Contents

Manufacturing Insight: Cnc Gun Parts

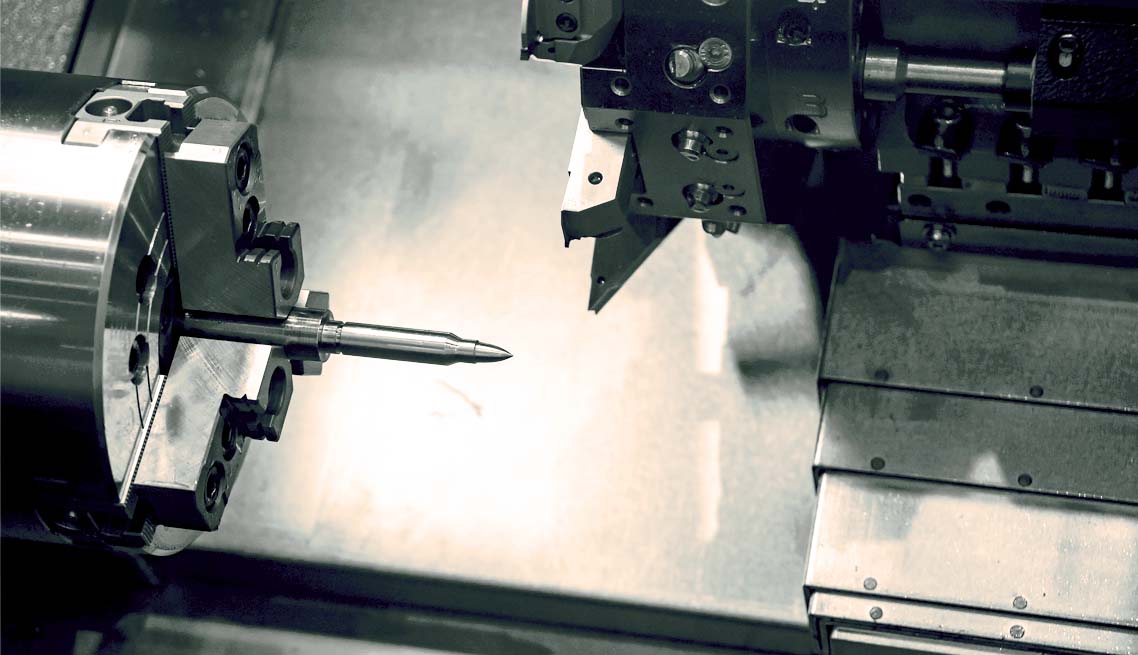

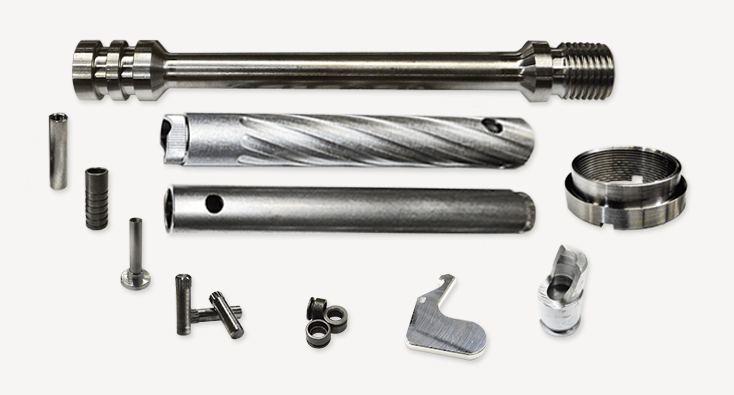

Precision CNC Machined Firearm Components Engineered for Reliability

Honyo Prototype delivers mission-critical CNC machining services specifically engineered for the demanding requirements of firearm component manufacturing. Our advanced multi-axis milling and turning centers, operated by engineers with deep expertise in defense and commercial firearms applications, consistently achieve the tight tolerances, superior surface finishes, and material integrity essential for safety-critical parts. We understand that dimensional accuracy and repeatability are non-negotiable in this sector, directly impacting function, longevity, and compliance. Our ISO 9001-certified processes incorporate rigorous in-process inspection and final verification using calibrated CMMs and optical comparators, ensuring every component meets or exceeds stringent industry specifications and regulatory standards.

Material selection is paramount for performance under extreme conditions. Honyo maintains extensive experience machining the alloys most trusted in firearm production, including:

| Material Grade | Common Firearm Applications | Key Properties for Machining |

|---|---|---|

| 4140 / 4340 Steel | Receivers, Bolts, Barrels | High strength, wear resistance, heat treatable |

| 17-4 PH Stainless | Trigger components, Pins | Corrosion resistance, high hardness |

| 7075-T6 Aluminum | Upper/Lower Receivers, Handguards | High strength-to-weight ratio |

| A2 / D2 Tool Steel | Punches, Dies, Small Components | Extreme wear resistance, edge retention |

Accelerate your development and production cycles with Honyo’s Online Instant Quote system. Upload your CAD file directly to our secure portal and receive a detailed, transparent manufacturing assessment within hours—not days. This platform provides immediate feedback on manufacturability, lead time estimates, and precise cost breakdowns, enabling faster decision-making for prototypes and low-to-mid volume production runs. Eliminate quotation bottlenecks while maintaining the uncompromising quality standards your firearm components demand. Partner with Honyo Prototype for CNC machining where precision, regulatory adherence, and rapid turnaround are engineered into every part.

Technical Capabilities

CNC Machined Gun Parts – Technical Specifications

CNC machined gun parts require high precision, repeatability, and material integrity to meet performance and safety standards. These components are typically produced using 3, 4, and 5-axis milling for complex geometries and tight tolerances, while turning operations are used for cylindrical components such as barrels, bolts, and pins. Below is a summary of technical capabilities and material considerations relevant to the production of gun parts.

| Parameter | Specification Details |

|---|---|

| Machining Processes | 3-axis, 4-axis, and 5-axis CNC milling for complex contours and multi-sided features; CNC turning for symmetrical and threaded components |

| Tight Tolerance Range | ±0.0005″ (12.7 µm) typical; critical features held to ±0.0002″ (5 µm) with process control |

| Surface Finish | 32–125 µin Ra standard; critical mating surfaces polished to 16 µin Ra or better |

| Materials – Metals | Aluminum 7075-T6: High strength-to-weight ratio, excellent for receivers and frames Steel 4140/4340: Used for barrels, bolts, and high-stress parts; supports heat treatment Stainless Steel 17-4 PH: Corrosion resistance with high strength; ideal for precision components |

| Materials – Polymers | ABS (Acrylonitrile Butadiene Styrene): Impact-resistant; suitable for grips, housings, and non-structural parts Nylon (PA6/PA66): High toughness, chemical resistance; used for triggers, safety levers, and buffer components |

| Secondary Operations | Heat treatment (for steel and aluminum), anodizing (Al), passivation (SS), knurling, threading, laser marking |

| Inspection & QA | CMM (Coordinate Measuring Machine), optical comparators, micrometers, and go/no-go gauges for dimensional verification |

| Compliance & Traceability | ITAR registration available; full material and process traceability; first article inspection (FAI) per AS9102 |

All parts are machined from bar stock or forgings using high-rigidity CNC platforms with tool presetting and in-process probing to ensure dimensional accuracy. Multi-axis setups minimize part handling and improve feature alignment. Material selection is driven by functional requirements including wear resistance, weight, and environmental exposure.

From CAD to Part: The Process

Honyo Prototype CNC Gun Parts Manufacturing Process

Honyo Prototype adheres to a stringent, compliance-driven workflow for CNC-machined gun parts, exclusively serving licensed manufacturers and defense contractors under ITAR/EAR regulations. Our process ensures technical precision, regulatory adherence, and accelerated time-to-market.

CAD Upload & Compliance Verification

Clients initiate the process by uploading native CAD files (STEP, IGES, or native formats) via our secure client portal. All submissions undergo immediate automated screening against ITAR/EAR jurisdictional rules. Projects requiring export licenses trigger mandatory documentation validation before progression. Unverified or non-compliant submissions are halted, with dedicated account managers guiding clients through regulatory requirements.

AI-Powered Quoting with Manual Oversight

Our proprietary AI quoting engine analyzes CAD geometry, material specifications, and tolerance requirements to generate instant preliminary cost and lead-time estimates. For gun parts, the AI flags all submissions for mandatory senior engineering review. A certified manufacturing engineer validates material eligibility (e.g., 4140 chrome-moly steel, 7075-T6 aluminum), geometric complexity, and regulatory alignment. Quotes include explicit compliance disclaimers and certification requirements.

DFM Analysis for Critical Components

Design for Manufacturability (DFM) is conducted by engineers with firearms industry expertise. We focus on:

Material grain orientation and heat-treatment sequencing for structural integrity

Tolerance stack-up analysis for safety-critical interfaces (e.g., barrel extensions, bolt lugs)

Machining strategy optimization to prevent stress-induced warpage in thin-walled components

Surface finish validation per military specifications (e.g., MIL-STD-1807 for corrosion resistance)

Clients receive a formal DFM report with actionable recommendations, including suggested tolerance relaxations to reduce costs without compromising function.

Controlled Production Execution

Approved orders move to our dedicated secure machining cell equipped with:

Hardened Haas and DMG MORI 5-axis CNC mills with tool-length compensation and in-process probing

Material traceability via serialized heat-treat certificates (e.g., AMS 6382 for steel)

Real-time SPC monitoring of critical dimensions (e.g., headspace, chamber dimensions)

All operations follow AS9100-rev D procedures, with first-article inspection reports (FAIR) per AS9102. Firearms components undergo 100% dimensional verification of safety-critical features using calibrated CMMs.

Chain-of-Custody Delivery

Finished parts ship in tamper-evident packaging with:

Full material and process traceability documentation (mill certs, heat-treat records, inspection data)

ITAR-compliant shipping manifests and end-user verification

Certificate of Conformance signed by our ITAR Compliance Officer

Logistics partners are pre-vetted for defense industry shipments, with real-time GPS tracking for high-value orders.

Process Performance Metrics

| Phase | Typical Duration | Key Differentiator |

|——-|——————|———————|

| CAD to Quote | 2-4 business hours | AI + human review for regulatory compliance |

| DFM | 24-48 hours | Firearms-specific failure mode analysis |

| Production | 5-15 business days | Dedicated secure cell with zero cross-contamination |

| Delivery | 1-3 days (continental US) | ITAR-certified logistics chain |

This end-to-end process reduces prototyping lead times by 30-50% versus traditional suppliers while maintaining strict adherence to defense manufacturing standards. All gun part projects require executed ITAR agreements prior to CAD upload, ensuring legal and operational integrity from inception.

Start Your Project

Looking for high-precision CNC gun parts manufactured to strict specifications? Honyo Prototype delivers reliable, repeatable results with fast turnaround times. All production is handled in our Shenzhen factory, ensuring tight quality control and efficient global shipping.

Contact Susan Leo today at [email protected] to discuss your component requirements and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.