Contents

Manufacturing Insight: Cnc Machine Basics

Understanding CNC Machine Fundamentals for Precision Manufacturing

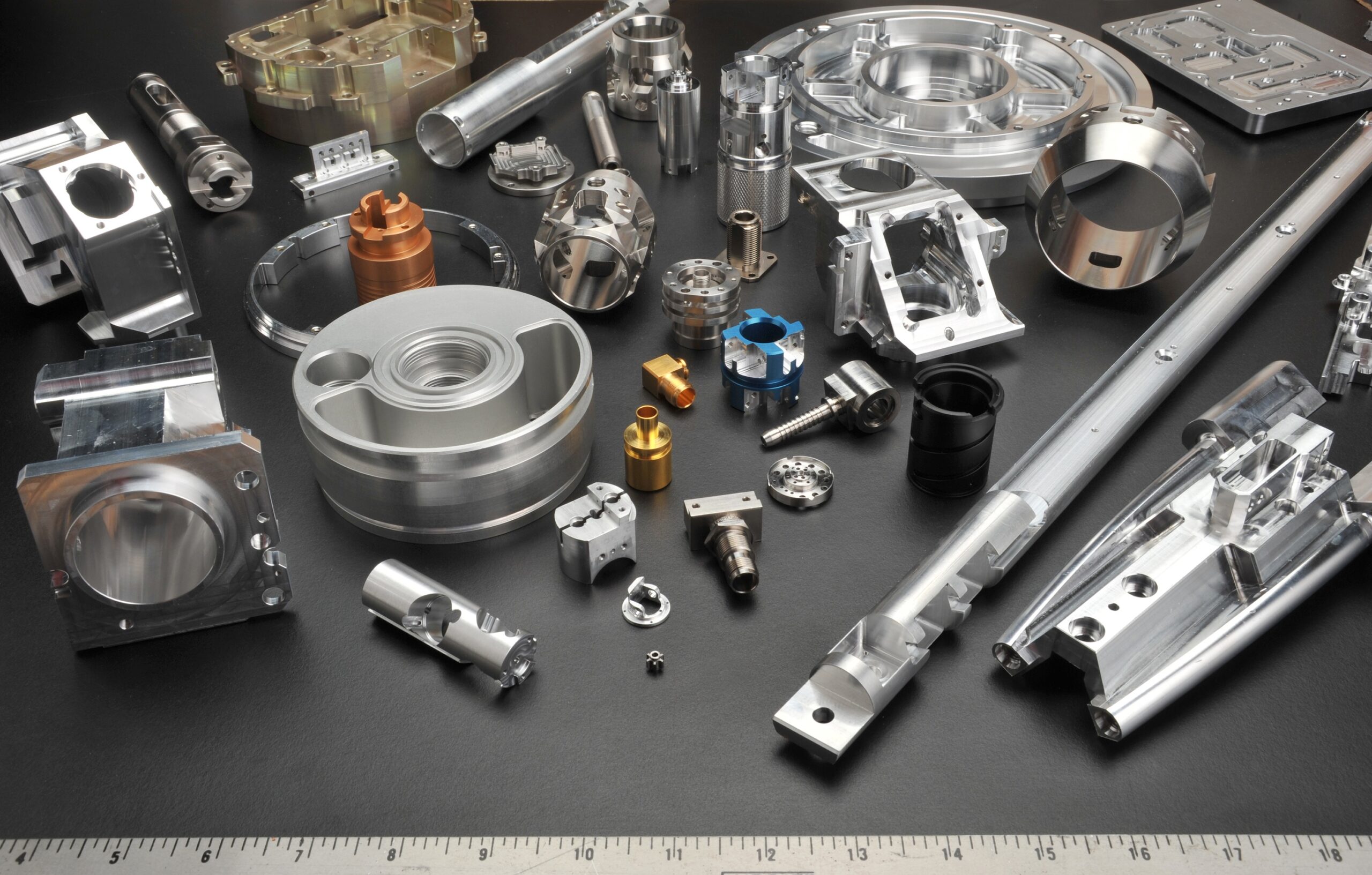

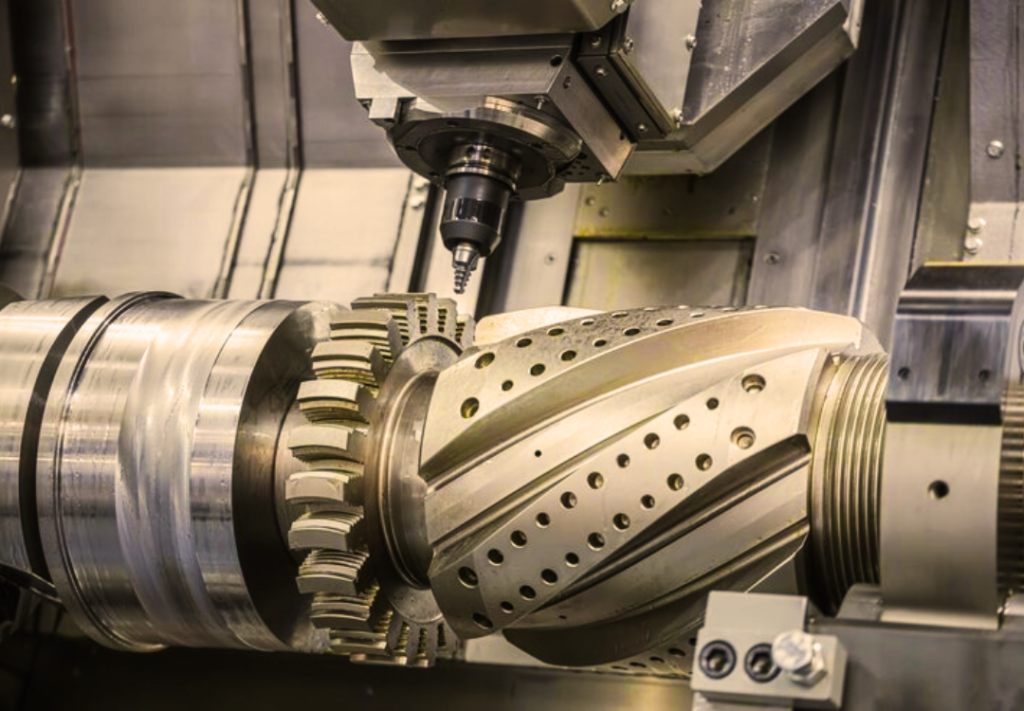

Computer Numerical Control (CNC) machining remains the cornerstone of modern precision manufacturing, transforming digital designs into high-tolerance physical components through automated, multi-axis cutting processes. At Honyo Prototype, we leverage this foundational technology to deliver exceptional prototyping and low-volume production services, ensuring dimensional accuracy, material integrity, and repeatability for demanding engineering applications. Our expertise spans 3-axis, 4-axis, and 5-axis milling, turning, and multi-tasking operations, accommodating complex geometries in metals, plastics, and composites with tolerances as tight as ±0.005 mm.

Honyo’s CNC Machining Capabilities

We specialize in rapid iteration for engineering validation, functional testing, and bridge production, utilizing advanced HAAS, DMG MORI, and Makino equipment maintained to stringent calibration standards. Our process integrates CAD/CAM-driven toolpath optimization with real-time in-process inspection, minimizing lead times without compromising on critical surface finishes or structural requirements. Material versatility includes aerospace-grade aluminum, stainless steel, titanium, PEEK, and engineered plastics, all processed under ISO 9001-certified quality controls.

Accelerating Your Development Timeline

To streamline your project initiation, Honyo Prototype offers an Online Instant Quote system. Upload your STEP or IGES files to receive a detailed manufacturability analysis and competitive pricing within minutes—no manual submission delays. This transparent, data-driven approach empowers engineering teams to validate design feasibility and budget early, accelerating time-to-prototype by eliminating traditional quotation bottlenecks.

Partner with Honyo to transform conceptual designs into mission-critical components through CNC machining precision engineered for innovation. Explore our capabilities and initiate your project with real-time quoting today.

Technical Capabilities

CNC Machine Basics – Technical Specifications Overview

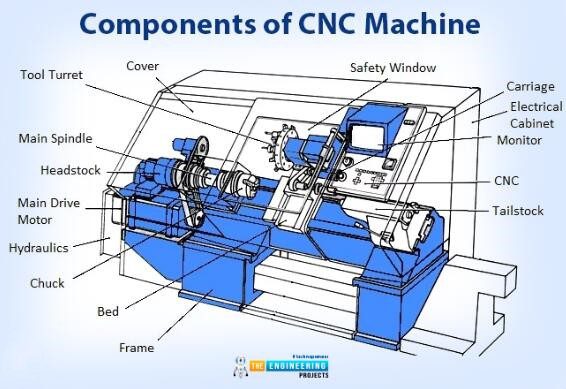

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computerized controls and rotating cutting tools to remove material from a workpiece. The following table outlines key technical specifications and capabilities for 3-axis, 4-axis, and 5-axis CNC milling machines, as well as CNC turning centers, with emphasis on tight tolerance production and compatibility with common engineering materials such as Aluminum, Steel, ABS, and Nylon.

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Notes on Tight Tolerance Capability |

|---|---|---|---|---|---|

| Axes of Motion | X, Y, Z | X, Y, Z, A (rotary around X) | X, Y, Z, A, B (or C) | X, Z (radial and axial) | 5-axis enables complex geometries with high precision; tighter tolerances on multi-faceted parts |

| Typical Positioning Accuracy | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.003 mm (±0.0001″) | ±0.005 mm (±0.0002″) | High-end machines achieve ±0.001 mm with calibration and environmental control |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm | Critical for batch consistency in precision components |

| Spindle Speed Range | 8,000 – 20,000 RPM | 8,000 – 20,000 RPM | 10,000 – 30,000 RPM | 3,000 – 12,000 RPM | Higher speeds support fine finishes in Aluminum and plastics |

| Cutting Tolerances | ±0.025 mm typical | ±0.025 mm typical | ±0.012 mm achievable | ±0.012 mm typical | Tight tolerances (±0.005 mm) possible with precision tooling and metrology |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.4 – 1.6 µm | 0.8 – 1.6 µm | Fine finishes critical for sealing, mating, or aesthetic surfaces |

| Common Tooling | End mills, drills, taps | Same as 3-axis + indexing | High-precision end mills, ball nose | Turning inserts, grooving tools | Carbide and diamond-coated tools used for tight tolerance and long tool life |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | All materials machined with optimized feeds/speeds; Nylon and ABS require chip control |

| Aluminum Machining | Excellent (high material removal) | Excellent with indexing | Optimal for complex parts | Suitable for turned components | Easy to machine; tolerances ±0.01 mm achievable consistently |

| Steel Machining | Good (slower speeds) | Good | Excellent for hardened steels | Excellent for shafts, pins | Pre-hardened and stainless steels require rigid setups for tight tolerances |

| ABS Machining | Very good (low heat build-up) | Very good | Excellent for enclosures | Limited (rarely turned) | Use sharp tools and light cuts to prevent melting; tolerances ±0.05 mm typical |

| Nylon Machining | Good (slight elasticity) | Good | Good for wear components | Possible for bushings, gears | Clamping must avoid deformation; moisture absorption affects dimensional stability |

| Work Envelope (Typical) | 500 x 400 x 300 mm | 500 x 400 x 300 mm + rotary | 400 x 300 x 250 mm | Max 300 mm dia x 500 mm length | Smaller 5-axis machines favor precision over size |

| Applications | Flat parts, housings, plates | Indexed features, slots | Aerospace, medical, molds | Shafts, pins, fasteners | Tight tolerance critical in aerospace, medical, and optical industries |

Notes on Material and Tolerance Performance

Aluminum (6061, 7075): Most machinable metal; excellent for high-speed milling and tight tolerance work. Minimal thermal expansion allows stable precision.

Steel (1018, 4140, Stainless 303/316): Requires rigid setups and proper tooling. Achieving ±0.01 mm tolerances demands slow, controlled passes and thermal management.

ABS: Low melting point; best machined with sharp, polished tools at moderate speeds. Dimensional stability supports ±0.05 mm tolerances with proper fixturing.

Nylon (6, 66, GF-filled): Prone to swelling with moisture; pre-dry material before precision machining. Slight spring-back requires over-travel or post-process measurement.

Honyo Prototype utilizes 5-axis milling and precision turning centers to achieve tight tolerance requirements across all compatible materials, supported by in-process inspection and environmental controls to maintain repeatability.

From CAD to Part: The Process

Honyo Prototype’s CNC machining service follows a rigorously defined workflow designed for precision, efficiency, and client transparency. This process, distinct from CNC machine operation fundamentals, outlines our client-facing service sequence from initial design submission to final delivery. We emphasize seamless integration of advanced digital tools with expert engineering oversight at every stage.

CAD File Upload and Validation

Clients initiate the process by uploading native or neutral CAD file formats (STEP, IGES, Parasolid, or native SOLIDWORKS/Creo/Fusion 360) via our secure customer portal. Our system performs immediate automated validation checks for file integrity, unit consistency, and geometric completeness. Files failing validation trigger an instant notification to the client specifying required corrections, preventing downstream delays. This step ensures the digital foundation for manufacturing is technically sound before proceeding.

AI-Powered Quoting Engine

Validated CAD files enter our proprietary AI quoting system. This engine cross-references the geometry against real-time databases encompassing material costs, machine availability (3-axis, 5-axis, mill-turn), tooling requirements, and shop floor capacity. It applies learned parameters from thousands of historical jobs to generate an accurate, detailed quote within two hours. The quote explicitly breaks down costs by material, machining time, setup, and secondary operations, providing full cost transparency without requiring manual estimator intervention for standard geometries.

Engineering-Led Design for Manufacturability (DFM) Analysis

Following quote acceptance, our manufacturing engineering team conducts a comprehensive DFM review. This is not an automated check but a value-added engineering service performed by experienced CNC specialists. The goal is proactive optimization to enhance manufacturability, reduce lead times, and lower costs while preserving functional intent. Key focus areas include:

| DFM Analysis Category | Specific Checks | Typical Client Benefit |

|---|---|---|

| Geometry & Tolerances | Minimum wall thickness, undercuts, deep cavities, non-standard hole depths, tolerance stack-up feasibility | Eliminates costly secondary operations or specialized tooling |

| Material Selection | Machinability index vs. part function, material waste optimization | Reduces machining time and raw material cost |

| Feature Optimization | Consolidation of multiple setups, avoidance of thin ribs prone to chatter, simplification of complex contours | Lowers risk of scrap and shortens cycle time |

| Fixturing Strategy | Identification of optimal datum surfaces, clamping points, and potential need for custom fixtures | Ensures part stability and dimensional accuracy |

The engineer provides a formal DFM report with actionable recommendations, often including annotated CAD visuals. Client approval of the DFM report is mandatory before production release, ensuring alignment on any design modifications.

Precision CNC Production Execution

Approved designs move to production on our network of calibrated CNC machines (DMG MORI, Haas, Mazak), all maintained to stringent ISO standards. Each job undergoes:

Rigorous first-article inspection (FAI) per AS9102 standards for critical features

In-process checks at defined intervals using calibrated CMMs and optical comparators

Real-time machine monitoring for tool wear, vibration, and thermal drift

Dedicated project management tracking against the committed schedule

Material traceability and full process documentation are maintained throughout. Complex assemblies receive coordinated multi-machine scheduling to ensure component compatibility.

Quality-Controlled Delivery

Final inspection occurs against the original CAD model and client specifications using our Zeiss CMM and vision systems. All parts ship with a comprehensive inspection report detailing critical dimensions and material certifications. We utilize climate-controlled logistics partners with real-time tracking. Standard lead times are 5-10 business days for prototypes and 10-15 for low-volume production, with expedited options. Parts are packaged with custom foam inserts for impact resistance, and delivery confirmation with tracking details is provided automatically. We maintain a 99.2% on-time delivery rate for conforming orders.

Start Your Project

Looking to deepen your understanding of CNC machine basics? Whether you’re new to precision manufacturing or seeking reliable prototyping and production support, Honyo Prototype provides expert engineering guidance and hands-on capabilities from our ISO-certified factory in Shenzhen, China.

For technical inquiries or to request educational resources on CNC machining processes, materials, tolerances, and best practices, contact Susan Leo directly at [email protected]. Let us help you make informed decisions from design to delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.