Introduction: Navigating the Global Market for cnc machine book

Navigating the complexities of the global market for CNC machine books can be a daunting task for international B2B buyers seeking to enhance their manufacturing capabilities. Sourcing the right CNC machine book not only equips professionals with essential knowledge but also addresses the pressing challenge of keeping pace with rapid technological advancements in digital manufacturing. This guide serves as a comprehensive resource, covering various types of CNC machine books, their applications across industries, and the nuances of supplier vetting to ensure quality and reliability.

In today’s interconnected marketplace, understanding the intricacies of CNC technology is critical for businesses aiming to optimize production processes and improve overall efficiency. From foundational texts that introduce core principles to advanced manuals that delve into programming and automation, this guide empowers B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to make informed purchasing decisions. It highlights key factors such as cost considerations, the importance of digital integration, and the latest trends in Industry 4.0, ultimately aiding in selecting resources that align with specific operational needs.

By navigating this essential guide, companies can not only enhance their workforce’s technical proficiency but also drive innovation and competitiveness in their respective markets.

Understanding cnc machine book Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Programming Handbooks | Focus on G-code programming, often includes tutorials and practical examples. | Training CNC programmers and operators | Pros: Comprehensive learning resources; Cons: Can be technical and dry for beginners. |

| Machine Shop Trade Secrets | Tips and techniques for efficient machining processes, often written in an accessible style. | General machining practices and optimization | Pros: Practical insights; Cons: Less focus on advanced CNC topics. |

| Digital Manufacturing Guides | Covers the integration of CNC with digital technologies, Industry 4.0, and automation. | Advanced manufacturing and automation sectors | Pros: Relevant for modern manufacturing; Cons: May require prior knowledge of CNC. |

| CNC Design and Engineering Books | Focus on design principles and engineering considerations for CNC machines. | CNC machine design and engineering | Pros: In-depth technical knowledge; Cons: May not cater to operators or beginners. |

| Additive Manufacturing Texts | Explores the intersection of CNC and additive manufacturing technologies. | R&D in advanced manufacturing | Pros: Cutting-edge insights; Cons: Niche focus may not appeal to all buyers. |

What are the Key Characteristics of CNC Programming Handbooks?

CNC Programming Handbooks, such as Peter Smid’s works, are essential for professionals looking to master G-code programming. These books provide structured tutorials that break down complex concepts into manageable sections. They are suitable for both novices and experienced machinists wanting to refresh their skills. When purchasing, buyers should consider the book’s focus on specific CNC control systems, as many are tailored to popular brands like Fanuc.

How Do Machine Shop Trade Secrets Benefit B2B Buyers?

Machine Shop Trade Secrets offer practical tips and techniques aimed at improving machining efficiency. Written in an engaging style, these books are designed to be easily digestible, making them ideal for busy professionals. They are particularly beneficial for B2B buyers in manufacturing settings who seek actionable insights without delving into overly technical jargon. When selecting a title, buyers should evaluate the relevance of the topics covered to their specific operational challenges.

What Insights Do Digital Manufacturing Guides Provide?

Digital Manufacturing Guides address the modern landscape of CNC machining, emphasizing the integration of digital technologies and automation. These resources are vital for businesses aiming to transition into Industry 4.0 practices. They often require a foundational understanding of CNC technology, making them more suitable for professionals in managerial or engineering roles. Buyers should consider how well the content aligns with their organization’s digital transformation goals when making a purchase.

Why Should Buyers Consider CNC Design and Engineering Books?

CNC Design and Engineering Books focus on the technical aspects of CNC machinery, covering design principles and engineering methodologies. These texts are essential for engineers and designers involved in creating CNC machines. B2B buyers in engineering firms should prioritize these resources if they aim to enhance their design processes. It is crucial to assess the book’s depth and technicality to ensure it meets the expertise level of the intended audience.

How Do Additive Manufacturing Texts Fit into the CNC Landscape?

Additive Manufacturing Texts explore the synergies between CNC machining and additive manufacturing technologies. These books are particularly relevant for R&D departments and companies looking to innovate in production methods. They provide insights into how CNC can complement additive processes. When considering these texts, buyers should evaluate their current and future manufacturing strategies to determine the relevance of additive technologies in their operations.

Key Industrial Applications of cnc machine book

| Industry/Sector | Specific Application of cnc machine book | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision machining of aircraft components | Enhanced accuracy and reduced production costs | Supplier certifications, material quality, lead times |

| Automotive | Manufacturing of engine parts and assemblies | Improved efficiency and scalability | Availability of CNC technology, maintenance support |

| Medical Devices | Production of surgical instruments and implants | High precision and regulatory compliance | Compliance with health regulations, material sourcing |

| Electronics | Fabrication of circuit boards and enclosures | Increased production speed and reduced waste | Technology compatibility, supplier reliability |

| Energy | Production of turbine components and renewable energy systems | Cost reduction and improved operational efficiency | Material standards, technical support, delivery times |

How Is the CNC Machine Book Used in Aerospace Applications?

In the aerospace sector, the CNC machine book serves as a vital resource for manufacturers involved in the precision machining of aircraft components. The book provides insights into CNC programming techniques and the operational principles of CNC machines, enabling engineers to produce parts with high accuracy and minimal tolerance deviations. This precision is crucial in aerospace manufacturing, where even slight errors can lead to significant safety issues. For international buyers, understanding the certification standards and material specifications outlined in the book can streamline sourcing processes and ensure compliance with industry regulations.

What Role Does the CNC Machine Book Play in Automotive Manufacturing?

The automotive industry leverages the CNC machine book for the manufacturing of engine parts and assemblies. The book discusses various CNC machining processes that enhance efficiency and scalability, allowing manufacturers to meet high production demands. By adopting the practices detailed in the book, companies can reduce cycle times and improve product quality. B2B buyers from regions like South America and Africa must consider the availability of advanced CNC technology and the support services offered by suppliers to maximize their investment in these machining solutions.

How Is the CNC Machine Book Relevant for Medical Device Production?

In the medical device industry, the CNC machine book is essential for producing surgical instruments and implants that require high precision. It offers guidelines on CNC operations and programming tailored to meet stringent regulatory compliance standards. This ensures that the produced devices are not only effective but also safe for patient use. For international buyers, understanding the nuances of material sourcing and compliance with health regulations is critical, as these factors directly influence product quality and market acceptance.

How Does the CNC Machine Book Impact Electronics Manufacturing?

The electronics sector utilizes the CNC machine book for the fabrication of circuit boards and enclosures. The book provides techniques for optimizing CNC machining processes, which can significantly increase production speed while minimizing waste. This efficiency is vital in a fast-paced industry where time-to-market is crucial. International buyers should focus on technology compatibility and supplier reliability when sourcing CNC solutions, as these elements can affect the overall production timeline and product quality.

What Benefits Does the CNC Machine Book Offer in Energy Sector Applications?

In the energy sector, particularly in renewable energy, the CNC machine book guides the production of turbine components and other critical systems. The insights provided help businesses achieve cost reductions and improve operational efficiency through optimized machining processes. Buyers in this sector, especially from regions like the Middle East, should consider the technical support and material standards outlined in the book to ensure that their sourcing decisions align with the demanding requirements of energy production and sustainability initiatives.

3 Common User Pain Points for ‘cnc machine book’ & Their Solutions

Scenario 1: Difficulty in Understanding CNC Programming Fundamentals

The Problem: Many B2B buyers, especially those new to CNC machining, struggle with the complexities of CNC programming. This challenge is exacerbated in regions where access to hands-on training is limited. Without a solid understanding of G-code and programming principles, operators may face steep learning curves, leading to production errors, increased downtime, and inefficient use of machinery. This knowledge gap can hinder their ability to optimize processes and meet client demands, ultimately impacting their bottom line.

The Solution: To address this issue, B2B buyers should invest in comprehensive CNC programming books that cater to different skill levels. Books like “CNC Programming Handbook” by Peter Smid offer structured tutorials that break down G-code into manageable sections. Buyers should prioritize resources that include both theoretical explanations and practical exercises. Additionally, forming study groups or partnerships with local technical institutions can provide collaborative learning opportunities. Engaging in hands-on workshops, when available, can further reinforce the learning from these books, ensuring that the workforce is well-equipped to handle CNC programming challenges effectively.

Scenario 2: Inadequate Knowledge of CNC Machine Components

The Problem: Another common pain point for B2B buyers is the lack of detailed knowledge regarding the various components and systems of CNC machines. This deficiency can lead to improper machine setup, misalignment issues, and inefficient maintenance practices. In regions where technical support is scarce, buyers may find themselves unable to troubleshoot issues effectively, resulting in costly downtimes and repairs.

The Solution: To overcome this challenge, it is crucial for buyers to source CNC machine books that offer in-depth explanations of machine components and their functionalities. “The CNC Handbook” serves as an excellent resource, detailing everything from drive controls to tool management. Buyers should also consider creating a repository of manuals and guides that can be easily accessed by operators and technicians. Investing in training sessions based on the content of these books will not only enhance understanding but also promote a culture of continuous learning, enabling teams to operate and maintain CNC machines more effectively.

Scenario 3: Navigating the Transition to Industry 4.0

The Problem: As manufacturing evolves toward Industry 4.0, B2B buyers often face challenges integrating traditional CNC machining practices with advanced technologies like IoT and automation. This transition can be daunting, especially for companies with a legacy workforce that may not be familiar with digital manufacturing concepts. The fear of obsolescence and the complexities of adapting to new technologies can create resistance to change, ultimately affecting competitiveness in the market.

The Solution: To facilitate this transition, B2B buyers should seek out CNC machine books that address the concepts of digital manufacturing and Industry 4.0. Resources that provide case studies and implementation strategies can be particularly beneficial. For instance, chapters dedicated to digital integration in “The CNC Handbook” can guide readers on how to implement these technologies step-by-step. Furthermore, forming partnerships with tech companies specializing in CNC automation can provide additional insights and support. Regularly scheduled training sessions that focus on the intersection of CNC machining and digital tools can empower employees, making the transition smoother and more efficient. By embracing these educational resources, companies can better prepare their teams for the future of manufacturing.

Strategic Material Selection Guide for cnc machine book

What Are the Common Materials Used in CNC Machining?

When selecting materials for CNC machining, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: Aluminum, Steel, Plastic, and Titanium. Each material has unique characteristics that can significantly impact the performance of CNC machines and the end products they produce.

How Does Aluminum Perform in CNC Machining?

Aluminum is a popular choice in CNC machining due to its lightweight and excellent machinability. It has a high strength-to-weight ratio and good corrosion resistance, making it suitable for various applications, including aerospace and automotive components. Aluminum can withstand temperatures up to 600°F (315°C) and has a pressure rating that varies based on the specific alloy used.

Pros: Aluminum is relatively inexpensive, easy to machine, and offers good thermal conductivity. It is also readily available in various forms, such as sheets and extrusions.

Cons: While durable, aluminum can be less robust than steel and may not be suitable for high-stress applications. Additionally, certain alloys can be more challenging to machine, increasing manufacturing complexity.

Impact on Application: Aluminum is compatible with various media, including water and oils, making it versatile for different environments. However, it may not be ideal for applications requiring high-temperature resistance.

Considerations for International Buyers: Compliance with standards like ASTM and DIN is crucial, especially for buyers in regions like Europe and the Middle East, where regulatory requirements may be stringent.

What Are the Advantages of Steel in CNC Machining?

Steel is renowned for its strength and durability, making it an excellent choice for heavy-duty applications. It has a high-temperature rating, often exceeding 1,500°F (815°C), and is resistant to wear and deformation under stress. Steel’s corrosion resistance can be enhanced through various treatments, such as galvanization or coating.

Pros: Steel is highly durable and can handle high-stress environments. It is also relatively cost-effective compared to other high-performance materials.

Cons: Steel can be more challenging to machine than aluminum, leading to increased manufacturing complexity and costs. It may also be heavier, which can be a disadvantage in weight-sensitive applications.

Impact on Application: Steel’s compatibility with various media, including corrosive substances, makes it suitable for industrial applications. However, its weight may limit its use in lightweight designs.

Considerations for International Buyers: Buyers should be aware of common standards such as ASTM A36 or DIN 17100 for structural steel, ensuring compliance with local regulations.

How Do Plastics Compare in CNC Machining?

Plastics, such as polycarbonate and nylon, are increasingly used in CNC machining due to their lightweight and versatile properties. They typically have lower temperature ratings, usually around 200°F (93°C), and can be susceptible to chemical degradation.

Pros: Plastics are cost-effective and easy to machine, allowing for complex designs. They are also resistant to corrosion and can be made transparent or colored.

Cons: While lightweight, plastics may not offer the same strength as metals, making them unsuitable for high-stress applications. Their temperature resistance is also limited, which can be a drawback in certain environments.

Impact on Application: Plastics are compatible with a wide range of media but may not perform well in high-temperature or high-pressure situations.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties is vital, especially for buyers in regions with strict quality control measures.

What Makes Titanium a Unique Choice for CNC Machining?

Titanium is known for its exceptional strength-to-weight ratio and corrosion resistance, making it ideal for aerospace and medical applications. It can withstand temperatures up to 1,600°F (870°C) and has excellent biocompatibility.

Pros: Titanium’s durability and light weight make it suitable for high-performance applications. Its resistance to corrosion is unmatched, particularly in harsh environments.

Cons: Titanium is more expensive than other materials and can be challenging to machine due to its toughness, leading to higher manufacturing costs.

Impact on Application: Titanium’s compatibility with various media, including saline solutions, makes it ideal for medical implants and aerospace components.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM F136 for titanium used in medical applications, particularly in regions with strict regulatory frameworks.

Summary Table of Material Selection for CNC Machining

| Material | Typical Use Case for cnc machine book | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and easy to machine | Less robust than steel | Low |

| Steel | Structural components, heavy machinery | High durability and strength | More challenging to machine | Med |

| Plastic | Consumer goods, housings | Cost-effective and versatile | Limited strength and temperature resistance | Low |

| Titanium | Aerospace, medical implants | Exceptional strength-to-weight ratio | High cost and machining difficulty | High |

This guide provides a comprehensive overview of material selection for CNC machining, equipping B2B buyers with the insights needed to make informed decisions based on their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc machine book

What Are the Main Stages of Manufacturing Processes for CNC Machines?

The manufacturing processes for CNC machines involve several critical stages that ensure precision, quality, and efficiency. Understanding these stages is essential for B2B buyers looking to procure CNC machines that meet their operational requirements.

1. Material Preparation

Material preparation is the foundational step in CNC manufacturing. This stage involves selecting the appropriate raw materials, which may include metals, plastics, or composites, based on the intended application. Key techniques during this phase include material cutting, shearing, and surface treatment to remove imperfections. Proper material selection and preparation directly impact the final product’s quality and performance, making this stage crucial for B2B buyers focused on durability and reliability.

2. Forming

The forming stage encompasses various processes that shape the prepared materials into the desired forms. Techniques such as milling, turning, and drilling are commonly employed in CNC machining. Each method utilizes computer-controlled machinery to achieve high precision and repeatability. B2B buyers should consider suppliers that offer advanced forming techniques and equipment, as this can significantly enhance production capabilities and product quality.

3. Assembly

Assembly is where the individual components produced during the forming stage are brought together to create the final product. This may involve manual assembly or automated processes, depending on the complexity of the assembly. Quality assurance during this stage is vital, as even minor discrepancies can lead to significant functional issues. Buyers should evaluate the assembly processes of potential suppliers to ensure they have robust quality control measures in place.

4. Finishing

Finishing processes are critical for achieving the desired surface quality and functional characteristics of CNC machined products. Techniques such as grinding, polishing, and coating are commonly used to enhance aesthetics and performance. This stage is particularly important for B2B buyers in industries like aerospace or automotive, where surface integrity can affect performance and compliance with industry standards.

How Is Quality Assurance Implemented in CNC Machine Manufacturing?

Quality assurance (QA) in CNC machine manufacturing is essential for ensuring that products meet stringent international standards and customer specifications. Understanding the key aspects of QA can help B2B buyers make informed decisions when selecting suppliers.

What Are the Relevant International Standards for Quality Assurance?

B2B buyers should be aware of various international standards that govern quality assurance in manufacturing. One of the most recognized standards is ISO 9001, which outlines requirements for a quality management system. Compliance with ISO 9001 ensures that suppliers maintain consistent quality and continuous improvement processes.

In addition to ISO standards, industry-specific certifications may be necessary, depending on the application. For instance, the CE mark is essential for products sold in the European Economic Area, while API standards are crucial for suppliers in the oil and gas industry. Buyers should verify that their suppliers hold the relevant certifications to ensure compliance with industry regulations.

What Are the Key Quality Control Checkpoints in CNC Manufacturing?

Quality control (QC) is implemented at various checkpoints throughout the manufacturing process. Key QC checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components for quality before they enter the production process. This ensures that only materials meeting specifications are used, reducing the risk of defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor quality. This can include dimensional checks, functional tests, and visual inspections to identify any deviations from specifications early in the process.

-

Final Quality Control (FQC): Once the product is completed, a comprehensive final inspection is performed to ensure it meets all design specifications and quality standards. This may involve functional testing, stress testing, and performance evaluations.

What Common Testing Methods Are Used in CNC Quality Assurance?

Testing methods play a crucial role in quality assurance. B2B buyers should be familiar with common testing techniques used to evaluate CNC machined products:

-

Dimensional Inspection: This method involves measuring the dimensions of the finished product using tools such as calipers, micrometers, or coordinate measuring machines (CMM). Ensuring that dimensions are within specified tolerances is critical for functionality.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle testing, and dye penetrant testing are employed to identify internal and surface defects without damaging the product. This is particularly important in industries where safety is paramount.

-

Functional Testing: This involves subjecting the product to operational conditions to verify its performance. For example, a CNC machined component may be tested under load to ensure it can withstand operational stress.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to implement strategies to verify the quality control processes of potential suppliers. Here are some actionable steps:

Conducting Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should consider both scheduled and surprise audits to assess compliance with quality standards and identify areas for improvement.

Reviewing Quality Reports

Requesting quality reports from suppliers can offer transparency into their QC processes. These reports should detail inspection results, defect rates, and corrective actions taken to address any quality issues. Reviewing these documents can help buyers gauge the supplier’s commitment to quality.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These organizations can conduct thorough inspections and testing, offering buyers peace of mind regarding the quality of their purchases.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is critical, especially when sourcing from regions with varying standards and practices. Buyers from Africa, South America, the Middle East, and Europe should consider the following:

-

Cultural Differences: Different regions may have varying approaches to quality and manufacturing practices. Buyers should be aware of these cultural nuances and adapt their expectations accordingly.

-

Regulatory Compliance: International regulations can be complex, and buyers must ensure that their suppliers comply with both local and international standards. This may involve additional certification processes or documentation.

-

Logistics and Supply Chain Considerations: The logistics of transporting CNC machines and components across borders can introduce risks to quality. Buyers should work closely with suppliers to ensure that products are handled and stored appropriately during transit.

In conclusion, understanding the manufacturing processes and quality assurance practices in CNC machine production is essential for B2B buyers. By focusing on these aspects, buyers can ensure they partner with suppliers who prioritize quality and reliability, ultimately enhancing their operational capabilities and competitiveness in the market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc machine book’

In the competitive landscape of CNC machining, selecting the right educational resources is critical for enhancing operational efficiency and workforce competency. This guide serves as a practical checklist for B2B buyers aiming to procure CNC machine books, ensuring informed decisions that align with technical needs and business objectives.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of your sourcing strategy. Identify the areas of CNC technology that need emphasis, such as programming, machine operation, or maintenance. This clarity will help you focus on books that meet your operational needs.

- Consider your team’s skill level: Are you looking for beginner-friendly resources or advanced technical guides?

- Focus on relevant topics: Ensure the books cover essential subjects like G-code programming, machine setup, and troubleshooting.

Step 2: Research Author Credentials

The credibility of the authors is paramount when selecting educational material. Investigate their backgrounds to ensure they possess extensive experience and recognition in the CNC field.

- Look for industry experience: Authors with hands-on experience in CNC machining and teaching are likely to provide practical insights.

- Check for publications: A history of published works or contributions to industry journals indicates a deep understanding of the subject matter.

Step 3: Evaluate Content Relevance and Depth

Not all CNC books are created equal; therefore, scrutinizing the content is essential. Look for books that provide a comprehensive overview while also diving into specifics relevant to your operations.

- Assess the table of contents: Ensure it includes critical topics like CNC programming, automation, and troubleshooting.

- Seek practical examples: Books that incorporate case studies or practical applications will enhance understanding and retention.

Step 4: Verify Reviews and Recommendations

Before making a purchase, gather insights from other professionals in the field. Reviews and recommendations can provide valuable perspectives on the book’s effectiveness and applicability.

- Utilize online forums and communities: Engage with machinists and industry experts on platforms like LinkedIn or specialized CNC forums.

- Check for ratings on educational sites: Websites that specialize in technical literature often have user reviews that can guide your decision.

Step 5: Consider Format and Accessibility

The format of the book can significantly impact its usability. Determine if you prefer physical copies or digital formats based on your team’s reading habits and accessibility needs.

- Evaluate digital options: E-books can be more accessible and offer search functionalities that enhance usability.

- Check for supplemental materials: Some books may come with additional resources like online tutorials, videos, or software that can enrich the learning experience.

Step 6: Assess Cost vs. Value

While budget constraints are a reality, it’s crucial to assess the value derived from the book against its cost. Invest in quality resources that will provide long-term benefits to your team.

- Analyze the ROI: Consider the potential improvements in productivity and efficiency that knowledgeable staff can bring.

- Look for bulk purchase options: Some suppliers may offer discounts for bulk orders, making it more cost-effective to equip your entire team.

Step 7: Finalize Supplier Selection

After evaluating your options, choose a supplier that aligns with your procurement strategy. Ensure they provide reliable customer service and support for any inquiries post-purchase.

- Request sample chapters or previews: Before finalizing, ask for a preview to ensure the book meets your expectations.

- Confirm return policies: Understanding the return or exchange policy can safeguard your investment, should the book not meet your needs.

By following this structured approach, B2B buyers can confidently select CNC machine books that enhance their team’s competencies and align with their operational goals.

Comprehensive Cost and Pricing Analysis for cnc machine book Sourcing

What Are the Key Cost Components Involved in Sourcing CNC Machine Books?

When sourcing CNC machine books, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: This encompasses the costs related to paper, printing, binding, and any digital formats. High-quality materials may increase the overall price, particularly for illustrated or hardcover editions.

-

Labor: This includes the costs associated with authors, editors, designers, and production staff. Expertise in CNC technology can drive up labor costs, as highly knowledgeable professionals are often required to ensure the content is accurate and valuable.

-

Manufacturing Overhead: General operational costs such as utilities, rent, and administrative expenses also contribute to the final pricing. Efficient management of these overhead costs can result in more competitive pricing.

-

Tooling: For specialized books that may require unique printing techniques or formats, tooling costs can add to the price. This is particularly relevant for books featuring advanced graphics or unique layouts.

-

Quality Control (QC): Ensuring that the final product meets industry standards involves additional costs related to quality assurance processes. This is vital for maintaining the credibility of the publication, especially in a technical field like CNC machining.

-

Logistics: Shipping and handling costs can vary significantly based on destination, volume, and shipping methods. This is particularly important for international buyers who must account for customs and import duties.

-

Margin: The profit margin added by publishers and distributors also plays a role in the final price. Margins can vary based on the market segment, competitive landscape, and perceived value of the book.

How Do Price Influencers Affect CNC Machine Book Sourcing?

Several factors influence the pricing of CNC machine books, which buyers should consider:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often result in discounts, making it essential for buyers to assess their needs accurately. Establishing relationships with suppliers can also lead to better pricing for larger orders.

-

Specifications/Customization: Customized content or formats can increase costs. Buyers should weigh the benefits of tailored materials against their budget constraints.

-

Materials: The choice of materials affects both the durability and cost of the book. For instance, hardcover editions typically cost more than paperback versions.

-

Quality/Certifications: Books with certifications or endorsements from reputable industry bodies may command higher prices due to perceived value. Buyers should consider whether these certifications are essential for their needs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may offer higher-quality products but at a premium price, while newer suppliers might provide lower costs but with potential risks.

-

Incoterms: Understanding the shipping terms agreed upon can significantly affect the overall cost. Incoterms dictate who is responsible for various costs and risks during shipping, which can be crucial for international buyers.

What Buyer Tips Can Help in Negotiating Prices for CNC Machine Books?

B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiate: Always engage in price negotiations. Many suppliers are open to discussions, especially for bulk orders, which can lead to significant savings.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the purchase price. This includes considering the book’s longevity, relevance, and potential return on investment in terms of knowledge gained.

-

Understand Pricing Nuances: Be aware that prices may vary significantly based on geographical location and market demand. Buyers should research regional pricing trends to ensure they are making competitive offers.

-

Leverage Relationships: Build strong relationships with suppliers to gain insights into pricing strategies and potential discounts. Trust and familiarity can often lead to better terms and conditions.

Disclaimer on Indicative Prices

Prices for CNC machine books can fluctuate based on various factors, including market demand, supplier pricing strategies, and shipping costs. Therefore, it is advisable to seek multiple quotations and conduct thorough market research before making purchasing decisions.

Alternatives Analysis: Comparing cnc machine book With Other Solutions

In the rapidly evolving landscape of CNC machining, B2B buyers often seek various resources to enhance their understanding and operational efficiency. While a CNC machine book serves as a valuable educational tool, there are alternative solutions that can also facilitate learning and practical application in this field. This section compares the CNC machine book with two viable alternatives: online courses and simulation software.

Comparison Table

| Comparison Aspect | Cnc Machine Book | Online Courses | Simulation Software |

|---|---|---|---|

| Performance | Comprehensive knowledge | Interactive learning | Hands-on practice |

| Cost | Moderate ($100+) | Varies ($50 to $500+) | High ($500 to $2,000+) |

| Ease of Implementation | Simple to access | Requires internet access | Requires technical setup |

| Maintenance | No maintenance required | Regular updates needed | Software updates necessary |

| Best Use Case | In-depth theoretical knowledge | Practical skills and certification | Skill development and testing |

How Do Online Courses Compare to CNC Machine Books?

Online courses offer a dynamic and interactive approach to learning CNC machining. They often feature video lectures, quizzes, and community forums that enable learners to engage actively with the material. This method is particularly beneficial for those who prefer guided instruction and immediate feedback. However, the cost can vary significantly depending on the provider and course length, and learners must have reliable internet access. While online courses provide practical skills and certification options, they may not cover the theoretical depth found in comprehensive CNC machine books.

What Are the Advantages of Simulation Software Over CNC Machine Books?

Simulation software allows users to practice CNC machining in a virtual environment, providing a hands-on experience without the risk of material waste. This software can mimic real-world machining scenarios, enabling users to test their skills and troubleshoot problems in a safe setting. The primary downside is the higher cost associated with purchasing and maintaining such software, as well as the need for specific hardware and technical expertise for installation. Simulation software is ideal for companies looking to train employees in a controlled environment, but it may not replace the foundational knowledge provided by a CNC machine book.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the right educational resource for CNC machining, B2B buyers should consider their specific needs, budget, and learning preferences. A CNC machine book is an excellent choice for those seeking in-depth knowledge and a comprehensive understanding of CNC technology. In contrast, online courses and simulation software can cater to those who prioritize practical skills and interactive learning. Evaluating the advantages and limitations of each alternative will empower buyers to make informed decisions that align with their operational goals and workforce development strategies.

Essential Technical Properties and Trade Terminology for cnc machine book

What Are the Key Technical Properties to Consider in CNC Machinery?

When investing in CNC machinery, understanding critical specifications is essential for ensuring that the equipment meets operational requirements and quality standards. Here are some key technical properties to consider:

-

Material Grade

The material grade of CNC components affects durability and performance. Common materials include steel, aluminum, and composite materials. For B2B buyers, selecting the right material grade is crucial as it impacts the machine’s longevity and its ability to withstand operational stresses, thereby influencing maintenance costs and production efficiency. -

Tolerance Levels

Tolerance defines the permissible limit of variation in a physical dimension. CNC machines often operate within tight tolerances, which can range from ±0.01 mm to ±0.1 mm depending on the application. Understanding tolerance is vital for B2B buyers as it directly affects product quality and the ability to meet client specifications, particularly in industries like aerospace and automotive where precision is paramount. -

Axis Configuration

CNC machines can have various axis configurations, typically ranging from 3-axis to 5-axis systems. The configuration determines the machine’s capability to perform complex shapes and intricate designs. Buyers must consider their specific manufacturing needs; for instance, a 5-axis machine allows for greater flexibility and efficiency in part production, reducing setup times and increasing throughput. -

Spindle Speed

The spindle speed (measured in RPM) is crucial for determining the machining efficiency and the type of materials that can be processed. Higher spindle speeds can lead to faster production rates but may also require advanced cooling systems to prevent overheating. B2B buyers should evaluate spindle speed in conjunction with their material processing needs to optimize productivity while maintaining quality. -

Power Rating

The power rating of a CNC machine (usually expressed in kilowatts) indicates the machine’s capability to handle various cutting operations. A higher power rating allows for the machining of tougher materials and more complex geometries. Buyers must assess their production demands and select machines with adequate power ratings to ensure efficient and effective machining processes.

Which Trade Terms Are Essential for Understanding CNC Machine Transactions?

Navigating the CNC machinery market involves familiarizing oneself with common industry terminology that influences purchasing decisions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In CNC machinery, OEMs provide essential components like motors and controls. Understanding this term helps buyers identify reputable suppliers and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is particularly important for B2B buyers looking to manage inventory costs effectively. Knowing the MOQ helps businesses plan their purchases and negotiate better terms with suppliers. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. This process is vital for B2B buyers to obtain competitive pricing and evaluate different suppliers based on their offerings, thus ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms is crucial for B2B transactions as they define who pays for shipping, insurance, and duties, thereby minimizing the risk of misunderstandings. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for B2B buyers to manage production schedules and inventory levels effectively, particularly in industries where timely delivery is critical to maintaining competitive advantage.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing CNC machines, ensuring alignment with their operational goals and market demands.

Navigating Market Dynamics and Sourcing Trends in the cnc machine book Sector

What Are the Current Market Dynamics and Key Trends in the CNC Machine Book Sector?

The CNC machine book sector is witnessing significant transformation driven by advancements in technology and evolving market demands. A key driver is the shift towards digital manufacturing and automation, which emphasizes the need for comprehensive resources that cover not just operational techniques but also the theoretical foundations of CNC technology. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly seeking educational materials that provide both practical skills and theoretical knowledge, facilitating a smoother transition to Industry 4.0 practices.

Emerging trends include the integration of online learning platforms and digital editions of CNC manuals, which cater to a global audience. Buyers are now looking for books that not only cover traditional machining techniques but also delve into modern advancements like additive manufacturing, energy-efficient practices, and the use of robotics. As the manufacturing landscape becomes more competitive, the emphasis on upskilling through authoritative texts has intensified. Moreover, sourcing decisions are heavily influenced by the availability of localized content that addresses specific regional challenges and opportunities.

In addition, the increasing importance of networking and collaboration in manufacturing is shaping the way buyers approach their sourcing strategies. They are now more inclined to seek out publications that are not only educational but also foster community engagement, allowing them to connect with other professionals in the field.

How Is Sustainability and Ethical Sourcing Impacting the CNC Machine Book Sector?

Sustainability and ethical sourcing are paramount considerations for B2B buyers in the CNC machine book sector. The environmental impact of manufacturing processes has led to a growing demand for resources that advocate for greener practices. Books that emphasize sustainable machining techniques, energy-efficient production, and waste reduction are becoming essential tools for organizations aiming to enhance their environmental responsibility.

The importance of ethical supply chains cannot be overstated. B2B buyers are increasingly scrutinizing the origins of the materials used in CNC machine books. Publications that feature certifications such as FSC (Forest Stewardship Council) for paper sourcing or that highlight eco-friendly printing processes are gaining traction. This trend is not merely a passing phase; it reflects a broader commitment to sustainability that resonates with stakeholders and customers alike.

Moreover, as businesses seek to bolster their brand image, there is a shift towards sourcing educational materials that align with corporate social responsibility (CSR) goals. Companies are looking for books that not only educate but also inspire and guide them towards sustainable practices in their operations. This growing emphasis on sustainability is expected to continue shaping sourcing trends in the CNC machine book sector.

What Is the Brief Evolution and History of CNC Machine Books Relevant to B2B Buyers?

The evolution of CNC machine books is closely tied to the advancements in manufacturing technology. Initially, resources focused primarily on manual machining techniques, reflecting the artisan skills that characterized early manufacturing. As numerical control (NC) technology emerged in the mid-20th century, so too did the need for educational materials that could bridge the gap between traditional machining and the new automated processes.

The introduction of CNC technology in the 1970s marked a pivotal moment, leading to a surge in specialized publications aimed at engineers and machinists. These early texts laid the groundwork for comprehensive guides that encompass a wide array of topics, from basic programming to advanced automation techniques. Over the years, as the industry has evolved towards digital integration and smart manufacturing, CNC machine books have adapted, incorporating contemporary practices such as Industry 4.0, additive manufacturing, and sustainable machining processes.

Today, B2B buyers are not only interested in the technical aspects of CNC machining but also in how these practices can be applied within the context of global market dynamics, regulatory frameworks, and sustainability initiatives. The history of CNC machine books reflects an ongoing commitment to education and adaptation, ensuring that professionals are well-equipped to navigate the complexities of modern manufacturing.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc machine book

-

How do I choose the right CNC machine book for my needs?

When selecting a CNC machine book, consider your current knowledge level and specific interests, such as programming, operation, or maintenance. Look for books that provide a solid foundation in CNC technology and cover essential topics like G-code programming, machine setup, and troubleshooting. Reviews and recommendations from industry professionals can be invaluable. Additionally, assess the book’s relevance to your region’s machining practices and the specific CNC systems you use. -

What is the best CNC machine book for beginners?

For beginners, “CNC Programming Handbook” by Peter Smid is highly recommended due to its comprehensive coverage of G-code programming and practical examples. Another excellent choice is “Metalworking Sink or Swim” by Tom Lipton, which combines machining principles with tips and tricks. These books provide foundational knowledge while being approachable, ensuring a solid start in CNC machining. -

How can I ensure the quality of a CNC machine book before purchasing?

To ensure quality, check for author credentials and industry experience, as well as reviews from other buyers. Look for books published by reputable publishers in the engineering field, as these typically have undergone rigorous quality checks. Previewing the book’s table of contents can also help you assess whether it covers the topics relevant to your needs. -

What should I consider regarding supplier vetting when sourcing CNC machine books?

When vetting suppliers for CNC machine books, evaluate their reputation and track record in the industry. Check for certifications, customer reviews, and their return policy. Additionally, inquire about their distribution channels, especially if you’re sourcing internationally, to ensure timely delivery and availability of the latest editions. Strong communication with suppliers can also provide insights into their reliability and service quality. -

Are there customization options available for CNC machine books?

Some publishers offer customization options, such as special editions tailored to specific industries or applications. If you’re looking for bulk purchases for training programs or corporate use, inquire about personalized content or branded editions that can include your company’s logo or specific case studies. This can enhance the relevance and applicability of the material to your team. -

What are the typical minimum order quantities (MOQs) for CNC machine books?

MOQs can vary by supplier, but for bulk orders, many publishers set a minimum of 10 to 50 copies. If you’re ordering for a training program or educational institution, you may negotiate lower MOQs. Always discuss potential discounts for larger orders, as many suppliers are willing to accommodate bulk purchases to foster long-term partnerships. -

What payment terms should I expect when purchasing CNC machine books internationally?

Payment terms can vary significantly based on the supplier and your location. Common options include upfront payment, partial payment upon order confirmation, or payment on delivery. For international transactions, be aware of currency exchange rates and potential fees. Using secure payment methods, such as credit cards or escrow services, can help mitigate risks associated with international purchases. -

How can I manage logistics when importing CNC machine books?

When importing CNC machine books, consider working with logistics partners experienced in international shipping. They can assist with customs clearance, tariffs, and delivery timelines. Ensure that the supplier provides accurate shipping documentation to avoid delays. Additionally, discuss shipping options that align with your budget and urgency, including air freight for faster delivery or sea freight for cost savings on larger orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Cnc Machine Book Manufacturers & Suppliers List

1. CNC Cookbook – CNC Programming Handbook & Machine Shop Trade Secrets

Domain: cnccookbook.com

Registered: 2007 (18 years)

Introduction: 1. CNC Programming Handbook, Third Edition by Peter Smid – Focuses on GCode programming, particularly Fanuc controls. Recommended to be used alongside a free G-Code tutorial for better understanding.

2. Machine Shop Trade Secrets by James Harvey – A comprehensive Tips and Techniques book for machinists, with a revised edition available. Includes a separate CNC book titled “CNC Trade Secrets,” whi…

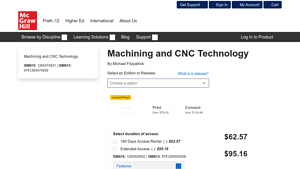

2. McGraw-Hill Education – Machining and CNC Technology

Domain: mheducation.com

Registered: 2000 (25 years)

Introduction: {“title”: “Machining and CNC Technology”, “author”: “Michael Fitzpatrick”, “ISBN10”: “1265474931”, “ISBN13”: “9781265474935”, “release_year”: “2024”, “edition”: “4th Edition”, “pricing”: {“eBook”: “$62.57”, “print”: “$78.00”, “Connect”: “$134.66”}}

3. Barnes & Noble – CNC Machining Book

Domain: barnesandnoble.com

Registered: 1995 (30 years)

Introduction: {“title”: “CNC Machining Book: The Everything Book to CNC Programming and More”, “author”: “Arthur Robinson”, “format”: “eBook”, “price”: “$4.97”, “BN ID”: “2940151529709”, “publisher”: “RCP”, “publication_date”: “05/02/2015”, “file_size”: “357 KB”, “description”: “Learn everything there is to know about CNC machines, including 3 basic motion types, data transfer methods, and understanding CNC.”, …

4. Access Engineering Library – CNC Design and Operation Techniques

Domain: accessengineeringlibrary.com

Registered: 2008 (17 years)

Introduction: This company, Access Engineering Library – CNC Design and Operation Techniques, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for cnc machine book

In the competitive landscape of CNC machining, strategic sourcing of knowledge and resources is paramount for achieving operational excellence. The insights gleaned from authoritative texts like The CNC Handbook and other essential readings underscore the necessity for professionals to be well-versed in both fundamental and advanced CNC concepts. This knowledge equips engineers and machinists to optimize production processes, reduce variability, and enhance product quality, ultimately driving profitability.

Moreover, as international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of digital manufacturing, leveraging these educational resources can facilitate informed decision-making. Understanding the latest advancements in CNC technology, from Industry 4.0 to energy-efficient practices, is crucial for staying ahead of market demands.

Looking ahead, the CNC landscape is poised for rapid transformation. Buyers are encouraged to invest in not just the machinery but also in the continuous learning that will keep their teams adept and competitive. By prioritizing strategic sourcing of knowledge and technology, businesses can position themselves for sustainable growth and innovation in the evolving global market. Embrace this opportunity to enhance your operations and drive success in your CNC endeavors.