Pros: Plastics can reduce overall vehicle weight, contributing to fuel efficiency. They are also cost-effective for low-volume production and can be easily customized.

Cons: Plastics may not offer the same level of durability or heat resistance as metals, making them less suitable for high-stress applications. Additionally, they may have limitations in terms of temperature and pressure ratings.

Impact on Application: Plastics are compatible with many automotive environments, but buyers should consider the specific requirements of their applications, including compliance with international standards.

Summary Table of Material Selection for CNC Machined Car Parts

| Material | Typical Use Case for cnc machine car parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine components, structural parts | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Steel | Chassis, suspension components | High strength and cost-effective | Heavier and prone to corrosion | Low |

| Titanium | Exhaust systems, high-performance parts | Exceptional strength-to-weight ratio | High cost and machining complexity | High |

| Plastics | Interior components, non-structural parts | Lightweight and customizable | Limited durability under stress | Low |

This strategic material selection guide provides international B2B buyers with insights into the best materials for CNC machined car parts, helping them make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc machine car parts

What Are the Main Stages of Manufacturing CNC Machine Car Parts?

The manufacturing process for CNC machine car parts involves several critical stages, each designed to ensure precision and quality. Understanding these stages is vital for international B2B buyers to assess the capabilities and reliability of their suppliers.

1. Material Preparation: How is Raw Material Selected and Processed?

The first step in manufacturing CNC machined car parts is the selection and preparation of raw materials. Common materials include metals such as aluminum, steel, and titanium, as well as plastics. Suppliers typically source these materials based on the specific requirements of the automotive application, such as strength, weight, and corrosion resistance.

Once selected, the materials undergo various preparatory processes, including cutting them to size and ensuring they are free from defects. This preparation is essential for achieving the desired tolerances and surface finishes later in the manufacturing process.

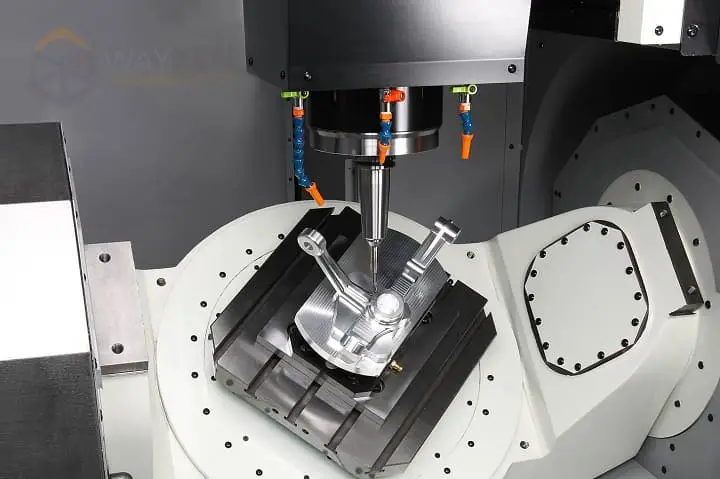

2. Forming: What Techniques Are Employed in CNC Machining?

The core of CNC machining involves several processes, including milling, turning, drilling, and grinding. Each technique is selected based on the design and complexity of the part being manufactured. For instance:

- CNC Milling: This technique is used for creating intricate shapes and features on a part. It is particularly effective for producing flat surfaces and slots.

- CNC Turning: Ideal for cylindrical parts, turning involves rotating the workpiece against a cutting tool to achieve precise dimensions.

- CNC Drilling and Grinding: These processes are crucial for creating holes and achieving fine surface finishes.

Advanced CNC machines often incorporate multi-axis capabilities, allowing for more complex geometries to be produced in a single setup, which enhances efficiency and reduces lead times.

3. Assembly: How Are Components Brought Together?

In cases where parts are composed of multiple components, assembly becomes a crucial stage. This may involve mechanical fastening, welding, or adhesive bonding, depending on the design requirements. The assembly process must be meticulously controlled to ensure that all parts fit together precisely and function as intended.

4. Finishing: What Surface Treatments Are Commonly Used?

The finishing stage involves applying surface treatments to enhance the aesthetic and functional properties of the parts. Common finishing techniques include anodizing, powder coating, and polishing. These treatments can improve corrosion resistance, reduce friction, and enhance appearance.

Moreover, finishing is critical for meeting specific industry standards and customer specifications, making it an integral part of the manufacturing process.

What Quality Assurance Standards Are Relevant for CNC Machined Car Parts?

Quality assurance is essential in the manufacturing of CNC machined car parts, especially for international buyers who require compliance with various standards.

ISO 9001: How Does It Ensure Quality Management?

ISO 9001 is the most recognized quality management standard globally. It provides a framework for manufacturers to ensure consistent quality in their processes and products. Compliance with ISO 9001 indicates that a manufacturer has established effective quality management systems, which is crucial for B2B buyers seeking reliable suppliers.

Industry-Specific Standards: What Certifications Should Buyers Look For?

In addition to general quality standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are important for certain applications. These certifications ensure that products meet rigorous safety and performance standards relevant to their respective industries.

What Are the Key Quality Control Checkpoints in CNC Manufacturing?

Quality control (QC) is integrated into various stages of the manufacturing process to ensure that parts meet specifications.

1. Incoming Quality Control (IQC): How Is Raw Material Quality Assessed?

IQC involves inspecting raw materials upon receipt to verify that they meet specified standards. This may include checking for material properties, dimensions, and surface conditions. Effective IQC helps prevent defects from entering the production process.

2. In-Process Quality Control (IPQC): How Is Quality Monitored During Production?

During the manufacturing process, IPQC involves regular inspections and measurements to ensure that parts are being produced according to specifications. This may include monitoring machine performance, tooling conditions, and part dimensions at various intervals.

3. Final Quality Control (FQC): What Happens Before Parts Are Shipped?

FQC is conducted after the manufacturing process is completed. This stage involves comprehensive inspections and tests, including dimensional checks, functional testing, and surface finish evaluations. Parts must pass FQC before they are approved for shipment to customers.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control is crucial for ensuring product reliability.

Supplier Audits: What Should Buyers Look For?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. Buyers should look for evidence of compliance with ISO standards, industry-specific certifications, and robust quality management systems.

Quality Reports: How Can They Provide Assurance?

Requesting quality reports from suppliers can provide insight into their quality control performance. These reports should detail the results of IQC, IPQC, and FQC processes, along with any corrective actions taken for non-conformances.

Third-Party Inspections: When Should They Be Considered?

Engaging third-party inspection services can offer an additional layer of assurance for buyers. These independent entities can conduct audits and quality checks to verify that the supplier adheres to required standards and specifications.

What Are the Nuances of Quality Control for International Buyers?

International buyers must navigate various quality control nuances, including differing standards and regulatory requirements across regions. Buyers should familiarize themselves with local regulations and ensure that their suppliers are compliant with both international and regional standards.

Moreover, understanding the cultural and operational differences in manufacturing practices can facilitate better communication and collaboration with suppliers, ultimately leading to improved quality outcomes.

By comprehensively understanding the manufacturing processes and quality assurance practices involved in CNC machined car parts, international B2B buyers can make informed decisions and establish strong partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc machine car parts’

Introduction

Sourcing CNC machine car parts requires a strategic approach to ensure quality, efficiency, and cost-effectiveness. This step-by-step checklist serves as a practical guide for B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your procurement process and establish a reliable supply chain for your automotive components.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications of the CNC machined parts you need. This includes dimensions, tolerances, materials, and any specific industry standards they must meet. Precise specifications help in communicating your requirements to suppliers, ensuring they can deliver products that meet your expectations.

- Considerations:

- Identify any unique features or functionalities required.

- Specify the materials (e.g., aluminum, steel, or plastic) based on performance needs.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers with expertise in CNC machining for automotive applications. Look for companies that specialize in the specific parts you require and have a track record of reliability and quality.

- Tips:

- Utilize industry directories and trade shows to find reputable manufacturers.

- Check online reviews and testimonials to gauge supplier credibility.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of potential suppliers to ensure they can meet your production demands. This includes evaluating their machinery, technology, and workforce expertise in CNC machining.

- Key Areas to Examine:

- Types of CNC machines available (e.g., 5-axis, milling, turning).

- The flexibility of production volumes, from prototyping to mass production.

Step 4: Verify Supplier Certifications

Confirm that the suppliers hold relevant certifications, such as ISO 9001, which indicate adherence to quality management standards. Certifications demonstrate a commitment to quality and can be a deciding factor in supplier selection.

- Why This Matters:

- Certifications provide assurance of consistent quality and process reliability.

- They may also be a requirement for compliance with industry regulations.

Step 5: Request and Analyze Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, lead times, and payment terms. Analyze these quotes not only for cost but also for the value offered, including service and support.

- What to Look For:

- Transparency in pricing and terms.

- Potential for discounts on bulk orders or long-term contracts.

Step 6: Conduct Quality Assurance Checks

Before finalizing your supplier, conduct quality assurance checks, such as requesting sample parts or reviewing quality control processes. This step helps ensure that the supplier can meet your quality standards before committing to larger orders.

- Important Actions:

- Ask for reports on previous quality audits or inspections.

- Evaluate the supplier’s ability to handle quality issues if they arise.

Step 7: Establish Clear Communication Channels

Establish robust communication channels with your chosen supplier to facilitate smooth operations. Clear communication is vital for addressing any issues that may arise during production and ensuring timely delivery.

- Best Practices:

- Set up regular check-ins or progress reports.

- Utilize project management tools to track orders and updates effectively.

By following these steps, B2B buyers can enhance their sourcing strategies for CNC machine car parts, leading to improved product quality and overall efficiency in their operations.

Comprehensive Cost and Pricing Analysis for cnc machine car parts Sourcing

What Are the Key Cost Components in CNC Machined Car Parts?

When sourcing CNC machined car parts, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly impacts cost. Common materials for automotive parts include aluminum, steel, and plastics. Prices fluctuate based on global supply and demand, so it’s advisable to keep abreast of market trends.

-

Labor: Labor costs can vary widely depending on the region and the complexity of the machining operations. Skilled labor is essential for maintaining high precision and quality, which can increase costs but is necessary for critical automotive components.

-

Manufacturing Overhead: This encompasses costs related to utilities, equipment maintenance, and factory operations. Efficient production processes can help minimize overhead and should be a consideration when selecting a supplier.

-

Tooling: Specialized tooling is often required for CNC machining. These costs can be significant, especially for custom parts, and should be factored into the total price.

-

Quality Control (QC): Ensuring that parts meet industry standards involves additional costs for quality inspections and certifications. Investing in robust QC processes can prevent costly defects later in the supply chain.

-

Logistics: Transportation costs for sourcing and delivering parts must be included in the cost structure. International shipping, tariffs, and handling fees can add substantial expenses, particularly for buyers from Africa, South America, and the Middle East.

-

Margin: Suppliers will include a profit margin in their pricing. This can vary based on market competition and the perceived value of the service provided.

What Price Influencers Should Buyers Consider?

Several factors can influence the pricing of CNC machined car parts:

-

Volume/MOQ: Bulk orders typically reduce the per-unit cost. Understanding the minimum order quantities (MOQ) can help in negotiating better terms.

-

Specifications and Customization: Custom parts with specific tolerances or unique designs usually incur higher costs. Clear specifications can help suppliers provide accurate quotes.

-

Materials: The type of material selected directly influences cost. High-performance materials may offer better durability but come at a premium.

-

Quality and Certifications: Parts that require specific certifications or adherence to stringent quality standards will generally cost more. It’s essential to verify that suppliers can meet these requirements.

-

Supplier Factors: The reputation and location of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but can provide peace of mind.

-

Incoterms: Understanding the terms of trade, including who is responsible for shipping and insurance, can impact overall costs. Buyers should clarify these terms to avoid unexpected expenses.

What Are the Best Tips for Negotiating CNC Machined Parts Pricing?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

-

Understand Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider logistics, maintenance, and potential downtime costs associated with the parts. A cheaper part might end up being more expensive in the long run.

-

Leverage Volume: If possible, consolidate orders to increase volume. This not only lowers the price per unit but also strengthens your bargaining position.

-

Be Clear About Specifications: Provide precise specifications upfront to avoid misunderstandings that could lead to additional costs later.

-

Research Market Rates: Being informed about prevailing market prices for materials and machining services can strengthen your negotiating position.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and priority service. Trust and reliability often yield better terms.

Disclaimer on Pricing

While this analysis provides a framework for understanding costs and pricing, actual prices may vary based on specific project requirements, market conditions, and supplier negotiations. Always request detailed quotes and consider multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing cnc machine car parts With Other Solutions

Exploring Alternatives to CNC Machine Car Parts

In the automotive industry, selecting the right manufacturing method is crucial for achieving the desired quality, efficiency, and cost-effectiveness. While CNC machining has become a popular choice for producing car parts, several alternative methods exist that may better suit specific needs. This section evaluates CNC machine car parts against other viable solutions, such as traditional machining and additive manufacturing (3D printing).

| Comparison Aspect | Cnc Machine Car Parts | Traditional Machining | Additive Manufacturing (3D Printing) |

|---|---|---|---|

| Performance | High precision and repeatability | Moderate precision; depends on operator skill | High complexity; limited by material properties |

| Cost | Moderate; cost-efficient for large volumes | Generally lower initial cost, but higher labor costs | High material costs; cost-effective for small batches |

| Ease of Implementation | Requires skilled operators and setup | Familiar technology; easy to implement | Requires specialized knowledge for design and operation |

| Maintenance | Moderate; regular calibration needed | High; wear and tear on tools require frequent replacement | Low; minimal mechanical parts involved |

| Best Use Case | High-volume production with precision needs | Low to medium volume, simple parts | Rapid prototyping and custom parts |

Understanding the Alternatives

Traditional Machining

Traditional machining encompasses various manual techniques, such as milling, turning, and drilling, which are performed by skilled operators. The primary advantage of traditional machining is its lower initial setup cost, making it an attractive option for low-volume production. However, the reliance on human skill can lead to variability in part quality and longer lead times. Additionally, traditional machining often requires more maintenance due to wear and tear on tools.

Additive Manufacturing (3D Printing)

Additive manufacturing, commonly known as 3D printing, constructs parts layer by layer from digital models. This method excels in producing complex geometries and customized parts, making it ideal for rapid prototyping. However, the materials used in 3D printing can be more expensive, and the technology may not yet match the precision and durability of CNC machining for certain automotive applications. Despite this, its flexibility in design and ability to reduce waste can be significant advantages for specific projects.

Making the Right Choice for Your Needs

When determining the best manufacturing solution for automotive parts, B2B buyers should consider several factors, including production volume, cost constraints, and specific part requirements. CNC machining is optimal for high-volume production where precision and repeatability are paramount. In contrast, traditional machining may be suitable for smaller projects with simpler designs, while additive manufacturing is the go-to for rapid prototyping and customization. By assessing the unique demands of each project, buyers can select the most appropriate method to achieve their objectives efficiently and effectively.

Essential Technical Properties and Trade Terminology for cnc machine car parts

What Are the Key Technical Properties of CNC Machine Car Parts?

Understanding the essential technical properties of CNC machine car parts is crucial for B2B buyers, especially when sourcing components for automotive applications. Here are several critical specifications that buyers should consider:

-

Material Grade

The material grade indicates the type and quality of the raw material used in manufacturing car parts. Common materials include aluminum, steel, and titanium. Each material has unique properties, such as strength, weight, and corrosion resistance, which directly impact the performance and durability of the part. Selecting the appropriate material grade is vital for meeting industry standards and ensuring the longevity of vehicle components. -

Tolerance

Tolerance refers to the allowable variation in dimensions of a part. In the automotive industry, tight tolerances (often within ±0.01 mm) are essential for ensuring parts fit together correctly and function as intended. High precision in CNC machining allows manufacturers to maintain these tolerances consistently, which is crucial for safety and performance. Buyers should specify tolerance requirements in their RFQs to ensure compliance with their design specifications. -

Surface Finish

Surface finish describes the texture and smoothness of a part’s surface. It is important not only for aesthetic reasons but also for functionality, as it can affect friction, wear, and corrosion resistance. Common surface finishes include anodizing, plating, and polishing. Buyers should consider the required surface finish based on the part’s application, as this can influence both performance and cost. -

Weight

The weight of a car part can significantly affect the overall vehicle performance, including fuel efficiency and handling. Lightweight materials are often preferred in modern automotive design to enhance performance. Buyers should consider the weight specifications of parts, especially for components that contribute to the vehicle’s structural integrity and aerodynamics. -

Production Volume

Production volume refers to the number of parts produced in a single manufacturing run. Understanding whether the need is for low-volume custom parts or high-volume production can influence the choice of CNC machining processes and pricing. Buyers should communicate their anticipated production volume to ensure suppliers can meet their needs efficiently.

What Are Common Trade Terms in CNC Machining for Automotive Parts?

Familiarity with industry jargon can streamline communication and ensure clarity in transactions. Here are some essential trade terms relevant to CNC machining in the automotive sector:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold to another company, which then sells the final product. In the automotive industry, OEM parts are those made by the vehicle manufacturer or authorized suppliers. Understanding the distinction between OEM and aftermarket parts is crucial for buyers seeking quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce or sell. This term is particularly relevant for B2B buyers looking to manage costs and inventory. Understanding MOQs helps businesses determine their purchasing strategy and negotiate better terms with suppliers. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. When sourcing CNC machined parts, issuing an RFQ allows buyers to obtain competitive quotes, ensuring they receive fair pricing based on their technical specifications. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. They clarify aspects like who pays for shipping, insurance, and customs duties. Familiarity with Incoterms helps buyers understand shipping costs and risks involved in international transactions. -

Lead Time

Lead time is the time taken from placing an order to the delivery of the product. In the automotive industry, shorter lead times can significantly impact production schedules and market responsiveness. Buyers should inquire about lead times when negotiating contracts to ensure alignment with their project timelines.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing CNC machine car parts, ultimately enhancing their supply chain efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the cnc machine car parts Sector

What Are the Key Trends Shaping the CNC Machine Car Parts Market?

The CNC machine car parts market is witnessing a dynamic transformation driven by several global factors. A significant driver is the increasing demand for precision and quality in automotive manufacturing. As industries strive for efficiency, the adoption of advanced CNC technologies—such as multi-axis machining and automation—has surged. This shift not only enhances production speed but also ensures consistent quality, which is crucial for maintaining competitive advantage in international markets, particularly in regions like Europe and the Middle East.

Emerging technologies, including artificial intelligence and IoT, are reshaping sourcing strategies. These innovations enable real-time monitoring and predictive maintenance of CNC machines, reducing downtime and optimizing production processes. For B2B buyers, particularly in Africa and South America, leveraging these technologies can streamline operations and enhance supply chain visibility.

Furthermore, sustainability is becoming a core consideration in sourcing trends. With increasing regulatory pressures and consumer demand for environmentally friendly practices, suppliers are adopting greener manufacturing processes. This trend is particularly relevant for international buyers looking to align with global sustainability standards while also appealing to eco-conscious consumers in their regions.

How Is Sustainability and Ethical Sourcing Influencing B2B Purchasing Decisions?

Sustainability and ethical sourcing have become paramount in the CNC machine car parts sector. The environmental impact of manufacturing processes is under scrutiny, prompting businesses to prioritize suppliers who demonstrate commitment to reducing carbon footprints. Buyers are increasingly seeking suppliers who utilize eco-friendly materials and processes, such as recycled metals and energy-efficient machinery.

Ethical supply chains are equally important, with transparency becoming a key criterion for many B2B buyers. Establishing partnerships with suppliers who prioritize fair labor practices and sustainable sourcing not only mitigates reputational risks but also strengthens brand loyalty among consumers. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential credentials that buyers look for in suppliers.

Furthermore, the integration of ‘green’ certifications is proving beneficial in differentiating suppliers in a competitive market. By adopting sustainable practices and obtaining relevant certifications, suppliers can enhance their attractiveness to international buyers who are increasingly focused on ethical considerations.

How Has the CNC Machine Car Parts Industry Evolved Over Time?

The evolution of CNC machining in the automotive sector has been remarkable, dating back to its inception in the mid-20th century. Initially, CNC machines were primarily used for simple tasks, but advancements in technology have transformed them into sophisticated systems capable of executing complex geometries with high precision.

The introduction of automation and robotics has further revolutionized production capabilities, allowing manufacturers to achieve unparalleled efficiency and repeatability. This evolution has not only reduced costs but has also enabled the production of intricate parts that meet the stringent requirements of modern vehicles. As the automotive industry continues to innovate, CNC machining remains at the forefront, adapting to new materials and design challenges, ultimately enhancing the quality and performance of car parts.

Overall, understanding these market dynamics and trends is crucial for international B2B buyers seeking to navigate the evolving landscape of CNC machine car parts effectively. By aligning sourcing strategies with technological advancements and sustainability practices, buyers can position themselves competitively in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc machine car parts

-

How do I choose the right CNC machining supplier for automotive parts?

Selecting the right supplier involves evaluating several key factors. First, check their industry experience and expertise in automotive CNC machining. Request references and case studies to gauge their reliability. Additionally, assess their quality assurance processes, certifications (like ISO 9001), and capabilities for customization. It’s also wise to consider their production capacity and lead times to ensure they can meet your demand. Finally, communication and responsiveness are crucial; a supplier that understands your needs will facilitate smoother transactions. -

What types of materials are commonly used in CNC machining for car parts?

CNC machining for automotive applications typically employs a range of materials, including metals like aluminum, steel, and titanium, due to their strength and durability. Plastics, such as ABS and nylon, are also popular for lightweight components. The choice of material often depends on the part’s specific requirements, including weight, cost, and performance. Discussing material options with your supplier can help you find the best fit for your application while balancing functionality and budget constraints. -

What are the typical lead times for CNC machined automotive parts?

Lead times can vary significantly based on several factors, including complexity, volume, and the supplier’s current workload. Generally, for small to medium runs, expect lead times of 2 to 6 weeks. Larger orders may require additional time for production and quality checks. It’s advisable to communicate your timeline needs upfront and establish a clear schedule with your supplier. Additionally, consider suppliers who offer expedited services if you have urgent requirements. -

Can I customize CNC machined parts to fit my specific requirements?

Yes, CNC machining is highly adaptable, allowing for significant customization. Whether you need unique dimensions, specific tolerances, or particular surface finishes, most suppliers can accommodate your requests. When discussing your project, provide detailed specifications and drawings to ensure accurate production. Keep in mind that while customization is possible, it may affect lead times and costs, so clarify these aspects with your supplier early in the process. -

What are the minimum order quantities (MOQs) for CNC machined parts?

MOQs for CNC machined parts can vary widely among suppliers. Some may offer low MOQs for prototype runs or custom parts, while others might require larger quantities for cost-effectiveness. Typically, MOQs can range from as few as 10 to several hundred pieces, depending on the complexity and type of part. It’s beneficial to discuss your needs directly with potential suppliers to find one that aligns with your order volume and budget. -

What payment terms should I expect when sourcing CNC machined parts?

Payment terms in B2B transactions can differ significantly based on the supplier and your relationship with them. Common terms include upfront payments, deposits (usually 30-50%), and net payment terms ranging from 30 to 90 days after delivery. Always clarify payment terms before entering into a contract, and consider discussing options for secure payment methods, such as letters of credit, especially when dealing with international suppliers to minimize risk. -

How do I ensure quality assurance in CNC machining processes?

To ensure quality assurance, request information about the supplier’s quality control processes. Reputable suppliers will have documented procedures for inspections and testing, often including certifications like ISO 9001. Ask about their use of precision measurement tools and techniques throughout the production process. Additionally, consider requesting samples or prototypes before placing large orders to verify that the parts meet your specifications and quality standards. -

What logistics considerations should I keep in mind when importing CNC machined parts?

When importing CNC machined parts, logistics play a crucial role in ensuring timely delivery. First, assess the shipping methods available, such as air freight for speed or sea freight for cost-effectiveness. Understand the customs regulations and tariffs that may apply to your imports, especially if you are sourcing from a different continent. Collaborating with logistics partners who specialize in international trade can streamline the process, helping you navigate any complexities and ensuring compliance with all regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cnc Machine Car Parts Manufacturers & Suppliers List

1. Phillips Corp – CNC Machines for Automotive Industry

Domain: phillipscorp.com

Registered: 1996 (29 years)

Introduction: Types of CNC Machines Used in the Automotive Industry: 1. CNC Lathe Machines: Used for producing symmetrical parts like shafts, axles, and bearings from metals, plastics, and wood. 2. CNC Milling Machines: Ideal for creating complex parts such as engine blocks, transmission cases, and cylinder heads. 3. CNC Drilling Machines: Used for punching holes in engine blocks and other components. 4. CNC Gr…

2. Panek Precision – CNC Machining Services

Domain: panekprecision.com

Registered: 1998 (27 years)

Introduction: Automotive CNC Machining Services including CNC Turning, CNC Vertical Machining, CNC Horizontal Machining, CNC Prototyping, Multi-Spindle Screw Machining, and Robotics & Automation. Common CNC Machined Automotive Parts: Suspension parts, Exhaust components, Fuel rails, Dowel Pins, Fluid system components, Brake System Components, Bushings, Emission system components, Timing Covers, Valve Retainers…

3. CNC Machining – Essential Guide for Bike Parts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The user is interested in getting into CNC machining for small auto and bike parts, specifically bike light helmet and bar mounts, and suspension linkage parts. They are looking for advice on what CNC machine to start with, necessary tools, and budget considerations. The largest parts they envision needing are no more than 8 to 10 inches in length or height. Recommendations include considering a m…

4. 3DS – CNC Machining Solutions

Domain: 3ds.com

Registered: 1995 (30 years)

Introduction: CNC Machining in the automotive industry includes services such as 3D Printing, CNC Machining, Laser Cutting, Injection Molding, Sheet Metal, and Forming. Key materials used are plastics, metals (aluminum, steel, titanium), ceramics, composites, sand, and wax. CNC machining is a production technique that utilizes computer-controlled machines for high precision, speed, repeatability, and flexibilit…

5. Yijin Solution – High-Precision Automotive CNC Machining

Domain: yijinsolution.com

Registered: 2019 (6 years)

Introduction: Automotive CNC Machining Services specializing in high-precision custom car parts and prototypes for OEMs, tier suppliers, and aftermarket manufacturers. Key components manufactured include engine and powertrain components, transmission system parts, fuel system components, brake system components, suspension and steering parts, custom automotive fasteners, specialized chassis components, turbocha…

6. Wellste – CNC Auto Parts

Domain: wellste.com

Registered: 2016 (9 years)

Introduction: CNC auto parts are car components produced by CNC machining methods including turning, milling, and drilling. Wellste offers low-volume project support and bulk production capabilities. Key features include:

– ISO9001 certification

– Common CNC machining tolerance of 0.01mm, with capabilities down to 0.001mm

– Unique customization based on customer design drawings

– Free samples available in the i…

7. GN Corporations – CNC Machining Services for Automotive

Domain: gncorporations.com

Registered: 1998 (27 years)

Introduction: CNC Machining Services for the Automotive Industry; High-quality and durable parts; Strong understanding in CNC machining automotive parts; Years of experience and certifications; Multi-axis machines including 5-Axis CNC Milling, 5-Axis Water Jet Cutters, and 9-Axis CNC Mill & Turn; Capable of using materials such as Steel, Plastic, Aluminum, Rubber, Copper, and Titanium; Quality assurance process…

8. 3018-PROVer – CNC Router for Engraving and Light Cutting

Domain: grassrootsmotorsports.com

Registered: 1999 (26 years)

Introduction: CNC router (3018-PROVer) with a work envelope of 300x180mm (about 11×7 inches), priced around $200 to $314 depending on upgrades. Features include an offline controller, limit switches, emergency stop, and tool touch probe. Designed for engraving and light cutting, comparable in power to a Dremel. Commonly sold under various brand names.

9. BBT Fabrications – Custom CNC Machined Parts

Domain: bbtfabrications.com

Registered: 2016 (9 years)

Introduction: Custom CNC machining services for custom cars and hot rods. Products include outside rear view mirrors, inside rear view mirrors, AC control panels, door handles, and more. Some parts are universal fit applications, while others are designed for specific models like 1967-81 Firebirds and Camaros, and Square body Chevy C10 trucks. The company offers made-to-order parts and welcomes custom requests.

Strategic Sourcing Conclusion and Outlook for cnc machine car parts

In the rapidly evolving automotive landscape, the strategic sourcing of CNC machined car parts is paramount for manufacturers seeking to enhance quality, reduce costs, and accelerate production timelines. By leveraging CNC technology, businesses can achieve unparalleled precision and repeatability, ensuring that every component meets stringent industry standards. This is especially critical for international buyers in regions like Africa, South America, the Middle East, and Europe, where the demand for high-quality automotive parts continues to rise.

The value of strategic sourcing lies in its ability to facilitate access to advanced manufacturing capabilities, foster supplier relationships, and optimize supply chain efficiencies. As competition intensifies, the ability to source CNC machined components from reliable partners will distinguish successful enterprises from their peers.

Looking ahead, international B2B buyers are encouraged to embrace these advancements in CNC machining. By investing in strategic sourcing initiatives today, companies can position themselves to capitalize on future innovations and market opportunities. Take the next step in transforming your automotive production process—connect with suppliers who can deliver the precision and quality your business deserves.