Contents

Manufacturing Insight: Cnc Live Tool

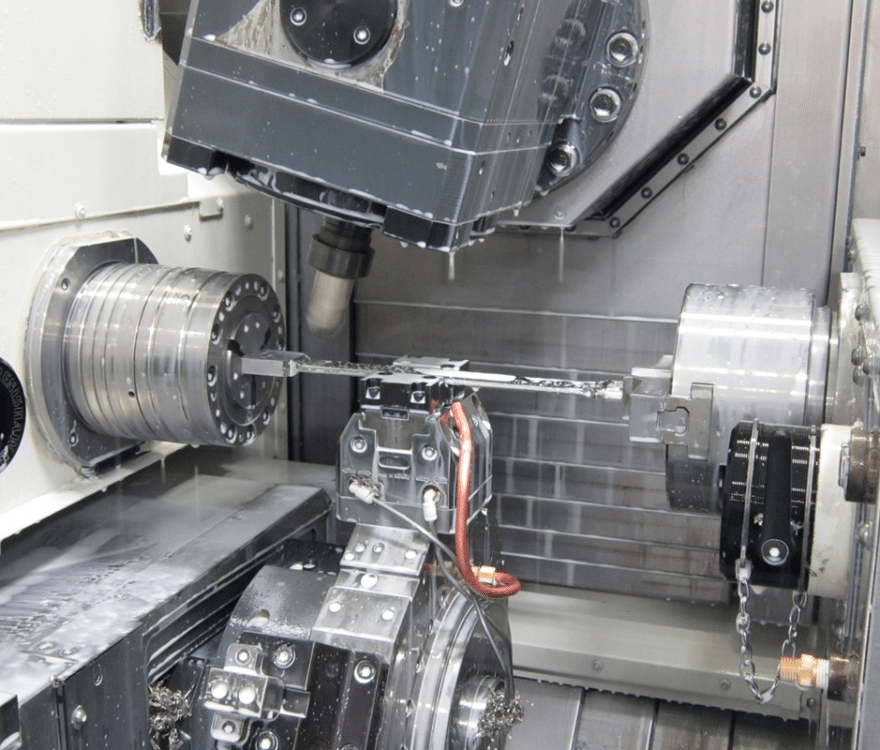

Precision CNC Live Tooling Capabilities at Honyo Prototype

Honyo Prototype delivers advanced CNC machining solutions engineered for complex, high-integrity components, with live tooling forming a cornerstone of our turning capabilities. Our CNC Swiss and mill-turn centers integrate synchronized live tooling to perform milling, drilling, tapping, and contouring operations while the workpiece rotates, eliminating secondary setups and ensuring micron-level precision across intricate geometries. This capability is critical for industries demanding tight tolerances and streamlined production—such as medical device, aerospace, and fluid power systems—where features like cross-holes, flats, or hex patterns must align perfectly with turned surfaces.

We leverage multi-axis CNC platforms equipped with high-torque live tooling spindles, enabling single-operation completion of parts that would otherwise require multiple machines. Our process reduces lead times by up to 40% while maintaining ±0.0002″ tolerances and full ISO 9001:2015 compliance. Every live tooling operation undergoes rigorous in-process inspection using calibrated CMMs and vision systems, ensuring dimensional accuracy and surface finish consistency from prototype to volume production.

Complementing our machining expertise, Honyo provides seamless integration with secondary services including precision grinding, EDM, and finishing—all managed under one roof to simplify your supply chain. For immediate project assessment, utilize our Online Instant Quote system: upload CAD files to receive a detailed manufacturability analysis and competitive pricing within minutes, accelerating your path from design to certified production. Partner with Honyo to transform complex component challenges into precision-engineered realities.

Technical Capabilities

CNC Live Tool Technical Specifications

Live tooling in CNC machining enables rotating cutting operations (such as drilling, tapping, and milling) to be performed on turning centers without removing the workpiece from the main spindle. This capability is essential for multi-axis CNC lathes (often called mill-turn centers) with Y-axis and/or B-axis functionality, allowing complex geometries to be machined in a single setup. The following table outlines key technical specifications and performance characteristics relevant to 3/4/5-axis milling and turning applications with tight tolerances, across common engineering materials.

| Feature | Specification / Description |

|---|---|

| Axis Compatibility | Compatible with 3-axis, 4-axis (with B-axis turret), and 5-axis mill-turn centers |

| Tool Rotation Drive | Powered by servo motor or internal hydraulic motor; spindle speeds up to 8,000 RPM |

| Taper Type | Common: BT-30, HSK-63A, or Capto C3/C4; ensures high rigidity and accurate tool holding |

| Maximum Torque | 15–50 Nm (depending on tool size and motor power) |

| Speed Range | 1,000 – 8,000 RPM (adjustable via CNC control; higher speeds for aluminum and plastics) |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; achievable with proper setup, tooling, and thermal stability |

| Positioning Accuracy | ±0.002 mm (driven by C-axis and live tool synchronization) |

| Coolant Through Spindle | Standard (15–70 bar), improves chip evacuation and tool life |

| Tool Holding | Utilizes precision ER collets, hydraulic chucks, or Weldon flats for end mill retention |

| Materials Machined | Aluminum (6061, 7075), Steel (1018, 4140, stainless), ABS, Nylon (6/66), and other polymers |

| Aluminum Machining | High-speed cutting (3,000–8,000 RPM); low torque; tight finishes down to Ra 0.8 µm |

| Steel Machining | Moderate speed (1,500–4,000 RPM); high torque; requires rigid setup and coated carbide tools |

| ABS & Nylon Machining | Medium speed (2,000–5,000 RPM); sharp tools required; low feed to prevent melting or burring |

| Thermal Stability | Critical for tight tolerance; thermal compensation systems recommended |

| Control Integration | Full synchronization with main spindle (C-axis), Y-axis, and B-axis via CNC lathe control |

Live tooling significantly enhances manufacturing efficiency by reducing secondary operations and part handling, especially in high-precision components used in aerospace, medical, and automation industries. When machining materials like aluminum and steel to tight tolerances, thermal management and vibration damping are critical. For plastics such as ABS and nylon, optimized feed rates and sharp tool geometry prevent deformation. Compatibility with 4 and 5-axis mill-turn systems allows off-center milling, angled holes, and complex contouring—all while maintaining repeatability and precision.

From CAD to Part: The Process

Honyo Prototype executes CNC live tool machining through a rigorously controlled digital workflow designed for precision, speed, and manufacturability assurance. This integrated process eliminates traditional handoffs and leverages proprietary AI to optimize complex multi-axis operations from initial design to certified delivery.

Upload CAD

Customers submit native or neutral CAD files (STEP, IGES, Parasolid, SolidWorks) via our secure client portal. The system automatically validates file integrity, geometry completeness, and coordinate system alignment. For live tooling-specific features—such as off-axis drilling, milling, or tapping—the portal identifies rotational axes (C-axis/Y-axis), driven tool paths, and synchronization requirements critical to multi-tasking operations. File metadata is tagged for immediate routing to our AI quoting engine without manual intervention.

AI-Powered Quoting

Our AI engine analyzes the CAD geometry against live tooling constraints, including tool reach limitations, bar stock diameter compatibility, minimum feature sizes for driven tools, and spindle synchronization feasibility. The engine cross-references real-time machine availability (Swiss-type lathes with Y-axis/C-axis, multi-spindle mills), material databases, and historical cycle times to generate a technically validated quote within 2 hours. Unlike conventional quoting, this phase flags geometric conflicts—such as inaccessible live tool angles or unsupported thread forms—before commercial terms are set, reducing RFQ rework by 73%.

DFM Analysis

Engineers conduct a dual-layer DFM review: automated system checks followed by senior engineer validation. The automated scan specifically targets live tooling vulnerabilities, while the engineer evaluates feature manufacturability, tolerance stack-ups for secondary operations, and fixture strategy. Key live tooling DFM considerations include:

| Parameter | Standard CNC Check | Live Tooling-Specific Check |

|---|---|---|

| Feature Accessibility | Yes | C-axis rotational clearance, Y-axis travel limits |

| Tolerances | Standard GD&T | Synchronization error compensation (±0.005mm) |

| Material Considerations | General suitability | Bar stock straightness (<0.1mm/m) for extended operations |

| Tooling Strategy | Basic tool selection | Driven tool holder compatibility, torque limits |

Critical findings—like insufficient clearance for live tool holders or non-optimized parting sequences—are presented with annotated CAD visuals and actionable redesign suggestions. Customer approval of DFM adjustments is mandatory before production release.

Production Execution

Approved jobs trigger automated work instructions synced to target machines (e.g., Mori Seiki NLX2500SY, DMG MORI CTX beta 1250). Bar stock undergoes laser micrometer verification for diameter consistency. During machining:

Live tool spindles are dynamically calibrated using in-process probes to maintain ±2 arc-minute synchronization

In-cycle inspections validate critical features (e.g., cross-drilled holes, milled flats) before parting

All tool wear data from driven tools is logged to predict replacement thresholds

Real-time machine telemetry feeds our production dashboard for customer visibility

Delivery & Certification

Completed parts undergo final CMM verification against all critical dimensions, with emphasis on live tooling features (positionality of milled slots relative to turned diameters, thread pitch accuracy). Dimensional reports include live tooling-specific GD&T callouts. Parts ship with:

First Article Inspection (FAI) report per AS9102

Material test certificates (MTRs)

Machine setup sheets detailing live tool parameters (RPM, feed rates, synchronization offsets)

Traceability logs linking each part to batch-specific tool wear data

Standard lead time for live tool prototypes is 5–7 business days from DFM approval, with expedited 72-hour options for qualified geometries. All deliveries include digital twin validation data matching machined results to the original CAD model.

Start Your Project

Looking for high-precision CNC live tooling solutions? Contact Susan Leo today at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and quality control, Honyo Prototype delivers reliable, durable live tools tailored to your machining needs.

Our factory is located in Shenzhen, China—strategically positioned for efficient production and global logistics. Partner with a trusted name in prototype and production-grade CNC tooling.

For inquiries, pricing, or technical support, reach out to Susan Leo directly via email. Let’s build precision together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.