Introduction: Navigating the Global Market for cnc files for sale

In today’s fast-paced manufacturing landscape, sourcing high-quality CNC files for sale can be a daunting challenge for international B2B buyers. With the diverse range of applications—from woodworking to metal fabrication—identifying the right suppliers and file types to match specific project needs is critical. This comprehensive guide delves into the nuances of the global CNC files market, equipping buyers with insights into various types of files, their applications, and essential factors for supplier vetting.

Buyers from regions such as Africa, South America, the Middle East, and Europe (including markets like Brazil and Nigeria) will benefit from understanding the quality, compatibility, and licensing options available for CNC files. With a focus on measurable outcomes, this resource not only highlights cost considerations but also provides actionable strategies for making informed purchasing decisions.

As the industry continues to evolve, staying abreast of technological advancements and vendor reliability is essential to thrive in competitive markets. By leveraging the insights shared in this guide, businesses can effectively navigate the complexities of sourcing CNC files, ensuring they invest wisely and maximize their return on investment in any project. Explore the world of CNC files to streamline operations and elevate project outcomes.

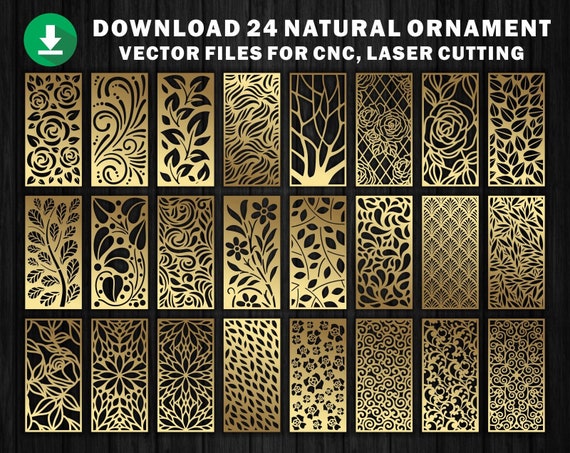

Understanding cnc files for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| STL Files | Primarily for 3D printing, offers intricate designs and geometries | Product prototyping, intricate designs | Pros: Highly detailed, suitable for 3D modeling. Cons: Limited to specific manufacturing methods. |

| SVG Files | Scalable vector graphics; easily resized without quality loss | Sign-making, decorative items | Pros: Versatile, compatible with various machines. Cons: Limited detail for 3D applications. |

| DXF Files | Widely recognized CAD format, good for 2D and 3D applications | Engineering, architecture | Pros: Industry standard, compatible with many software. Cons: May require additional training to optimize use. |

| CRV Files | Specific to VCarve Pro, includes detailed parameters for CNC cutting | Custom furniture, inlay designs | Pros: Tailor-made for CNC machines; often easier to use. Cons: May not be compatible with all software. |

| Project Bundles | Collections of multiple designs aimed at specific themes or projects | Bulk production, educational purposes | Pros: Cost-effective, comprehensive solutions. Cons: May include designs not immediately useful for all buyers. |

What Are the Key Characteristics of STL Files for CNC?

STL files are essential for 3D printing, representing detailed solid models. They are ideal for businesses involved in product design and prototyping, where high fidelity and complexity are crucial. Buyers should consider the compatibility of STL files with their printing technology and the level of detail required for their projects, ensuring they match their CNC capabilities for precise output.

How Do SVG Files Benefit B2B Applications?

SVG files offer scalable vector graphics, making them versatile for both 2D and low-detail 3D designs. They are commonly used in sign-making and decorative arts, appealing to markets focusing on visual branding. When purchasing SVG files, B2B buyers should assess compatibility with their machinery, particularly for cutting tasks, and consider the range of sizes they may need.

Why Are DXF Files Considered Industry Standards?

DXF files are widely recognized in various industries for their adaptability in CAD applications. Their ability to support both 2D and 3D designs makes them ideal for engineering and architectural projects. When selecting DXF files, B2B buyers should ensure they understand how to utilize these files within their existing software solutions, factoring in any required training or support.

Why Choose CRV Files for CNC Machining?

CRV files are specifically designed for VCarve Pro users, complete with detailed parameters that aid in CNC cutting. These files are excellent for creating bespoke furniture pieces and intricate inlaid designs. Buyers interested in CRV files should evaluate their CNC machine’s compatibility with this file type, as misuse can lead to inefficiencies or project failures.

What Are the Advantages of Purchasing Project Bundles?

Project bundles offer collections of files aligned with specific themes, allowing businesses to execute bulk production or educational initiatives efficiently. They provide a cost-effective way to access a variety of designs. However, B2B buyers should examine the content of these bundles to ensure they meet their specific needs and prevent unwarranted purchases of less relevant designs.

Key Industrial Applications of cnc files for sale

| Industry/Sector | Specific Application of cnc files for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture designs using CAD files | Enhanced design versatility and reduced time to market | Look for files compatible with existing machinery; verify licensing options. |

| Architectural Signage | Creation of architectural signs and displays | Ability to create intricate designs that enhance brand visibility | Ensure file formats match CNC router capabilities; consider regional regulations. |

| Crafting and DIY | Hobbyist projects for local artisans | Access to unique designs that enhance product offerings | Evaluate material compatibility and design flexibility; check user reviews. |

| Automotive Parts | Production of custom automotive components | Optimized production processes and cost savings on custom parts | Confirm specifications match machinery; assess supplier support options. |

| Electronics Enclosures | Design and cutting of electrical housings | Improved aesthetics and functionality of electronic products | Ensure accuracy in file details to avoid production defects; consider international standards. |

How Are CNC Files Beneficial for Furniture Manufacturing?

In the furniture manufacturing industry, CNC files play a vital role by providing precise training outlines and detailed designs that save time and enhance creativity. Companies can utilize these digital files for items such as custom tables, chairs, and cabinetry, resulting in unique offerings that attract discerning customers. African and South American manufacturers must prioritize compatibility with their CNC machines and consider local licensing requirements to enhance their market reach effectively.

What is the Role of CNC Files in Architectural Signage?

Architectural signage utilizes CNC files to produce tailored signs that blend functionality with aesthetics. These files enable businesses to create customized, intricate designs that improve brand representation and customer engagement. Middle Eastern and European firms should ensure that the files are compliant with regional regulations and formats compatible with local CNC equipment to effectively cater to local markets.

How Do CNC Files Support Crafting and DIY Industries?

In the crafting and DIY sectors, CNC files offer hobbyists an array of unique design opportunities for local artisans. These files empower users to bring their artistic visions to life, resulting in distinctive products that stand out in competitive markets. Buyers in regions like Nigeria should focus on material compatibility and versatility while also considering community support and resources to maximize the benefits of their CNC investments.

Why are CNC Files Important for Automotive Parts Production?

CNC files are crucial for producing custom automotive components, enabling manufacturers to streamline operations and reduce lead times. They aid in creating precise parts that meet industry standards, ultimately driving down costs and improving product quality. For international buyers, particularly in South America, it’s important to ensure that files match the machinery specifications and that aftermarket support is readily available.

How Can Electronics Enclosures Benefit From CNC Files?

In the electronics industry, utilizing CNC files for designing enclosures enhances both aesthetics and functionality. These files enable companies to produce housings that are not only visually appealing but also provide robust protection for sensitive components. European firms must focus on accurate file specifications and compliance with international standards to avoid production errors and facilitate seamless integration into larger assemblies.

3 Common User Pain Points for ‘cnc files for sale’ & Their Solutions

Scenario 1: Navigating Compatibility Issues with CNC Files

The Problem:

For international B2B buyers, especially those in regions with varying technological capabilities, one of the major challenges is ensuring compatibility of CNC files with existing machinery and software. Different manufacturers use distinct CNC standards, file formats, and software versions. A buyer might purchase a cutting file designed in VCarve Pro, only to find that their CNC machine is incompatible because it runs an outdated version or supports only specific file formats like STL or DXF. This incompatibility not only creates frustration but can lead to costly delays in production.

The Solution:

To mitigate compatibility issues, buyers should thoroughly familiarize themselves with their CNC equipment’s specifications and capabilities before sourcing files. It’s advisable to purchase CNC files from vendors that provide multiple file formats, such as DXF, AI, and SVG, as this ensures flexibility in terms of software compatibility. When reviewing potential purchases, check for clear documentation that specifies the file’s required software versions and settings such as feed rate and plunge rate. Additionally, consider engaging with suppliers who offer pre-sales consultations to assess compatibility, as well as those who provide customer support for any queries regarding file utilization.

Scenario 2: Understanding Licensing Restrictions and Usage Rights

The Problem:

Another common issue for B2B buyers entering the CNC files market is the complexity surrounding licensing agreements. Buyers may discover that certain files come with restrictions on resale or usage, which can limit their ability to incorporate purchased designs into marketable products. For instance, a company seeking to manufacture customized items using CNC files might be hindered by strict licensing terms that do not allow for commercial use without an additional fee or specific license type, leading to unexpected costs and planning complications.

The Solution:

Before completing a purchase, buyers must carefully review the licensing agreements associated with any CNC files of interest. It is beneficial to look for vendors that offer transparent pricing models, such as tiered options based on the intended use—personal vs. commercial licenses. Engage suppliers that provide clear guidelines on what specific uses are permitted or restricted. For businesses planning to resell products made from these designs, consider opting for extended commercial licenses when available. Additionally, joining membership programs or platforms that offer comprehensive rights for a subscription fee can provide long-term access to high-quality files without worrying about individual licensing restrictions.

Scenario 3: Dealing with Quality Assurance and Design Consistency

The Problem:

Many B2B buyers experience frustration over design quality and consistency when purchasing CNC files. Due to the variability in seller expertise, some designs may not meet the necessary standards for precision or durability, resulting in products that are subpar or unusable. This inconsistency can harm a business’s reputation if they rely on third-party files for essential projects, particularly when delivering on client expectations is critical.

The Solution:

To ensure high-quality designs, buyers should prioritize purchasing from well-established sellers with verified reviews and a good reputation in the CNC community. Look for suppliers that provide detailed descriptions, sample outputs, and real-life client testimonials. Buyers can also take advantage of online forums or user groups focused on CNC businesses to seek recommendations for trusted CNC file vendors. It may also be wise to start with smaller sample purchases to assess the quality before committing to larger orders. Additionally, suppliers who offer file guarantees or customer support can provide peace of mind, ensuring that buyers can address any discrepancies quickly and efficiently, thus maintaining their production flow and quality standards.

Strategic Material Selection Guide for cnc files for sale

When selecting materials for CNC files tailored for B2B applications, understanding the properties of common materials is crucial for ensuring optimal product performance and market suitability. This analysis focuses on wood, acrylic, aluminum, and MDF, examining their distinct characteristics and implications for buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Wood for CNC Files?

Wood remains a popular choice for CNC machining due to its versatility and aesthetic appeal. Key properties include excellent machinability and a natural finish that enhances visual appeal. Regarding temperature and pressure ratings, wood performs adequately under normal conditions but can expand or contract with changes in humidity.

Pros and Cons

The primary advantage of wood is its availability and lower cost compared to metals. It can be easily sourced and customized. However, wood’s durability is contingent on its type; hardwoods like oak outperform softer woods in strength and longevity. Additionally, wood can be susceptible to moisture, resulting in warping or changes in dimension. This is particularly salient for climates with high humidity, necessitating specific treatments or sealants.

For international buyers, compliance with various wood regulations related to harvesting and treatment is important. Standards like the Forestry Stewardship Council (FSC) certification should be considered to ensure sustainable sourcing.

How Does Acrylic Perform in CNC Applications?

Acrylic is known for its clarity and ability to mimic glass, making it a favored choice for applications requiring visual appeal. Key properties include high impact resistance and a low weight compared to glass. It offers a smooth finish that can enhance product quality.

Pros and Cons

The primary advantage of acrylic is its aesthetic versatility and ease of manipulation. It can be cut, engraved, and formed with relative ease, opening a myriad of applications from signage to decorative elements. However, while acrylic is tough, it is more prone to scratching than glass, and the heat generated during cutting can lead to melted edges if not managed correctly.

Buyers should consider the specific regulations concerning the use of acrylic in their respective markets. Since acrylic is often subject to plastics regulations, compliance with regional standards such as ASTM or REACH may be necessary.

What Unique Advantages Does Aluminum Offer in CNC Machining?

Aluminum is a lightweight yet durable metal widely used in CNC projects for its strength-to-weight ratio. With excellent corrosion resistance and good thermal and electrical conductivity, aluminum is ideal for applications requiring stability under varying temperature and pressure conditions.

Pros and Cons

A key advantage is that aluminum allows for intricate designs while maintaining structural integrity. It’s also recyclable, which is a pivotal aspect for sustainability-focused companies. However, the cost of aluminum can be higher than other materials, and the complexities involved in machining it may necessitate specialized tools and processes, increasing overall manufacturing complexity.

For international B2B buyers, not only must standards like ASTM or JIS be adhered to, but there’s also the necessity to evaluate the availability of aluminum in local markets and potential import tariffs.

Why Is MDF Considered for CNC Applications?

Medium-Density Fiberboard (MDF) is known for being smooth and uniform, making it particularly well-suited for intricate cuts. With good machinability and a smooth finish, MDF is often chosen for prototype designs or furniture applications.

Pros and Cons

MDF is typically more affordable than solid wood and is easy to paint and glue, which appeals to both manufacturers and end-users. However, it has lower moisture resistance and can swell when exposed to excess humidity, limiting its use in certain environments. Also, MDF can be heavier than wood, impacting shipping costs for international buyers.

It’s crucial for buyers from regions with specific emissions regulations to consider the formaldehyde levels in MDF products. Compliance with standards such as E0 or E1 can help ensure that products are suitable for their market’s environmental compliance needs.

Summary Table: Material Comparison for CNC Files

| Material | Typical Use Case for cnc files for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture items, decorative products | Natural aesthetics and easy sourcing | Susceptible to moisture and warping | Medium |

| Acrylic | Signage, decorative elements, protective covers | Aesthetic versatility and ease of manipulation | Prone to scratching and melting during cuts | Medium |

| Aluminum | Structural components, intricate designs | Lightweight and excellent corrosion resistance | Higher cost and more complex machining | High |

| MDF | Prototyping and furniture applications | Smooth finish and affordability | Poor moisture resistance and heavy weight | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for cnc files for sale

What are the Main Stages in the Manufacturing Process of CNC Files?

The manufacturing of CNC files for sale involves several key stages, each essential for ensuring quality and usability. The stages include material preparation, design creation, fabrication execution, and final adjustments. The process starts by refining raw data inputs into manageable design formats such as STL, SVG, and DXF. Following this, designers create files using software like VCarve or Fusion 360, translating ideas into ready-to-cut files.

In the fabrication stage, the files undergo precise calculations and settings adjustments to align with machine capabilities, including feed rate and spindle speed. This meticulous preparation is crucial to ensure that the design translates efficiently to the machinery. After the initial cutting process, files may be subjected to final adjustments, refining intricate details that enhance the overall quality of the end product.

How are Quality Control Measures Implemented During CNC File Production?

Quality assurance in the production of CNC files is paramount, especially for B2B buyers who depend on precision and reliability. Adhering to international standards, such as ISO 9001, is essential in maintaining a structured approach to quality management. Notably, these standards emphasize a framework for continuous improvement, which is crucial when producing files for diverse applications.

Quality control begins with Incoming Quality Control (IQC), where initial checks are performed on inputs, such as software and design scalability. Throughout the production phases, In-Process Quality Control (IPQC) checkpoints ensure that output consistently meets design specifications. This involves using simulation software to verify that the machined part will match the intended design, thereby catching potential errors early.

Finally, Final Quality Control (FQC) occurs before files are delivered. This step guarantees that files are operational in the intended CNC equipment and confirms compatibility with various software applications.

What are Common Testing Methods Used in CNC File Quality Assurance?

Common testing methods involve both qualitative assessments and quantitative measurements. Functional testing ensures the files produce the expected outputs when used in CNC machines. Simulations that mimic actual machining conditions can also be performed. This helps verify the efficiency of feed speeds and tool paths, confirming that the output aligns with predefined parameters.

Moreover, some suppliers perform stress testing on designs, subjecting them to varying operational conditions to determine durability and precision under extreme scenarios. Documentation of these tests provides B2B buyers with invaluable insight into the reliability of the files they are purchasing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those operating in areas with varying standards, it is crucial to establish trust in suppliers’ quality control processes. Requesting Comprehensive Quality Assurance documentation is a straightforward first step; suppliers should provide insight into their QC processes, including IQC, IPQC, and FQC reports.

Audits are an effective way to assess supplier quality firsthand. Many suppliers are open to undergoing third-party audits, which can provide thorough evaluations of their production processes against established industry benchmarks. Buyers should inquire about past audits and certifications, understanding how suppliers maintain compliance with international certifications such as ISO and CE.

Furthermore, establishing communication channels for ongoing quality updates can greatly strengthen buyer-supplier relationships. Regular check-ins and the sharing of performance data or incident reports allow for continuous feedback loops, enabling both parties to improve quality over time.

How Do Certification Nuances Affect International B2B Buyers?

Different regions have distinct regulatory standards, which can complicate the purchasing decision for international buyers. For example, European Union members are governed by CE marking regulations, while many African and South American countries recognize ANSI (American National Standards Institute) as a benchmark. Understanding these nuances allows buyers to align supplier offerings with local regulations.

Buyers should also consider the implications of certifications on delivery timelines and costs. Suppliers with reputable certifications may cost more but offer better reliability and after-sales services. Engaging in comprehensive discussions about these certifications ensures that buyers are making informed decisions that align with their operational compliances and business objectives.

How Should Buyers Approach Sourcing CNC Files Internationally?

When sourcing CNC files, particularly from suppliers located in different continents, several best practices can streamline the process. Leverage online research to identify suppliers who have a proven track record and positive reviews from other B2B buyers. Platforms dedicated to CNC products can be valuable resources.

Additionally, participating in forums and industry groups can provide insights into reliable suppliers and emerging trends. Networking with other businesses in similar markets can yield introductions to vetted suppliers who understand the local climate and regional demands.

Establish clear expectations regarding quality and delivery from the outset. Providing comprehensive specifications and project requirements to suppliers fosters a transparent partnership. Ultimately, fostering long-term relationships with suppliers who prioritize quality assurance will lead to a reliable pipeline of CNC files that meet the varying needs of diverse industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc files for sale’

This guide provides a strategic roadmap for B2B buyers looking to procure CNC files effectively. Navigating the marketplace for CNC designs can be complex, especially for international buyers across diverse regions such as Africa, South America, the Middle East, and Europe. This checklist outlines essential steps to ensure a smooth sourcing process that aligns with your technical and operational needs.

Step 1: Identify Your Needs and Applications

Begin by clearly defining the types of CNC files you require and how they will be used in your operations.

– Consider the materials you will work with (wood, metal, plastic) and the specific applications (furniture, decorative items, industrial parts).

– Understanding your needs will help you filter out irrelevant options and focus on files that enhance your productivity.

Step 2: Specify File Formats and Compatibility

CNC files come in various formats like STL, SVG, DXF, and CRV; it is crucial to determine which formats are compatible with your CNC machinery and software.

– Verify whether your current setup can handle these file types effectively.

– This ensures you do not invest in files that you cannot operationalize, saving both time and resources.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet your potential CNC file suppliers to ensure they meet industry standards and can provide reliable products.

– Request samples of previous work or client testimonials to gauge quality and reliability.

– It’s also beneficial to check if they offer customer support for troubleshooting, which can be invaluable for resolving issues quickly.

Step 4: Review Licensing Agreements

Pay special attention to the licensing agreements attached to the CNC files.

– Understand the restrictions imposed, especially concerning resale and product modifications.

– Ask about extended commercial licenses if you plan to sell products made from these files, ensuring you maintain legal compliance in your operations.

Step 5: Check for Updates and New Designs

CNC design is a dynamic field with new innovations and patterns emerging regularly.

– Subscribe to newsletters or monitor suppliers’ websites for updates on new designs.

– Regularly refreshing your project files can keep your offerings innovative and in line with market trends.

Step 6: Understand Support and After-sales Services

Evaluate what kind of support is available post-purchase.

– Determine if the supplier provides installation assistance, design modifications, or troubleshooting support.

– Strong after-sales support can significantly affect your overall satisfaction and project success.

Step 7: Place Test Orders Before Bulk Purchases

Finally, do not commit to large orders without placing a test order first.

– This allows you to assess the quality and suitability of the CNC files in a real-world scenario without overcommitting financially.

– Once you’re satisfied, you can confidently proceed with larger orders or explore ongoing project subscriptions.

By following these steps, B2B buyers can streamline the sourcing process for CNC files and enhance their production capabilities effectively. clear focus on quality, compatibility, and supplier reliability can lead to successful project outcomes.

Comprehensive Cost and Pricing Analysis for cnc files for sale Sourcing

In analyzing the B2B cost structure and pricing for CNC files for sale, it’s crucial to understand the various components that contribute to the total costs involved in sourcing these digital assets.

What Are the Key Cost Components for CNC Files?

-

Materials & Tools: Although digital files have a minimal material cost, the software and tools used to create these files (such as CAD and CAM systems) are significant investments. Firms typically leverage high-quality software versions like VCarve Pro, which can cost users anywhere between a few hundred to several thousand USD for licenses.

-

Labor Costs: Talent acquisition in this niche often includes experienced designers and engineers. Salaries can vary widely based on region and expertise. In markets like Europe, North America, or regions with a strong tech industry, expect higher labor costs. Conversely, sourcing from regions like Africa or South America might offer cost advantages but could also have implications for quality.

-

Manufacturing Overhead: This includes overhead costs tied to operational efficiency. Companies often factor in electricity, maintenance of machinery, and workspace rental. Although these are more relevant for physical product manufacturing, for CNC file creators, it includes server storage and digital marketing costs.

-

Quality Control (QC): Ensuring that the files meet professional standards before sale is paramount. This could mean investing in additional quality checks, beta testing with CNC machines, or user trials, which can further influence the production costs.

-

Logistics: Though not applicable in the traditional sense for digital products, logistics here pertains to the distribution of files. Efficient website hosting and cybersecurity measures are necessary to ensure safe and reliable file transfers, impacting the overall cost structure.

-

Profit Margins: Depending on the competitive landscape, profit margins on CNC files can vary. Creators may set lower margins to penetrate new markets or maintain higher prices based on exclusivity and the uniqueness of designs.

What Influences CNC File Pricing?

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases, encouraging B2B buyers to invest in larger volumes. Understanding supplier pricing tiers can yield significant cost savings.

-

Customization and Specifications: Highly tailored CNC designs or specific formats (like SVG, AI, DXF) may come with a premium price. Custom project requirements can lead to higher costs due to additional design time and technical expertise.

-

Quality Certifications: Files that come with certifications or proven test results for usability and quality command higher prices. Purchasing from reputable sources that guarantee file performance can be beneficial for buyers seeking reliability.

-

Supplier Reputation & Support: When choosing suppliers, those that offer extended customer service or technical support may have higher pricing structures but provide long-term value, particularly for B2B buyers navigating complex CNC projects.

-

Incoterms: Although mainly relevant in traditional trade contexts, understanding delivery terms for any accompanying services or materials from suppliers can streamline procurement processes and minimize unexpected costs.

What Are Effective Buyer Tips for Cost Efficiency in CNC Files?

-

Negotiate: Given the variability in pricing, engaging in discussions about customization, bulk orders, or ongoing contracts can yield better rates. Establish long-term relationships with suppliers for added loyalty incentives.

-

Consider Total Cost of Ownership (TCO): Analyze not just upfront costs but also factors like potential downtime associated with poor-quality files or the need for additional alterations post-purchase.

-

Be Aware of Regional Pricing Nuances: International buyers, especially from Africa or South America, should take exchange rates, potential tariffs, and local demand into account, as these can significantly affect the final purchase price.

-

Request Trials or Samples: Before making significant purchases, requesting trial files or sample projects can help assess quality without committing to larger investments.

In summary, understanding the cost structure and pricing nuances associated with CNC files while utilizing effective negotiation strategies can empower B2B buyers, ensuring smart and value-driven purchasing decisions.

Alternatives Analysis: Comparing cnc files for sale With Other Solutions

Introduction to Alternative Solutions for CNC Files

In the world of CNC machining and design, buyers often seek efficient and effective ways to create custom products. While purchasing CNC files for sale offers a straightforward approach to accessing ready-made designs, alternative solutions may also provide distinct advantages tailored to specific business needs. This analysis will explore and compare CNC files against alternative design methods to help B2B buyers make informed purchasing decisions.

Comparison Table

| Comparison Aspect | CNC Files For Sale | Custom Design Services | DIY Design Software |

|---|---|---|---|

| Performance | High-quality, standardized designs | Tailored to specific needs | Variable, depends on user skill |

| Cost | Usually low to moderate upfront costs | Higher costs, depending on complexity | One-time purchase, variable costs |

| Ease of Implementation | Quick downloads, immediate usage possible | Time-consuming, requires consultation | Learning curve involved |

| Maintenance | Minimal, updates depend on the provider | Ongoing support from designer | Requires personal upkeep |

| Best Use Case | Quick projects requiring a variety of designs | Complex projects needing customization | Personalized designs at an affordable price |

What Are Custom Design Services and Their Benefits?

Custom design services involve hiring professionals or design firms to create CNC files tailored specifically to a client’s requirements. This method boasts the highest level of customization, catering to unique business projects, from specific dimensions to specialized functionalities. The main advantage is that you gain designs perfectly aligned with your specifications. However, this approach typically incurs higher costs and longer lead times, necessitating careful consideration.

How Does DIY Design Software Compare to CNC Files?

DIY design software enables users to create their CNC designs using applications such as VCarve or Fusion 360. This provides maximum flexibility, allowing for designs to be adjusted in real-time based on business needs. The cost can be lower than hiring professionals, especially for businesses with ongoing design requirements. However, a steep learning curve may deter some users, potentially leading to variations in design quality based on the user’s skill level.

Conclusion: Choosing the Right CNC Solution for Your Business Needs

Selecting the right solution for accessing CNC designs hinges on balancing several factors, including project complexity, desired customization, and budget constraints. For businesses requiring quick access to a wide range of designs, purchasing CNC files for sale is often the most efficient choice. In contrast, custom design services are ideal for those needing highly specialized solutions. DIY software provides an excellent option for businesses with internal design capabilities, offering the freedom to create and modify designs at their own pace.

By defining project requirements and evaluating the pros and cons of each alternative, B2B buyers can confidently choose the approach that best aligns with their operational goals and market strategies.

Essential Technical Properties and Trade Terminology for cnc files for sale

What are the essential technical specifications for CNC files?

When investing in CNC files for sale, understanding key technical specifications can be crucial for ensuring compatibility and performance in your projects. Below are several critical properties relevant to B2B buyers:

-

File Format: The choice of file format—such as STL, DXF, or SVG—is paramount as different CNC machines require specific formats. Ensure your cutting equipment supports the file format before purchase to avoid downstream complications.

-

Parameters for Cutting: Specifications like feed rate, spindle speed, and plunge rate are vital. These parameters determine the effectiveness of the Machining process and can affect the quality of the end product. Adhering to the recommended parameters can prevent tooling damage and unnecessary waste.

-

Material Compatibility: CNC files are generally created to work with specific materials, such as hardwood, plastic, or metal. Knowing the material you plan to use will help you select CNC files that deliver optimal cutting results, ensuring durability and adherence to design specifications.

-

Tolerance Levels: Tolerance refers to the permissible limit of variation in a physical dimension. Precise tolerances are critical, particularly for applications requiring close fits or assemblies. Understanding the tolerance specified in CNC files ensures that your final products meet required standards, which is particularly important in industries like aerospace or automotive.

Which trade terms should B2B buyers understand when dealing with CNC files?

Familiarity with industry jargon can streamline negotiations and procurement processes. Here are some essential terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer): This refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding this term is essential when dealing with CNC file purchases, as it can denote the source (quality) of the design files being sold.

-

MOQ (Minimum Order Quantity): This is the smallest quantity that a supplier is willing to sell in a single order. Knowing the MOQ can help you plan purchases effectively, particularly in bulk arrangements that might offer discounted pricing.

-

RFQ (Request for Quotation): An RFQ is a business process in which a buyer solicits price offers from potential suppliers. When purchasing CNC files, sending out RFQs can help identify competitive pricing and terms, ultimately leading to better procurement decisions.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce (ICC), which clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps to clarify issues like liability, shipping costs, and delivery times, reducing the risk of miscommunication during transactions.

-

Licensing Terms: Many CNC file vendors offer different licensing agreements, such as personal use, commercial use, or extended commercial licenses. Knowing the differences allows you to select a licensing option that fits your business model, preventing potential legal complications down the line.

In summary, grasping these essential technical properties and trade terminology is invaluable for B2B buyers in the CNC file market. These insights not only facilitate more successful transactions but also ensure your projects are executed efficiently and to a high standard.

Navigating Market Dynamics and Sourcing Trends in the cnc files for sale Sector

What Are the Current Trends Influencing the CNC Files for Sale Market?

In the rapidly evolving landscape of CNC files for sale, several key market drivers and trends are emerging. Digital transformation across industries is propelling the demand for precision manufacturing and customized solutions. Businesses are increasingly seeking CNC files that streamline production processes and enhance efficiency. High-quality, ready-made files that cater to various applications—from woodworking to metalworking—are becoming essential as firms aim to reduce lead times and increase agility.

Among the current trends, the rise of subscription models is noteworthy. Buyers are increasingly interested in platforms that offer a variety of design files for a monthly fee, enabling consistent access to updated materials without large upfront investments. Additionally, cloud-based design software integrations are facilitating easier collaboration among teams, making it simpler for international buyers, especially from regions like Africa and South America, to access and utilize CNC files effectively.

Moreover, there’s a noticeable uptick in the demand for localized designs. B2B buyers are searching for CNC files that resonate culturally or regionally, accommodating specific tastes and preferences. This shift is particularly relevant for buyers operating in diverse markets in Brazil or Nigeria, where aesthetic values and design inspirations vary significantly.

How Are Sustainability and Ethical Sourcing Impacting the CNC Files Market?

With global awareness about environmental sustainability at an all-time high, the CNC files for sale sector is positioned to play a role in promoting eco-friendly practices. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainability, which is becoming a significant consideration in purchasing decisions. The environmental impact of material sourcing for CNC file projects is under scrutiny; manufacturers are encouraged to utilize sustainable woods, recycled metals, and biodegradable materials in their creations to minimize waste.

Ethical sourcing practices are becoming paramount. Buyers are looking for manufacturers who not only provide high-quality files but also ensure that their production processes are humane and fair. Suppliers that achieve certifications for sustainable practices, such as FSC (Forest Stewardship Council) for wood sourcing or engage in responsible waste management, are gaining favor among international buyers. This trend is particularly pivotal in regions that are eco-conscious, such as parts of Europe, where heightened regulatory standards are actively promoting responsible sourcing.

Furthermore, buyers are seeking CNC files that enable them to contribute to sustainability efforts. This includes designs that reduce material waste or enable the upcycling of scrap materials, reinforcing the connection between technology and environmental responsibility.

How Has the CNC Files Sector Evolved Over Time?

The CNC files for sale market has undergone significant transformations over the last few decades. Originally dominated by bespoke design and manual processes, the advent of digital technologies has reshaped the landscape, making CNC file availability more widespread and accessible. The introduction of CAD software revolutionized design capabilities, enhancing precision and allowing for intricate designs to be easily created and shared.

In the initial years, businesses relied heavily on specific software for CNC equipment, limiting file interchangeability. However, advancements in file formats, like SVG and DXF, have broadened their compatibility across various machines and software, creating a more inclusive environment for creators and manufacturers alike. As global needs evolve, the industry is seeing a convergence of craftsmanship and technology, emphasizing efficiency while accommodating a diverse range of creative insights. This evolution has stimulated international trade and collaboration, facilitating the global exchange of ideas and designs that cater to an array of cultural and regional preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc files for sale

-

How do I ensure compatibility of CNC files with my existing machines?

It’s crucial to verify that the CNC files you purchase are compatible with your current hardware and software. Check the specified file formats provided by suppliers—common formats include STL, DXF, SVG, and Vectric CRV. Ensure that your CNC machine can operate these formats and that you are using the latest software versions. Additionally, inquire about any specific machine settings like feed rates and spindle speeds that need to be adjusted for optimal results. -

What factors should I consider when selecting a supplier for CNC files?

Evaluating a supplier requires thorough research. Look for established companies with strong customer reviews and a history of timely deliveries. Assess their file offerings—do they have diversity in designs and formats? Ensure they provide clear licensing terms and support after purchase. Engaging in direct communication with potential suppliers can also give insights into their customer service quality and willingness to customize files according to your specific needs. -

What is the typical minimum order quantity (MOQ) for CNC files?

MOQs can vary significantly between suppliers. Many offer single files for purchase, while others may set a minimum for bulk buying to ensure operational efficiency. If you plan to order in larger volumes, negotiate for better pricing and discounts, which can be advantageous for your business. Understanding a supplier’s MOQ policy before ordering is critical to avoid inconvenience. -

How can I customize CNC files for my projects?

Customization of CNC files often depends on the supplier’s offerings. Many suppliers allow for modifications based on your requirements, whether it’s resizing a file or altering design elements. Ensure to communicate clearly what adjustments you need, and consider working with suppliers who provide comprehensive design services or user-friendly software to facilitate your customization process. -

What payment terms are commonly available for purchasing CNC files?

Payment terms can differ greatly among suppliers; however, most accept a variety of payment methods, including credit cards, PayPal, and bank transfers. Some may offer discounts for upfront payments or bulk purchases. Always clarify refund policies and payment security measures. If your order exceeds a certain amount, inquire about potential payment plans or installment options to facilitate larger transactions. -

How can I ensure the quality of the CNC files I intend to buy?

Quality assurance starts with researching the supplier’s reputation and customer feedback regarding file precision and usability. Requesting sample files or reviewing their demo designs can also help assess quality before making a larger commitment. Ensure that the files come with detailed specifications regarding design parameters to guarantee they meet your quality standards. -

What logistics considerations should I be aware of when purchasing CNC files internationally?

When buying CNC files from international suppliers, assess the speed and reliability of their delivery methods. Most files are digital and sent via email, so checking the supplier’s delivery time and their support for various file formats is essential. Digital files typically do not incur shipping costs, but ensure alphanumeric file organization is coherent to avoid confusion in project management. -

What licensing options are available when purchasing CNC files?

Licensing can significantly affect how you use the CNC files after purchase. Most suppliers offer standard licenses for personal use, but commercial licenses are available for those intending to sell products made from the designs. Some suppliers provide extended licenses for broader use, so it’s important to clarify the license terms before making a purchase to avoid legal issues down the line. Always ask for written clarification on any licensing agreements included with your order.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cnc Files For Sale Manufacturers & Suppliers List

1. Broinwood – CNC File Designs

Domain: broinwood.com

Registered: 2018 (7 years)

Introduction: This company, Broinwood – CNC File Designs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Two Moose Design – CNC STL Files

Domain: twomoosedesign.com

Registered: 2018 (7 years)

Introduction: {“CNC_FILES”: [{“name”: “3D Square Plates STL File”, “price”: “8.99”}, {“name”: “3D Round Plates STL File”, “price”: “8.99”}, {“name”: “3D Chinese Spoon STL File”, “price”: “8.99”}, {“name”: “3D Deviled Egg Tray STL File”, “price”: “8.99”}, {“name”: “3D Pie Server STL File”, “price”: “8.99”}, {“name”: “3D Round Mallet STL File”, “price”: “8.99”}, {“name”: “3D Skull Mallet STL File”, “price”: “8.99…

3. Etsy – Key Product Features

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: Cnc File – Etsy Categories includes over 5,000 items. Key product features include:

1. Sellers can promote their items using Etsy’s advertising platform.

2. Personalizable items and options to exclude digital items.

3. Price range: items under $25.

4. Availability of Star Seller items.

5. Delivery within 7 days, shipping from the United States.

Sample products:

– MEGA BUNDLE CNC Files For Router…

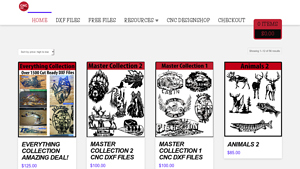

4. CNC DXF Files – Amazing Deal!

Domain: cncdxffiles.com

Registered: 2016 (9 years)

Introduction: [{‘name’: ‘Amazing Deal!’, ‘price’: ‘$125.00’}, {‘name’: ‘Master Collection 2 CNC DXF Files’, ‘price’: ‘$100.00’}, {‘name’: ‘Master Collection 1 CNC DXF Files’, ‘price’: ‘$100.00’}, {‘name’: ‘Animals 2’, ‘price’: ‘$85.00’}, {‘name’: ‘Signs’, ‘price’: ‘$85.00’}, {‘name’: ‘Layered Wall Scenes’, ‘price’: ‘$85.00’}, {‘name’: ‘Clocks CNC DXF Files’, ‘price’: ‘$80.00’}, {‘name’: ‘Entryway Gates’, ‘price…

5. Lunyee CNC – Variety of CNC Files

Domain: lunyeecnc.com

Registered: 2021 (4 years)

Introduction: 41 products in stock including various CNC files such as:

– 100 + Puzzle Vector for Children (HK$25.00, 45% off)

– 2 Hearts Cross Religious 3D CNC Router Files (Sale price HK$22.00, regular price HK$40.00)

– 233 Dog Peek SVG for Laser Cut (Regular price HK$113.00)

– 3D relief STL file of a Welcome To Our Wine Cellar wall sign (Sale price HK$75.00, regular price HK$142.00)

– Alignment Guides Cam C…

6. CNC File Sharing – Ultimate Resource Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ultimate list of CNC file sharing sites: 1. Drawings Obrary 2. Maslow Community Garden 3. FreePatternsArea (templates and projects) 4. Ameede (download wait time) 5. FreeDXF (signup required, free & paid content) 6. LaraDesignCnc (curated marketplace, paid) 7. CNC Cookbook (free DXF files) 8. CNC File Sharing (signup required) 9. ToolsToday Pattern Directory (free and paid content) 10. Scan2CAD (m…

7. eBay – CNC Files and Vector Graphics

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 4,200+ results for CNC files including 3D STL files, DXF files for plasma and laser cutting, and 2D vector files. Products available range from new to used, with conditions listed as new (4,045 items), used (128 items), and not specified (591 items). Price range starts from under $4.00 to over $15.00. Brands include RATTM and unbranded items. Various machine types supported: 3 Axis Router Machine,…

8. Design Bundles – Premium CNC Files Collection

Domain: designbundles.net

Registered: 2016 (9 years)

Introduction: Cnc Files Collection, premium license for personal or commercial use, downloadable purchases anytime. Featured products: 1. Romantic Couple Laser Cut Ready Files – Crescent Moon SVG $4.90 2. Highland Cow SVG | Butterfly Welcome Sign | Laser Cut Files $6.20 3. Spring Welcome Sign SVG | Umbrella SVG | Laser Cut Files $6.20 4. Easter Bunny SVG| Easter Welcome Sign SVG | Laser Cut Files $6.20 5. Book …

9. Designs by Donnie – Wine Rack

Domain: designsbydonnie.com

Registered: 2018 (7 years)

Introduction: [{‘product_name’: ‘Wine Rack’, ‘price’: 48.0}, {‘product_name’: ‘Phone Holder’, ‘price’: 48.0}, {‘product_name’: ‘Scroll Base’, ‘price’: 48.0}, {‘product_name’: ‘Transformer’, ‘price’: 40.0}, {‘product_name’: ‘Toilet Cloud Holder’, ‘price’: 48.0}, {‘product_name’: ‘Spider Platter’, ‘price’: 48.0}, {‘product_name’: ‘Taco Holder’, ‘price’: 48.0}, {‘product_name’: ‘Large & Small Snow Flake Dish’, ‘pr…

Strategic Sourcing Conclusion and Outlook for cnc files for sale

Through strategic sourcing of CNC files for sale, international B2B buyers can unlock unique opportunities to enhance their manufacturing capabilities. This guide has highlighted the importance of selecting quality designs that cater to specific market needs, particularly in regions like Africa, South America, the Middle East, and Europe. By offering files that align with local craftsmanship preferences, businesses can gain a competitive edge while maximizing production efficiency.

In addition, the diversity of file formats, such as STL, SVG, and DXF, provides buyers with the flexibility to adopt designs tailored for various CNC machines. Looking ahead, it is crucial for buyers to stay abreast of emerging trends in CNC technology and design. Engaging with reputable suppliers can also lead to innovative collaborations and sustained growth in your business landscape.

Ultimately, as the demand for precision and customization continues to rise, investing in high-quality CNC files will not just drive profitability but also elevate your brand’s identity. Now is the time to explore potential partnerships and invest in CNC file solutions that resonate with your business’s vision. Seize this opportunity to elevate your operations and establish a strong foothold in the global market.