Contents

Manufacturing Insight: Cnc Lathe Drill Holder

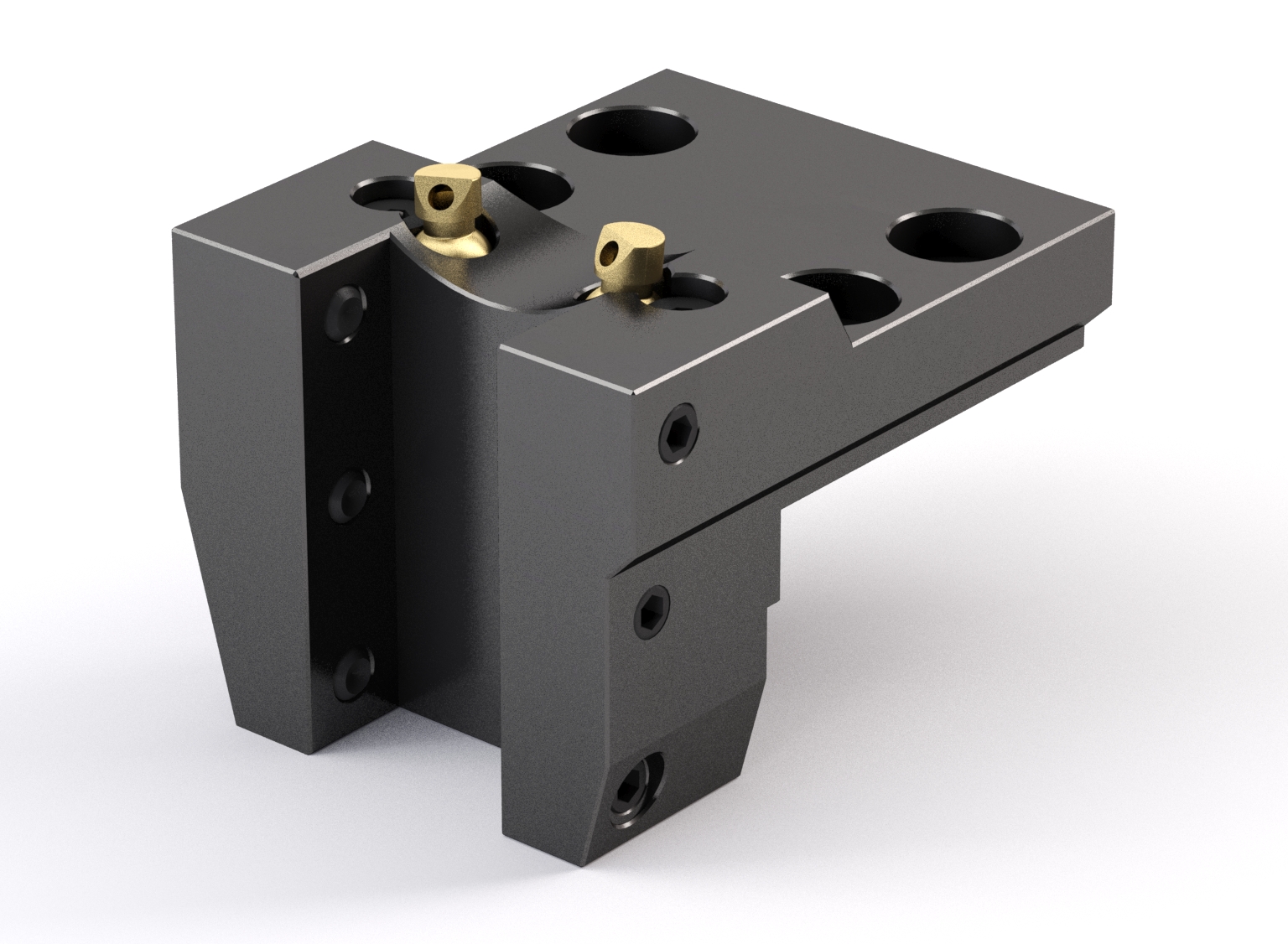

Precision CNC Lathe Drill Holders Engineered for Uncompromising Performance

At Honyo Prototype, we understand that the reliability of your CNC lathe operations hinges on the precision of every component, especially critical tooling interfaces like drill holders. Our specialized CNC machining services deliver drill holders engineered to exacting tolerances, ensuring minimal runout, superior concentricity, and extended tool life under demanding production conditions. Leveraging multi-axis milling and turning centers with sub-micron repeatability, we master materials ranging from hardened tool steels to exotic alloys, guaranteeing geometric accuracy and thermal stability that prevent chatter, deflection, and premature tool failure.

Each drill holder undergoes rigorous in-process metrology and final inspection using calibrated CMMs and optical comparators, validating compliance to ISO 2768-mK or customer-specific GD&T requirements. Our engineering team collaborates closely with clients to optimize holder geometry for specific applications—whether deep-hole drilling, high-speed machining, or micro-boring—translating design intent into robust, production-ready components that maximize your machine uptime and part quality.

Accelerate your prototyping or low-volume production timeline with Honyo’s Online Instant Quote system. Upload your STEP or IGES files to receive a detailed manufacturability assessment and competitive pricing within hours, not days. Experience how our technical expertise and streamlined digital workflow eliminate quoting bottlenecks while delivering the precision your CNC lathe operations demand.

Material & Tolerance Capabilities

| Parameter | Standard Capability | Extended Capability |

|——————–|—————————|—————————|

| Tolerance | ±0.005 mm | ±0.001 mm (sub-micron) |

| Surface Finish | Ra 0.8 µm | Ra 0.2 µm (mirror-grade) |

| Materials | 4140, 17-4PH, A2, D2 | Inconel 718, Titanium Ti-6Al-4V |

| Max Work Envelope | Ø 300 mm x 500 mm length | Ø 600 mm (5-axis) |

Technical Capabilities

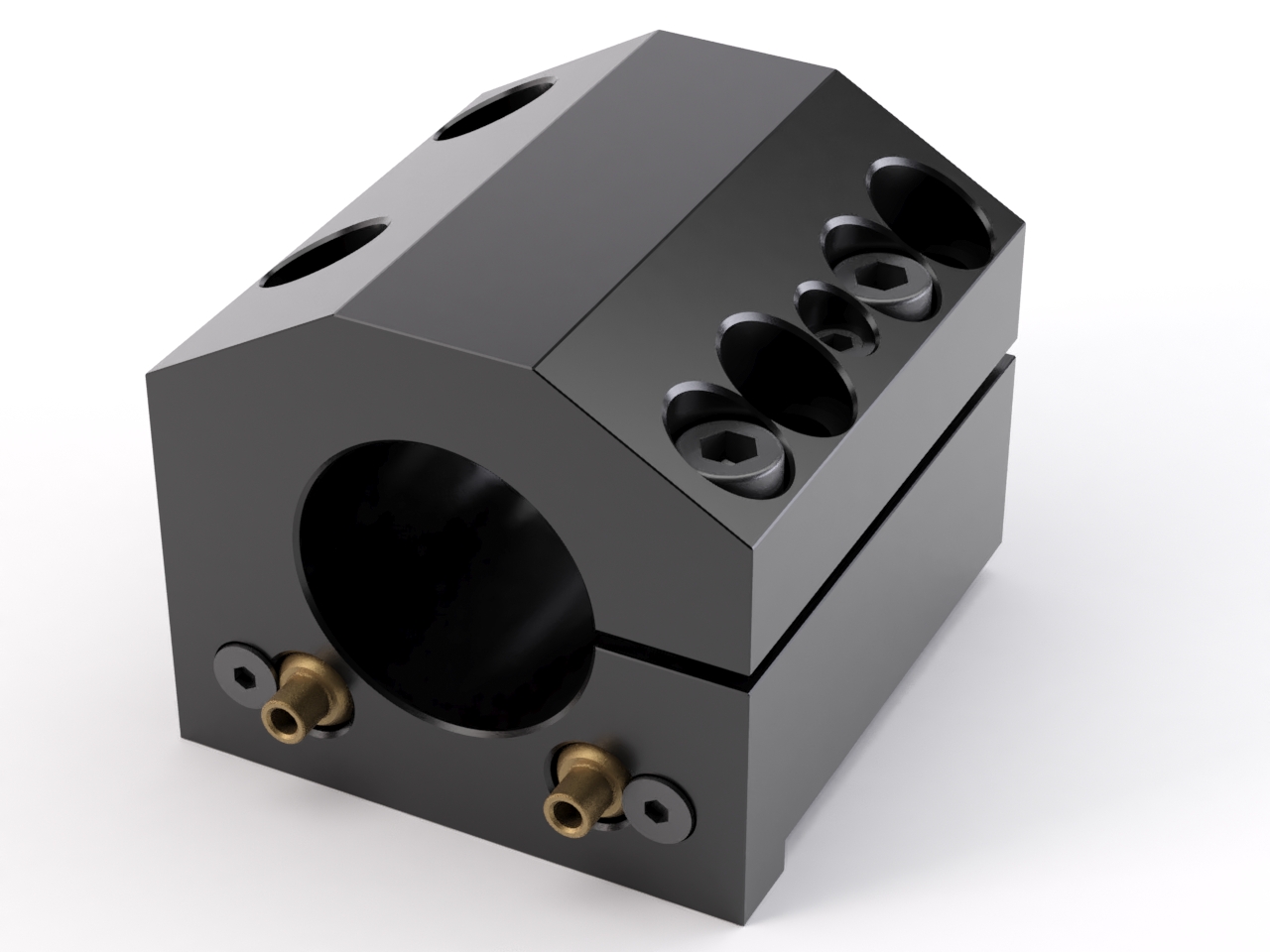

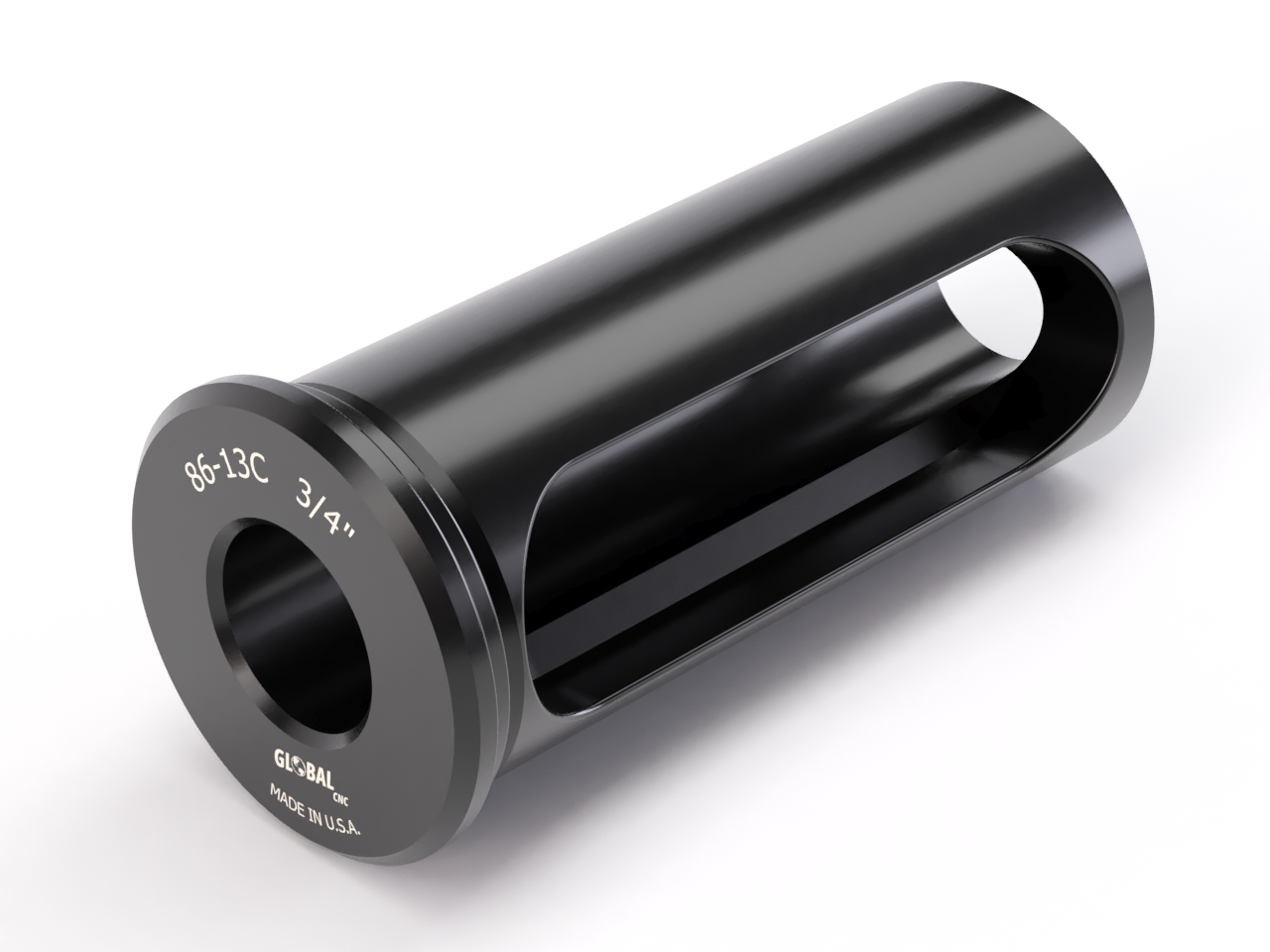

The CNC lathe drill holder is a critical tooling component designed to securely hold and precisely position drill bits during turning and milling operations on CNC lathes and multi-axis machines. Optimized for high rigidity, accuracy, and repeatability, it supports tight tolerance machining (±0.0005″ or better) across a range of materials including aluminum, steel, ABS, and nylon. These holders are commonly integrated into 3, 4, or 5-axis CNC systems where complex geometries and high precision are required.

| Parameter | Specification |

|---|---|

| Compatible Machines | 3-Axis, 4-Axis, and 5-Axis CNC Lathes with Milling Capability |

| Tool Interface | Standard: CAT40, BT40, HSK-A63; Custom options available |

| Holder Diameter | 0.75″ (19.05 mm) to 1.5″ (38.1 mm), depending on application and machine spindle capacity |

| Maximum RPM | Up to 12,000 RPM (dependent on balance grade and setup) |

| Tolerance Capability | ±0.0002″ (5 µm) typical; achievable with proper setup and high-precision collet systems |

| Collet Types Supported | ER20, ER25, TG-LOK, hydraulic, and shrink-fit options for enhanced runout accuracy |

| Runout Accuracy | < 0.0001″ (2.5 µm) at tool tip when properly maintained and balanced |

| Materials Compatibility | Aluminum (6061, 7075), Steel (1018, 4140, Stainless), ABS, Nylon (6/66), and other engineering plastics |

| Clamping Force | High-torque retention via precision-ground taper and drawbar mechanism |

| Surface Treatment | Hardened and ground steel bodies; some models with anti-vibration damping coatings |

| Tool Change Support | Automatic Tool Changer (ATC) compatible in 4/5-axis configurations |

| Vibration Damping | Integrated damping features in premium models for improved surface finish and tool life |

| Cooling Compatibility | Internal through-coolant passages available (optional) |

| Typical Applications | Drilling, tapping, reaming, and light milling during live tooling operations in turning centers |

This drill holder ensures stable tool engagement during simultaneous turning and milling operations, especially in high-mix, low-volume prototype and production environments. Its design supports rapid tool changes, minimal runout, and excellent concentricity—critical for maintaining tight tolerances across diverse material types. For non-metallic materials like ABS and nylon, reduced cutting forces and optimized feed rates are applied, while the holder’s rigidity prevents deflection and ensures dimensional accuracy.

From CAD to Part: The Process

Honyo Prototype executes a streamlined yet rigorous process for CNC lathe drill holder production, ensuring precision and efficiency from initial upload to final delivery. This structured workflow minimizes errors and maximizes manufacturability for critical tooling components.

Upload CAD

Customers initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via Honyo’s secure client portal. For drill holders, we specifically require geometric data of the shank interface (e.g., CAT, BT, HSK), taper specifications (e.g., 7:24), coolant passages, and critical tolerance callouts. Incomplete submissions trigger an automated notification requesting supplemental documentation to avoid downstream delays.

AI Quote Generation

Our proprietary AI engine analyzes the CAD geometry, material selection (typically 4140 alloy steel or equivalent for drill holders), and surface finish requirements to generate an instant preliminary quote. The system cross-references real-time machine availability, raw material costs, and historical cycle times for similar precision components. Crucially, the AI flags potential manufacturability risks such as excessive aspect ratios in coolant channels or non-standard taper angles before human review.

Engineer-Validated DFM

All quotes undergo mandatory DFM review by our CNC applications engineering team specializing in rotary tooling. For drill holders, this phase focuses on: verifying collet compatibility with specified shank tolerances (typically H6 for shanks), confirming runout-critical features meet ISO 2768-mK standards, and optimizing coolant hole drilling sequences to prevent deflection. Engineers provide actionable feedback within 4 business hours—common revisions include adjusting chamfer dimensions for collet retention or modifying internal radii to accommodate deep-hole drilling toolpaths. Customer approval of DFM recommendations is required before proceeding.

Precision Production

Approved orders move to dedicated CNC lathe cells equipped with live tooling and high-pressure coolant systems essential for drill holder fabrication. Key production steps include: pre-heat treated stock verification per AMS 6350, simultaneous turning of precision tapers and shank features on dual-spindle lathes, deep-hole drilling of coolant passages with gun drills, and final grinding of critical surfaces to achieve ≤0.005mm runout. Each operation undergoes in-process CMM validation against the approved DFM, with material certificates and first-article inspection reports documented in real time.

Quality-Controlled Delivery

After final passivation and laser marking of part numbers, drill holders undergo 100% functional testing using master gages to verify taper engagement and collet seating. Dimensional reports including taper gauge readings and runout measurements are compiled into the shipment documentation. Parts ship via tracked freight with serialized packaging; standard lead time is 3-5 business days from DFM approval. Customers receive automated shipping notifications with real-time logistics tracking and permanent access to quality records through our client portal.

Start Your Project

For inquiries about our CNC lathe drill holder, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring precision engineering and efficient production for your prototyping and machining needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.