Contents

Manufacturing Insight: Cnc Lathe Tool Holder Types

Understanding CNC lathe tool holder types is fundamental to achieving precision, efficiency, and reliability in turning operations. Selecting the appropriate holder—whether for standard turning inserts, complex boring bars, live tooling, or specialized grooving applications—directly impacts critical factors like tool rigidity, vibration damping, thermal growth management, and ultimately, part quality and cycle time. At Honyo Prototype, our decades of CNC machining expertise extend deeply into the nuances of tooling systems. We leverage this knowledge alongside state-of-the-art CNC lathes and milling centers to deliver exceptional prototype and low-volume production components across demanding industries like aerospace, medical, and automotive.

Our comprehensive CNC machining services are engineered for precision and speed, utilizing advanced materials and rigorous quality control protocols. We recognize that optimal tool holder selection is not an isolated decision but an integral part of the machining strategy we develop for each unique project. To streamline your path from design to physical part, Honyo Prototype offers an industry-leading Online Instant Quote system. This platform provides transparent, competitive pricing within seconds, allowing you to accurately assess project feasibility and accelerate your timeline without delay.

Accelerate Your Project with Honyo Prototype

Access our Online Instant Quote system today for fast, accurate pricing on your CNC machining requirements, backed by our expertise in precision tooling and manufacturing excellence.

Technical Capabilities

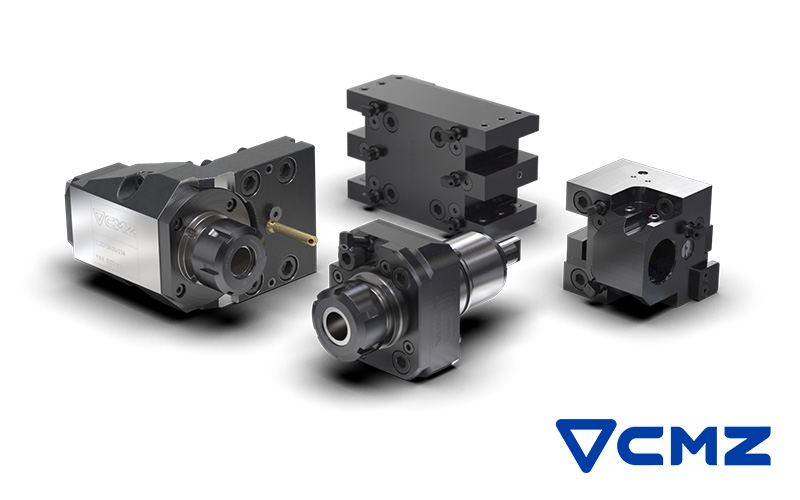

CNC lathe tool holders are critical components in precision machining, especially in applications involving 3/4/5-axis milling, turning operations, and tight-tolerance requirements. These holders secure cutting tools and ensure rigidity, accuracy, and repeatability during high-speed and high-load machining. While the holder itself is typically made from high-strength steel or alloy steel for durability and vibration damping, the discussion of materials such as aluminum, ABS, and nylon usually pertains to tooling accessories, enclosures, or non-structural components rather than the tool holder body.

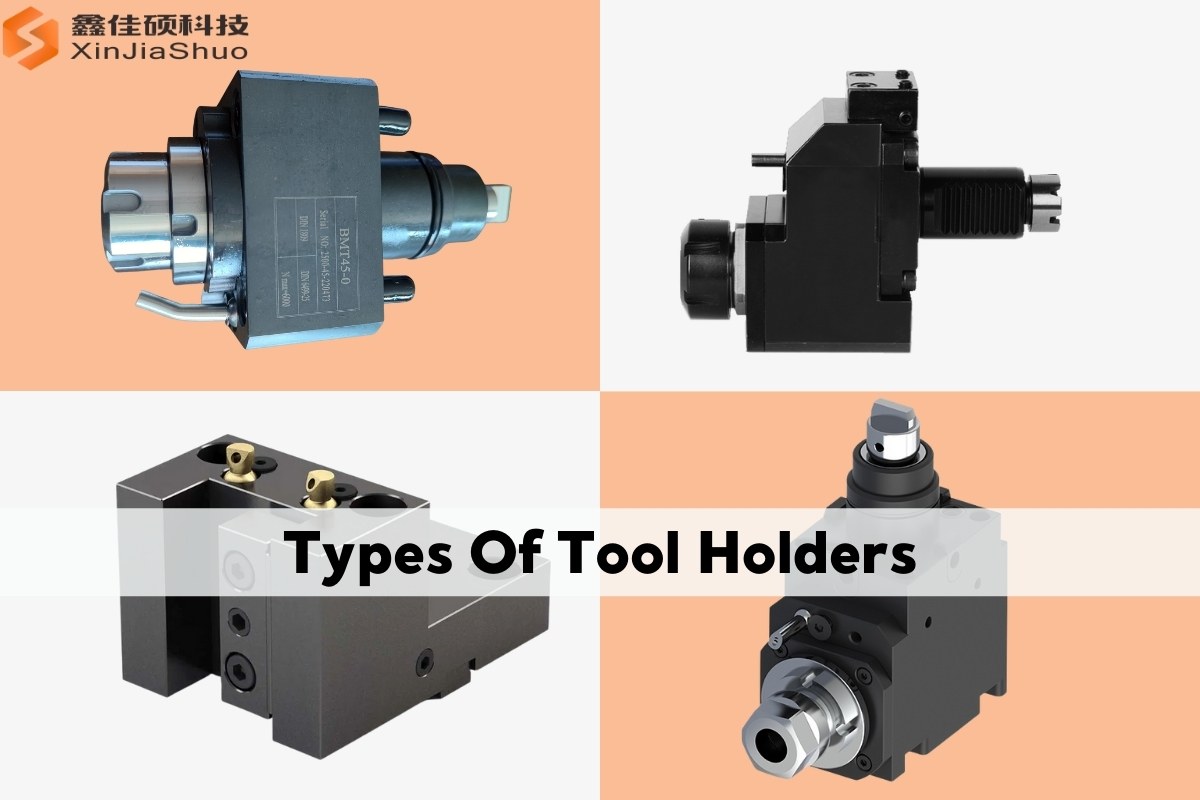

Below is a technical overview of common CNC lathe tool holder types used in precision turning and multi-axis environments, including compatibility, performance characteristics, and material considerations.

| Tool Holder Type | Axis Compatibility | Max Runout (μm) | Taper/Interface Standard | Clamping Mechanism | Typical Use Case | Body Material | Notes on Other Materials (Aluminum, Steel, ABS, Nylon) |

|---|---|---|---|---|---|---|---|

| VDI (Vertical Diamond Interface) | 2/3/4-axis Turning | ≤5 | VDI 30, VDI 40, VDI 50 | Rigid screw clamp | Turning centers, live tooling | Alloy Steel (e.g., 20MnCr5) | Aluminum used in lightweight tool blocks; ABS/Nylon not used in load-bearing parts |

| BMT (Bolt-Mounted Tool) | 3/4/5-axis Turning | ≤3 | BMT 45, BMT 55, BMT 65 | Bolt-down rigid mount | High-speed turning, Y-axis milling | Hardened Steel (e.g., 42CrMo4) | Steel dominates; aluminum adapters may reduce weight in non-critical areas |

| Capto (Cone and Face Drive) | 3/4/5-axis Mill-Turn | ≤2 | C3, C4, C5, C6 | Polygon taper + face contact | Multi-tasking machines | High-strength Alloy Steel | Fully metallic interface; no plastic use in interface zones |

| ER Collet Chuck Holder | 3/4/5-axis Milling & Turning | ≤5 | ISO 30, ISO 40, HSK 63A | ER collet (spring sleeve) | Small toolholding, threading, drilling | Alloy Steel with heat treatment | ABS/Nylon not used; aluminum housings rare due to rigidity needs |

| Hydraulic Expansion Holder | 3/4/5-axis Milling | ≤3 | CAT 40, HSK 63A, SK 40 | Hydraulic pressure expansion | High-precision milling, tight tolerance | Steel with internal hydraulic chamber | Internal seals may use elastomers; no structural use of ABS/Nylon |

| Shrink Fit Holder | 3/4/5-axis Milling | ≤2 | HSK 63A, SK 40, CAT 40 | Thermal interference fit | Ultra-precision milling, aerospace | Tool steel with high thermal stability | All-metal construction; incompatible with polymers in core structure |

| Live Tool Holder (for Turning Centers) | 3/4/5-axis Mill-Turn | ≤5 | VDI/BMT with internal gearing | Motor-driven internal spindle | Milling on turning centers | Alloy Steel, case-hardened | Bearings/seals may use PTFE; ABS/Nylon not in torque path |

Technical Notes:

Runout: Critical for tight-tolerance work; values below 5 μm are required for precision finishing. Shrink fit and Capto systems offer the best concentricity.

Material Use: The primary material for all high-precision tool holders is hardened or alloy steel to withstand high torque, thermal loads, and maintain rigidity. Aluminum may be used in non-cutting structural adapters or mounting blocks to reduce weight but is avoided in high-torque zones.

Polymers (ABS, Nylon): These materials are not used in the structural or interface components of CNC lathe tool holders. They may appear in protective caps, storage fixtures, or non-load-bearing housings for electronics in live tooling, but never in the clamping or transmission path.

Multi-axis Compatibility: BMT and Capto systems are preferred in 5-axis mill-turn environments due to their high rigidity, compact design, and accurate repeatability.

For applications requiring tight tolerances (±0.001 mm or better), shrink fit, hydraulic, or Capto holders are recommended due to minimal runout and high damping characteristics.

From CAD to Part: The Process

Honyo Prototype applies specialized engineering rigor to CNC lathe tool holder production, recognizing their critical role in machining precision, tool life, and process stability. Our integrated workflow ensures dimensional accuracy, material integrity, and interface compatibility specific to lathe tooling systems. Below is the detailed process flow for CNC lathe tool holder types:

Upload CAD

Clients submit detailed 3D models of lathe tool holders (e.g., VDI, Capto, BMT, or custom interfaces) via our secure portal. We require explicit specifications including interface standard (e.g., VDI 30/40/50, Capto C3-C8), shank geometry, coolant channel routing, clamping mechanism details, and critical tolerances per ISO 10889 or DIN 69880. Incomplete submissions trigger immediate automated validation checks requesting missing parameters essential for lathe-specific functionality.

AI Quote

Our AI engine analyzes the CAD geometry against a database of 12,000+ lathe tool holder variants to identify potential manufacturability conflicts. It cross-references material requirements (e.g., 42CrMo4 for steel holders, solid carbide for micro-tooling), interface standards, and thermal stability needs. The system generates a preliminary quote within 2 hours, highlighting cost drivers specific to tool holders such as:

Precision grinding of taper interfaces (±0.002mm tolerance)

Hardened surface treatments (e.g., 58-62 HRC for wear resistance)

Dynamic balancing requirements for high-RPM applications

DFM (Design for Manufacturability)

Honyo’s senior manufacturing engineers conduct a dedicated DFM review focused on lathe tool holder failure modes. Key assessments include:

Verification of clamping force distribution to prevent tool pull-out during interrupted cuts

Analysis of coolant channel integrity under 70+ bar pressure

Evaluation of stress concentrations at transition radii using FEA simulation

Confirmation of runout compliance (<0.003mm TIR at tool interface)

We provide actionable feedback within 24 hours, such as recommending modified relief angles for chip evacuation or suggesting alternative materials for thermal expansion management in heavy-duty turning.

Production

Manufacturing occurs in climate-controlled cells with dedicated lathe tool holder protocols:

Material Preparation: Bar stock undergoes ultrasonic testing for internal defects; 42CrMo4 is stress-relieved at 600°C prior to machining

Machining Sequence:

Primary operations use Makino T2 + T4 lathes with Renishaw tool setters for in-process verification. Critical stages include:

Rough turning of shank geometry with ±0.02mm tolerance

Precision grinding of taper interfaces using CNC jig grinders (±0.0015mm)

Hard turning of clamping surfaces post-heat treatment

Quality Validation:

Each holder undergoes 3-stage inspection:

1. CMM verification of interface geometry against master gauges

2. Functional testing in actual lathe spindles with dial indicators measuring TIR

3. Dye penetrant testing for surface cracks on hardened components

Delivery

All lathe tool holders ship with comprehensive documentation including:

Certificate of Conformance to ISO 2768-mK and interface-specific standards

Individual runout test reports showing measurement points

Material test reports with traceable heat numbers

Recommended torque specifications for clamping mechanisms

Standard lead time is 8-12 business days from DFM approval, with expedited options for critical production tooling. Each holder is vacuum-sealed with corrosion inhibitors and shipped in custom foam fixtures to prevent shipping-induced deformation.

This end-to-end process ensures Honyo’s lathe tool holders achieve sub-micron repeatability in production environments, directly contributing to our clients’ reduced tool changeovers and extended cutting tool life. We maintain ISO 9001:2015 certification with additional controls specific to precision tooling components.

Start Your Project

Explore our comprehensive range of CNC lathe tool holder types designed for precision, durability, and optimal machining performance. Engineered to meet strict industry standards, our tool holders support a variety of turning applications and are compatible with major CNC lathe systems.

Manufactured in-house at our Shenzhen facility, we maintain full control over quality and delivery timelines, ensuring you receive reliable, high-performance components on schedule.

For technical specifications or custom solutions, contact Susan Leo at [email protected]. Let us support your production needs with expert guidance and factory-direct pricing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.