Contents

Manufacturing Insight: Cnc M-Code List

Understanding CNC M-Code Fundamentals for Precision Manufacturing

At Honyo Prototype, we recognize that mastery of CNC programming—particularly M-codes governing machine tool control, auxiliary functions, and workflow sequencing—is foundational to achieving micron-level precision and repeatability in complex prototyping and low-volume production. Our engineering team leverages this granular control to optimize cycle times, ensure process stability, and eliminate costly errors in every machined component, from aerospace fixtures to medical device housings. This reference list details essential M-codes to clarify their operational impact, reflecting Honyo’s commitment to transparent, engineer-to-engineer collaboration.

Why M-Codes Matter in High-Integrity Machining

M-codes directly influence critical outcomes: spindle orientation for multi-axis contouring, coolant activation during high-temp alloy cutting, or pallet change synchronization in unmanned operations. Misapplication can induce tool chatter, surface finish defects, or machine downtime. Honyo’s CNC machining services integrate these commands within ISO-compliant programs rigorously validated through our 5-axis simulation suite, ensuring your design intent translates flawlessly to physical parts. Our AS9100-certified processes treat M-code logic not as background syntax but as a strategic lever for yield improvement and material efficiency.

Accelerate Your Project Timeline with Honyo’s Expertise

Leverage this technical resource to align your design for manufacturability with proven machine control standards. When you’re ready to transform specifications into precision-engineered reality, Honyo Prototype delivers seamless scalability from prototype to bridge production. Utilize our Online Instant Quote platform for real-time pricing on CNC milling, turning, and multi-axis machining—featuring automated DFM feedback and lead time estimation within minutes. Submit your STEP/IGES files today to experience how our technical rigor and digital workflow integration reduce time-to-part by up to 40%.

| Service Capability | Technical Scope | Quality Assurance |

|---|---|---|

| 3-5 Axis CNC Machining | Aluminum, Titanium, Stainless Steel, Plastics | ISO 2768-mK, CMM Reporting |

| Tolerance Range | ±0.0002″ (5µm) for critical features | First Article Inspection (FAI) |

| Max Work Envelope | 28″ x 18″ x 20″ (711 x 457 x 508 mm) | PPAP Level 3 Support |

Technical Capabilities

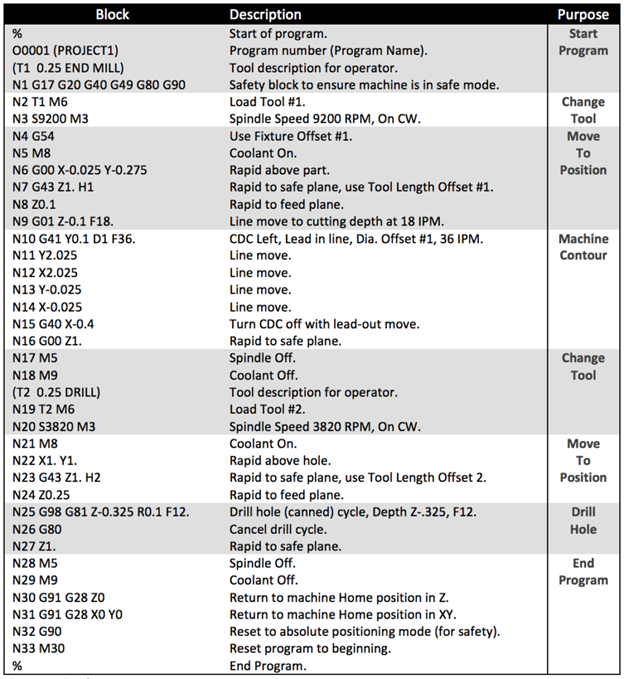

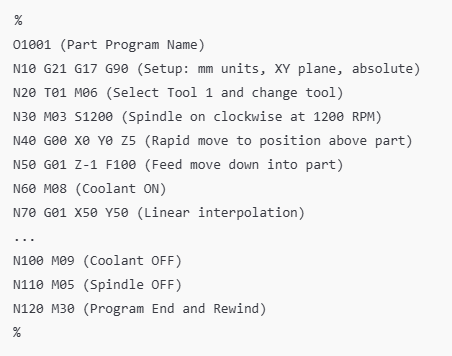

The M-codes in CNC programming are auxiliary commands that control machine functions such as coolant flow, spindle start/stop, pallet changes, and program termination. These codes are standardized across most CNC systems (e.g., Fanuc, Siemens, Haas), though some variations may exist by manufacturer. Below is a technical reference table of commonly used M-codes in 3-axis, 4-axis, and 5-axis milling, as well as CNC turning operations, particularly in applications requiring tight tolerances (±0.0005″ to ±0.005″, depending on feature and material).

These operations are routinely performed on materials including Aluminum (6061-T6, 7075-T6), Steel (1018, 4140, Stainless 303/316), ABS, and Nylon—each presenting unique challenges in thermal expansion, chip evacuation, and surface finish requirements.

| M-Code | Function | Application Context | Relevance to Tight Tolerance | Material Considerations |

|---|---|---|---|---|

| M00 | Program Stop | Pauses program for inspection or tool verification | Used during setup or mid-job checks to verify dimensional accuracy | Critical in multi-setup parts (e.g., Aluminum housings, Nylon seals) |

| M01 | Optional Stop | Operator-enabled pause; used for in-process inspection | Allows probing or touch-off checks without full program halt | Useful in high-precision steel components where thermal drift occurs |

| M02 | End of Program | Terminates main program (older control systems) | Signals completion; ensures no unintended tool paths follow | Standard across all materials and machine types |

| M03 | Spindle On (Clockwise) | Starts spindle rotation in CW direction | Required for most milling and turning operations | Speed/torque settings vary: Aluminum (high RPM), Steel (lower RPM, high torque) |

| M04 | Spindle On (Counterclockwise) | Starts spindle CCW; used for left-hand tools or specific tapping | Applied in thread milling or back-boring operations | Important in ABS/nylon to prevent material smearing |

| M05 | Spindle Stop | Stops spindle rotation | Ensures safety and accuracy during tool changes or probing | Critical before touch-probe routines in precision steel parts |

| M06 | Tool Change | Initiates automatic tool change (ATC) | Minimizes downtime and maintains repeatability | Essential in multi-tool 5-axis operations on complex aluminum molds |

| M07 | Mist Coolant On | Engages mist coolant system | Provides minimal lubrication with visibility; used in precision finishing | Preferred in aluminum to reduce thermal distortion |

| M08 | Flood Coolant On | Activates full coolant flow | Controls temperature in high-material-removal operations | Vital in steel turning and deep milling to maintain tolerance |

| M09 | Coolant Off | Turns off all coolant | Prevents contamination during probing or part unloading | Used before cleaning parts made of hygroscopic materials like Nylon |

| M19 | Spindle Orient | Positions spindle at a fixed angular location | Required for tool changes on vertical mills and face milling | Ensures consistent tool seating in high-accuracy 4-axis fixtures |

| M30 | Program End & Reset | Ends program and resets control | Standard for batch production; prepares machine for next cycle | Used in high-volume turning of ABS components |

| M98 | Call Subprogram | Invokes a subprogram (e.g., pocketing routine) | Increases code efficiency in complex 5-axis paths | Reduces programming errors in repetitive steel part features |

| M99 | Return from Subprogram | Exits subprogram and returns to main program | Supports modular programming in multi-feature parts | Enhances repeatability in aluminum aerospace brackets |

Notes on Material and Process Integration:

Aluminum: Requires high spindle speeds and sharp tooling. M07/M08 help manage heat; M06 ensures tool wear is minimized via frequent changes.

Steel: Demands rigid setups and consistent coolant (M08), especially in deep cavities. M01 stops allow for thermal compensation checks.

ABS & Nylon: Low melting points require reduced friction. M04 may be used for back tapering; minimal coolant (M07 or M09) prevents warping.

Tight Tolerance Work: Relies on M00/M01 for probing cycles, M19 for precise tool alignment, and M98/M99 for repeatable feature machining.

This M-code set supports high-precision CNC operations across complex geometries in multi-axis environments, ensuring consistency, accuracy, and process control across diverse engineering materials.

From CAD to Part: The Process

Honyo Prototype CNC Manufacturing Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for CNC machining projects, ensuring precision, efficiency, and client transparency. The process begins with CAD file submission and concludes with certified delivery. Crucially, the term “CNC M-code list” refers to internal machine-specific programming instructions (e.g., coolant on/off, spindle stop) generated during production setup. Clients interact with engineering deliverables—not raw M-codes—which remain proprietary to Honyo’s manufacturing execution system. Below is the standardized workflow:

Upload CAD

Clients submit 3D CAD models (STEP, IGES, or native formats) via Honyo’s secure portal. Our system validates file integrity, geometry completeness, and manufacturability against minimum feature tolerances (e.g., hole depth-to-diameter ratios). Unsupported formats trigger immediate client notification for resubmission.

AI-Powered Quoting

Honyo’s proprietary AI engine processes the CAD data against live parameters: machine availability, material stock, tooling libraries, and historical cycle times. Unlike static quoting tools, our system factors in dynamic variables like current shop floor load and material market pricing. Quotes include geometric tolerance validation, material cost breakdowns, and lead time estimates within 2 business hours.

DFM Analysis and Engineering Collaboration

Automated DFM (Design for Manufacturability) checks precede human review. The system flags high-risk features: thin walls (<0.5mm), deep cavities (depth >6× diameter), or non-standard tolerances (±0.005mm). A dedicated manufacturing engineer contacts the client within 24 hours to discuss optimizations—such as adjusting draft angles or consolidating features—reducing cost by 15–30% on average. Client approval of the final DFM report is mandatory before production.

Production Execution

Honyo’s CAM team generates optimized toolpaths using Mastercam and Fusion 360. M-codes (machine control commands) and G-codes are auto-generated, rigorously simulated in Vericut to prevent collisions, and validated against the approved DFM report. All operations occur on certified Haas/DMG MORI centers with in-process probing for first-article inspection. Real-time machine telemetry feeds our MES (Manufacturing Execution System), enabling live progress tracking for clients.

Delivery and Certification

Final parts undergo CMM validation against AS9100-compliant protocols. Each shipment includes:

Dimensional inspection reports (per ISO 10360)

Material certs (e.g., EN AW-6082-T6)

Surface roughness validation (Ra values)

Traceability logs linking to machine operator and tooling batches

Standard lead time is 7–12 business days post-DFM approval; expedited delivery (3–5 days) is available for qualified projects.

DFM Impact Comparison

| Parameter | Industry Standard DFM | Honyo Prototype DFM |

|——————–|————————|———————-|

| Optimization Depth | Basic geometry checks | Full cost/tolerance simulation |

| Client Collaboration | Post-quote email | Dedicated engineer call within 24h |

| Cost Reduction | 5–10% | 15–30% |

| Risk Mitigation | Reactive (post-failure)| Proactive (pre-production) |

This closed-loop process eliminates guesswork, ensuring parts meet specifications on the first run. Honyo treats M-code generation as an internal efficiency lever—not a client deliverable—focusing client communication on engineering outcomes and quality documentation.

Start Your Project

For a comprehensive CNC M-code list and technical support, contact Susan Leo at [email protected]. Honyo Prototype operates a precision manufacturing facility in Shenzhen, providing expert CNC machining services for prototyping and low-volume production. Reach out to ensure your machining programs align with industry-standard M-code practices.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.