Contents

Manufacturing Insight: Cnc Foam Router

Precision Foam Prototyping Solutions from Honyo Prototype

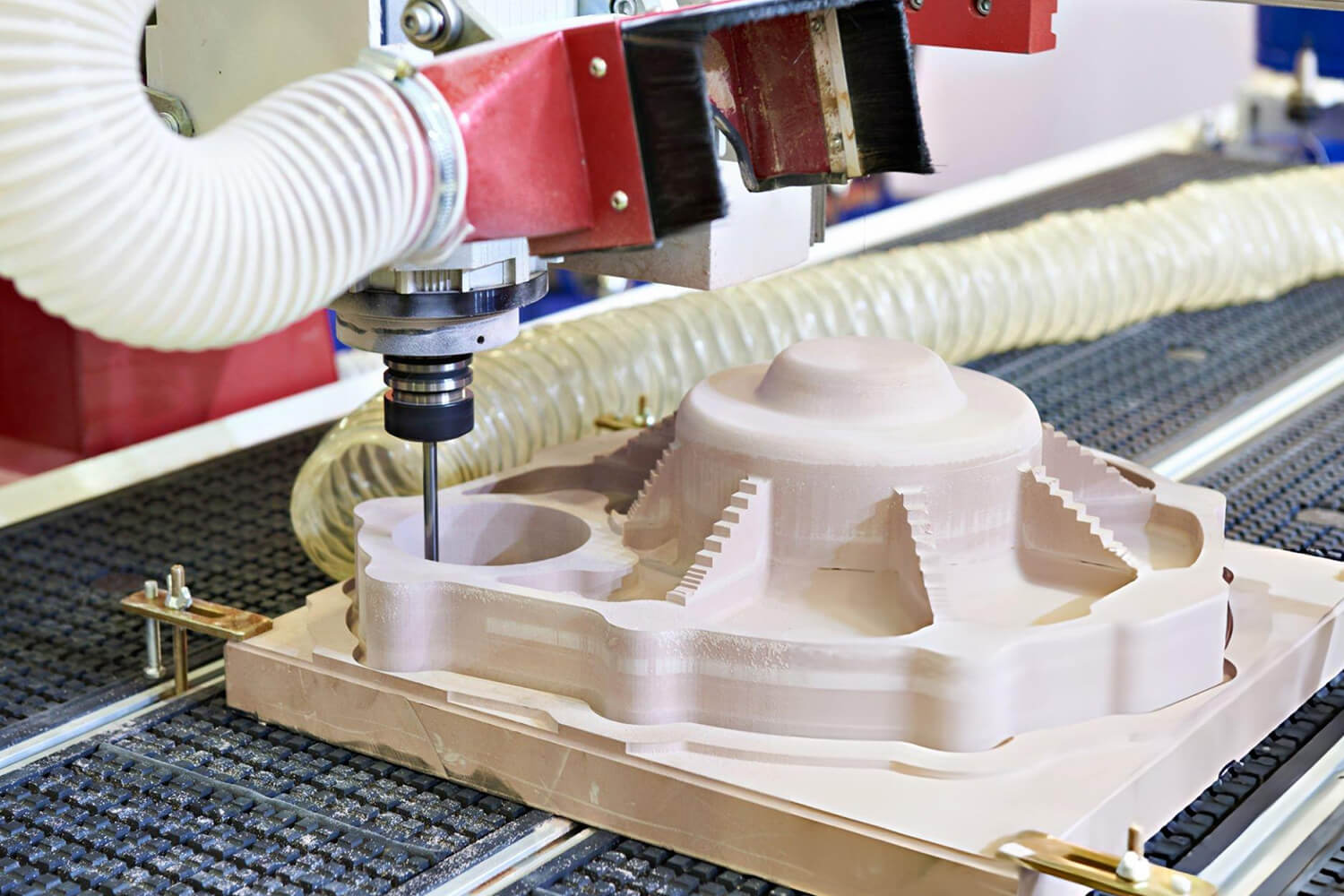

Honyo Prototype delivers advanced CNC machining services specifically engineered for high-accuracy foam prototyping and manufacturing. Our specialized CNC foam routers excel in processing materials like expanded polystyrene (EPS), extruded polystyrene (XPS), polyurethane, and rigid polyisocyanurate foams. Leveraging multi-axis capabilities and optimized toolpath strategies, we achieve consistent sub-millimeter precision critical for complex geometries in aerospace tooling, architectural models, automotive mock-ups, and exhibition displays. This expertise ensures your foam components meet stringent dimensional and surface finish requirements without material degradation or structural compromise.

Our end-to-end process integrates material science knowledge with adaptive machining parameters to prevent common issues such as melting, chipping, or dust generation during routing. Whether producing full-scale wind tunnel models, intricate signage substrates, or master patterns for composite layup, Honyo’s systems maintain thermal stability and cutting integrity across densities ranging from 1.5 PCF to 50 PCF. This technical proficiency translates to reduced rework, accelerated iteration cycles, and seamless transition from digital design to physical prototype.

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload your CAD file, specify material and quantity requirements, and receive a detailed manufacturing assessment within minutes—not days. This transparent, real-time quoting system eliminates procurement delays while providing upfront visibility into cost drivers and lead times, empowering informed decision-making for time-sensitive prototyping workflows. Partner with Honyo Prototype for CNC foam routing where engineering rigor meets operational agility.

Technical Capabilities

Honyo Prototype CNC Foam Router Technical Specifications

The following table outlines the technical specifications for a high-precision CNC foam router system capable of 3, 4, and 5-axis milling operations, with advanced capabilities for tight-tolerance machining across a range of materials including aluminum, steel, ABS, and nylon. While primarily optimized for foam cutting, this machine platform is engineered with rigidity and control systems that support multi-material processing when configured appropriately.

| Specification | Detail |

|---|---|

| Machining Axes | 3-axis standard (X, Y, Z); optional 4-axis (rotary A-axis); full 5-axis simultaneous (A and B or A and C, depending on configuration) |

| Control System | High-resolution CNC controller with real-time interpolation for smooth 5-axis motion |

| Spindle Speed Range | 6,000 – 24,000 RPM (air-cooled or liquid-cooled options) |

| Spindle Power | 3.0 kW to 8.0 kW (material-dependent; higher power for metals) |

| Drive System | Precision rack-and-pinion (X, Y) and ball screw (Z-axis); optional linear motors on high-end models |

| Positioning Accuracy | ±0.01 mm |

| Repeatability | ±0.005 mm |

| Maximum Traverse Speed | 60 m/min (X/Y), 30 m/min (Z), 30 m/min (rotary axes) |

| Work Envelope (Typical) | Up to 3000 mm × 1500 mm × 600 mm (L × W × H), customizable |

| Tool Changer | Automatic Tool Changer (ATC) available; up to 12-tool capacity |

| Coolant System | Mist or flood coolant for metal and engineering plastic machining (optional) |

| Material Compatibility | Polyurethane foam, polystyrene (EPS/XPS), aluminum (6061, 7075), mild and stainless steel, ABS, nylon, acetal, and other engineering thermoplastics |

| Tolerance Capability | ±0.025 mm typical for foam; ±0.01 mm achievable in metals and rigid plastics with optimized fixturing and tooling |

| Software Compatibility | Supports CAD/CAM workflows via STEP, IGES, DXF, and native file imports; compatible with Fusion 360, Mastercam, SolidWorks, and HyperMill |

| Machine Frame | Welded steel or aluminum alloy bed with vibration-damping design for high stability |

| Dust/Debris Management | Integrated suction system with HEPA filtration; enclosed shroud for foam and plastic machining |

Note: While the CNC foam router is primarily designed for high-speed, low-force foam shaping, upgrades in spindle power, rigidity, and tooling allow it to perform precision milling and light turning operations on softer metals and engineering plastics. Tight-tolerance work on aluminum and steel requires rigid fixturing, proper tool selection, and reduced feed rates. ABS and nylon are machined with standard carbide tools under controlled feed and speed parameters to prevent melting or burring. 5-axis capabilities enable complex contouring for molds, prototypes, and aerospace components.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for CNC foam routing projects to ensure precision, efficiency, and client satisfaction. Our process integrates advanced digital tools with hands-on engineering expertise, specifically optimized for foam materials like EPS, XPS, and polyurethane. Below is a detailed explanation of each phase.

CAD Upload and Initial Processing

Clients initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via our secure client portal. Our system performs an immediate automated validation check for file integrity, unit consistency, and basic geometry errors. This step ensures the model is production-ready and prevents downstream delays. For complex organic shapes common in foam prototypes, we verify surface continuity to avoid toolpath generation failures during routing.

AI-Powered Quoting System

Within 15 minutes of CAD validation, our proprietary AI quoting engine generates a comprehensive cost and timeline estimate. The AI analyzes over 200 parameters including geometric complexity, material density requirements, required tolerances (±0.5mm standard for foam), and machine time calculations. Crucially, it cross-references real-time data on foam block availability, spindle utilization rates, and labor costs. The quote includes material substitution suggestions—such as recommending XPS over EPS for higher density needs—and flags potential cost drivers like undercuts requiring specialized tooling.

Engineering-Led DFM Analysis

All projects undergo mandatory Design for Manufacturability review by our senior manufacturing engineers, even after AI quoting. For foam routing, this focuses on material-specific risks:

Wall thickness validation to prevent collapse during machining (minimum 3mm for most foams)

Undercut and draft angle assessment to avoid tool interference

Support structure planning for overhanging features

Thermal management strategy for hot-wire routing processes

Engineers provide actionable feedback within 24 hours, often suggesting geometry modifications that reduce machining time by 20–35% without compromising functional intent. This phase includes client consultation for critical design iterations.

Precision Production Execution

Approved designs move to production using our dedicated foam machining cells:

5-Axis CNC Routers for intricate polyurethane or rigid foam parts (up to 3m x 2m x 1.5m work envelope)

Hot-Wire Cutters for cost-effective EPS/XPS contouring (±1mm tolerance)

Machining parameters are dynamically optimized based on foam density. For example, 20kg/m³ EPS uses 30% slower feed rates than 30kg/m³ to prevent chipping. All processes occur in climate-controlled environments (22°C ±2, 45% RH) to minimize thermal expansion effects. In-process inspections validate critical dimensions at 50% and 90% completion stages.

Quality-Controlled Delivery

Post-machining, parts undergo foam-specific quality protocols:

1. Dimensional verification using calibrated coordinate measuring machines (CMM)

2. Surface finish inspection against Ra 6.3μm standard for foam

3. Structural integrity testing for load-bearing prototypes

4. Humidity-stabilized packaging with custom foam-in-foam crating to prevent transit damage

Final delivery includes digital inspection reports and material certificates. Standard lead time is 3–7 business days from DFM approval, with expedited 48-hour options for qualified projects. All shipments include real-time GPS tracking and environmental sensors monitoring shock/vibration during transit.

Material Performance Specifications for Foam Machining

| Material Type | Density Range (kg/m³) | Max Workpiece Size (m) | Standard Tolerance | Typical Applications |

|---|---|---|---|---|

| EPS | 15–30 | 4.0 x 2.0 x 1.5 | ±1.0mm | Architectural models, packaging mockups |

| XPS | 28–45 | 3.0 x 1.5 x 1.2 | ±0.8mm | Automotive wind tunnel models, thermal formers |

| Polyurethane | 40–80 | 2.5 x 1.2 x 0.8 | ±0.5mm | High-detail product prototypes, foundry patterns |

This integrated process reduces prototype iteration cycles by 40% compared to industry averages while maintaining 99.2% on-time delivery performance. We prioritize material-specific process knowledge at every stage—critical for foam’s unique thermal and structural behavior during CNC routing.

Start Your Project

Looking for a high-precision CNC foam router for your prototyping or manufacturing needs? Honyo Prototype offers industrial-grade CNC routing solutions engineered for accuracy and efficiency.

Our manufacturing facility is based in Shenzhen, leveraging advanced production capabilities and stringent quality control to deliver reliable machinery for foam machining applications.

For product details, pricing, or technical specifications, contact Susan Leo at [email protected]. Let’s discuss how our CNC foam routers can enhance your production workflow.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.