Guide Contents

Project Insight: Cnc Lathe Uses

Why Speed and Precision Are Non-Negotiable in Modern Product Development

The Critical Balance: Time-to-Market vs. Performance

Speed is survival: For hardware startups, delays in prototyping can mean missed market windows. Every day counts when iterating on design, testing, and scaling.

Precision = reliability: Even minor deviations in tolerances can cause catastrophic failures in high-stakes applications (e.g., medical implants or aerospace components). Accuracy isn’t optional—it’s the foundation of functional parts.

Precision Engineering: Beyond Tolerances to Product Integrity

±0.01mm tolerances: Our CNC lathes deliver micron-level precision consistently, ensuring parts meet exacting specifications for critical industries like automotive, robotics, and healthcare.

Complex geometries, flawless execution: 3/4/5-axis machining capabilities handle intricate designs—from aerospace fittings to microfluidic devices—without compromising surface finish or dimensional accuracy.

Accelerating Innovation with Digital Manufacturing

✅ Online Instant Quote: Get real-time pricing and lead times in seconds—no manual quotes or waiting. Our platform instantly analyzes your design for manufacturability.

✅ AI-Powered Optimization: Automated DFM checks identify potential issues before production, reducing revisions and cutting lead times by up to 40%.

✅ 3-Day Prototype Turnaround: Leverage our Shenzhen-based automated workflow to receive high-precision parts faster than traditional manufacturers—no trade-offs on quality.

Partner with Honyo Prototype to Bring Your Vision to Life

As a leader in precision digital manufacturing, Honyo Prototype bridges the gap between innovation and production. Founded by Susan Leo, we combine cutting-edge CNC technology with a seamless, AI-driven platform to deliver functional prototypes and end-use parts at unmatched speed and accuracy. Whether you’re iterating on a first prototype or scaling to volume production, we ensure your designs hit the market faster—with precision that works.

“Innovation dies in delays. At Honyo, we turn your CAD files into reality—faster, smarter, and with zero compromise on precision.”

— Susan Leo, Founder of Honyo Prototype

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

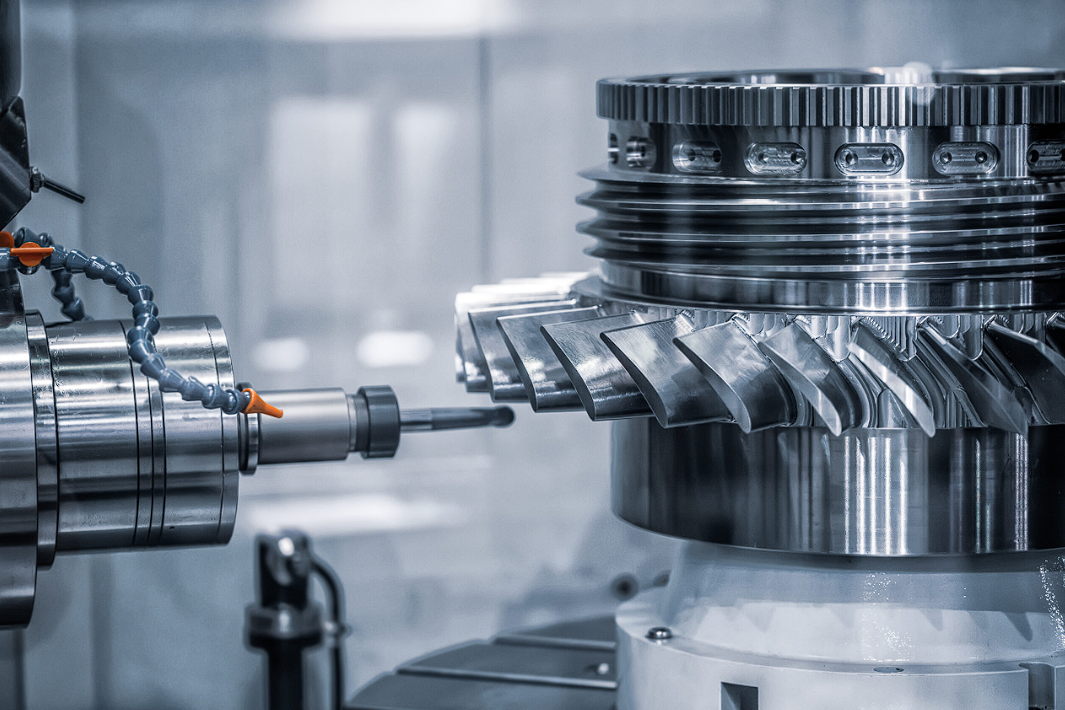

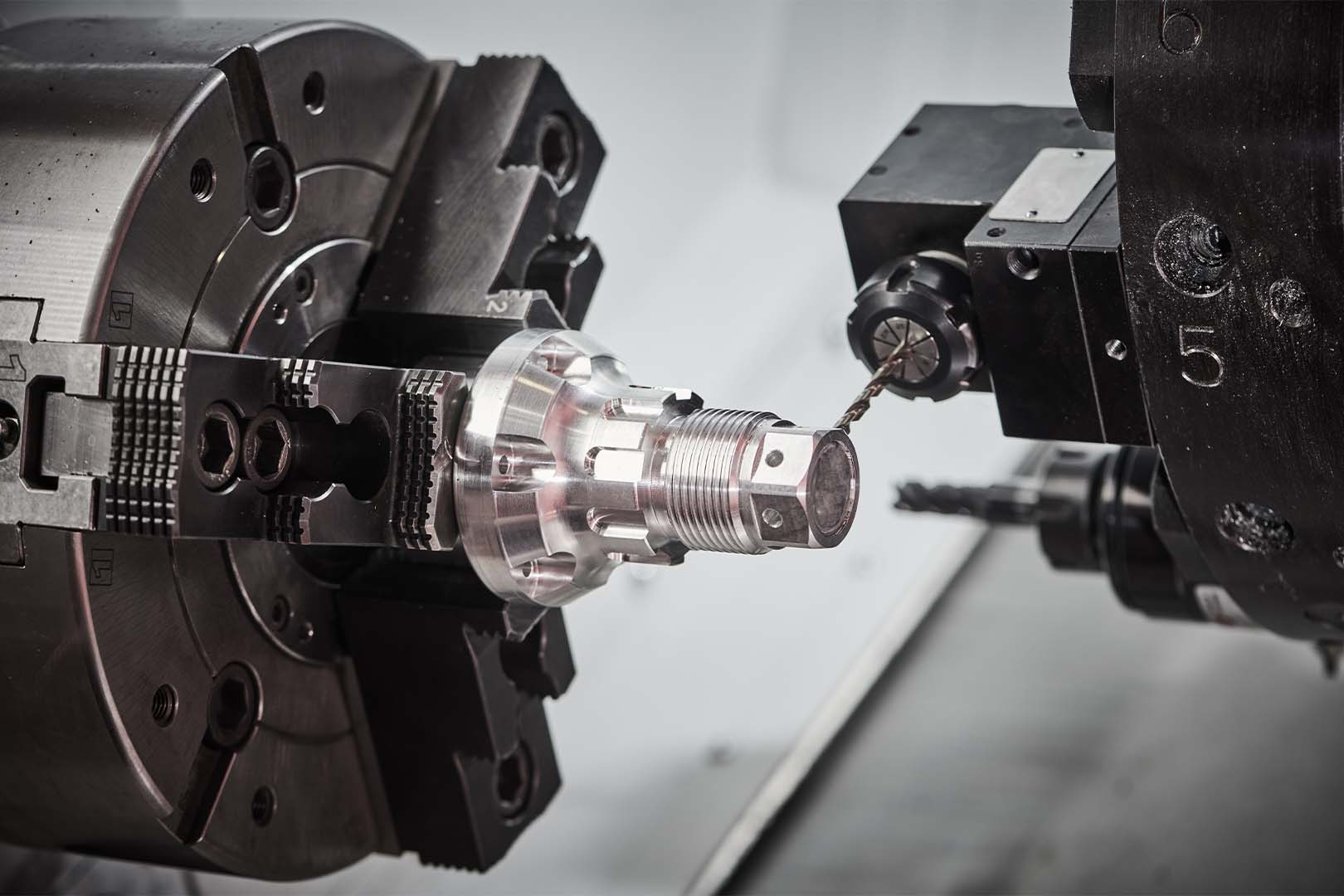

Precision CNC Lathe Technology

Multi-Axis Machining Expertise: 3/4/5-axis capabilities for complex geometries, minimizing setups and maximizing efficiency—ideal for aerospace, medical, and high-performance automotive components.

Micron-Level Precision: Consistently achieve ±0.01mm tolerances for functional prototypes and end-use parts, ensuring compliance with the most stringent industry standards.

Scalable Production Capacity

Seamless Scaling: From 1 prototype to 10,000+ units—no minimum order constraints. Perfect for hardware startups validating designs or scaling to full production without bottlenecks.

Flexible Scheduling: Adapt instantly to your project phase, whether rapid iteration or high-volume runs, with zero compromise on quality or lead times.

Rigorous Quality Assurance

ISO 9001 Certified Processes: End-to-end quality control with in-process inspections and final CMM verification for dimensional accuracy and material integrity.

Zero-Defect Commitment: Strict QC protocols ensure every part meets specifications, reducing rework and accelerating time-to-market.

Digital-First Service Experience

Instant Online Quotes: AI-powered platform delivers accurate pricing in seconds—no manual quotes or delays.

Expedited Lead Times: 3–5 day prototype turnaround with express options for urgent projects, keeping your innovation cycle agile.

Transparent Collaboration: Real-time project tracking via cloud portal, with proactive updates from design validation to final delivery.

Materials & Surface Finishes

Material Options & Finishes for Precision CNC Lathe Parts

Precision Material Selection Guide

Choosing the right material is critical for achieving functional performance, durability, and cost efficiency in CNC lathe operations. Honyo’s precision machining capabilities (±0.01mm tolerances) ensure optimal results across all material types:

Aluminum 6061: Lightweight, corrosion-resistant, and highly machinable. Ideal for aerospace prototypes, automotive components, and electrical housings. Maintains tight tolerances with minimal thermal deformation during high-speed machining.

Aluminum 7075: High-strength alloy for structural applications. Used in drone frames, military hardware, and high-load mechanical parts. Delivers exceptional rigidity while holding precision under stress.

Stainless Steel 304: Food-safe and corrosion-resistant. Perfect for medical devices, food processing equipment, and architectural elements. Consistent performance in CNC lathes for intricate geometries.

Stainless Steel 316: Superior corrosion resistance for marine, chemical, and surgical applications. Maintains dimensional accuracy in harsh environments, ensuring long-term reliability.

Brass: Excellent electrical conductivity and machinability. Best for valves, connectors, and decorative components requiring precise threads and smooth finishes.

PEEK: High-performance thermoplastic for extreme temperatures (-200°C to 260°C) and chemical exposure. Used in medical implants, aerospace seals, and semiconductor equipment. Engineered for dimensional stability during precision machining.

Surface Finishes to Enhance Performance & Aesthetics

Surface treatments optimize part functionality, longevity, and visual appeal while preserving critical tolerances:

Anodizing: Enhances aluminum corrosion resistance and wear properties. Available in clear or vibrant colors for both functional and aesthetic applications.

Painting: Custom color options for visual appeal or protection. Ideal for non-critical surfaces where aesthetics matter but precision isn’t compromised.

Polishing: Achieves mirror-like finishes for optical components, medical devices, and luxury products. Critical for surfaces requiring zero roughness and flawless reflectivity.

Powder Coating: Durable, scratch-resistant finish for structural parts exposed to outdoor elements. Offers broad color customization with UV stability.

Passivation: Removes surface contaminants from stainless steel, boosting corrosion resistance. Essential for medical and food industry components requiring sterile, high-purity surfaces.

Optimize Your Project with Honyo’s Smart Solutions

Online Instant Quote: Get real-time pricing for materials and finishes in seconds—no delays, no guesswork. Our platform calculates exact costs based on your design specs.

AI-Powered Material Selection: Our intelligent system analyzes your part requirements to recommend the optimal material and finish combo, cutting design iteration time by up to 40%.

Fast Turnaround: From prototype to production, we deliver precision parts in as little as 3 days—because innovation can’t wait.

“At Honyo Prototype, we don’t just machine parts—we engineer solutions. Whether you’re prototyping a medical device or scaling production for aerospace components, our precision CNC lathe expertise ensures every detail meets your exact specifications.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

At Honyo Prototype, we’ve redefined precision manufacturing with AI-driven efficiency—turning complex designs into flawless parts in record time. No guesswork, no delays. Just seamless innovation. Here’s how it works:

Step 1: Upload Your CAD File

Drag-and-drop your design files (STEP, STL, IGES, etc.) in seconds—no technical expertise required.

Enterprise-grade cloud security ensures your intellectual property remains protected throughout the process.

Step 2: Instant AI-Powered Quote

Our proprietary AI engine analyzes geometry, tolerances, and material requirements in real-time—delivering an accurate, itemized quote within seconds.

No hidden fees. No waiting days for estimates. Just transparent pricing tailored to your specs.

Optimize cost on the fly: adjust materials, quantities, or tolerances instantly to balance performance and budget.

Step 3: Smart DFM Analysis & Optimization

Automated checks flag potential manufacturing issues (e.g., undercuts, thin walls, or tooling conflicts) before production begins.

Our senior engineers review complex cases to suggest design tweaks that slash costs and accelerate timelines.

Receive actionable feedback—ensuring your part is production-ready from day one, with zero surprises.

Step 4: Precision Production & Real-Time Tracking

Leverage our 3/4/5-axis CNC lathes to achieve ±0.01mm tolerances for functional prototypes and end-use parts.

Track every stage of production via our customer portal: machining → quality control → shipping—updated in real-time.

Guaranteed on-time delivery with expedited options for urgent projects.

From CAD to part in record time—Honyo Prototype redefines precision manufacturing with AI-driven efficiency.

Start Your Project with Honyo

Start Your Project with Honyo: Precision Machining, Simplified

✨ Instant, AI-Powered Quoting

Upload your CAD file and receive a real-time, transparent quote in under 5 minutes

AI-driven DFMA (Design for Manufacturing & Assembly) analysis to eliminate hidden costs and optimize part geometry

Pricing tailored to your complexity, volume, and material—no guesswork, no surprises

⏱️ Unmatched Speed Without Compromise

Prototype to production in 3–5 days with expedited options for urgent needs

Dedicated project managers and agile Shenzhen/Dongguan facilities ensure same-day engineering support

Streamlined workflows reduce lead times while maintaining ±0.01mm tolerances for mission-critical parts

🔧 Precision Engineered for Real-World Applications

3/4/5-axis CNC lathes for complex geometries and high-precision functional prototypes

Tight-tolerance machining for aerospace, medical, IoT, and industrial end-use parts

Cost-effective solutions for small batches to high-volume runs—no minimum order constraints

👨🔬 Expert-Led Innovation from Day One

Founded by Susan Leo, our team combines 10+ years of precision manufacturing expertise with cutting-edge process optimization

Collaborative design reviews to reduce material waste, accelerate time-to-market, and future-proof your product

End-to-end support from initial concept to delivery—your success is our priority

Ready to transform your vision into reality?

📩 [email protected] | 📞 +86 139 2843 8620

📍 Visit our Shenzhen/Dongguan facilities for a hands-on consultation—where innovation meets precision.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.