Contents

Manufacturing Insight: Cnc Grinding Services

Precision CNC Grinding Services for Demanding Manufacturing Applications

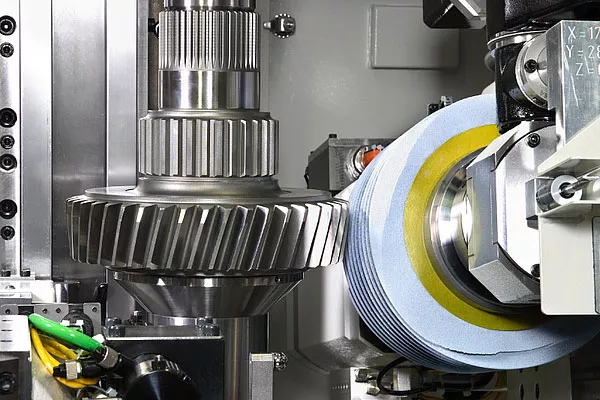

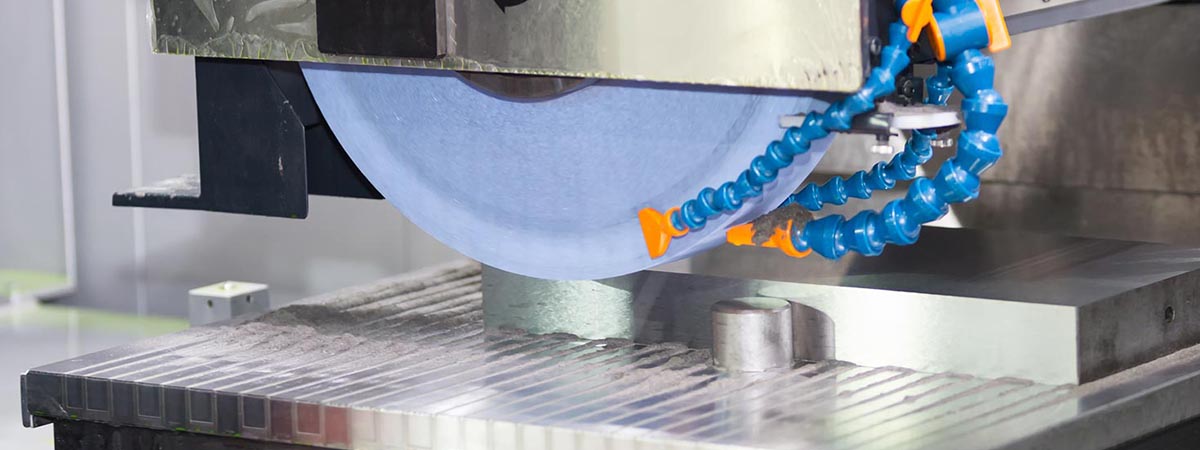

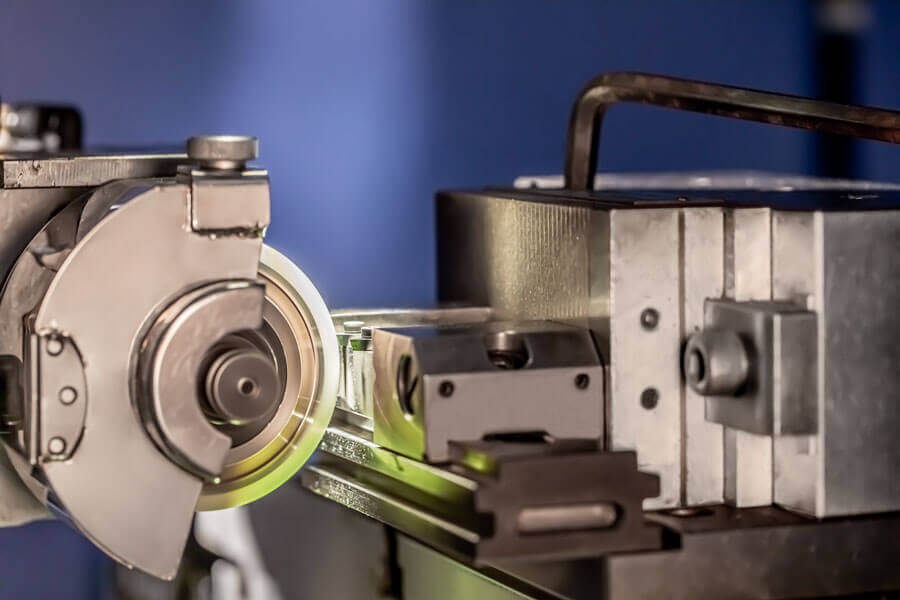

Honyo Prototype delivers advanced CNC grinding solutions engineered to achieve micron-level tolerances and superior surface finishes on complex components. Our specialized capabilities address critical requirements in aerospace, medical device, and industrial machinery sectors where geometric complexity and material integrity are non-negotiable. Utilizing state-of-the-art 5-axis CNC grinders and proprietary process controls, we consistently produce parts with sub-micron accuracy on hardened steels, carbides, ceramics, and exotic alloys—ensuring dimensional stability and fatigue resistance even under extreme operational conditions.

Our integrated CNC machining ecosystem extends beyond grinding to include milling, turning, and multi-axis fabrication, enabling seamless transition from prototype to low-volume production. Every process adheres to ISO 9001:2015 standards with real-time in-process metrology, eliminating rework cycles and accelerating time-to-market. For engineering teams requiring rapid validation, Honyo’s Online Instant Quote platform provides validated pricing and lead times within minutes—simply upload CAD files to receive DFM feedback and actionable cost data without sales intermediaries. This technical precision combined with digital procurement efficiency makes Honyo the strategic partner for mission-critical grinding applications demanding zero-defect outcomes.

Technical Capabilities

CNC grinding services at Honyo Prototype are engineered for high precision and repeatability, supporting complex geometries and tight tolerance requirements across a range of advanced materials. Our capabilities include 3, 4, and 5-axis milling, precision turning, and grinding operations, ensuring superior surface finishes and dimensional accuracy. These processes are ideal for aerospace, medical, automotive, and industrial applications where micron-level tolerances and material integrity are critical.

| Parameter | Specification Details |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning; CNC Grinding |

| Positioning Accuracy | ±0.0025 mm (±0.0001″) |

| Repeatability | ±0.001 mm (±0.00004″) |

| Tolerance Range | As tight as ±0.005 mm (±0.0002″) typical; achievable down to ±0.001 mm with grinding |

| Surface Finish (Ra) | As low as 0.2 µm (8 µin) achievable with fine grinding and polishing |

| Max Work Envelope | 5-Axis: 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in); Turning: Ø500 x 1000 mm (Ø19.7 x 39.4 in) |

| Spindle Speed | Up to 24,000 RPM (high-speed milling); Grinding spindles up to 60,000 RPM |

| Materials Supported | Aluminum (6061, 7075, etc.), Steel (4140, 1018, Stainless 303/316), ABS, Nylon (6, 66) |

| Material Forms | Bar stock, plate, forgings, castings, pre-machined components |

| Coolant Systems | High-pressure through-spindle coolant; flood and mist options |

| Inspection Equipment | CMM, optical comparators, micrometers, surface roughness testers, laser scanners |

| Certifications | ISO 9001:2015 compliant processes; full traceability and first-article inspection (FAI) |

Our 5-axis CNC grinding and milling centers allow simultaneous multi-axis motion for complex contours and undercuts, reducing setup time and improving accuracy. Tight tolerance features such as bores, slots, threads, and sealing surfaces are consistently held within specification. Materials like Aluminum and Steel are processed with optimized toolpaths and coolant strategies to prevent thermal distortion, while engineering plastics such as ABS and Nylon are machined using sharp tooling and controlled feed rates to minimize burring and maintain dimensional stability.

From CAD to Part: The Process

Honyo Prototype delivers precision CNC grinding services through a rigorously controlled digital workflow designed for accuracy, efficiency, and seamless client collaboration. Our process begins with the secure upload of your CAD model to our proprietary platform, where geometric complexity and critical features are immediately analyzed. This initiates our AI-powered quoting system, which rapidly generates a technically validated cost estimate within minutes. Unlike basic automated systems, our AI cross-references historical production data, material properties, machine capability matrices, and real-time shop floor conditions to ensure quote accuracy while flagging potential geometric constraints requiring engineering review.

Following client approval of the quote, the project enters our mandatory Design for Manufacturability (DFM) phase. Honyo’s senior grinding engineers conduct a detailed technical assessment focusing specifically on grindability factors often overlooked in standard machining. This includes evaluating part geometry for wheel access, analyzing thermal distortion risks during grinding, verifying achievable surface finishes against material hardness, and optimizing stock removal sequences. We provide actionable DFM feedback within 24 hours, collaborating with your team to resolve issues like inadequate grinding relief features or unrealistic tolerances before production begins. This proactive step prevents costly iterations and ensures first-time-right outcomes.

Upon DFM sign-off, parts move to production on our dedicated CNC cylindrical, ID, OD, and surface grinding centers. Each job undergoes strict process validation where we establish machine-specific parameters including wheel specification (grit type, bond, grade), coolant composition, infeed rates, and spark-out cycles tailored to your material. Real-time process monitoring with laser micrometers and acoustic emission sensors ensures dimensional stability within micron-level tolerances. Every critical dimension is verified through in-process CMM checks against your print, with full traceability maintained via our digital work order system.

Final inspection confirms all specifications including geometric tolerances, surface roughness, and material integrity before parts proceed to controlled packaging. We utilize climate-controlled shipping with serialized tracking for delivery, accompanied by a comprehensive inspection report documenting every verified dimension and process parameter. This closed-loop workflow eliminates communication gaps and guarantees that complex ground components meet the most stringent aerospace, medical, and semiconductor industry requirements.

Key CNC grinding capabilities and parameters are maintained across our facility as follows:

| Parameter | Capability Range | Measurement Standard |

|---|---|---|

| Tolerance (Diameter) | ±0.00005″ (1.27 µm) typical | ASME Y14.5-2018 |

| Surface Finish (Ra) | 2-16 µin (0.05-0.4 µm) | ISO 4287 |

| Materials Processed | Tool steels, stainless, carbides, ceramics, exotic alloys | ASTM/AMS standards |

| Max Workpiece Diameter | 12″ (305 mm) | Per machine model |

| Max Workpiece Length | 48″ (1219 mm) | Per machine model |

This integrated approach transforms CNC grinding from a standalone operation into a predictable, data-driven manufacturing solution where technical risk is systematically mitigated at each phase. Clients receive not just precision-ground parts, but full process transparency and engineering partnership from digital submission to certified delivery.

Start Your Project

Looking for precision CNC grinding services? Honyo Prototype delivers high-accuracy, repeatable results for demanding manufacturing applications. Our state-of-the-art facility in Shenzhen is equipped with advanced CNC grinding technology and staffed by experienced engineers committed to quality and on-time delivery.

For project inquiries or to request a quote, contact Susan Leo at [email protected]. Let us support your prototyping and production needs with precision engineering you can trust.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.