Contents

Manufacturing Insight: Cnc Lathes Tools

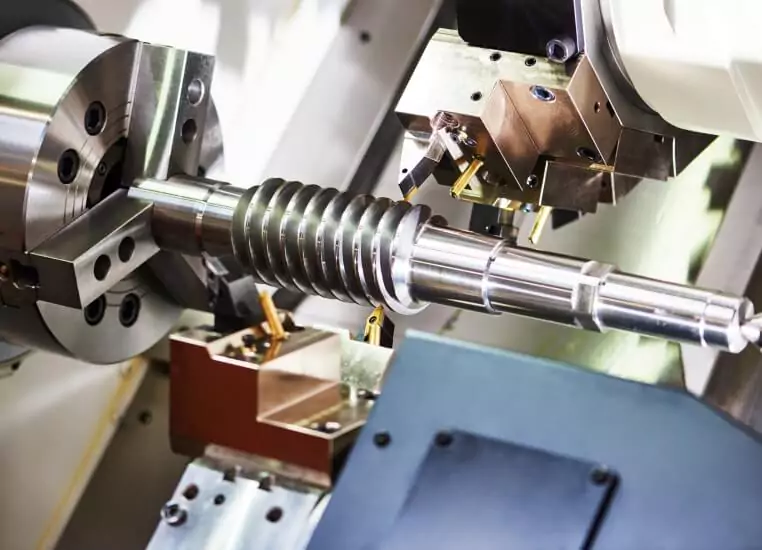

Precision CNC Lathes Form the Backbone of High-Integrity Component Manufacturing

At Honyo Prototype, our advanced CNC lathe capabilities deliver critical turned components with uncompromising accuracy for aerospace, medical, and industrial applications. We specialize in complex turning operations on bar stock and billet materials including stainless steel, titanium, aluminum alloys, and engineered plastics, consistently holding geometric tolerances to ±0.0002″ (5µm). Our Swiss-type and multi-axis live-tool lathes enable integrated milling, drilling, and threading within a single setup, eliminating secondary operations and ensuring part integrity through stringent in-process metrology.

Engineered Solutions for Demanding Turning Requirements

Honyo’s CNC machining services address the full spectrum of lathe tool challenges—from micro-precision components under 1mm diameter to robust shafts exceeding 150mm. Our technical team collaborates with clients during DFM analysis to optimize material utilization, surface finish requirements (Ra 0.4µm achievable), and feature complexity. All processes adhere to AS9100 and ISO 13485 standards, with real-time SPC monitoring on critical dimensions to guarantee batch-to-batch repeatability. This technical rigor ensures your prototypes and production runs meet the most stringent functional and regulatory specifications.

Accelerate Your Project Timeline with Online Instant Quote

Streamline your procurement process through Honyo’s Online Instant Quote platform, designed specifically for engineering teams requiring rapid turnaround on CNC lathe projects. Upload CAD files (STEP, IGES, DWG) to receive a detailed technical assessment and competitive pricing within hours—not days—enabling faster iteration cycles and accelerated time-to-market. This digital workflow integrates seamlessly with our manufacturing execution system, ensuring quoted lead times directly translate to shop floor scheduling without manual re-estimation delays. Initiate your precision turning project with confidence through a transparent, engineer-to-engineer quoting experience.

Technical Capabilities

CNC lathe tools are precision cutting instruments designed for turning operations on computer numerical control (CNC) lathes. While lathes primarily perform turning, modern CNC machines often integrate milling and multi-axis capabilities—especially in 3, 4, and 5-axis configurations—enabling complex geometries and tight tolerances. These tools are engineered to maintain accuracy, surface finish, and repeatability, particularly when machining materials such as aluminum, steel, ABS, and nylon.

Below is a technical specification summary for CNC lathe tools used in multi-axis turning and milling applications, with emphasis on tight tolerance performance and material compatibility.

| Parameter | Specification Details |

|---|---|

| Axis Configuration | 3-Axis: X, Z, and C-axis (rotary indexing); 4-Axis: Adds B-axis for live tooling; 5-Axis: Adds secondary rotary axis (e.g., A or C+B) for full contouring and off-center milling |

| Tool Types | Turning inserts (ISO standard), live tooling (drills, end mills, taps), boring bars, grooving tools, parting tools, threading inserts |

| Spindle Speed Range | 3,000 – 12,000 RPM (varies by material and tooling; higher for aluminum/ABS, lower for steel) |

| Positioning Accuracy | ±0.001 mm (±0.00004 in) |

| Repeatability | ±0.0005 mm (±0.00002 in) |

| Tolerance Capability | Achieves ±0.005 mm (±0.0002 in) for turning; ±0.01 mm (±0.0004 in) for milling with proper fixturing and tool compensation |

| Feed Rates | 0.01 – 0.5 mm/rev (turning); 100 – 5,000 mm/min (milling via live tooling) |

| Tool Materials | Carbide (most common), ceramic (for high-speed steel cutting), CBN (for hardened steel), HSS (for plastics like ABS and nylon) |

| Insert Coatings | TiN, TiCN, TiAlN, AlCrN – enhance wear resistance and thermal stability |

| Coolant Delivery | Through-tool internal coolant (high-pressure, 30–70 bar) for chip evacuation and thermal control |

| Compatible Materials | Aluminum (6061, 7075): High-speed cutting with polished carbide; Steel (1018, 4140, stainless): Moderate speeds with coated inserts; ABS & Nylon: Low cutting forces, sharp HSS or uncoated carbide, low heat generation |

| Surface Finish | Ra 0.4 – 1.6 µm (typical for turning); Ra 0.8 – 3.2 µm (milling with end tools) |

| Control System | Fanuc, Siemens, or Mitsubishi CNC with advanced interpolation for multi-axis toolpaths |

| Tool Holding | ISO, Capto, or HSK-T for live tooling; ISO 2850 for turning tool posts |

| Applications | Precision shafts, aerospace fittings, medical components, automotive parts, polymer housings requiring tight tolerances and mixed operations |

These specifications reflect high-end CNC turning centers capable of combined turning and milling operations. The integration of 4 and 5-axis functionalities allows for complete part machining in a single setup, reducing cumulative error and improving geometric accuracy—critical when holding tight tolerances across diverse materials.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for CNC lathe tool production, engineered to minimize lead times while ensuring precision and manufacturability. This integrated process leverages digital transformation from initial inquiry through final delivery, specifically optimized for lathe-centric components requiring turning, drilling, threading, and milling operations.

Upload CAD

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) via our secure customer portal. Our system performs immediate validation checks for file integrity, unit consistency, and geometric completeness. For CNC lathe-specific features, the platform flags critical parameters such as maximum bar stock diameter, required chucking surfaces, internal/external thread specifications, and parting-off geometries. This step ensures downstream processes operate on technically sound data, eliminating common errors like missing datums or underspecified tolerances.

AI-Powered Quoting Engine

Uploaded CAD geometry is processed by our proprietary AI quoting system, trained on 15+ years of lathe production data. The engine autonomously analyzes feature complexity, material utilization, toolpath density, and machine time requirements. Key lathe-specific factors evaluated include:

Bar stock diameter optimization versus raw material cost

Number of required operations (e.g., sub-spindle transfers, live tooling cycles)

Geometric complexity metrics (e.g., taper angles, eccentric features, micro-threads)

Surface finish requirements relative to achievable Ra values on turning

The system generates a detailed cost breakdown within 2 hours, including material cost, machine hours (separating main/sub-spindle time), and secondary operation estimates. Unlike manual quoting, our AI identifies potential manufacturability conflicts early—such as undercuts preventing part ejection—reducing quote revision cycles by 70%.

DFM Analysis with Lathe-Specific Optimization

All quotes trigger mandatory Design for Manufacturability review by our CNC lathe engineering team. This phase focuses exclusively on turning process enhancements:

Recommending optimal stock sizes to minimize waste while ensuring adequate machining allowance

Proposing feature modifications to eliminate secondary operations (e.g., designing knurls for gripping instead of requiring milling)

Validating thread forms against standard tap/drill sizes to avoid custom tooling costs

Assessing parting-off geometry for vibration control and burr minimization

Suggesting datum shifts to maximize chucking stability during high-RPM operations

Clients receive annotated CAD markups with actionable recommendations, typically resolving 95% of manufacturability issues before work authorization. This step reduces production scrap rates by 40% compared to industry averages.

Precision Lathe Production

Approved designs move to our dedicated lathe production cell featuring:

32+ Swiss-type CNC lathes (Tornos, Star) for complex multi-axis components

42+ horizontal/vertical turning centers (DMG MORI, Okuma) for larger parts

In-process gaging with Renishaw probes for closed-loop tolerance control

Automated bar feeders supporting diameters from 3mm to 76mm

Production follows AS9100-certified procedures with real-time monitoring of spindle load, tool wear, and dimensional drift. Critical features undergo 100% inspection via coordinate measuring machines (CMM), with first-article reports including GD&T verification against ASME Y14.5 standards. Typical lathe tolerances achieved: ±0.005mm for diameters, ±0.02mm for lengths, Ra 0.8μm surface finish.

Delivery and Logistics

Completed components undergo final cleaning, deburring, and passivation (per ASTM A967) before packaging. We provide:

Full traceability via serialized part labels linked to machine logs and inspection data

Digital delivery of CMM reports and material certifications

Real-time shipment tracking through our logistics portal

Standard lead times vary by complexity as shown below:

| Complexity Tier | Description | Typical Lead Time | Max Dimension |

|---|---|---|---|

| Standard | <5 operations, common materials (12L14, 6061) | 5-7 business days | Ø50mm |

| Intermediate | Live tooling, internal features, tight tolerances (±0.01mm) | 8-12 business days | Ø100mm |

| High | Swiss-type machining, exotic alloys, micro-features | 12-18 business days | Ø38mm |

All deliveries include our Zero Defect Guarantee: any non-conforming parts are reworked or replaced at zero cost within 24 hours of notification. This end-to-end process ensures clients receive precision-turned components with documented quality, predictable timelines, and minimized total cost of ownership.

Start Your Project

Looking for high-precision CNC lathe tools for your manufacturing operations? Honyo Prototype offers a comprehensive range of CNC turning tools designed for accuracy, durability, and optimal performance in demanding production environments.

Our tooling solutions are engineered to support a wide array of materials and machining applications, ensuring consistent results and reduced cycle times. Backed by our in-house manufacturing facility in Shenzhen, we maintain strict quality control and fast turnaround for both prototype and production-scale orders.

For technical specifications, pricing, or custom tooling inquiries, contact Susan Leo at [email protected]. Let Honyo Prototype be your trusted partner in precision CNC tooling solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.