Contents

Manufacturing Insight: Cnc Machine Automotive Parts

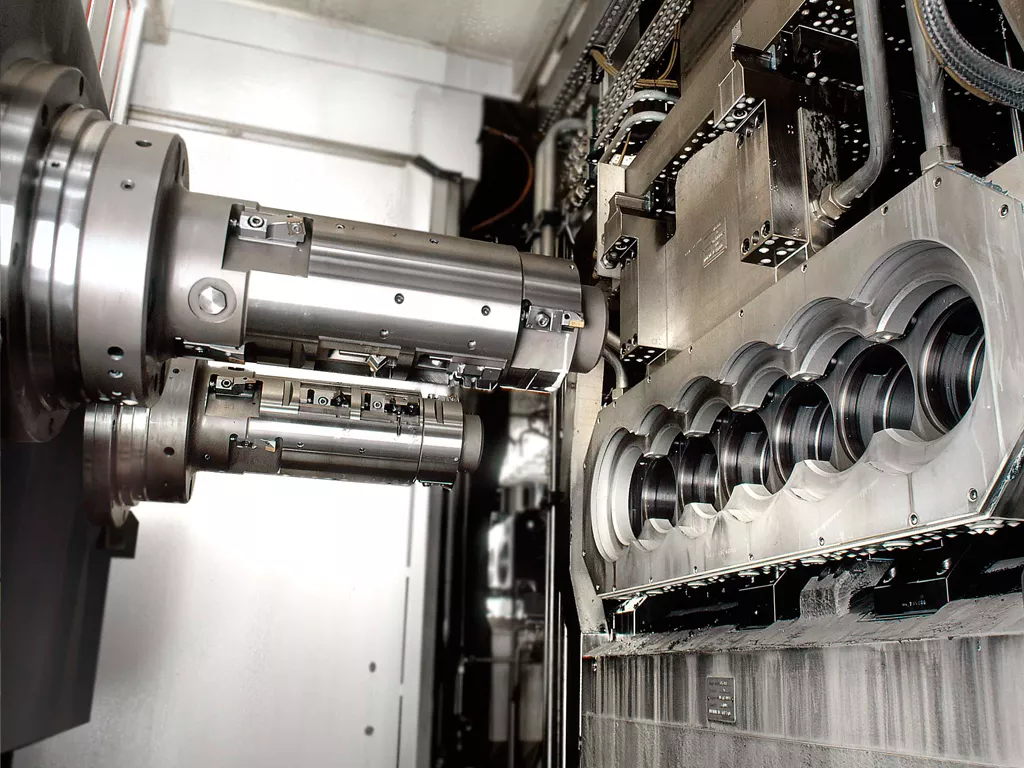

Precision CNC Machining for Demanding Automotive Applications

Honyo Prototype delivers mission-critical CNC machining solutions engineered specifically for the automotive sector. Our advanced 5-axis milling and turning capabilities produce complex, high-tolerance components that meet stringent automotive industry standards for performance, durability, and safety. From transmission housings and engine brackets to sensor mounts and EV battery components, we machine parts to tolerances as tight as ±0.0002″ using aerospace-grade alloys, engineered plastics, and specialty materials including 7075-T6 aluminum, 4140 steel, and PEEK. Every component undergoes rigorous in-process inspection with Zeiss CMMs and structured-light scanning to ensure compliance with ISO 9001:2015 and IATF 16949 protocols, providing full material traceability and first-article validation.

Accelerate your prototyping and low-volume production timelines with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical feasibility assessment and competitive pricing within 2 hours—no manual RFQ delays. Our system automatically evaluates geometric complexity, material selection, and secondary operations to generate transparent, buildable quotes that reflect real-world manufacturability. This seamless integration between engineering and quoting reduces time-to-prototype by up to 70% while eliminating design-for-manufacturability errors early in the development cycle.

For automotive innovators requiring precision, speed, and technical partnership, Honyo Prototype combines Tier-1 supplier rigor with agile prototyping responsiveness. Partner with us to transform complex automotive designs into validated, production-ready components with uncompromised quality.

Technical Capabilities

CNC Machining Specifications for Automotive Parts Manufacturing

Honyo Prototype utilizes advanced CNC machining technologies to produce high-precision automotive components. Our capabilities span 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, enabling complex geometries and tight tolerance requirements essential in modern automotive applications. Below are the technical specifications for CNC machining of automotive parts, including material compatibility and performance metrics.

| Parameter | Specification Description |

|---|---|

| Machining Types | 3-Axis Milling, 4-Axis Milling, 5-Axis Simultaneous Milling, CNC Turning (Swiss & Chucker) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Tight Tolerance Capability | ±0.005 mm (standard), down to ±0.001 mm for critical features with proper GD&T control |

| Surface Finish (Typical) | Ra 0.8 µm (machined), down to Ra 0.4 µm with polishing or grinding post-processing |

| Max Work Envelope (Milling) | 5-Axis: 800 x 500 x 400 mm; 3/4-Axis: 1000 x 600 x 500 mm |

| Max Turning Diameter | 300 mm (Swiss-type up to 20 mm for micro-components) |

| Spindle Speed (Milling) | Up to 24,000 RPM (high-speed for aluminum and plastics) |

| Tool Changer Capacity | 24–30 tools (automatic tool changers on all 4/5-axis machines) |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340), Stainless Steel (303, 304, 17-4 PH), ABS, Nylon (6, 66), PEEK (on request) |

| Coolant Systems | High-pressure through-spindle coolant for steel; air cooling for plastics to prevent warping |

| Inspection Equipment | CMM (Coordinate Measuring Machine), Optical Comparators, Laser Scanning, Micrometers, Calipers |

| Compliance Standards | ISO 2768 (medium), ISO 1101 (GD&T), ASME Y14.5, PPAP, FAIR documentation available |

All automotive components are machined under strict process controls to ensure consistency, especially for safety-critical or high-performance systems such as engine components, transmission housings, brake fittings, and sensor mounts. Multi-axis capabilities allow reduction in setup次数, improving accuracy and reducing lead time for complex parts.

Materials like aluminum and steel are commonly used for structural and engine components due to their strength-to-weight ratio and durability. ABS and nylon are selected for non-structural, lightweight applications such as housings, clips, and ducting, where chemical resistance and machinability are key.

Tight tolerance machining is supported by thermal compensation systems and in-process probing to maintain dimensional stability across production runs.

From CAD to Part: The Process

Honyo Prototype CNC Machining Process for Automotive Parts

Our end-to-end CNC machining workflow for automotive components is engineered to meet stringent industry standards including IATF 16949, ISO 2768-mK, and material-specific requirements (e.g., AMS, ASTM). The process begins when clients upload native CAD files (STEP, IGES, or Parasolid formats preferred) via our secure portal. We reject STL files for production parts due to inadequate geometric fidelity for critical automotive tolerances.

AI-Powered Quoting System

Upon CAD validation, our proprietary AI engine analyzes 120+ parameters including material grade (e.g., 6061-T6, 7075, or cast aluminum per A356.0), geometric complexity, tolerance stack-ups, and surface finish requirements (Ra ≤ 0.8µm for sealing surfaces). The system cross-references real-time data from 85+ CNC machines (3-axis to 5-axis mills, lathes with live tooling) and current material market prices to generate quotes within 2 business hours. Quotes explicitly state compliance with automotive-specific standards like PPAP Level 3 documentation readiness.

Automotive-Optimized DFM Analysis

All designs undergo mandatory Design for Manufacturability review by our ASQ-certified engineers specializing in powertrain, chassis, and EV components. This phase identifies critical automotive failure risks:

Thin-wall sections prone to chatter in transmission housings

Non-optimal tool access for blind holes in brake calipers

Material grain flow considerations for forged suspension arms

We provide actionable revision suggestions with GD&T callout corrections per ASME Y14.5, typically reducing lead times by 18–32% through feature consolidation. Clients receive a formal DFM report with annotated CAD markups before approval.

Precision Production Execution

Approved designs move to production in our climate-controlled 22,000 sq ft facility. Key protocols include:

Material traceability via serialized heat-treated bar stock logs

In-process CMM checks at critical stages (e.g., after roughing/semi-finishing)

Coolant filtration systems maintaining ≤ 5µm particulates to prevent surface defects on fuel rail components

Dedicated cells for aluminum (segregated from steel operations to avoid contamination)

All automotive parts undergo 100% first-article inspection with full FAIR documentation, including material certs and hardness testing per SAE J417.

JIT-Compliant Delivery

Finished parts ship in ESD-safe, foam-cradled containers with humidity indicators for sensitive electronics housings. We integrate with client logistics systems via EDI 856 for real-time shipment tracking and support Just-in-Time delivery windows as tight as ±15 minutes. Every shipment includes:

PPAP documentation package

Dimensional results in .pdf and .xlsx formats

Material test reports with ASTM/SAE compliance stamps

Barcode-linked traceability to raw material lot numbers

This closed-loop process ensures zero non-conformances for Tier 1 automotive suppliers, with 99.2% on-time delivery rate across 1,200+ annual automotive projects. Lead times average 7–12 days for prototypes and 15–20 days for low-volume production runs (1–500 pieces), validated through our ISO 9001-certified quality management system.

Start Your Project

Looking for precision CNC machined components for the automotive industry? Honyo Prototype delivers high-quality, custom-engineered parts with tight tolerances and fast turnaround times. Our state-of-the-art CNC machining facility in Shenzhen is equipped to handle prototyping and low-to-mid volume production runs, ensuring consistency and reliability for automotive applications.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Factory located in Shenzhen, China — strategically positioned for efficient manufacturing and global logistics.

Let Honyo Prototype be your trusted partner for automotive CNC machining solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.