Contents

Manufacturing Insight: Cnc Houston

Precision CNC Machining Services in Houston

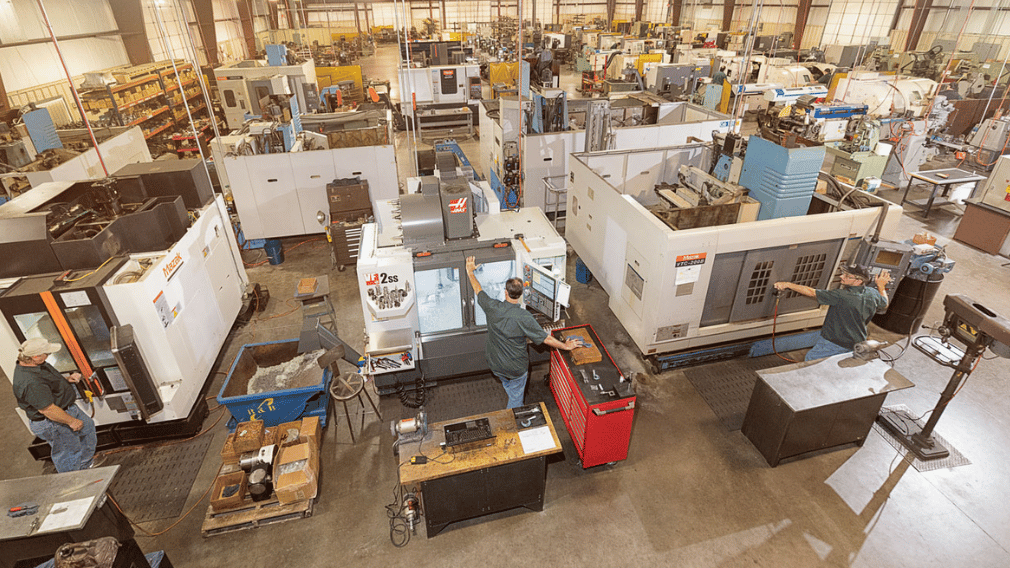

Honyo Prototype delivers advanced CNC machining solutions for demanding industrial applications across the Houston region and beyond. Our facility combines state-of-the-art 3-, 4-, and 5-axis milling and turning centers with rigorous quality control processes to produce complex components meeting tight tolerances down to ±0.0002 inches. We specialize in rapid prototyping through low-volume production runs for aerospace, energy, medical, and industrial sectors, utilizing materials ranging from aluminum and stainless steel to titanium and high-performance polymers.

Engineers and procurement teams accelerate project timelines through our Online Instant Quote system, which provides actionable pricing and lead time estimates within hours—not days. This digital workflow eliminates traditional procurement delays while ensuring transparency for precision-machined parts requiring strict adherence to AS9100 and ISO 9001 standards.

Our Houston-based manufacturing cell maintains dedicated capacity for urgent RFQs, supported by in-house metrology (CMM, OGP) and expert engineering review to resolve manufacturability challenges before machining begins. Partner with Honyo for CNC services where technical precision, material expertise, and responsive quoting converge to de-risk your supply chain.

Technical Capabilities

Honyo Prototype provides high-precision CNC machining services in Houston, specializing in multi-axis milling and turning operations for industries requiring tight tolerance components. Our advanced CNC capabilities support a wide range of engineering-grade materials, ensuring dimensional accuracy, repeatability, and superior surface finish.

Below are the technical specifications for our CNC machining services:

| Feature | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (2-axis and multi-axis) |

| Tolerance Capability | ±0.0002″ (5 µm) for critical features; standard tolerance ±0.001″ (25 µm) |

| Maximum Work Envelope | Milling: 24″ × 36″ × 20″ (600 × 900 × 500 mm); Turning: Ø16″ × 48″ (400 × 1220 mm) |

| Spindle Speed | Up to 15,000 RPM (high-speed options available for aluminum and plastics) |

| Positioning Accuracy | ±0.0001″ (2.5 µm) |

| Repeatability | ±0.0001″ (2.5 µm) |

| Surface Finish | As-machined: 32–125 µin Ra; post-processed options down to 8 µin Ra available |

| Supported Materials | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 316), ABS, Nylon (6, 66, GF-filled), and other engineering plastics and alloys |

| Coolant Options | Flood coolant, mist coolant, air blast, and dry machining for sensitive materials |

| Fixture Systems | Modular fixturing, vacuum tables, custom soft jaws, and tombstone pallets for high-volume runs |

| Quality Assurance | In-process inspection using CMM, optical comparators, micrometers, and calipers; full First Article Inspection (FAI) reports available |

Our Houston facility maintains strict process controls and is ISO 9001-compliant, ensuring consistent quality across prototyping and low-to-mid volume production runs. Materials such as aluminum and steel are machined with optimized toolpaths and rigid setups to maintain tight tolerances, while engineering plastics like ABS and nylon are handled with specialized cutting strategies to prevent deformation and achieve precise geometries.

From CAD to Part: The Process

Honyo Prototype utilizes a standardized, technology-driven manufacturing process across all facilities including our Houston operation. The term ‘cnc houston’ refers to our Computer Numerical Control machining services delivered through our Houston-based production center, leveraging the same core workflow as our global network. This process ensures rapid turnaround, engineering rigor, and consistent quality for prototype and low-volume production parts.

Upload CAD

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid, SolidWorks, etc.) via our secure online portal. The system performs an immediate format validation check to confirm file integrity and compatibility with our machining systems. Houston-based engineering teams gain instant access to the geometry data, material specifications, and any client-provided notes or special requirements documented during upload.

AI Quote Generation

Our proprietary AI engine analyzes the validated CAD geometry within minutes, calculating critical parameters including part volume, feature complexity, required tool changes, machine time estimates, and material utilization. This analysis integrates real-time data on machine availability at the Houston facility, current workload, material costs, and secondary operation requirements. Clients receive a detailed, transparent quote typically within 30 minutes, specifying lead time, unit cost, and any initial manufacturability flags requiring review.

Engineering DFM Analysis

Following quote acceptance, Houston-based manufacturing engineers conduct a formal Design for Manufacturability (DFM) review. This is not an automated step but a critical human-led assessment focusing on:

Machinability of specified materials (e.g., aluminum 6061-T6, stainless steel 303/316, engineered plastics)

Feasibility of tolerances (±0.005″ standard, ±0.001″ achievable with process control)

Optimization of part orientation and fixture strategy for 3-axis, 4-axis, or 5-axis milling

Identification of potential improvements to reduce cycle time or cost (e.g., standardizing hole sizes, modifying non-critical radii)

Assessment of secondary operations such as tapping, deburring, or surface finishing requirements

Engineers collaborate directly with the client to resolve any issues, providing specific recommendations and alternative solutions before programming begins.

Production Execution

Approved designs move to the Houston production floor where our CNC machining cells operate under strict quality protocols:

CAM programming uses Mastercam and Fusion 360, optimized for Haas and DMG MORI equipment

First-article inspection (FAI) is performed against client drawings using calibrated CMMs and optical comparators

In-process inspections verify critical dimensions during machining runs

Statistical process control (SPC) monitors key parameters for production consistency

All Houston facility processes adhere to ISO 9001:2015 standards with full material traceability and documented work instructions for every job.

Delivery and Logistics

Completed parts undergo final quality verification against all specifications before packaging. The Houston facility leverages strategic logistics partnerships for:

Local delivery within the Greater Houston metropolitan area (typically next-day)

Ground shipping across Texas and the Southern US (2-3 business days)

Air freight coordination for national or international destinations

Clients receive real-time shipment tracking and full documentation including inspection reports, material certifications, and process validation records. Our Houston operation maintains buffer stock of common engineering materials to support urgent requests without supply chain delays.

Start Your Project

Looking for precision CNC services in Houston? Partner with Honyo Prototype for fast, reliable, and high-quality CNC machining solutions.

Contact Susan Leo at [email protected] to discuss your project requirements.

While our advanced manufacturing facility is located in Shenzhen, China, we provide seamless international support with quick turnaround times and strict quality control for clients in Houston and beyond.

Let’s engineer excellence together—reach out today to request a quote or submit your design files.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.