Contents

Manufacturing Insight: Cnc Laser Marking

Precision Identification Through Integrated CNC Laser Marking

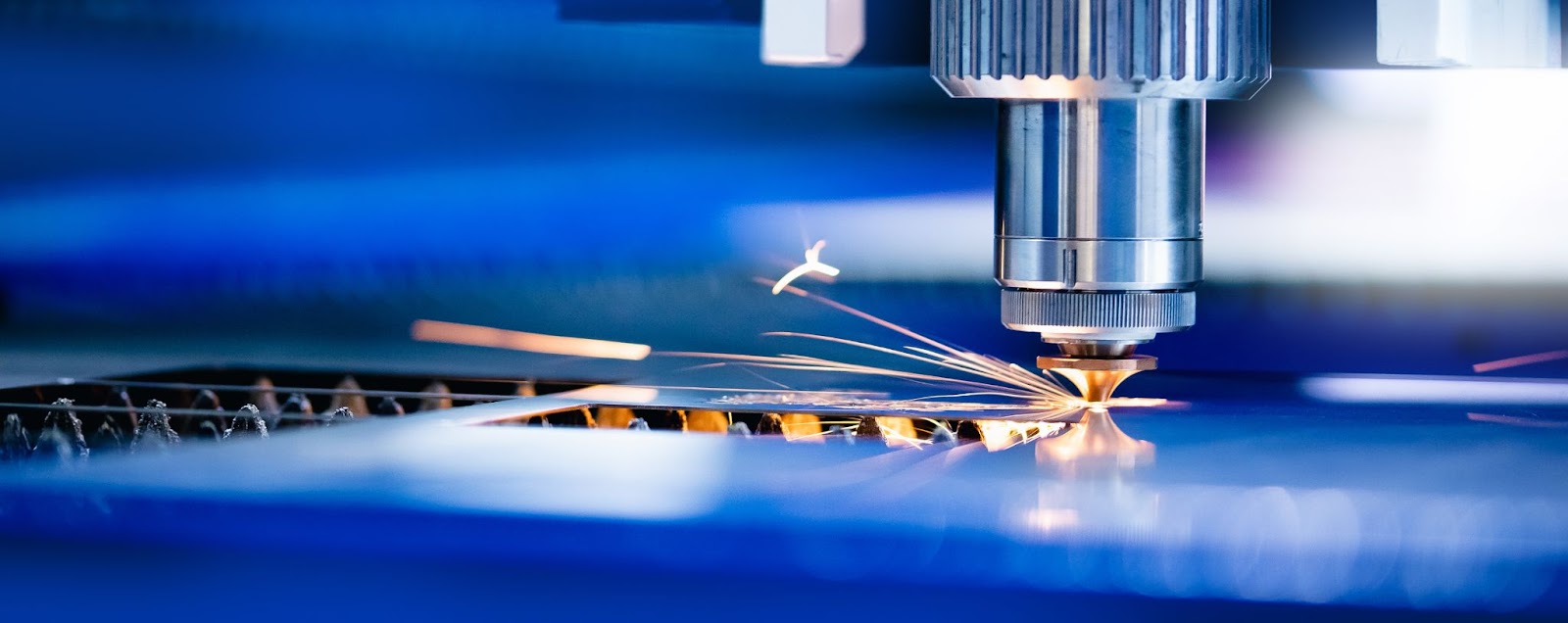

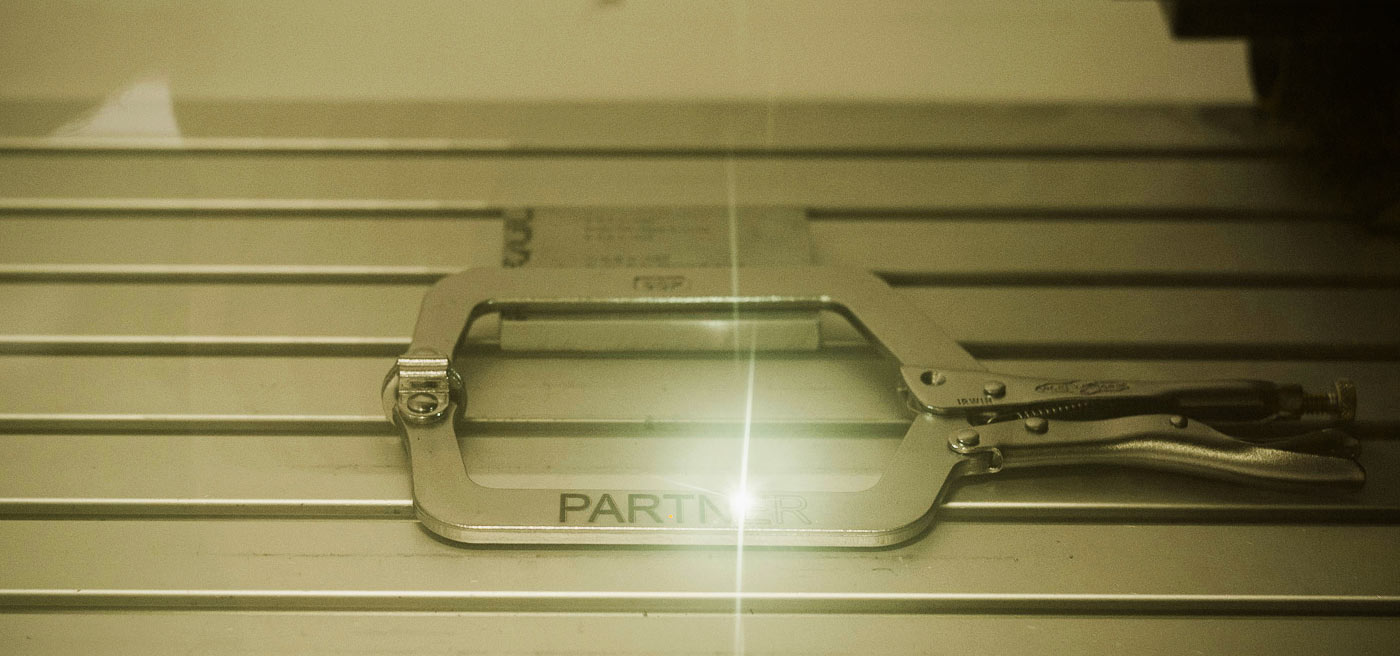

Honyo Prototype delivers end-to-end CNC machining solutions engineered for prototyping and low-volume production, where traceability and component integrity are non-negotiable. Our advanced CNC laser marking capability seamlessly extends these services, providing permanent, high-contrast identification directly integrated into your machining workflow. Unlike post-process methods, our fiber laser systems execute precise marking during CNC operations—ensuring zero part handling, eliminating alignment errors, and maintaining critical geometric tolerances. This sub-surface engraving technique works across metals (including stainless steel, aluminum, and titanium) and engineering plastics without compromising material strength or surface finish.

Operational Efficiency Meets Engineering Rigor

Laser marking at Honyo is not an isolated service but a value-added extension of our core CNC machining expertise. We program marking sequences within the same G-code environment used for milling and turning, synchronizing data matrix codes, serial numbers, or logos with your part’s functional geometry. This integration reduces lead times by up to 40% compared to third-party marking vendors while adhering to ISO 13485 and AS9100 traceability standards. Material compatibility and mark depth are rigorously validated during our DFM analysis, ensuring readability under harsh operational conditions—from aerospace hydraulics to medical implant sterilization cycles.

Accelerate Prototyping Decisions with Real-Time Cost Clarity

For engineering teams under time-to-market pressure, Honyo’s Online Instant Quote platform provides immediate, transparent pricing for combined CNC machining and laser marking. Upload your STEP or IGES file to receive a detailed quote within minutes, including material utilization, marking complexity adjustments, and delivery timelines—all without sales team dependencies. This digital workflow empowers rapid iteration, turning design concepts into fully traceable, production-ready prototypes in as few as 5 business days. Trust Honyo to embed precision identification where it belongs: within the manufacturing process itself.

Technical Capabilities

CNC laser marking is a precision engraving process integrated into advanced machining workflows, commonly used alongside 3-axis, 4-axis, and 5-axis milling and turning operations. It enables permanent, high-contrast marking of part IDs, serial numbers, barcodes, logos, and calibration data directly onto components with tight tolerance requirements. The process uses focused laser beams to alter the surface of materials through annealing, engraving, or foaming, depending on the substrate. It is especially valuable in aerospace, medical, and automotive industries where traceability and part accuracy are critical.

Laser marking complements high-precision CNC machining by maintaining dimensional integrity—marks are applied with micron-level accuracy without inducing mechanical stress. When combined with multi-axis milling and turning, the marking head can access complex geometries, ensuring consistent placement on contoured or angled surfaces. Typical tolerance for feature placement in laser marking is ±0.025 mm, aligning with tight-tolerance machining standards.

The following table outlines technical specifications for CNC laser marking in the context of multi-axis milling and turning operations, including compatibility with key materials:

| Parameter | Specification |

|---|---|

| Axis Integration | Compatible with 3-axis, 4-axis, and 5-axis CNC milling and turning centers |

| Marking Method | Fiber laser (1064 nm wavelength); pulsed operation for controlled ablation |

| Laser Power | 20 W to 50 W (standard for metal and engineering plastics) |

| Marking Speed | 100 mm/s to 2000 mm/s (adjustable based on depth and contrast requirements) |

| Spot Diameter | 0.02 mm to 0.05 mm (enables fine detail and small character marking) |

| Positioning Accuracy | ±0.01 mm (dependent on CNC system calibration and laser head integration) |

| Repeatability | ±0.005 mm |

| Feature Placement Tolerance | ±0.025 mm (typical for serialized part marking in high-precision applications) |

| Compatible Materials | Aluminum, Steel (including stainless and tool steels), ABS, Nylon |

| Aluminum Marking | Dark anneal or engrave; high contrast with minimal surface disruption |

| Steel Marking | Annealing (dark marks) or deep engraving; excellent durability and readability |

| ABS Marking | Foaming (light marks) or carbonization (dark marks); clean, non-abrasive |

| Nylon Marking | Carbonization produces high-contrast dark marks; suitable for traceability |

| Integration with CNC Systems | Direct G-code control or PLC interface; synchronized with machining cycles |

| Software Support | Compatible with CAD/CAM suites (e.g., Mastercam, Siemens NX, Fusion 360) |

| Typical Applications | Part serialization, UID marking, barcodes, logos, calibration indicators |

This integration ensures that laser marking does not compromise the geometric accuracy achieved through precision milling and turning. Materials such as aluminum and steel respond well to fiber laser marking with durable, corrosion-resistant results, while engineering thermoplastics like ABS and nylon allow for high-contrast, non-invasive identification—critical for components requiring strict traceability under tight-tolerance manufacturing standards.

From CAD to Part: The Process

Honyo Prototype CNC Laser Marking Process Overview

Honyo Prototype executes CNC laser marking through a streamlined, technology-driven workflow designed for precision, speed, and manufacturability assurance. This process begins with client-supplied CAD data and concludes with certified delivery, integrating automation and engineering expertise at critical stages. Below is a technical breakdown of each phase.

CAD Upload and Data Processing

Clients initiate the process by uploading native CAD files (STEP, IGES, or native SOLIDWORKS/Inventor formats) via Honyo’s secure customer portal. Our system automatically parses geometric features, layer information, and material specifications embedded in the CAD model. Non-native formats (e.g., DXF, DWG) undergo manual validation to ensure vector integrity and scale accuracy, as raster-based files or incorrect units may compromise marking fidelity. This stage enforces strict data hygiene to prevent downstream errors.

AI-Powered Quoting Engine

Uploaded CAD data feeds directly into Honyo’s proprietary AI quoting system, which analyzes part geometry, marking complexity (e.g., text depth, logo intricacy), material type, and volume requirements. The AI cross-references real-time machine availability, material costs, and historical production metrics to generate a technically validated quote within two hours. Key parameters assessed include laser dwell time per feature, path optimization potential, and substrate compatibility risks. Clients receive granular cost breakdowns tied to engineering constraints, not just dimensional metrics.

Engineering-Led DFM Analysis

Before production, all projects undergo mandatory Design for Manufacturability (DFM) review by Honyo’s applications engineering team. This phase identifies and resolves laser marking-specific issues: material reflectivity affecting beam absorption, thermal distortion risks in thin-walled sections, minimum feature size validation against laser spot diameter (typically 20–50 µm), and optimal marking orientation to avoid shadowing. Engineers collaborate with clients to suggest adjustments—such as altering mark depth from 0.1 mm to 0.05 mm for aluminum substrates—to enhance yield without compromising functional requirements. DFM sign-off is required prior to job release.

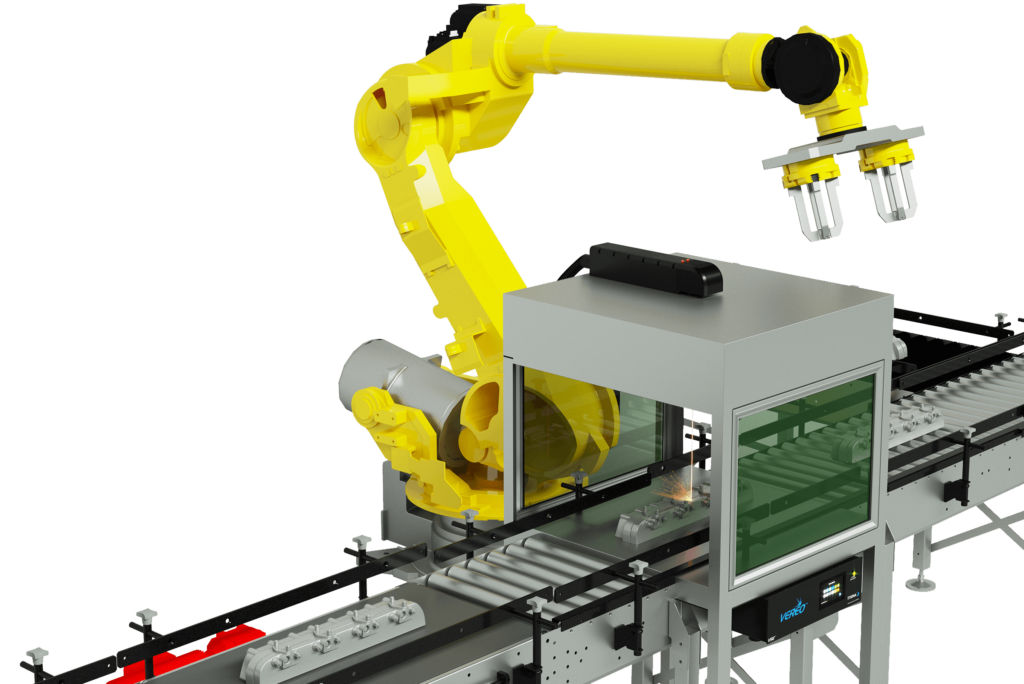

CNC Laser Marking Production

Approved jobs proceed to Honyo’s climate-controlled production floor, utilizing fiber laser systems (IPG Photonics or equivalent) with CNC-controlled galvanometer scanners. Key production controls include:

| Parameter | Specification Range | Quality Control Method |

|---|---|---|

| Laser Wavelength | 1064 nm (standard) | Spectrometer calibration |

| Marking Depth | 0.01–0.5 mm | Profilometer verification |

| Positional Accuracy | ±0.02 mm | CMM spot-checking |

| Surface Contrast | >70% (post-process) | Spectrophotometer measurement |

Parts are fixtured using custom vacuum chucks or precision jigs to minimize vibration. Real-time monitoring tracks beam power stability and fume extraction efficiency. All markings undergo 100% visual inspection against client-specified contrast/legibility standards, with non-conforming units reworked immediately.

Certified Delivery and Traceability

Completed orders receive serialized inspection reports detailing measured mark depth, positional accuracy, and material lot traceability. Parts are packaged in anti-static, humidity-controlled containers with tamper-evident seals. Honyo provides digital delivery confirmation including process validation data (e.g., laser power logs, inspection images) via the client portal. Standard lead time from DFM approval to shipment is 3–5 business days, with expedited options available for prototyping cycles. This closed-loop process ensures regulatory compliance for industries including medical device and aerospace, where permanent part identification is mandated.

Start Your Project

Interested in precision CNC laser marking services? Contact Susan Leo at [email protected] to discuss your project requirements.

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, ensuring high accuracy, fast turnaround, and consistent quality for all laser marking applications. From prototyping to low-volume production, we deliver reliable results tailored to your specifications.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.