Contents

Manufacturing Insight: Cnc Files For Metal

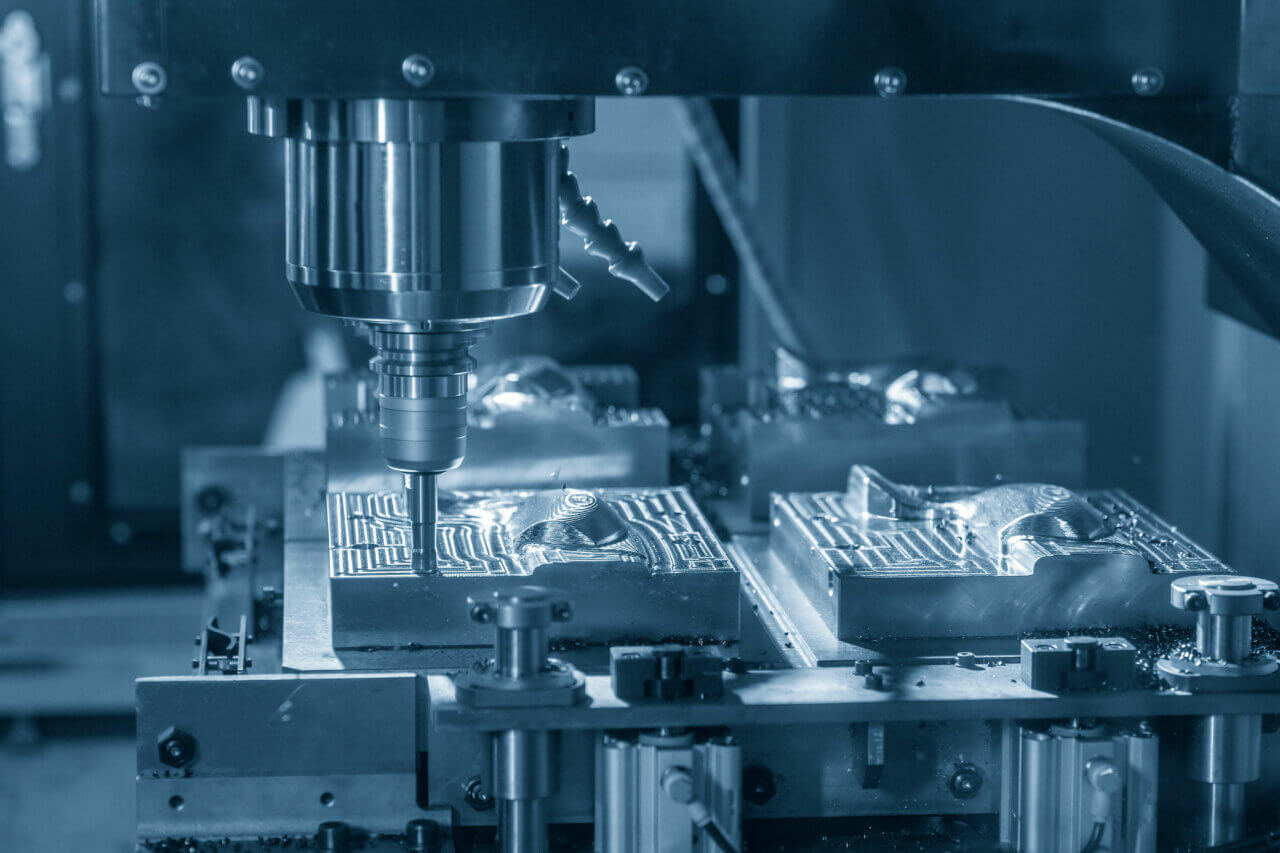

Precision CNC File Processing for Sheet Metal Fabrication

At Honyo Prototype, we engineer high-integrity sheet metal components directly from your CAD/CAM data, transforming complex CNC files into precision-engineered parts with zero compromise. Our advanced manufacturing ecosystem supports industry-standard formats including DXF, DWG, STEP, and IGS, ensuring seamless integration with your design workflow while maintaining strict geometric and dimensional tolerances. Every file undergoes automated validation against material-specific bend allowances, tooling constraints, and laser/cutting path optimization protocols to eliminate manufacturability errors before production begins.

Accelerate Prototyping with Real-Time Quoting

Leverage our proprietary Online Instant Quote platform to receive production-ready cost and lead time estimates in under 60 seconds—no manual submissions or email delays. The system dynamically analyzes your uploaded CNC file, cross-referencing material grade, thickness, feature complexity, and secondary operations against live machine capacity and material inventory. This technical rigor ensures quotes reflect actual manufacturability, not theoretical approximations, empowering faster procurement decisions for low-volume production and rapid prototyping.

Partner with Honyo to convert digital designs into certified sheet metal assemblies with end-to-end traceability, from file upload through precision forming, welding, and finishing. Our ISO 9001-certified processes deliver aerospace, medical, and industrial-grade components on schedule, every time. Upload your CNC file today and experience frictionless fabrication engineered for speed and accuracy.

Technical Capabilities

Technical specifications for CNC files used in metal fabrication processes such as laser cutting, bending, and welding require precise formatting and adherence to design standards to ensure manufacturability. While ABS and Nylon are not metals, they are included here for comparative context as they may be processed using similar CNC equipment in hybrid fabrication environments.

The following table outlines key technical parameters and material considerations for CNC programming in laser cutting, bending, and welding operations:

| Parameter | Laser Cutting | Bending | Welding |

|---|---|---|---|

| File Format | DXF, DWG, or native CAD (STEP, IPT, SLDPRT) | DXF with flat pattern or folded model | STEP or IGES with assembly references |

| Tolerance | ±0.1 mm – ±0.2 mm | ±0.2° angular, ±0.1 mm linear | ±0.5 mm for fit-up, ±1° for alignment |

| Kerf Compensation | Required (material and thickness dependent) | N/A | N/A |

| Bend Allowance | N/A | Must be calculated (K-factor 0.3–0.5 typical) | N/A |

| Minimum Hole Diameter | ≥1.0 mm (steel), ≥1.2 mm (aluminum) | ≥1.5x material thickness | ≥2.0x material thickness (if near weld zone) |

| Minimum Feature Size | ≥0.8 mm (fine cut), ≥2.0 mm (standard) | ≥4x material thickness for slots/notches | ≥3x material thickness for access |

| Edge Quality (Ra) | 3–6 µm (laser cut surface) | As formed, no requirement | As welded, typically 12.5–25 µm (as deposited) |

| Material – Aluminum | 5052, 6061, 6082 (up to 25 mm) | 5052, 6061 (good formability) | 5083, 6061 (weldable grades) |

| Material – Steel | Mild steel (A36, S235, S355), up to 40 mm | CRCA, HRCA (up to 25 mm) | A36, S355 (common structural steels) |

| Material – ABS | Not applicable (thermoplastic) | Not applicable | Not applicable |

| Material – Nylon | Not applicable | Not applicable | Not applicable |

| Notes | Reflective materials (Al) require fiber laser | Grain direction affects bend cracking risk | Pre-cleaning required for Al and steel |

Additional Notes:

Aluminum: Highly reflective and thermally conductive; requires fiber laser for cutting. Welding requires shielding gas (e.g., argon) and proper joint preparation.

Steel: Carbon steel is ideal for CO₂ or fiber laser cutting. Mild steel is preferred for bending and welding due to ductility and weldability.

ABS & Nylon: These are non-metallic thermoplastics and are generally not processed via metal welding or bending. They may be laser cut with CO₂ lasers but require separate setups due to melting behavior and fume hazards. Not compatible with metal-forming tools or welding processes.

Design for Manufacturing (DFM): Include bend reliefs, avoid sharp internal corners, maintain consistent material thickness across parts intended for welding, and account for heat distortion in welded assemblies.

All CNC files must be validated for geometry accuracy, layer integrity (in DXF), and proper scaling before release to production.

From CAD to Part: The Process

Honyo Prototype CNC Metal Manufacturing Workflow

Honyo Prototype executes a streamlined, technology-driven process for metal CNC machining, ensuring precision, efficiency, and transparency from initial design to final delivery. The workflow integrates AI-powered automation with expert engineering oversight to minimize errors and accelerate time-to-part.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (e.g., STEP, IGES, Parasolid, SolidWorks, Fusion 360) via our secure online portal. Our system validates file integrity, units, and geometry compatibility. Supported formats include:

| Format Type | Common Extensions |

|---|---|

| Native CAD | .sldprt, .ipt, .iam, .f3d |

| Neutral | .stp, .igs, .x_t, .x_b |

Incomplete or non-manufacturable geometries trigger immediate client notifications for rapid correction, preventing downstream delays.

AI-Powered Preliminary Quote

Upon CAD validation, our proprietary AI engine analyzes geometry, material requirements, tolerances, and surface finishes to generate a real-time cost and lead time estimate. This system cross-references live data on material costs, machine availability, and historical production metrics. The AI output provides a preliminary quote within minutes, but it is explicitly labeled as non-binding—final pricing requires DFM validation to address manufacturability nuances AI cannot fully resolve.

Engineering-Led DFM Analysis

All metal parts undergo mandatory Design for Manufacturability (DFM) review by Honyo’s senior manufacturing engineers. This phase combines AI-driven suggestions with human expertise to:

Identify non-optimal features (e.g., deep cavities, thin walls, tight tolerances)

Recommend material-specific adjustments (e.g., aluminum 6061 vs. stainless steel 304)

Propose cost-saving alternatives without compromising function

Validate toolpath feasibility and fixture requirements

Clients receive a detailed DFM report with actionable feedback and revised quotes within 24 hours. Only after client approval of DFM recommendations does the project advance.

Precision CNC Production

Approved designs move to our climate-controlled production floor featuring Haas, DMG MORI, and Makino CNC centers. Key production protocols include:

Material certification verification (Mill Test Reports for aerospace/medical grades)

First-article inspection per AS9102 or PPAP standards where required

In-process CMM checks for critical dimensions

Real-time machine monitoring for tool wear and vibration control

All metal parts undergo final inspection using Zeiss CMMs or optical comparators, with reports documenting GD&T compliance.

Certified Delivery

Finished parts ship in anti-corrosive packaging with full traceability documentation. Standard deliverables include:

Dimensional inspection report (PDF and hard copy)

Material certification (MTR)

As-machined CAD model with revision stamp

Shipping manifest with tracking via DHL/FedEx

Lead times average 5–10 business days for prototypes and 10–15 for low-volume production, with expedited options available. Honyo guarantees on-time delivery through dynamic scheduling and buffer capacity allocation.

This integrated workflow reduces prototyping cycles by 30–50% compared to traditional vendors while maintaining ISO 9001:2015 compliance. Critical to our success is the human-AI collaboration: AI accelerates quoting and flags obvious issues, but our engineers’ domain expertise ensures manufacturability and quality for mission-critical metal components.

Start Your Project

Need precision CNC files for metal parts? Partner with Honyo Prototype for accurate, high-quality manufacturing tailored to your specifications.

Our Shenzhen-based factory leverages advanced CNC machining technology to deliver reliable results for prototyping and production.

Contact Susan Leo today at [email protected] to discuss your project and get a fast quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.