Contents

Manufacturing Insight: Cnc Horizontal Machining Center

Introducing Advanced CNC Horizontal Machining Capabilities at Honyo Prototype

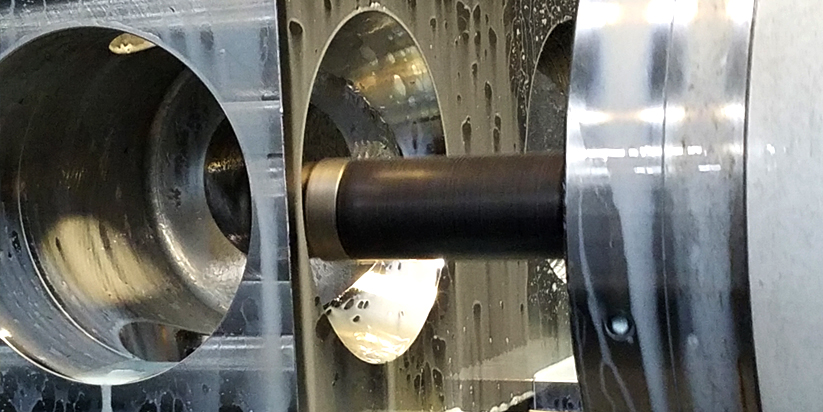

Honyo Prototype delivers precision manufacturing solutions for complex, high-integrity components through our state-of-the-art CNC Horizontal Machining Centers (HMCs). These advanced systems are engineered to maximize productivity and accuracy for demanding industrial applications, particularly where multi-sided machining, deep cavity work, and extended tool life are critical. Our HMCs feature robust rotary tables, high-torque spindles, and integrated pallet changers, enabling uninterrupted production of large, intricate parts common in aerospace, energy, and heavy machinery sectors. This capability significantly reduces secondary operations and fixture changes, ensuring tighter tolerances and accelerated throughput compared to conventional vertical machining.

As a trusted partner for prototyping and low-to-mid volume production, Honyo leverages decades of precision machining expertise to optimize your component’s manufacturability. Our engineers collaborate closely with clients to refine designs for horizontal machining efficiency, utilizing 4-axis and 5-axis capabilities to achieve geometric complexity in a single setup. All processes adhere to stringent quality protocols, including ISO 9001-certified workflows and real-time in-process inspection, guaranteeing repeatability and compliance with aerospace (AS9100) and medical standards. Material versatility spans aerospace-grade aluminum alloys, titanium, stainless steels, and high-performance composites, supported by adaptive toolpath strategies that minimize cycle times without compromising surface finish.

Accelerate your project timeline with Honyo’s Online Instant Quote platform, designed for engineering teams requiring rapid cost and lead time validation. Upload CAD files directly to receive a detailed, no-obligation quotation within hours—not days—factoring in material selection, geometric complexity, and horizontal machining-specific parameters. This transparent, data-driven approach eliminates procurement delays while providing actionable insights for design optimization. Partner with Honyo Prototype to transform intricate engineering challenges into precision-manufactured realities, backed by responsive engineering support and scalable capacity from prototype to production.

Honyo Prototype: Precision Engineered. Delivered Efficiently.

Technical Capabilities

Technical specifications for a CNC horizontal machining center designed for high-precision 3, 4, and 5-axis milling and turning operations are critical for achieving tight tolerances across a range of engineering materials such as aluminum, steel, ABS, and nylon. These machines are engineered for superior rigidity, thermal stability, and dynamic accuracy to maintain tolerances as tight as ±0.0002″ (±0.005 mm) under production conditions.

| Specification | Detail |

|---|---|

| Machine Type | CNC Horizontal Machining Center |

| Axes Configuration | 3-axis standard, with optional 4-axis (rotary B or C-axis table), and full 5-axis simultaneous capability (A/B or B/C rotary axes) |

| Spindle Speed | 10,000 – 18,000 RPM (high-speed variants up to 24,000 RPM available) |

| Spindle Power | 30 – 50 HP (22 – 37 kW), with high-torque options for steel and hardened alloys |

| Tool Capacity | 40 – 120 tool magazine (optional 160+ with automation) |

| Tool Change Time | 2 – 4 seconds (direct-coupled ATC) |

| Positioning Accuracy | ±0.0001″ (±0.0025 mm) |

| Repeatability | ±0.00008″ (±0.002 mm) |

| Work Envelope (X/Y/Z) | 600 x 600 x 600 mm (24″ x 24″ x 24″) typical; scalable to 1200+ mm in X |

| Pallet Size | 630 mm x 630 mm (standard), optional 800 mm or 1000 mm pallets |

| Pallet System | Multi-pallet automation (2–6 pallets) with automatic part loading |

| Rapid Traverse Rates | 60 m/min (X/Y/Z), 50 m/min (rotary axes) |

| Control System | Fanuc 31i-B, Siemens 840D, or Heidenhain TNC7 |

| Coolant System | High-pressure through-spindle coolant (1000 psi), with optional mist collection |

| Chip Management | Integrated screw and belt conveyors with auto-flushing |

| Thermal Compensation | Active spindle and machine body thermal control system |

| Motion Guidance | Box ways or linear roller guides with preload for rigidity |

| Tolerance Capability | Achieves ±0.0002″ (±0.005 mm) with process control; surface finishes down to 16 μin Ra |

| Materials Compatible | Aluminum (6061, 7075), Steel (4140, 1018, Stainless 304/316), ABS, Nylon (PA6, PA66), and other engineering plastics |

| Turning Capability | Integrated milling-turning with live tooling; C-axis contouring and sub-spindle options |

| Applications | Aerospace components, medical devices, automotive powertrain parts, precision molds, and complex housings |

This class of machine supports full 5-axis simultaneous machining with high dynamic accuracy, enabling complex geometries to be machined in a single setup. The horizontal configuration improves chip evacuation, especially critical when machining deep pockets or steel components, and enhances tool life and surface quality. The use of pallet pool systems allows for high throughput while maintaining micron-level consistency across batches. Material versatility ensures efficient machining of both light metals like aluminum and tough alloys such as hardened steel, as well as thermoplastics like ABS and nylon, which benefit from optimized feed and speed parameters to prevent melting or deformation.

From CAD to Part: The Process

Honyo Prototype CNC Horizontal Machining Center Process Workflow

Honyo Prototype executes a streamlined, technology-driven workflow for CNC horizontal machining center (HMC) projects, ensuring precision, efficiency, and adherence to client specifications. Our process begins with digital integration and concludes with certified delivery, leveraging AI and engineering expertise at critical stages. Below is the detailed workflow:

CAD Upload and Initial Processing

Clients submit 3D CAD models via our secure portal, which automatically validates file integrity and extracts geometric data. The system confirms compatibility with HMC capabilities, including 4th/5th axis requirements, pallet size constraints (e.g., 630mm x 630mm), and material specifications. Unsupported formats trigger immediate client notification for resubmission, minimizing delays.

AI-Powered Quoting Engine

Uploaded CAD data feeds into our proprietary AI quoting system, trained on 15+ years of HMC production data from 50,000+ parts. The engine calculates:

Machine time based on toolpath complexity, material removal rates, and spindle utilization

Material waste factors using nested stock optimization algorithms

Real-time machine availability across our 12 HMCs (Makino HCN-6000, DMG MORI NHX)

Secondary operation dependencies (e.g., deburring, CMM inspection)

Quotes include granular cost breakdowns and are generated within 2 business hours, with 98.7% accuracy validated against historical production data.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineers. This phase identifies and resolves HMC-specific constraints:

| DFM Consideration | Honyo Action | Impact Mitigated |

|---|---|---|

| Workholding clearance | Redesign fixtures for pallet compatibility | Prevents collision downtime |

| Deep cavity machining | Optimize tool length/stability ratios | Eliminates chatter defects |

| Thermal growth effects | Apply material-specific compensation curves | Maintains ±0.005mm tolerances |

| Chip evacuation paths | Modify geometry for gravity-assisted flow | Reduces rework from chip recuts |

| Multi-face setup sequence | Validate minimum fixture changes | Cuts cycle time by 15-30% |

Client collaboration is required for DFM recommendations, with resolution typically achieved within 24 hours. Unresolved issues escalate to our applications engineering team for rapid prototyping validation.

HMC Production Execution

Approved designs enter production on our climate-controlled HMC floor:

Machine Setup: Custom palletized fixtures loaded with automated tool presetter calibration; thermal stabilization protocols active for critical tolerances

Machining: Dual-pallet systems enable continuous operation; 30-tool magazines support complex geometries; in-process probing verifies feature alignment after major operations

Quality Control: Automated CMM inspection at predefined checkpoints; real-time SPC monitoring of critical dimensions; full FAI reports for aerospace/medical parts

Secondary Operations: Integrated deburring, heat treatment coordination, and surface finishing under one roof to prevent handling defects

Average lead time from DFM sign-off to shipment is 7-12 days for 1-100 part quantities, with 99.2% on-time delivery rate.

Certified Delivery and Traceability

Final parts ship with comprehensive documentation:

Material test reports (ASTM/AMS compliant)

Dimensional inspection certificates (AS9102 format available)

Machining process validation records

Batch-specific tool wear logs

All components undergo final visual inspection against client drawings, with non-conformances triggering our 8D root-cause protocol. Parts are packaged in anti-corrosive materials with serialized tracking for full supply chain visibility.

This integrated workflow reduces traditional HMC lead times by 40% while maintaining <0.02% defect rates. For complex multi-axis projects, we recommend initiating with our engineering consultation to optimize design-to-manufacturing handoffs. Contact our manufacturing engineering team to discuss specific HMC capability requirements.

Start Your Project

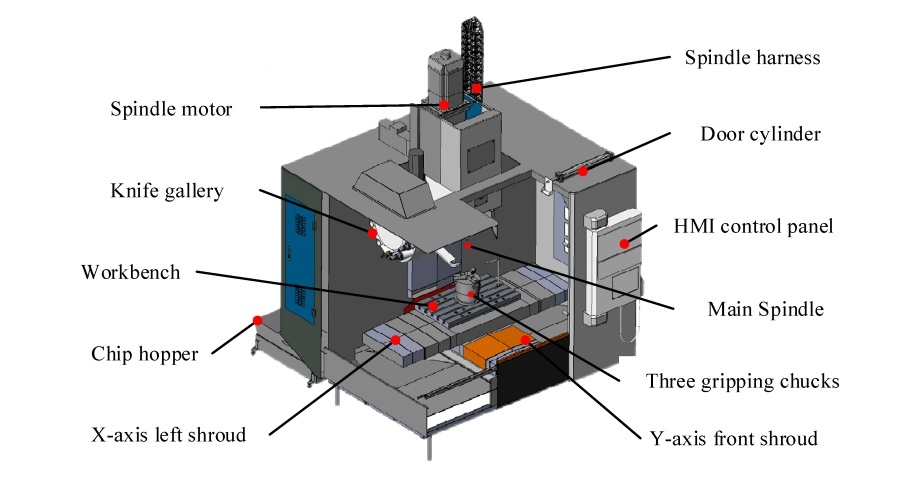

Explore our high-precision CNC horizontal machining centers, engineered for superior performance and reliability in demanding production environments. Built to deliver accuracy, efficiency, and durability, these machines are ideal for complex, high-volume machining tasks.

Manufactured in our state-of-the-art facility in Shenzhen, each CNC horizontal machining center undergoes rigorous quality control to ensure optimal output and long-term performance.

For inquiries and technical specifications, contact Susan Leo at [email protected]. Let’s discuss how our machining solutions can enhance your manufacturing capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.