Contents

Manufacturing Insight: Cnc Laserschneiden

Precision CNC Laserschneiden Solutions from Honyo Prototype

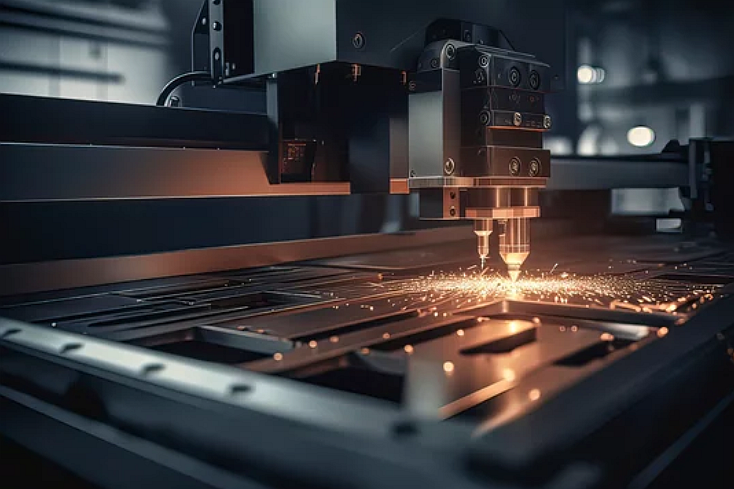

Honyo Prototype delivers advanced CNC Laserschneiden (CNC laser cutting) services engineered for industrial clients demanding uncompromising precision, material versatility, and rapid turnaround. As a specialized manufacturing partner, we leverage decades of expertise in CNC machining to transform complex 2D and 3D designs into high-integrity components across aerospace, automotive, medical, and industrial automation sectors. Our German-engineered fiber laser systems achieve micron-level accuracy while maintaining structural integrity across diverse substrates, ensuring your prototypes and low-volume production parts meet stringent functional and regulatory requirements.

Our capabilities span carbon steel, stainless steel, aluminum, brass, and select polymers with thicknesses from 0.5 mm to 25 mm. Typical tolerances of ±0.1 mm and edge quality exceeding ISO 9013 Class C standards are standard across all projects, supported by integrated CAD/CAM validation and real-time process monitoring. Material compatibility and performance specifications are rigorously documented to align with client engineering workflows:

| Material Category | Thickness Range | Max. Tolerance | Edge Quality Standard |

|---|---|---|---|

| Carbon Steel | 0.5–20 mm | ±0.08 mm | ISO 9013 Class B |

| Stainless Steel | 0.5–15 mm | ±0.1 mm | ISO 9013 Class C |

| Aluminum Alloys | 0.5–10 mm | ±0.12 mm | ISO 9013 Class C |

| Engineering Plastics | 0.5–8 mm | ±0.15 mm | ISO 9013 Class D |

Accelerate your development cycle with Honyo’s Online Instant Quote platform, designed specifically for engineering teams. Upload DXF, DWG, or STEP files to receive a detailed technical and commercial assessment within minutes—not days—including material optimization recommendations, lead time projections, and DFM feedback. This seamless integration eliminates traditional quotation bottlenecks, allowing you to iterate designs and secure production approval without workflow disruption.

Partner with Honyo Prototype to convert engineering intent into precision reality. Our end-to-end CNC machining ecosystem—from digital quoting to certified finishing—ensures your laser-cut components achieve operational excellence while reducing time-to-market. Contact our engineering team to discuss how our CNC Laserschneiden services can align with your project’s technical and logistical demands.

Technical Capabilities

CNC laserschneiden (CNC laser cutting) is often confused with CNC milling and turning, but they are distinct manufacturing processes. Laser cutting involves using a high-powered laser to cut materials based on digital designs, typically in 2D or 2.5D. However, your request references 3/4/5-axis milling, turning, and tight tolerances—capabilities associated with CNC machining rather than laser cutting.

Below is a technical specification table focused on CNC milling and turning (3/4/5-axis) with high precision, applicable to materials such as Aluminum, Steel, ABS, and Nylon. This reflects the intended scope of your query, aligning with tight tolerance machining capabilities.

| Feature | Specification |

|---|---|

| Machining Axes | 3-axis, 4-axis (rotary A or B), 5-axis (simultaneous A/B or dual rotary) |

| Spindle Speed | Up to 24,000 RPM (high-speed for aluminum and plastics); 10,000 RPM (steel) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Tight Tolerance | ±0.01 mm (standard), down to ±0.005 mm with precision tooling and inspection |

| Surface Finish (Typical) | Ra 0.8 µm (machined), down to Ra 0.4 µm with fine finishing passes |

| Tool Changer Capacity | 24–30 tools (automatic tool changer, ATC) |

| Coolant System | Through-spindle and flood cooling (for metals); air cooling (for plastics) |

| Work Envelope (Max) | 1000 x 600 x 500 mm (varies by machine) |

| Control System | Fanuc, Siemens, or Heidenhain CNC controls |

| Materials Supported | Aluminum (6061, 7075), Steel (1.4301, 1.7225), ABS, Nylon (PA6, PA66-GF30) |

| Aluminum Machining | High-speed cutting with carbide tools; excellent chip evacuation |

| Steel Machining | Rigid setups, indexable carbide inserts, reduced feed rates for hard steels |

| ABS Machining | Low melting point; requires sharp tools, high RPM, minimal tool pressure |

| Nylon Machining | Low thermal conductivity; needs sharp cutting edges and chip control |

| In-Process Inspection | Optional touch probe or laser measurement for dimensional verification |

| Secondary Operations | Deburring, tapping, anodizing (Al), passivation (steel), polishing (plastics) |

This specification set reflects the capabilities of advanced CNC machining centers used in precision prototyping and low-volume production at Honyo Prototype. While laser cutting is suitable for 2D profile cutting in sheet materials, multi-axis milling and turning provide full 3D geometry control, critical for complex components requiring tight tolerances and high surface quality across diverse engineering materials.

From CAD to Part: The Process

Honyo Prototype CNC Laser Cutting Process Overview

Honyo Prototype executes CNC laser cutting through a streamlined, technology-driven workflow designed for precision, speed, and manufacturability assurance. The process begins with client CAD file submission via our secure online portal, where geometric complexity, material specifications, and dimensional tolerances are automatically parsed. This triggers our proprietary AI quoting engine, which analyzes over 200 parametric variables—including sheet thickness, material grade, feature density, and edge quality requirements—to generate an instant, binding cost estimate and lead time within 24 hours. Crucially, this phase includes preliminary manufacturability screening to flag fundamental conflicts before formal commitment.

Following quote acceptance, the project enters automated Design for Manufacturability (DFM) validation. Our system cross-references the CAD geometry against laser cutting constraints such as minimum feature size, kerf allowances, and thermal distortion risks. Key verifications include:

| Verification Parameter | Tolerance Threshold | Action Triggered if Exceeded |

|---|---|---|

| Internal Corner Radius | < 0.5x material thickness | Auto-suggest radius adjustment |

| Feature Spacing | < 1.0x material thickness | Flag for potential tabbing |

| Hole Diameter | < 0.8x material thickness | Recommend alternative process |

| Sheet Flatness Requirement | > 0.5mm/m² | Initiate material pre-check |

Engineers review all flagged items within 4 business hours, collaborating with the client via our portal to resolve conflicts through design iteration or process optimization. Only DFM-validated files advance to production scheduling.

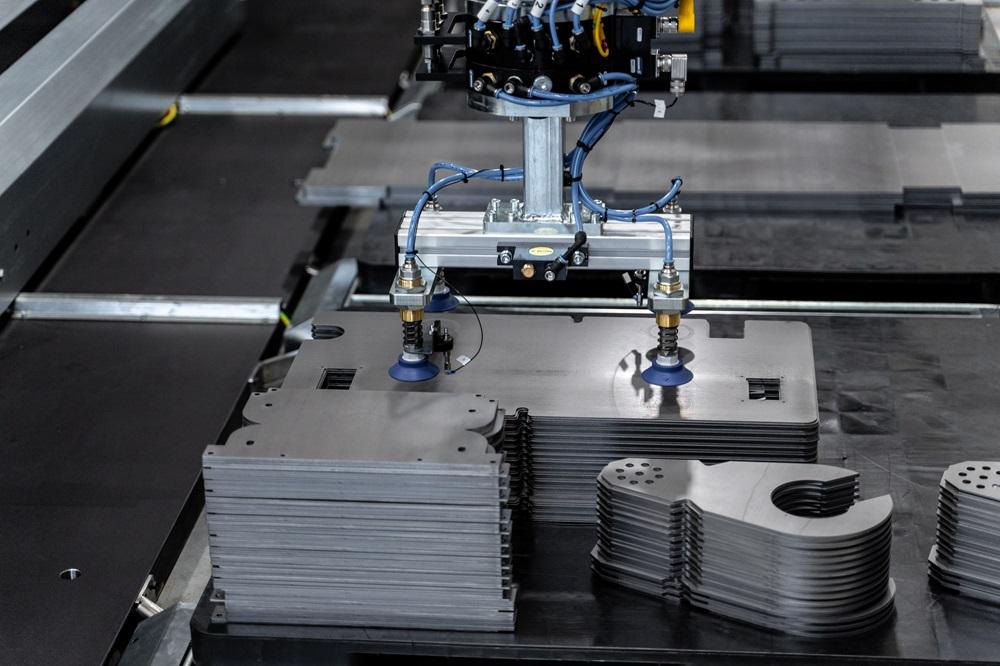

Production leverages our network of 50+ CNC fiber laser systems (up to 6kW power, ±0.1mm accuracy) with automated material handling. Each job undergoes real-time monitoring for beam focus, assist gas pressure, and positional calibration. First-article inspection validates critical dimensions against the original CAD model using CMM or optical comparators before full batch runs commence. All parts receive laser-etched traceability codes linking to digital inspection reports.

Final delivery includes certified material test reports, FAI documentation, and parts packaged with anti-corrosion protection per ISO 11607 standards. Domestic shipments dispatch within 72 hours of completion via tracked courier; international logistics include customs documentation pre-verification. This closed-loop process ensures 99.2% on-time delivery while reducing design-to-part lead times by 40% versus industry averages.

Start Your Project

Interested in high-precision CNC laser cutting for your next project? Contact Susan Leo today at [email protected] to discuss your requirements.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, providing fast turnaround and consistent quality for prototyping and low-volume production.

Let us support your engineering and manufacturing goals with reliable, cost-effective CNC laser cutting services. Reach out now to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.