Introduction: Navigating the Global Market for cnc laser pipe cutting machine

In the competitive landscape of global manufacturing, sourcing a CNC laser pipe cutting machine that meets specific operational needs can be a daunting challenge. With an increasing demand for precision and efficiency, international B2B buyers are tasked with evaluating various models, capabilities, and supplier reliability to ensure they invest wisely. This guide serves as an essential resource for navigating the complexities of the CNC laser pipe cutting machine market, providing insights into different types, applications across various industries, and critical supplier vetting processes.

From understanding the latest technological advancements in fiber laser systems to evaluating cost considerations, this guide is designed to empower B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, including regions like Germany and Nigeria. By delving into practical applications and showcasing the benefits of automated systems, we aim to equip decision-makers with the knowledge needed to make informed purchasing decisions.

Whether you’re looking to enhance production capabilities, improve cutting precision, or streamline operations, this comprehensive guide will help you navigate the global market effectively. Prepare to explore the vital factors that can influence your investment, ensuring that you select a CNC laser pipe cutting machine that aligns with your business goals and operational requirements.

Understanding cnc laser pipe cutting machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Tube Laser Cutters | Basic functionality for cutting round and square tubes. | General manufacturing, furniture, automotive | Pros: Cost-effective; Cons: Limited customization options. |

| High-Power Fiber Laser Cutters | Increased wattage for faster cutting and thicker materials. | Aerospace, heavy machinery, structural steel | Pros: High efficiency; Cons: Higher initial investment. |

| Automated Tube Cutting Systems | Integrated feeding systems for continuous production. | Mass production, automotive, construction | Pros: Labor-saving; Cons: Complexity in setup and maintenance. |

| Hybrid Tube and Sheet Cutters | Combines tube and sheet cutting capabilities in one machine. | Metal fabrication, HVAC, furniture | Pros: Versatile; Cons: May require more space and investment. |

| Specialty Profile Cutters | Designed for cutting unique shapes and profiles. | Custom fabrication, artistic applications | Pros: Customizable; Cons: Slower processing for complex shapes. |

What Are Standard Tube Laser Cutters and Their Applications?

Standard tube laser cutters are designed for basic cutting tasks, handling round and square tubes with ease. They are ideal for general manufacturing applications, including furniture production and automotive parts. Buyers should consider their budget and the volume of work, as these machines are cost-effective but may lack advanced features for customization.

How Do High-Power Fiber Laser Cutters Enhance Efficiency?

High-power fiber laser cutters are equipped with higher wattage, allowing them to cut through thicker materials at faster speeds. This makes them suitable for industries like aerospace and heavy machinery where precision and speed are crucial. While they offer significant efficiency gains, the initial investment can be considerable, so businesses should assess their production needs carefully.

What Advantages Do Automated Tube Cutting Systems Offer?

Automated tube cutting systems feature integrated feeding mechanisms that streamline the cutting process, making them ideal for mass production environments such as automotive manufacturing and construction. These systems save labor costs and increase production efficiency; however, they can be complex to set up and maintain, requiring skilled operators.

Why Choose Hybrid Tube and Sheet Cutters?

Hybrid tube and sheet cutters offer the versatility of cutting both tube and sheet materials, making them valuable in metal fabrication, HVAC, and furniture industries. Their multi-functionality can optimize production workflows, but buyers must consider the potential for increased space requirements and investment costs.

What Are the Benefits of Specialty Profile Cutters?

Specialty profile cutters are tailored for producing unique shapes and profiles, making them suitable for custom fabrication and artistic applications. While they provide high levels of customization, they may have slower processing speeds compared to standard machines, necessitating careful planning for production schedules.

Key Industrial Applications of cnc laser pipe cutting machine

| Industry/Sector | Specific Application of CNC Laser Pipe Cutting Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision cutting of structural components for machinery | Enhanced accuracy and reduced material waste | Machine versatility, power options, and automation features |

| Furniture Production | Custom tube designs for furniture frames and supports | Increased design flexibility and faster production times | Material compatibility and software for complex cuts |

| Construction | Fabrication of piping systems for HVAC and plumbing | Improved installation speed and reduced labor costs | Length and diameter capabilities, and ease of integration |

| Automotive | Cutting exhaust and chassis components | Lightweight design and improved fuel efficiency | Tolerance levels and ability to handle diverse materials |

| Energy Sector | Cutting pipes for renewable energy installations | Enhanced efficiency in energy production processes | Compliance with industry standards and material specifications |

How is CNC Laser Pipe Cutting Machine Used in Manufacturing?

In the manufacturing sector, CNC laser pipe cutting machines are utilized for precision cutting of structural components that form the backbone of various machinery. By providing high accuracy and reducing material waste, these machines enable manufacturers to optimize production processes. International buyers should consider the machine’s versatility, power options, and automation features to meet specific production needs, especially in regions like Africa and South America where manufacturing is growing rapidly.

What Role Does CNC Laser Cutting Play in Furniture Production?

For the furniture industry, CNC laser pipe cutting machines are essential for creating custom tube designs that serve as frames and supports. This technology allows for increased design flexibility and the ability to quickly produce complex shapes, which is crucial in a competitive market. Buyers from Europe, particularly Germany, should focus on material compatibility and software capabilities that facilitate intricate cuts to meet evolving consumer preferences.

How is CNC Laser Cutting Beneficial in Construction?

In construction, these machines are used to fabricate piping systems for HVAC and plumbing applications, significantly enhancing installation speed and reducing labor costs. The precision cuts provided by CNC laser technology ensure that components fit together seamlessly, which is vital for system efficiency. Buyers in the Middle East should prioritize machines with adequate length and diameter capabilities, as well as ease of integration into existing workflows.

What Advantages Does CNC Laser Cutting Offer to the Automotive Industry?

CNC laser pipe cutting machines are employed in the automotive sector to cut exhaust systems and chassis components, contributing to lightweight designs that improve fuel efficiency. The precision of laser cutting allows for tighter tolerances, which are essential in automotive manufacturing. International buyers should assess tolerance levels and the machine’s ability to handle diverse materials, as automotive standards can vary significantly across regions.

How is CNC Laser Cutting Transforming the Energy Sector?

In the energy sector, CNC laser pipe cutting machines facilitate the fabrication of pipes for renewable energy installations, enhancing efficiency in energy production processes. This technology allows for quick adaptations to changing designs and specifications, which is critical in a rapidly evolving industry. Buyers should ensure that their equipment complies with industry standards and meets specific material specifications to maintain operational integrity in energy projects.

3 Common User Pain Points for ‘cnc laser pipe cutting machine’ & Their Solutions

Scenario 1: High Operational Costs Due to Inefficient Cutting Processes

The Problem: Many B2B buyers face the challenge of high operational costs linked to outdated or inefficient cutting processes. Traditional methods, such as flame or plasma cutting, can lead to excessive material waste, longer production times, and increased labor costs. This inefficiency can significantly affect profit margins, especially for companies in competitive markets like automotive parts or construction where precision and cost-effectiveness are paramount. Buyers may feel overwhelmed when trying to justify the capital investment in a CNC laser pipe cutting machine, fearing it won’t deliver sufficient ROI.

The Solution: To overcome this challenge, buyers should conduct a thorough cost-benefit analysis of transitioning to CNC laser pipe cutting technology. They should consider machines that offer features such as automatic feeding systems and advanced software for nesting and optimization. By selecting a machine with a robust laser source, like those from reputable manufacturers, buyers can achieve high cutting speeds and precision, reducing material waste significantly. Additionally, investing in staff training on machine operation and maintenance can ensure maximum productivity. Ultimately, understanding the long-term savings on material costs and labor efficiency can make the investment in CNC laser cutting technology not just justifiable but essential.

Scenario 2: Complexity in Material Handling and Setup

The Problem: Another common pain point is the complexity involved in handling various materials and setting up the CNC laser cutting machine for different jobs. B2B buyers often deal with a range of materials, including round, square, and rectangular pipes, each requiring different settings and adjustments. This complexity can lead to setup errors, increased downtime, and a steep learning curve for operators, resulting in frustration and lost production time.

The Solution: To mitigate these issues, buyers should look for CNC laser cutting machines equipped with intuitive software and automated features that streamline the setup process. Machines that offer automatic material recognition and adjustment capabilities can significantly reduce setup times and the potential for errors. Additionally, investing in modular systems that allow for quick changeovers between different materials can enhance flexibility and efficiency. Establishing a standardized operating procedure (SOP) for material loading and machine settings can also help new operators quickly adapt, ensuring that the team remains productive and minimizing downtime.

Scenario 3: Difficulty in Achieving Consistent Quality Across Production Runs

The Problem: Achieving consistent quality in the final product is a critical concern for many B2B buyers of CNC laser pipe cutting machines. Variability in cutting quality can lead to rejected parts, rework, and dissatisfied customers, particularly in industries where precision is non-negotiable. Buyers may struggle to understand how to maintain quality control and ensure that the machine settings remain consistent across different production runs, leading to concerns about the reliability of the laser cutting technology.

The Solution: To ensure consistent quality, buyers should prioritize CNC laser cutting machines that include advanced monitoring and feedback systems. These systems can provide real-time data on cutting parameters, allowing for immediate adjustments if quality deviates from set standards. Implementing routine maintenance schedules and calibration checks can help maintain machine performance over time. Additionally, integrating quality control measures, such as automated inspection systems, can catch defects early in the production process. By focusing on these solutions, companies can enhance product quality, reduce waste, and build a reputation for reliability in their respective markets.

Strategic Material Selection Guide for cnc laser pipe cutting machine

What Are the Key Materials for CNC Laser Pipe Cutting Machines?

When selecting materials for CNC laser pipe cutting machines, it’s crucial to consider the properties and performance of each material in relation to the intended applications. Below, we analyze four common materials used in this context: carbon steel, stainless steel, aluminum, and brass.

How Does Carbon Steel Perform in CNC Laser Pipe Cutting Applications?

Key Properties: Carbon steel is known for its high tensile strength and toughness. It can withstand significant pressure and temperature variations, making it suitable for various industrial applications.

Pros & Cons: The primary advantage of carbon steel is its durability and cost-effectiveness. It is relatively inexpensive compared to other metals, which can significantly lower manufacturing costs. However, it is susceptible to corrosion if not properly treated, which can limit its lifespan in certain environments.

Impact on Application: Carbon steel is ideal for structural applications in construction and manufacturing. However, its susceptibility to rust means that it may not be suitable for applications involving exposure to moisture or corrosive substances.

Considerations for International Buyers: Compliance with standards such as ASTM A36 is essential. Buyers in regions like Germany and Nigeria should ensure that their suppliers adhere to local and international quality standards to avoid discrepancies in material quality.

What Are the Advantages of Using Stainless Steel in CNC Laser Cutting?

Key Properties: Stainless steel is renowned for its corrosion resistance, high strength, and ability to withstand high temperatures. It is non-reactive, making it suitable for food and medical applications.

Pros & Cons: The key advantage of stainless steel is its durability and low maintenance requirements. However, it is significantly more expensive than carbon steel, which can impact overall project budgets. Additionally, the manufacturing complexity can be higher due to the need for specialized cutting techniques.

Impact on Application: Stainless steel is widely used in industries such as food processing, pharmaceuticals, and automotive manufacturing due to its hygienic properties. Its resistance to corrosion makes it ideal for environments where cleanliness is paramount.

Considerations for International Buyers: Compliance with standards like ASTM A240 or DIN 1.4301 is critical. Buyers should be aware of the specific grades of stainless steel required for their applications, especially in regions with stringent regulations.

How Does Aluminum Compare for CNC Laser Pipe Cutting?

Key Properties: Aluminum is lightweight, has good corrosion resistance, and offers excellent thermal and electrical conductivity. It is also malleable, making it easy to shape and form.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can reduce shipping costs and make handling easier. However, it is generally less durable than steel and can be more expensive, depending on the alloy used.

Impact on Application: Aluminum is commonly used in aerospace, automotive, and construction applications where weight savings are crucial. Its corrosion resistance makes it suitable for outdoor applications.

Considerations for International Buyers: Buyers should consider compliance with standards such as ASTM B221 for aluminum extrusions. In regions like South America and the Middle East, understanding local preferences for specific aluminum alloys can enhance procurement strategies.

What Role Does Brass Play in CNC Laser Pipe Cutting?

Key Properties: Brass is an alloy of copper and zinc, known for its excellent machinability and corrosion resistance. It has good thermal and electrical conductivity, making it suitable for various applications.

Pros & Cons: The main advantage of brass is its aesthetic appeal and resistance to tarnishing, making it ideal for decorative applications. However, it is more expensive than carbon steel and may not be as strong, limiting its use in high-stress applications.

Impact on Application: Brass is often used in plumbing, electrical fittings, and musical instruments. Its corrosion resistance makes it suitable for applications involving exposure to moisture.

Considerations for International Buyers: Compliance with standards such as ASTM B36 is important. Buyers in Europe and Africa should be aware of the specific grades of brass that meet local regulations and market demands.

Summary of Material Selection for CNC Laser Pipe Cutting Machines

| Material | Typical Use Case for cnc laser pipe cutting machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components in construction and manufacturing | Cost-effective and durable | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals, automotive components | Corrosion resistant and hygienic | Higher cost and manufacturing complexity | High |

| Aluminum | Aerospace, automotive, construction applications | Lightweight and corrosion resistant | Less durable and potentially higher cost | Medium |

| Brass | Plumbing and electrical fittings, decorative items | Aesthetic appeal and tarnish resistance | More expensive and lower strength | Medium |

This guide provides a comprehensive understanding of the materials commonly used in CNC laser pipe cutting machines, enabling international B2B buyers to make informed decisions based on their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc laser pipe cutting machine

What Are the Main Stages in the Manufacturing Process of CNC Laser Pipe Cutting Machines?

Manufacturing CNC laser pipe cutting machines involves several critical stages that ensure the final product meets the high precision and quality required in various industries. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process is the careful selection and preparation of materials, typically high-strength steel or aluminum. Raw materials undergo a thorough inspection to verify their quality and compliance with industry standards. Suppliers often provide material certificates, which detail the chemical composition and mechanical properties. This ensures that the materials used can withstand the operational stresses of laser cutting.

Forming Techniques

Once the materials are prepared, they are subjected to various forming techniques. Advanced CNC machining centers cut and shape components with high precision, utilizing methods like laser cutting, water jet cutting, and punching. These processes are essential for creating the intricate parts required for the laser cutter’s functionality. For instance, the machine’s frame and structural components must be robust yet lightweight, allowing for efficient operation.

Assembly Process

The assembly stage is where the various components come together. Skilled technicians assemble the laser source, optical systems, and CNC controllers, ensuring that each part is correctly aligned and calibrated. This stage often employs automated assembly systems to enhance precision and reduce assembly time. Regular checks are conducted to ensure that the alignment and integration of components meet the specified tolerances.

Finishing Touches

The final stage involves finishing processes such as surface treatment and painting. Surface treatments, like anodizing or powder coating, enhance the machine’s durability and resistance to corrosion. Quality control teams conduct thorough inspections during this phase, ensuring that the machine not only meets aesthetic standards but also maintains functionality.

How Is Quality Assurance Implemented in CNC Laser Pipe Cutting Machine Manufacturing?

Quality assurance (QA) is critical in manufacturing CNC laser pipe cutting machines. It encompasses a series of processes and standards that ensure the machines are reliable, efficient, and safe for use.

What International Standards Are Relevant to CNC Laser Pipe Cutting Machines?

Manufacturers typically adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that processes are documented, monitored, and improved continuously. Additionally, certifications like CE (Conformité Européenne) signify compliance with health, safety, and environmental protection standards within the European market. For industries that require high reliability, such as oil and gas, certifications from organizations like the American Petroleum Institute (API) may also be necessary.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process to catch defects early and ensure compliance with specifications.

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to verify compliance with quality standards and specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages. This includes regular checks on dimensions, tolerances, and operational performance of machinery.

-

Final Quality Control (FQC): The final inspection assesses the completed CNC laser pipe cutting machine against all quality metrics before shipment. This includes functional testing and performance verification.

What Common Testing Methods Are Used?

Various testing methods are employed to ensure the machines meet quality standards. These include:

- Functional Testing: Verifying that all systems operate correctly under simulated conditions.

- Performance Testing: Assessing cutting speed, precision, and operational reliability.

- Safety Testing: Ensuring that all safety features function correctly to protect operators and the workplace.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, it is essential to verify the quality control practices of suppliers. Here are several strategies to ensure that a supplier meets high-quality standards:

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their quality management systems and production processes. Audits should evaluate compliance with ISO and other relevant standards, as well as the effectiveness of their quality control measures.

Requesting Quality Reports

Buyers should request detailed quality reports that outline the results of testing performed on the machines. These reports should include metrics on precision, reliability, and compliance with international standards.

Utilizing Third-Party Inspection Services

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can occur at various stages of production and help mitigate risks associated with international procurement.

What Are the Nuances of Quality Control for International B2B Buyers?

International buyers must be aware of specific nuances in quality control when sourcing CNC laser pipe cutting machines. For instance, varying standards and regulations across countries can affect compliance requirements. It is crucial for buyers to understand the certifications that are recognized in their respective markets.

Additionally, cultural differences may influence communication regarding quality expectations. Establishing clear communication channels and expectations can help mitigate misunderstandings and ensure that quality standards are consistently met.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for CNC laser pipe cutting machines is essential for B2B buyers. By focusing on these critical aspects, buyers can make informed purchasing decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc laser pipe cutting machine’

This guide serves as a practical checklist for B2B buyers aiming to procure CNC laser pipe cutting machines. With the growing demand for precision cutting in various industries, understanding the critical steps in sourcing such machinery is essential for making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s crucial to outline your specific requirements for the CNC laser pipe cutting machine. Consider factors such as the type of materials you will be cutting (e.g., steel, aluminum), the thickness of the pipes, and the dimensions of the tubes. This clarity will help you narrow down options that best fit your operational needs.

Step 2: Research Different Machine Models

Explore various models available in the market, each with unique features and capabilities. For instance, some machines offer enhanced automation with feeding systems, while others may provide higher wattage for faster cutting speeds. Understanding these differences will enable you to align the machine’s capabilities with your production goals.

Step 3: Evaluate Potential Suppliers

Prior to making a purchase, thoroughly vet potential suppliers. Request detailed company profiles, product specifications, and case studies demonstrating their machines in action. It’s also beneficial to seek references from other businesses in your industry or region to gauge reliability and performance.

Step 4: Check for Compliance and Certifications

Ensure that the CNC laser pipe cutting machines you are considering comply with relevant industry standards and safety regulations. Look for certifications such as CE or ISO, which indicate that the equipment meets specific quality and safety benchmarks. This step is crucial to avoid legal and operational risks down the line.

Step 5: Request Demonstrations or Samples

If possible, arrange for demonstrations of the machines you are interested in. Observing the cutting process firsthand will allow you to assess the machine’s precision, speed, and ease of operation. Additionally, some suppliers may offer sample cuts on your specific materials, providing a clearer picture of the machine’s capabilities.

Step 6: Consider After-Sales Support and Warranty

Investigate the after-sales support offered by the supplier, including maintenance services, spare parts availability, and technical support. A robust warranty can also provide peace of mind, ensuring that any issues can be addressed without significant costs. This ongoing support is vital for maintaining operational efficiency.

Step 7: Compare Pricing and Financing Options

Finally, gather detailed quotes from multiple suppliers and compare them not just on price but also on the value provided. Consider financing options that may be available, which can ease the initial capital outlay. Be cautious of significantly lower prices, as they may indicate a compromise in quality or service.

By following these steps, you can confidently navigate the process of sourcing CNC laser pipe cutting machines, ensuring that your investment aligns with your business needs and operational goals.

Comprehensive Cost and Pricing Analysis for cnc laser pipe cutting machine Sourcing

What Are the Key Cost Components in CNC Laser Pipe Cutting Machines?

When sourcing CNC laser pipe cutting machines, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. High-quality components, such as robust laser sources (e.g., IPG, Raycus), and durable machine frames can increase initial costs but provide better longevity and performance.

-

Labor: Labor costs encompass both manufacturing and assembly. Skilled labor is essential for precision machining, and regions with higher wage standards will see increased costs. Automation features can mitigate labor costs in the long run.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production processes can lower overhead costs, impacting the overall price.

-

Tooling: The specific tooling requirements for CNC machines can vary widely. Custom tooling may be necessary for specialized cuts, adding to initial expenses.

-

Quality Control (QC): Rigorous QC processes ensure machine reliability and performance. Higher QC standards may lead to increased costs but can reduce long-term operational issues.

-

Logistics: Shipping and handling costs can vary greatly based on the machine’s size and weight, as well as the shipping distance. International buyers should factor in customs duties and tariffs, especially when importing from regions like Europe or North America.

-

Margin: Supplier margins will depend on competition and market demand. Buyers should be aware of prevailing market rates to negotiate effectively.

How Do Price Influencers Affect CNC Laser Pipe Cutting Machine Costs?

Several factors influence the pricing of CNC laser pipe cutting machines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced unit prices due to economies of scale. Negotiating MOQs can significantly impact pricing strategies.

-

Specifications and Customization: Tailored machines with specific features or capabilities will generally command higher prices. Buyers should assess whether customization is essential for their operations.

-

Material Quality and Certifications: Machines that meet international quality certifications (like CE or ISO standards) may have higher upfront costs but can lead to better performance and reliability.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge more but offer enhanced support and warranty options.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial for determining the total landed cost. Buyers should clarify these terms to avoid unexpected expenses.

What Tips Can Buyers Use for Cost-Efficiency in CNC Laser Pipe Cutting Machines?

To navigate the complexities of sourcing CNC laser pipe cutting machines, consider the following strategies:

-

Negotiate Pricing: Don’t hesitate to negotiate with suppliers, especially for bulk purchases. Leverage your position as a buyer to secure better rates or additional services.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase prices, assess long-term operational costs, including maintenance, energy consumption, and downtime. A lower upfront cost may not translate to overall savings.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures based on local demand, labor costs, and material availability. Buyers from Africa, South America, the Middle East, and Europe should research local market conditions to negotiate effectively.

-

Consider After-Sales Support and Warranty: A machine with a robust warranty and comprehensive support can save costs related to repairs and downtime. Ensure that these factors are included in your evaluation.

-

Stay Informed About Market Trends: Regularly monitor market trends and technological advancements to make informed purchasing decisions. This knowledge can provide leverage in negotiations and help avoid obsolescence.

Disclaimer on Pricing

Prices for CNC laser pipe cutting machines can fluctuate based on market conditions and specific configurations. The figures provided are indicative and may vary significantly based on the factors discussed. Always request detailed quotations from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing cnc laser pipe cutting machine With Other Solutions

Understanding Alternatives to CNC Laser Pipe Cutting Machines

In the manufacturing landscape, CNC laser pipe cutting machines are prominent for their precision and efficiency in cutting metal tubes and profiles. However, businesses may explore alternative solutions that can meet their cutting needs while considering factors like cost, performance, and application. This analysis compares CNC laser pipe cutting machines with traditional flame cutting and plasma cutting methods, providing insights for B2B buyers in diverse markets.

| Comparison Aspect | CNC Laser Pipe Cutting Machine | Flame Cutting | Plasma Cutting |

|---|---|---|---|

| Performance | High precision, minimal kerf, and intricate designs | Moderate precision, larger kerf, slower speed | High speed, but less precision than laser |

| Cost | Higher initial investment, lower operating costs | Low initial cost, higher gas and operational costs | Moderate initial cost, varying consumable costs |

| Ease of Implementation | Requires skilled setup and programming | Relatively easy to set up and operate | Requires some training but easier than laser |

| Maintenance | Low maintenance with high durability | Moderate maintenance, dependent on gas supply | Moderate maintenance, wear on consumables |

| Best Use Case | Complex shapes and high-volume production | Thick materials and large components | Medium thickness, versatile for various metals |

Detailed Breakdown of Alternatives

Flame Cutting

Flame cutting, also known as oxy-fuel cutting, utilizes a mixture of oxygen and fuel gas to create a flame that melts metal. This method is particularly effective for cutting thick materials and is favored for its low initial investment. However, it produces a larger kerf and lower precision compared to laser cutting, making it less suitable for intricate designs. While setup and operation are relatively straightforward, ongoing costs related to gas supply can add up, impacting overall profitability for high-volume operations.

Plasma Cutting

Plasma cutting employs a high-velocity jet of ionized gas (plasma) to melt and remove material. This method is known for its speed and ability to cut through a variety of metals, including those that are too thick for laser cutting. Plasma cutting is more cost-effective than laser cutting in terms of initial investment and can handle diverse applications. However, it generally lacks the precision and edge quality of laser-cut components, making it less ideal for applications that require tight tolerances or intricate designs. Maintenance is also moderate due to wear on consumables, which can lead to increased operational costs over time.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a cutting solution, B2B buyers should carefully assess their specific production requirements, budget constraints, and the desired quality of finished products. CNC laser pipe cutting machines excel in precision and are ideal for complex, high-volume applications, but they come with higher upfront costs. On the other hand, flame and plasma cutting methods offer viable alternatives for different scenarios, particularly in terms of cost-effectiveness and ease of use. Ultimately, the decision should align with the strategic goals of the business, ensuring that the chosen method meets both current and future operational demands.

Essential Technical Properties and Trade Terminology for cnc laser pipe cutting machine

What Are the Essential Technical Properties of CNC Laser Pipe Cutting Machines?

When investing in CNC laser pipe cutting machines, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some key properties that should be considered:

1. Laser Power Output

Laser power is measured in watts (W) and typically ranges from 1500W to 6000W for industrial applications. Higher power output allows for faster cutting speeds and the ability to cut through thicker materials. For B2B buyers, selecting the appropriate power output is essential, as it directly affects production efficiency and the types of materials that can be processed.

2. Cutting Speed

Cutting speed is measured in meters per minute (m/min) and indicates how quickly the machine can cut through materials. Machines with higher cutting speeds can enhance productivity, making them more suitable for high-volume production environments. Buyers should assess their operational needs to choose a machine that balances speed with the required precision.

3. Material Compatibility

CNC laser pipe cutting machines can process various materials, including steel, aluminum, and stainless steel. Understanding the material compatibility is vital, as it determines the machine’s versatility and ability to meet specific production requirements. Buyers should ensure that the machine can handle the materials they intend to work with.

4. Tolerance and Precision

Tolerance refers to the allowable deviation from a specified dimension, typically measured in millimeters (mm). High precision and tight tolerances are critical for industries requiring exact specifications, such as aerospace or automotive manufacturing. A machine with a tolerance of ±0.1 mm ensures that components fit correctly, reducing the need for rework and scrap.

5. Automation Features

Many CNC laser pipe cutting machines come equipped with automation features, such as automatic feeders and self-centering chucks. These features streamline operations by reducing manual labor and increasing throughput. For B2B buyers, investing in machines with advanced automation can lead to significant labor savings and improved operational efficiency.

What Are Common Trade Terms Related to CNC Laser Pipe Cutting Machines?

Understanding industry jargon is essential for navigating the purchasing process effectively. Here are some common terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC laser cutting machines, buyers may work directly with OEMs for custom solutions or upgrades. Understanding OEM relationships can lead to better service and support.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers, as it helps in budgeting and planning inventory levels. Knowing the MOQ can prevent overcommitting to larger purchases that may not align with production schedules.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. For CNC laser pipe cutting machines, submitting an RFQ allows buyers to compare prices, specifications, and delivery terms from multiple suppliers, aiding in informed decision-making.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is vital for international transactions, as they clarify who bears the risk during transport and delivery, impacting overall costs and logistics.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. This term is particularly relevant for B2B buyers, as it affects project timelines and operational planning. A clear understanding of lead times can help in scheduling production runs and managing customer expectations.

In conclusion, being well-versed in both the technical properties and trade terminology associated with CNC laser pipe cutting machines equips B2B buyers with the knowledge necessary to make informed decisions, optimize their operations, and ultimately enhance their competitive edge in the market.

Navigating Market Dynamics and Sourcing Trends in the cnc laser pipe cutting machine Sector

What Are the Key Market Trends Driving the CNC Laser Pipe Cutting Machine Sector?

The CNC laser pipe cutting machine market is experiencing significant growth, driven by several global trends. The rise of automation and Industry 4.0 is reshaping manufacturing processes, emphasizing precision and efficiency. This shift is particularly evident in regions like Europe, where manufacturers are investing in advanced technologies to enhance productivity and reduce labor costs. For international B2B buyers, particularly in Africa, South America, and the Middle East, this presents an opportunity to adopt cutting-edge solutions that streamline operations and improve product quality.

Emerging technologies such as artificial intelligence (AI) and the Internet of Things (IoT) are also influencing sourcing strategies. Machines equipped with smart capabilities enable real-time monitoring and predictive maintenance, leading to reduced downtime and operational costs. As a result, buyers are increasingly seeking suppliers that offer these advanced features, ensuring their investments yield long-term benefits.

Moreover, the demand for custom and complex designs is escalating, prompting manufacturers to utilize CNC laser cutting machines that offer versatility in cutting various shapes and materials. This trend is particularly relevant for industries like automotive, aerospace, and construction, which require tailored solutions. International buyers should focus on suppliers that can provide flexible manufacturing capabilities, ensuring they meet the diverse needs of their markets.

How Important Is Sustainability and Ethical Sourcing in the CNC Laser Pipe Cutting Machine Sector?

Sustainability is becoming a critical consideration for B2B buyers in the CNC laser pipe cutting machine sector. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt greener practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability through their production methods and materials used. This includes sourcing machines that minimize waste, energy consumption, and emissions during operation.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are responsible and transparent. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) can guide buyers in selecting suppliers that adhere to high environmental and ethical standards. Additionally, incorporating ‘green’ materials, such as recyclable components and eco-friendly packaging, can enhance a company’s brand reputation and appeal to environmentally conscious consumers.

By aligning with suppliers that prioritize sustainability and ethical practices, B2B buyers can not only meet regulatory requirements but also foster goodwill and loyalty among customers who value corporate responsibility.

How Has the CNC Laser Pipe Cutting Machine Market Evolved Over Time?

The evolution of CNC laser pipe cutting machines can be traced back to advancements in laser technology and computer numerical control systems. Initially, laser cutting was primarily reserved for flat materials; however, as technology progressed, manufacturers began adapting it for tubular and profile cutting, unlocking new design possibilities.

In the early 2000s, the introduction of fiber laser technology revolutionized the market, offering improved cutting speeds, efficiency, and versatility over traditional CO2 lasers. This technological leap enabled manufacturers to cut a wider variety of materials with greater precision, further driving adoption across various industries.

Today, CNC laser pipe cutting machines are integral to modern manufacturing, offering enhanced automation, reduced labor costs, and the ability to produce complex shapes efficiently. As the market continues to evolve, ongoing innovations in software, machine design, and materials are expected to further transform the landscape, providing buyers with even more advanced solutions to meet their needs.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc laser pipe cutting machine

-

How do I choose the right CNC laser pipe cutting machine for my business needs?

Selecting the right CNC laser pipe cutting machine involves assessing your production requirements, including the types of materials you work with, the thickness of pipes, and the complexity of cuts needed. Consider the machine’s power options (ranging from 1500W to 6000W), cutting speed, and the size of the tubes you typically handle. Additionally, explore features like automation and software compatibility to enhance efficiency. Consulting with suppliers for demonstrations or case studies can also provide valuable insights tailored to your specific operations. -

What are the key factors to consider when sourcing CNC laser cutting machines internationally?

When sourcing CNC laser cutting machines globally, evaluate the supplier’s reputation, certifications (like CE or ISO), and past customer reviews. Ensure they offer comprehensive support, including installation, training, and after-sales service. Pay attention to logistics, including shipping costs and delivery times, especially for regions like Africa and South America. It’s also crucial to understand warranty terms and the availability of spare parts to minimize downtime in your operations. -

What customization options are typically available for CNC laser pipe cutting machines?

Many manufacturers offer customization options to meet specific production needs. Customizations can include variations in cutting head designs, additional software features for nesting and optimization, and adaptations for different pipe sizes and shapes. It’s also possible to modify the machine’s automation level, integrating features like automatic feeding systems to enhance productivity. Discuss your requirements with potential suppliers to ensure they can accommodate your specific needs. -

What is the minimum order quantity (MOQ) for CNC laser pipe cutting machines?

Minimum order quantities can vary significantly between suppliers and depend on factors such as the machine type and customization levels. Some manufacturers may allow single-unit purchases, especially for standard models, while others might set higher MOQs for custom or specialized machines. It’s advisable to clarify MOQ policies early in discussions to ensure alignment with your purchasing capabilities and production plans. -

What payment terms should I expect when purchasing a CNC laser cutting machine?

Payment terms can vary widely among suppliers. Common arrangements include a deposit (typically 30-50%) upfront, with the balance due upon delivery or installation. Some suppliers may offer financing options or installment plans, especially for larger investments. Ensure to discuss payment security measures, such as escrow services or letters of credit, particularly for international transactions, to protect your investment. -

How can I ensure quality assurance (QA) for CNC laser pipe cutting machines?

To ensure quality assurance, request detailed specifications and certifications from suppliers. Many reputable manufacturers perform rigorous testing on their machines before shipment. Ask about their quality control processes, including any warranties and service agreements. Additionally, consider arranging factory visits or requesting videos of the machines in operation to verify their performance and quality standards. -

What logistics considerations should I keep in mind when importing CNC laser cutting machines?

When importing CNC laser cutting machines, consider shipping methods, customs duties, and local regulations in your country. It’s essential to work with logistics providers experienced in handling heavy machinery to ensure safe transport. Understand the timeline for shipping and customs clearance, as delays can impact your production schedule. Additionally, confirm that the supplier provides the necessary documentation for smooth customs processing. -

What are the common applications for CNC laser pipe cutting machines in various industries?

CNC laser pipe cutting machines are widely used across industries such as automotive, furniture manufacturing, construction, and aerospace. Their precision cutting capabilities make them ideal for creating complex designs and profiles in metal pipes, which are essential in structural components, furniture frameworks, and machinery parts. The flexibility of laser cutting also allows for rapid prototyping and customization, catering to the diverse needs of modern manufacturing environments.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cnc Laser Pipe Cutting Machine Manufacturers & Suppliers List

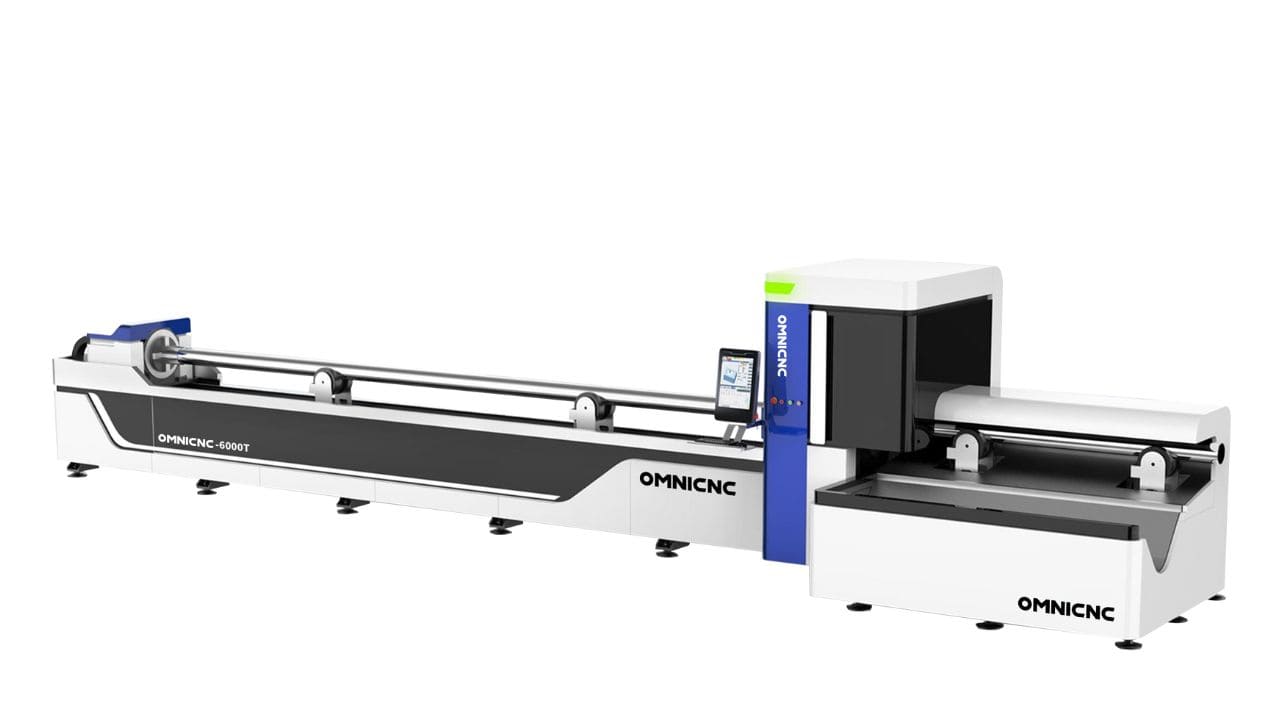

1. Hytek Tools – Tube Laser Cutters

Domain: hytektools.com

Registered: 2015 (10 years)

Introduction: Tube Laser Cutter – Hytek Tools offers various models including: 1. ROBOTUBE™ MODEL RT2 Fiber Laser Metal Tube Cutter starting at $182,000.00 2. ROBOTUBE™ MODEL RT3 Fiber Laser Metal Tube Cutter starting at $335,000.00 3. MODEL STC Sheet/Tube Cutter Combo starting at $175,000.00 4. MODEL STCE Sheet/Tube Cutter Combo starting at $199,000.00. Capabilities include 10ft, 20ft, 30ft, and 40ft tube cutt…

2. TRUMPF – Laser Tube Cutting Machines

Domain: trumpf.com

Registered: 1996 (29 years)

Introduction: Laser tube cutting machines from TRUMPF include the following models: TruLaser Tube 3000 fiber, which is economical and reliable for first-time users; TruLaser Tube 5000 fiber, known for record speeds and short processing times; and TruLaser Tube 7000 fiber, designed for maximum productivity with robust solid-state lasers for various materials and wall thicknesses. These machines offer solutions t…

3. STYLECNC – CNC Metal Pipe Laser Cutter

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: CNC Metal Pipe Laser Cutter with Automatic Feeding System

– Brand: STYLECNC

– Model: ST-FC6012K

– Laser Source: MAX, Raycus, IPG

– Power Options: 1500W, 3000W, 6000W

– Price Range: $25,000 – $66,800

– Features:

– Automatic feeder for loading and unloading tubes

– Chuck for rotating pipes

– Cuts round, square, rectangular, flat pipes, flanges, channel beams, U-tubes, and special-shaped metal…

4. BLM Group – Lasertube Cutting Systems

Domain: blmgroup.com

Registered: 2000 (25 years)

Introduction: Lasertube systems are 2D and 3D laser cutting systems for tubes, bars, and profiles, with diameters ranging from 12 mm to 610 mm (0.5″ to 24″) and lengths up to 18 m (60′). Key models include: LT5.10 (2D cut, tubes up to ∅ 4.72″), LTX (2D cutting mode, tubes up to ∅ 6″), LT6 (3D cutting mode, tubes up to ∅ 6″), LT7 (3D cutting mode, tube ∅ range min. 0.5″ to max. 6″), LT8.20 (3D cutting mode, tube…

5. Senfeng – Laser Metal Tube Cutter

Domain: senfenglaserusa.com

Registered: 2016 (9 years)

Introduction: Laser Metal Tube Cutter specifications include: 20′ length with diameters ranging from φ 0.7″ to 8.66″ (1kW-6kW), 20′ length with diameters from φ 0.6″ to 8.66″ (3kW-6kW), 30′ length with diameters from φ 0.8″ to 13.77″ (3kW-6kW), and 40′ length with diameters from φ 7.08″ to 14.96″ (4kW-12kW). The machines are designed for professional laser pipe and tube cutting, capable of cutting lengths from …

6. Accurl – Tube Laser Cutting Machine

Domain: accurl.com

Registered: 2012 (13 years)

Introduction: Tube Laser Cutting Machine – High-quality tube cutting. Features include automatic loading and unloading.

7. Bodor – Laser Tube Cutter

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Looking to purchase a laser tube cutter for cutting stainless steel (SS) tubing. Considering companies like Bodor and Trumpf. The quote from Bodor is around $100,000, while Trumpf machines are approximately $2 million. The user requires perfectly square cuts on the ends of the tubing without burrs or lubricants. Most tubing to be cut is thinner walled, with the thickest being .288 inches. The user…

8. SFCNC – Tube Laser Cutting Machines

Domain: sfcnclaser.com

Registered: 2011 (14 years)

Introduction: Product: Tube Laser Cutting Machine

Types:

– SF3015C Tube Laser Cutter (6m*Φ10-Φ160, 6m*Φ10-Φ220, 9m*Φ20-Φ350)

– Large H-shaped Steel Laser Cutting Machine SF1500CH (Laser power: 12-30kW, Max cutting thickness: 35-50mm, ±180° swing)

– Ultra Heavy Four-chuck Tube Laser Cutter SF12050HT (Circular tube: Φ50-Φ500mm, Square tube: 50*50-500*500, Laser power: 6kW-20kW)

– Tailing Tube Laser Cutting Machi…

9. FORSUN CNC – 6kW Fiber Laser Pipe and Tube Cutting Machine

Domain: forsuncnc.com

Registered: 2020 (5 years)

Introduction: {“Product Name”: “6kW Fiber Laser Pipe and Tube Cutting Machine”, “Brand”: “FORSUN CNC”, “Model”: “FS3015L-R(2000W)”, “Price”: “$8000.00”, “Price Range”: “$8000.00 to $9000.00”, “Payment Terms”: “T/T, Visa, Mastercard, American Express, Discover”, “Warranty”: “2 Years”, “Supply Ability”: “30 Sets / Month”, “Cutting Range”: {“Carbon Steel”: “0.1-16mm”, “Stainless Steel”: “0.1-6mm”, “Aluminum”: “0.1…

Strategic Sourcing Conclusion and Outlook for cnc laser pipe cutting machine

In conclusion, the strategic sourcing of CNC laser pipe cutting machines represents a significant opportunity for international B2B buyers looking to enhance their manufacturing capabilities. These advanced machines not only improve precision and efficiency but also reduce operational costs by eliminating several traditional cutting processes. By investing in CNC laser technology, companies can increase their production flexibility, allowing for the rapid adaptation to market demands while meeting stringent quality standards.

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the diverse offerings available—from compact, cost-effective models to high-capacity machines—will be crucial. Evaluating suppliers based on their technological advancements, after-sales support, and customization options can lead to more informed purchasing decisions.

As the global market for CNC laser cutting machines continues to expand, now is the time to leverage these innovations. Engage with trusted suppliers, explore financing options, and consider how these machines can revolutionize your production line. The future of precision manufacturing is bright, and proactive sourcing today will position your business for success tomorrow.