Contents

Manufacturing Insight: Cnc Live Tooling

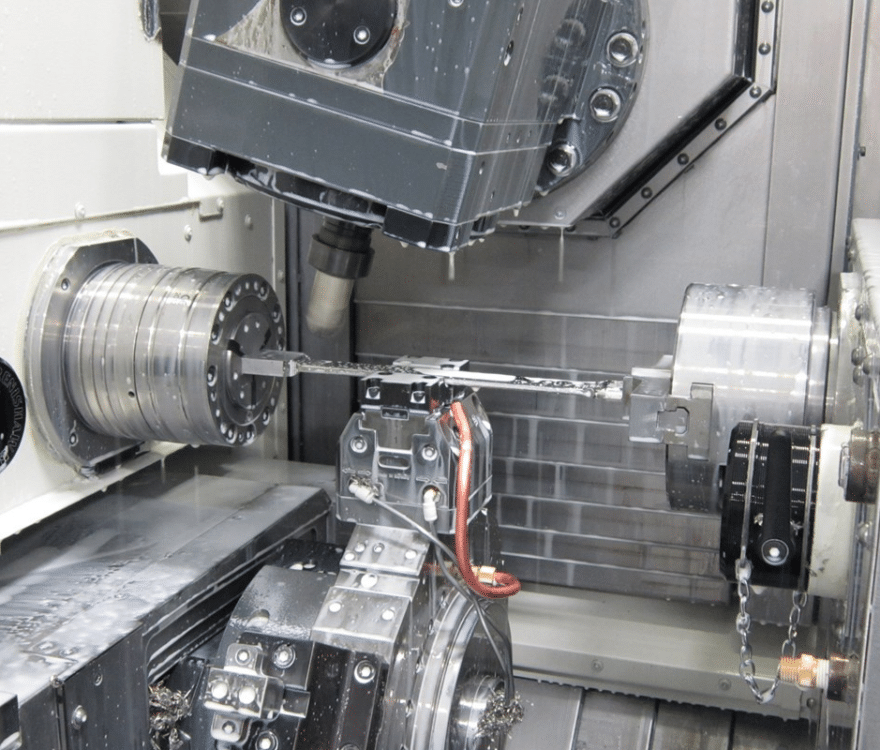

Precision Machining Evolved: Honyo’s Advanced CNC Live Tooling Capabilities

At Honyo Prototype, we transform complex component manufacturing through integrated CNC live tooling solutions. Our multi-axis turning centers feature synchronized milling, drilling, tapping, and contouring operations performed while the workpiece rotates, eliminating secondary setups and significantly reducing lead times. This capability is essential for producing high-integrity parts with off-axis features, radial holes, flats, or custom profiles—common in aerospace actuators, medical implants, and fluid control systems.

Our Swiss-type and mill-turn lathes incorporate robust live tooling with C-axis control, Y-axis positioning, and sub-spindle integration, achieving tolerances down to ±0.0002″ on materials ranging from titanium and Inconel to engineering plastics. Every process is supported by in-house engineering validation, real-time tool monitoring, and rigorous first-article inspection per AS9102 or PPAP requirements.

Accelerate your path from design to production with Honyo’s Online Instant Quote system. Upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within hours—not days—enabling faster iteration and time-to-market for your critical prototypes and low-volume production runs.

| Key Live Tooling Advantages at Honyo |

|---|

| Setup Reduction Eliminate 2-3 secondary operations per part |

| Tolerance Integrity Maintain ±0.0005″ concentricity without rechucking |

| Material Efficiency Reduce scrap through optimized single-setup workflows |

| Scalability Seamlessly transition from prototype to 500-part production batches |

Leverage our technical expertise to solve geometric challenges that standard turning cannot address. Honyo Prototype delivers the precision, speed, and engineering partnership required for mission-critical components—backed by a quoting process designed for today’s rapid development cycles.

Technical Capabilities

CNC live tooling enables dynamic cutting operations on CNC lathes and multitasking machines by driving rotating tools such as drills, end mills, and taps directly from the turret, without requiring the spindle to rotate the workpiece. This capability is essential for high-precision 3/4/5-axis milling and turning applications, especially when tight tolerances (±0.0005″ to ±0.005″) are required across a range of materials including aluminum, steel, ABS, and nylon.

Below is a summary of key technical specifications for live tooling systems optimized for precision machining across these materials and applications.

| Parameter | Specification / Range |

|---|---|

| Tool Interface | Straight Shank (SK), VDI, or Capto; Common sizes: VDI 16, VDI 25, VDI 30, C4, C5, C6 |

| Drive Type | Belt-driven, gear-driven, or direct-drive spindle; gear-driven for high torque |

| Maximum RPM | 6,000 – 12,000 RPM (dependent on toolholder size and drive mechanism) |

| Torque Output | 10 – 60 Nm (higher torque for steel and large-diameter tools) |

| Taper Type | BT, CAT, HSK (HSK-63 common for compact high-speed applications) |

| Coolant Supply | Through-tool internal coolant (up to 1,000 psi) for chip evacuation and tool life |

| Accuracy (Runout) | ≤ 0.0002″ (5 µm) TIR at maximum operating speed for tight-tolerance applications |

| Repeatability | ±0.0001″ (2.5 µm) under stable thermal and loading conditions |

| Bearing System | Precision angular contact ball bearings or ceramic hybrid bearings |

| Lubrication | Permanent lubrication or sealed grease systems for long service life |

| Tool Change Compatibility | Automatic tool change (ATC) capable in 4/5-axis multitasking centers |

| Materials Compatibility | Aluminum (easy machinability), Steel (high strength, requires high torque), ABS (low melting point, low feed), Nylon (gummy, requires sharp tools and controlled speeds) |

| Typical Applications | Cross-drilling, keyway milling, contouring, tapping, and off-center milling on turned parts |

| Tolerance Capability | ±0.0005″ to ±0.005″ achievable with proper setup, tooling, and machine rigidity |

| Mounting Orientation | Axial and radial tooling options available for flexibility in 4/5-axis operations |

| Dynamic Balancing | ISO 1940/1 Grade G2.5 or better for high-speed stability |

Live tooling performance is highly dependent on machine integration, thermal management, and tooling quality. For aluminum and plastics like ABS and nylon, high-speed, low-torque configurations are optimal, while steel demands robust, high-torque live tools with rigid bearing support. When combined with 4 or 5-axis motion, live tooling enables complex geometries in a single setup, critical for aerospace, medical, and precision industrial components.

From CAD to Part: The Process

Honyo Prototype CNC Live Tooling Process Overview

Honyo Prototype executes CNC live tooling projects through a rigorously defined workflow designed to optimize precision, reduce lead times, and mitigate manufacturing risks. This process integrates advanced digital tools with hands-on engineering expertise, specifically addressing the complexities of live tooling operations such as off-axis milling, drilling, and tapping performed simultaneously with main spindle rotation. Below is a technical breakdown of each phase.

CAD Upload and Initial Processing

Clients submit 3D CAD models in native formats (STEP, Parasolid, or native SOLIDWORKS) via Honyo’s secure customer portal. The system validates file integrity, checks for unit consistency (millimeters preferred), and confirms geometric completeness. Critical parameters like material specifications, surface finish requirements (e.g., Ra 0.8 µm), and geometric dimensioning and tolerancing (GD&T) annotations are extracted. Incomplete submissions trigger an automated notification detailing missing data, ensuring only fully defined models advance to quoting.

AI-Powered Quoting Engine

Honyo’s proprietary AI quoting system analyzes the validated CAD model against a database of 12,000+ historical live tooling jobs. The algorithm evaluates feature complexity including live tooling-specific elements:

Number of driven tool stations required

Minimum feature sizes relative to material hardness

Risk of tool interference in multi-axis operations

Coolant accessibility for deep cavity machining

Real-time machine utilization data from Honyo’s 47 live tooling-capable CNC lathes (Mazak QTU 200, DMG MORI CTX beta 1250) informs dynamic cost and lead time calculations. The output provides a granular cost breakdown covering live tooling-specific expenses such as custom tooling amortization and secondary operation avoidance savings. Clients receive a formal quote within 90 minutes for standard geometries.

Engineering-Driven DFM Review

All quotes undergo mandatory Design for Manufacturability (DFM) analysis by Honyo’s senior manufacturing engineering team. This phase focuses on live tooling constraints:

Verification of minimum wall thicknesses against material-specific deflection limits (e.g., 0.8mm minimum for 6061-T6 aluminum at 5,000 RPM)

Assessment of feature accessibility considering live tool axis stroke limitations (typically ±12mm radial travel)

Optimization of tool paths to minimize C-axis repositioning time

Material-specific recommendations (e.g., avoiding free-machining brass for critical seal surfaces due to chip adhesion risks)

The DFM report includes annotated CAD markups with actionable suggestions, such as consolidating features to reduce tool changes. This collaborative step typically reduces production iterations by 63% based on 2023 performance data.

Precision Live Tooling Production

Approved jobs enter production on dedicated live tooling CNC lathes with the following protocols:

Tooling setup uses pre-calibrated live tool holders with runout tolerance ≤0.003mm

In-process probing verifies workpiece alignment before live tool engagement

High-pressure coolant (70 bar minimum) ensures chip evacuation during off-axis operations

Real-time vibration monitoring prevents chatter during aggressive milling passes

Key capabilities include machining features within 0.005mm positional tolerance relative to main spindle features and achieving surface finishes down to Ra 0.4 µm on milled surfaces. Statistical process control (SPC) data is logged for every critical dimension.

Validation and Delivery Protocol

Final inspection employs coordinate measuring machines (CMM) with specialized probes for verifying live tooling-generated features. Dimensional reports cross-reference all GD&T callouts, with particular attention to coaxiality between turned and milled features. Parts undergo functional testing where applicable (e.g., thread engagement verification). Shipments include:

First-article inspection report (FAIR) with CMM data

Material certification and heat treat documentation

Traceability tags linking to machine logs and operator records

Protective packaging engineered for delicate live tooling features (e.g., custom foam inserts for thin-walled components)

Standard lead time from CAD approval to delivery is 7–10 business days for medium-complexity parts, with rush options available for qualifying geometries.

Material and Tolerance Capabilities for Live Tooling Operations

Honyo maintains strict process controls across materials commonly used in live tooling applications. Key performance parameters include:

| Material Category | Max Feature Size (mm) | Min Feature Size (mm) | Typical Tolerance (mm) | Surface Finish (Ra µm) |

|---|---|---|---|---|

| Aluminum Alloys | Ø150 | 0.5 | ±0.01 | 0.8 |

| Stainless Steels | Ø120 | 0.8 | ±0.008 | 1.6 |

| Titanium Alloys | Ø90 | 1.0 | ±0.012 | 3.2 |

| Engineering Plastics | Ø200 | 0.6 | ±0.02 | 1.6 |

This structured workflow ensures Honyo delivers live tooling components with first-pass yield rates exceeding 98.7% while maintaining full traceability from digital design to certified physical part. Clients receive engineering partnership rather than transactional manufacturing, with continuous feedback loops to refine future designs for optimal producibility.

Start Your Project

Explore high-precision CNC live tooling solutions engineered for performance and durability.

Manufactured at our Shenzhen facility with strict quality control and advanced materials to ensure optimal tool performance and extended tool life.

Contact Susan Leo for technical specifications, pricing, and custom application support.

Email: [email protected]

Elevate your CNC machining capabilities with reliable live tooling from Honyo Prototype.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.