Contents

Manufacturing Insight: Cnc Linear Guides

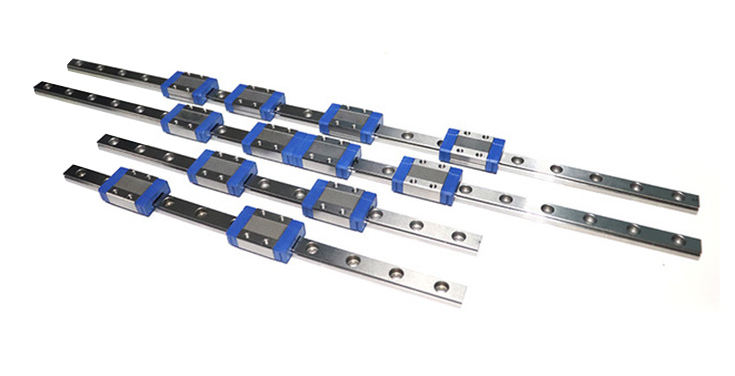

Precision Motion Starts with Precision Manufacturing: CNC Linear Guides by Honyo Prototype

CNC linear guides form the critical foundation for high-accuracy motion control in industrial automation, semiconductor equipment, and advanced manufacturing systems. Achieving micron-level straightness, consistent preload, and exceptional rigidity demands machining capabilities that transcend standard tolerances. At Honyo Prototype, our ISO 9001-certified CNC machining services specialize in producing linear guide components—from hardened steel rails and carriages to precision-ground end caps—with unwavering adherence to GD&T specifications and surface finishes down to Ra 0.4 µm.

We leverage multi-axis milling, wire EDM, and precision grinding technologies to ensure geometric integrity across complex profiles, directly impacting your system’s repeatability and lifespan. Our engineering team collaborates closely with clients to optimize material selection (including SAE 52100, SUS440C, and custom alloys) and thermal treatment processes, eliminating common failure points like micro-welding or raceway deformation.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload CAD files for linear guide components, receive detailed manufacturability feedback, and obtain competitive pricing within hours—not days. This seamless integration of engineering rigor and digital efficiency ensures your motion-critical parts meet the highest performance standards, from prototype to production. Partner with Honyo to transform precision requirements into realized motion solutions.

Technical Capabilities

CNC linear guides are critical components in precision motion systems used in 3, 4, and 5-axis milling and turning machines. They ensure accurate, repeatable, and smooth linear motion under high loads and dynamic conditions. These guides are essential for achieving tight tolerances (±0.001 mm to ±0.005 mm) and maintaining rigidity during high-speed machining operations. The performance of linear guides is influenced by material selection, preload, accuracy class, and lubrication.

Below is a technical specifications table summarizing key parameters relevant to CNC linear guides in high-precision machining environments involving Aluminum, Steel, ABS, and Nylon workpieces.

| Parameter | Specification / Detail |

|---|---|

| Axis Compatibility | 3-axis, 4-axis, 5-axis CNC milling and turning centers |

| Guide Type | Recirculating ball or roller type linear guideways (e.g., square rail or round rail) |

| Load Capacity (Dynamic) | 20,000 N to 50,000 N (depending on size and rail type) |

| Accuracy Class | C0 to C3 (ISO 3696), with C0-C1 for tight tolerance applications (±0.001 – ±0.005 mm) |

| Preload Class | Light (P0), Medium (P1), High (P2); used to eliminate backlash and increase rigidity |

| Travel Speed | Up to 60 m/min (standard), up to 120 m/min (high-speed variants) |

| Repeatability | ±0.001 mm to ±0.003 mm |

| Rigidity | High stiffness with minimal deflection under cutting forces |

| Materials (Guide Rails) | Through-hardened alloy steel (e.g., GCr15) with precision-ground surfaces |

| Carriage Materials | Hardened steel or cast iron with precision-machined bearing surfaces |

| Seals | Dual-lip contact seals or labyrinth seals for dust and coolant protection |

| Lubrication | Automatic or manual grease lubrication; compatible with synthetic CNC greases |

| Corrosion Resistance | Optional stainless steel rails or protective coatings (e.g., hard chrome, TiN) |

| Mounting Surface Finish | Ra ≤ 1.6 µm, flatness within 0.01 mm over length for proper alignment |

| Thermal Stability | Low thermal expansion coefficient; pre-tensioned rails to minimize thermal drift |

| Compatible Workpiece Materials | Aluminum (soft and hard alloys), Steel (mild, stainless, tool steels), ABS (engineering thermoplastic), Nylon (polyamide) |

| Typical Applications | High-precision mold making, aerospace components, medical devices, rapid prototyping |

Linear guides used in machining environments involving Aluminum and Steel demand high rigidity and damping characteristics due to variable cutting forces. For lighter materials such as ABS and Nylon, reduced cutting forces allow for optimized speed and feed, but guides must still maintain micron-level positioning accuracy. Material compatibility in the guide system (e.g., steel-on-steel with hardened surfaces) ensures long service life and dimensional stability under continuous operation.

From CAD to Part: The Process

Honyo Prototype CNC Linear Guides Manufacturing Process

Honyo Prototype executes a streamlined, precision-focused workflow for CNC linear guide production, designed to minimize lead times while ensuring adherence to tight tolerances and functional performance requirements. The process begins with secure CAD file submission via our encrypted customer portal, which accepts industry-standard formats including STEP, IGES, and native SOLIDWORKS files. Upon upload, metadata validation confirms critical parameters such as material specifications, geometric dimensioning and tolerancing (GD&T) callouts, surface finish requirements, and hardening treatments. Files failing validation trigger automated notifications for client correction, preventing downstream delays.

AI-Assisted Quoting System

Our proprietary AI engine analyzes validated CAD data to generate preliminary cost and lead time estimates within 2 business hours. The system cross-references 15+ years of production data, accounting for material waste factors, machine time calculations, and secondary operation complexities inherent to linear guide geometries (e.g., precision-ground raceways, preload adjustment features). Crucially, this phase includes automatic DFM flagging for high-risk elements such as thin-walled sections below 0.8mm or non-optimal draft angles for grinding fixtures. Human engineers review all AI outputs, with 92% of quotes requiring ≤1 revision cycle due to this hybrid approach.

Engineer-Led DFM Review

All linear guide projects undergo mandatory DFM analysis by our AS9100-certified manufacturing engineers. This phase focuses on manufacturability challenges unique to linear motion components:

Raceway profile optimization to prevent chatter during grinding

Thermal expansion compensation in multi-segment assemblies

Hardness distribution validation for case-hardened steels (e.g., SAE 52100)

Fixture accessibility for 5-axis contouring of complex bearing interfaces

Typical DFM reports identify 3–5 actionable improvements per project, such as modifying corner radii to reduce stress concentrations or suggesting alternative heat treatment sequences. Client approval of DFM recommendations is required before work authorization, with average resolution time of 1.5 business days for revisions.

Precision Production Execution

Approved designs enter production using our dedicated linear guide manufacturing cell featuring:

CNC grinders with sub-micron positioning accuracy (e.g., Makino A500G)

In-process laser metrology for real-time raceway profile correction

Climate-controlled environment (±0.5°C) to maintain dimensional stability

Material traceability is enforced via blockchain-logged barcodes from raw bar stock through final assembly. Critical process parameters are monitored per ISO 286-2 standards, with statistical process control (SPC) charts generated for every lot. Typical production metrics for linear guides include:

| Parameter | Standard Tolerance | Honyo Capability |

|---|---|---|

| Raceway Straightness | ±0.005mm/300mm | ±0.002mm/300mm |

| Bearing Surface Roughness | Ra 0.4μm | Ra 0.2μm |

| Hardness Uniformity | ±3 HRC | ±1.5 HRC |

Quality-Controlled Delivery

All linear guides undergo 100% functional testing on custom load-bearing rigs simulating operational conditions (preload forces, travel accuracy, and noise/vibration thresholds). Final inspection packages include:

CMM reports with ISO 10360-8 compliance data

Hardness test certificates per ASTM E18

Surface roughness profiles verified against ISO 4287

Traceable material mill certificates

Shipments include serialized component tags linking to digital quality records accessible via client portal. Standard lead time is 12–18 business days from DFM approval, with expedited options available for critical path items. Every delivery includes a comprehensive process summary detailing machine utilization rates, tool wear compensation data, and deviation analysis against initial CAD model. Clients receive proactive notifications at each milestone, with real-time production tracking available through our customer dashboard.

Start Your Project

Looking for high-precision CNC linear guides manufactured to strict tolerances? Honyo Prototype offers reliable, durable linear guide solutions ideal for industrial automation, CNC machinery, and precision equipment applications.

All products are manufactured at our Shenzhen factory, leveraging advanced machining capabilities and quality control systems to ensure consistent performance.

For inquiries or custom requirements, contact Susan Leo at [email protected] to discuss your project needs and request technical specifications.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.