Contents

Manufacturing Insight: Cnc Houston Tx

Precision CNC Machining Services in Houston TX

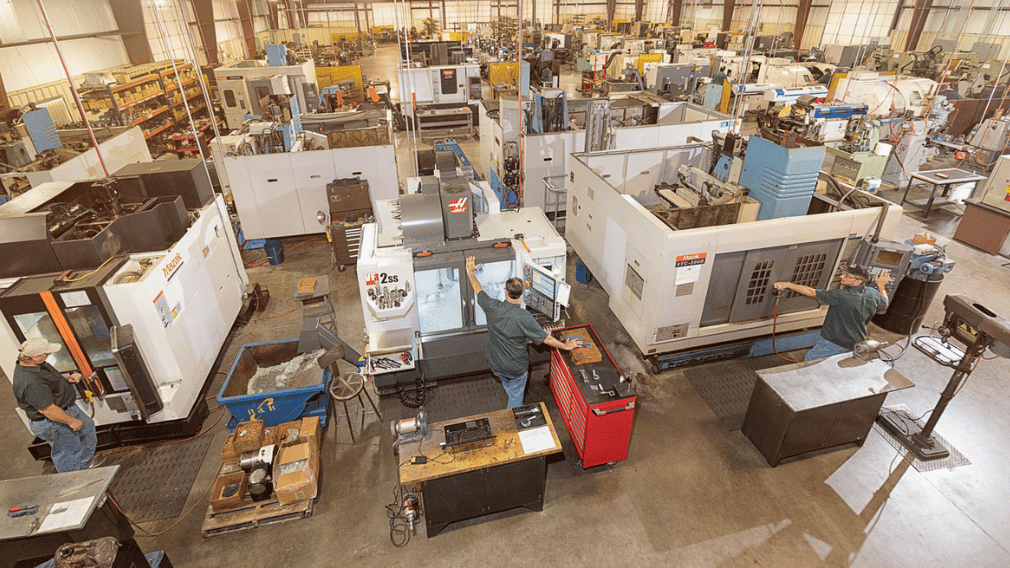

Honyo Prototype delivers advanced CNC machining solutions to industrial clients across Houston and the Gulf Coast region. Our facility combines state-of-the-art 3-, 4-, and 5-axis milling and turning centers with stringent ISO 9001-certified processes to produce complex components within tight tolerances of ±0.0002″. We specialize in low-to-medium volume production for aerospace, energy, medical, and industrial equipment sectors, utilizing materials ranging from aluminum alloys and titanium to exotic composites and high-performance plastics. Every project undergoes rigorous in-process inspection using CMM and optical measurement systems to ensure dimensional accuracy and surface finish compliance.

Accelerate Your Project Timeline with Online Instant Quotes

Honyo streamlines procurement through our proprietary Online Instant Quote platform, engineered specifically for time-sensitive manufacturing requirements. Upload your CAD file 24/7 to receive a detailed technical review and competitive pricing within minutes—not days. This system eliminates traditional quotation bottlenecks while providing transparent cost breakdowns for material, machining time, and finishing operations. For Houston-based engineering teams managing urgent prototyping or production deadlines, this capability ensures rapid validation of manufacturability and budget planning without vendor follow-up delays.

Technical Capabilities Overview

| Parameter | Specification |

|——————–|—————————————-|

| Max Work Envelope | 2000 x 1000 x 800 mm |

| Tolerance Range | ±0.0002″ to ±0.005″ (feature-dependent)|

| Material Types | Metals, Plastics, Composites, Ceramics |

| Lead Time Standard | 5-15 business days (varies by complexity)|

| Quality Compliance | ISO 9001:2015, AS9100D (aerospace) |

Honyo Prototype serves as Houston’s strategic partner for precision CNC machining where engineering integrity, on-time delivery, and responsive technical collaboration are non-negotiable requirements. Initiate your next project with immediate cost visibility through our Online Instant Quote system at honyoprototype.com.

Technical Capabilities

Honyo Prototype offers precision CNC machining services in Houston, TX, specializing in multi-axis milling and turning operations for industries requiring high accuracy and repeatability. Our capabilities include 3-axis, 4-axis, and 5-axis CNC milling, along with CNC turning, supporting a wide range of engineering-grade materials such as aluminum, steel, ABS, and nylon. We consistently achieve tight tolerances down to ±0.0002″ (5 µm), ensuring optimal performance for complex, mission-critical components.

Below is a summary of our technical capabilities:

| Capability | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including live tooling) |

| Tolerance | Standard: ±0.001″; Tight Tolerance: ±0.0002″ (5 µm) achievable with process control and inspection |

| Materials – Metals | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340), Stainless Steel (303, 304, 316), Tool Steels |

| Materials – Plastics | ABS, Nylon (6 & 6/6), Delrin (POM), PEEK, Polycarbonate, HDPE |

| Max Work Envelope (Milling) | 5-axis: 760 x 660 x 510 mm; 3/4-axis: Up to 1000 x 600 x 500 mm (varies by machine) |

| Max Turning Diameter | 300 mm; Max Length: 600 mm (bar stock capacity up to 500 mm) |

| Spindle Speed | Milling: Up to 24,000 RPM; Turning: Up to 6,000 RPM |

| Positioning Accuracy (Mill) | ±0.002 mm (0.00008″) per axis |

| Surface Finish | As-machined: 32–125 µin; Optional polishing to 8–16 µin Ra |

| Quality Control | In-process and final inspection using CMM, optical comparators, and micrometers; First Article Inspection (FAI) reports available |

| File Formats Accepted | STEP, IGES, DWG, DXF, SolidWorks, PDF (dimensioned prints) |

Our Houston facility is equipped with advanced CNC systems from Haas, DMG MORI, and MAZAK, enabling high-precision production of complex geometries across both prototyping and low-to-mid volume manufacturing runs. All components are machined under strict environmental and process controls to maintain consistency, especially in tight-tolerance applications.

From CAD to Part: The Process

Honyo Prototype CNC Manufacturing Process for Houston TX Operations

Honyo Prototype executes a streamlined, technology-driven CNC machining workflow optimized for precision and speed in our Houston TX facility. The process begins with digital CAD file submission via our secure client portal, accepting native formats including STEP, IGES, Parasolid, and native CAD system files (e.g., SolidWorks, Siemens NX, CATIA). Upon upload, our proprietary AI-powered quoting engine analyzes geometric complexity, material requirements, tolerance specifications, and feature density to generate an instant preliminary quote. This system cross-references real-time data on machine availability, material costs from regional Houston suppliers, and labor rates, ensuring accuracy within 95% of final pricing. Crucially, the AI output undergoes mandatory review by a Houston-based manufacturing engineer to validate feasibility and adjust for localized variables such as regional humidity impacts on aluminum alloys or lead times for exotic materials sourced through our Texas supply chain partners.

The Design for Manufacturability (DFM) phase follows immediately after quote acceptance. A dedicated Honyo engineer in Houston conducts a rigorous technical review focused on eliminating production risks specific to CNC machining. This includes verifying tool accessibility for deep pockets, assessing minimum wall thickness against deflection risks, optimizing hole depths to standard drill ratios, and identifying opportunities to consolidate features to reduce setups. Critical DFM parameters evaluated include:

| Parameter Category | Key Checks | Houston-Specific Consideration |

|---|---|---|

| Geometric Tolerancing | GD&T callout validity, CMM measurement feasibility | Alignment with AS9102 aerospace standards common in local clients |

| Material Selection | Machinability index, thermal stability | Verification of local supplier stock for 6061-T6, 7075, or 17-4PH stainless |

| Feature Optimization | Undercuts, internal radii, thin walls | Adjustment for vibration control in high-RPM milling of large castings |

Following DFM sign-off, jobs transition to production in our Houston cleanroom-controlled CNC facility. We deploy DMG MORI and Haas 3-5 axis vertical machining centers with Renishaw probing for in-process verification. Each run includes first-article inspection (FAI) per AS9102, with critical dimensions tracked via SPC software. For time-sensitive Houston projects, we prioritize local trucking through our dedicated logistics partner for same-day delivery within a 100-mile radius, while air freight coordination handles national shipments. All deliveries include comprehensive documentation: FAI reports, material certs, and dimensional validation data packaged digitally via our client portal. This integrated process ensures deterministic lead times—typically 3-5 days for prototypes and 7-10 days for low-volume production—with 100% traceability from CAD file to delivered part.

Start Your Project

Looking for precision CNC machining services in Houston, TX? Partner with Honyo Prototype for high-quality, on-demand manufacturing solutions.

Contact Susan Leo at [email protected] to discuss your project requirements and receive a fast, competitive quote.

While our advanced production facility is located in Shenzhen, China, we provide seamless support and shipping to clients in Houston and across North America. Our integrated quality control and engineering team ensure every component meets strict tolerances and industry standards.

For reliable CNC machining with rapid turnaround, reach out today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.