Introduction: Navigating the Global Market for cnc engraving software

In the ever-evolving landscape of manufacturing, sourcing the right CNC engraving software can be a daunting task for international B2B buyers. With numerous options available, ranging from free to premium solutions, businesses must navigate the complexities of software capabilities, compatibility with CNC machines, and varying price points. This guide aims to demystify the global market for CNC engraving software by providing a comprehensive overview of the types and applications available, along with insights into supplier vetting processes and cost considerations.

As a buyer, understanding the distinct features and functionalities of various CNC engraving software is crucial for optimizing production processes and ensuring high-quality outputs. Whether you are in Africa, South America, the Middle East, or Europe—regions that are witnessing significant growth in manufacturing—this guide empowers you to make informed purchasing decisions. We will explore essential software categories, including CAD and CAM solutions, and delve into the pros and cons of both free and commercial software options.

By the end of this guide, you will have a clearer perspective on how to select the software that aligns with your operational needs, budget, and strategic goals, enabling you to enhance your engraving capabilities and drive business success in a competitive global market.

Understanding cnc engraving software Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CAD Software | Allows design creation, typically 2D or 3D; may be free or paid. | Product design, prototyping | Pros: Diverse options, some free, supports complex designs. Cons: Steeper learning curves for advanced tools. |

| CAM Software | Converts designs into machine-readable G-code; may include CAD features. | Manufacturing, CNC machining | Pros: Essential for operation, often bundled with CAD. Cons: Can be costly; quality varies between products. |

| Integrated CAD/CAM | Combines both CAD and CAM functionalities in one package. | End-to-end CNC operations | Pros: Streamlined workflow, reduced software costs. Cons: May lack advanced features found in specialized software. |

| Engraving Software | Specialized for engraving tasks, often includes artistic features. | Sign making, decorative engraving | Pros: Tailored for engraving, user-friendly. Cons: Limited to engraving tasks, less versatile for other machining. |

| 3D Modeling Software | Focuses on creating complex 3D models; often includes sculpting tools. | Artistic applications, product design | Pros: High precision and creative freedom. Cons: Typically more expensive and complex; may require robust hardware. |

What Are the Key Characteristics of CAD Software for CNC Engraving?

CAD (Computer-Aided Design) software is essential for creating detailed designs and models that can be used in CNC engraving. It typically supports both 2D and 3D designs, allowing businesses to visualize and fine-tune their products before production. B2B buyers should consider the software’s compatibility with their CNC machines, ease of use, and whether it offers free trials or community support. While free options exist, professional-grade software may provide more robust features and customer support, making it a worthwhile investment for serious manufacturers.

How Does CAM Software Facilitate CNC Engraving?

CAM (Computer-Aided Manufacturing) software plays a critical role in converting CAD designs into machine-readable G-code, which instructs CNC machines on how to operate. This software is pivotal in ensuring that the engraving is executed accurately and efficiently. Buyers should evaluate the integration capabilities with existing CAD tools, the learning curve associated with the software, and overall cost. While some CAM software can be expensive, the efficiency gains in production can justify the investment, especially for high-volume operations.

What Are the Benefits of Integrated CAD/CAM Solutions?

Integrated CAD/CAM solutions combine the functionalities of both design and manufacturing software, allowing for a seamless workflow from concept to production. These systems can significantly reduce costs and complexity for businesses by eliminating the need for multiple software packages. B2B buyers should assess the specific features offered, such as customization options and user support. While integrated solutions may lack some advanced features of standalone software, they often provide sufficient capabilities for most engraving applications, making them ideal for small to medium-sized enterprises.

Why Choose Specialized Engraving Software?

Engraving software is specifically designed for tasks related to engraving, often featuring user-friendly interfaces and tools tailored for artistic applications. This type of software is ideal for businesses focused on sign-making, decorative engraving, or custom designs. Buyers should consider the software’s output quality, ease of use, and whether it includes features like design templates or artistic effects. While specialized software can simplify the engraving process, its limited functionality may not suit businesses looking for versatile machining solutions.

What Role Does 3D Modeling Software Play in CNC Engraving?

3D modeling software is essential for creating intricate designs that require a high level of detail and precision, often used in artistic applications or product design. This software typically includes advanced sculpting tools that allow users to manipulate designs in three dimensions. B2B buyers should evaluate the software’s capabilities in terms of rendering quality, compatibility with CNC machines, and system requirements. Although 3D modeling software can be more expensive and complex, it provides unparalleled creative freedom for businesses aiming to produce unique and detailed engravings.

Key Industrial Applications of cnc engraving software

| Industry/Sector | Specific Application of CNC Engraving Software | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom Tooling and Fixtures | Enhanced precision and reduced lead times | Compatibility with existing CNC machines and software |

| Signage and Advertising | Personalized Signage Production | Increased customer engagement and brand visibility | Material compatibility and design flexibility |

| Jewelry | Intricate Jewelry Design and Engraving | Unique product offerings and improved craftsmanship | Software capabilities for fine detail and material |

| Automotive | Component Marking and Identification | Streamlined production processes and quality assurance | Scalability for high-volume production |

| Aerospace | Precision Part Engraving | Compliance with stringent industry standards | Certification and support for complex designs |

How Is CNC Engraving Software Used in Manufacturing?

In the manufacturing sector, CNC engraving software is utilized for creating custom tooling and fixtures. This software enables manufacturers to design and produce components with high precision, significantly reducing lead times. Buyers in this sector should consider the software’s compatibility with existing CNC machinery and the ability to generate complex geometries that meet specific production requirements.

What Role Does CNC Engraving Software Play in Signage and Advertising?

CNC engraving software is essential for personalized signage production in the signage and advertising industry. It allows businesses to create unique and intricate designs that enhance customer engagement and brand visibility. When sourcing software, companies should evaluate material compatibility and the design flexibility offered by the software to accommodate various signage needs, from simple plaques to elaborate displays.

How Is CNC Engraving Software Transforming Jewelry Design?

In the jewelry industry, CNC engraving software facilitates intricate jewelry design and engraving. This technology allows jewelers to produce unique pieces with fine details, setting them apart from competitors. Buyers should focus on software capabilities that support precise engraving and the ability to work with different materials, ensuring the software can deliver the high-quality craftsmanship required in this sector.

Why Is CNC Engraving Software Critical for Automotive Component Marking?

CNC engraving software plays a crucial role in the automotive industry for component marking and identification. It helps streamline production processes and ensures quality assurance through precise engravings on parts. When sourcing this software, businesses need to consider its scalability for high-volume production and the ability to integrate with existing systems to maintain efficiency.

How Does CNC Engraving Software Enhance Precision in Aerospace?

In aerospace, CNC engraving software is vital for precision part engraving, which is necessary to meet stringent industry standards. This software enables the production of complex designs that are essential for safety and performance. Buyers in this sector should prioritize sourcing software that offers certification and robust support for complex designs, ensuring compliance with regulatory requirements and enhancing operational reliability.

3 Common User Pain Points for ‘cnc engraving software’ & Their Solutions

Scenario 1: Difficulty in Software Integration with Existing Machinery

The Problem: Many B2B buyers encounter significant challenges when integrating CNC engraving software with their existing machinery. This issue often stems from compatibility problems, especially when dealing with a mix of older and newer models. Buyers might invest in state-of-the-art engraving software only to find that it does not communicate effectively with their CNC machines, leading to production delays and increased operational costs. The frustration mounts as they juggle multiple software platforms that do not seamlessly work together, causing workflow disruptions and inefficiencies.

The Solution: To avoid these integration headaches, it is crucial for buyers to conduct thorough research before selecting CNC engraving software. Start by identifying the specifications and requirements of your existing machinery, including supported file formats and communication protocols. Look for software that explicitly states compatibility with your CNC models. Additionally, consider software that provides robust customer support and offers integration guides or plugins. Engage with your software vendor early in the decision-making process to discuss your specific needs and ensure they can provide the necessary support for a smooth integration. Investing in comprehensive training for your team on both the software and the machinery can also minimize disruptions during the transition period.

Scenario 2: High Costs of Professional CNC Engraving Software

The Problem: B2B companies often find themselves facing the daunting expense of high-quality CNC engraving software. This is particularly challenging for small to medium-sized enterprises (SMEs) operating on tight budgets. The costs associated with purchasing licenses, regular updates, and training can quickly escalate, leading to financial strain. Many companies are left with the dilemma of choosing between free software that lacks essential features and expensive options that may exceed their budget.

The Solution: To mitigate software costs, businesses should explore a hybrid approach. Start by evaluating free or low-cost options that offer the core features necessary for your engraving tasks. Many reputable software platforms provide trial versions or limited free functionalities that allow you to test their capabilities before making a financial commitment. Consider investing in a software solution that operates on a subscription model rather than a one-time purchase, as this can spread costs over time and provide access to regular updates. Furthermore, explore the possibility of collaborating with local educational institutions that may have access to advanced CNC software and could provide training resources or partnerships at reduced rates.

Scenario 3: Steep Learning Curve for New Users

The Problem: A common issue faced by B2B buyers is the steep learning curve associated with new CNC engraving software. Employees may struggle to adapt to complex interfaces and functionalities, which can lead to inefficiencies and frustration. This challenge is particularly pronounced in environments where team members have varying levels of technical proficiency. As a result, organizations may experience delays in project timelines and a dip in productivity as employees navigate the software.

The Solution: To address this learning curve, it is essential to prioritize training and ongoing support. Look for software providers that offer comprehensive onboarding programs and user-friendly resources, such as tutorials, webinars, and a robust community forum. Encourage a culture of continuous learning within your organization by setting up regular training sessions and inviting software representatives to conduct workshops. Additionally, consider creating a mentorship program where more experienced team members assist those who are new to the software. This collaborative approach not only fosters knowledge sharing but also enhances team cohesion and ensures that everyone is on the same page, ultimately leading to improved productivity and smoother operations.

Strategic Material Selection Guide for cnc engraving software

What Are the Key Materials Commonly Used in CNC Engraving Software?

When selecting materials for CNC engraving applications, it is crucial to understand the properties and performance characteristics of each material. Below, we analyze four common materials: wood, acrylic, aluminum, and stainless steel, focusing on their suitability for CNC engraving software from a B2B perspective.

How Does Wood Perform in CNC Engraving Applications?

Wood is a versatile material widely used in CNC engraving due to its natural aesthetic and ease of machining. Key properties include a low density, which allows for faster cutting speeds, and a variety of hardness levels depending on the type of wood.

Pros: Wood is relatively inexpensive, easy to source, and can be finished with various stains and coatings for enhanced aesthetics. It is also lightweight, making it suitable for a wide range of applications, from signage to decorative items.

Cons: Wood can warp or crack under temperature and humidity changes, which may affect the final product’s durability. Additionally, the presence of knots and grain can complicate engraving processes and lead to inconsistent results.

For international buyers, sourcing wood requires compliance with local regulations regarding sustainable forestry practices. Standards such as FSC (Forest Stewardship Council) certification are increasingly important in markets like Europe and North America.

What Are the Benefits of Using Acrylic in CNC Engraving?

Acrylic, or PMMA, is a popular choice for CNC engraving due to its clarity and ability to mimic glass. It has a high impact resistance and is available in various colors and finishes.

Pros: Acrylic is lightweight and easy to cut, allowing for intricate designs and detailed engravings. It also offers excellent weather resistance, making it suitable for both indoor and outdoor applications.

Cons: While acrylic is durable, it can scratch easily and may not withstand high temperatures, which can limit its use in certain applications. Additionally, it can be more expensive than wood and may require specialized cutting tools.

International buyers should be aware of potential import tariffs on acrylic products and the need for compliance with safety standards, particularly in the EU, where REACH regulations apply.

How Does Aluminum Compare for CNC Engraving?

Aluminum is a robust material often used for industrial applications, including CNC engraving. Its key properties include high strength-to-weight ratio and excellent corrosion resistance.

Pros: Aluminum is durable and can withstand harsh environments, making it ideal for outdoor signage and mechanical parts. It also has good thermal conductivity, which can be beneficial in certain applications.

Cons: The cost of aluminum can be significantly higher than wood or acrylic, and it requires specialized tools and techniques for engraving. Additionally, the machining process can generate heat, which may necessitate coolant to prevent warping.

For B2B buyers, understanding the local market for aluminum, including sourcing and pricing fluctuations, is essential. Compliance with standards such as ASTM or DIN is critical in regions like Europe and North America.

What Role Does Stainless Steel Play in CNC Engraving?

Stainless steel is known for its exceptional strength and corrosion resistance, making it a preferred choice for high-end applications.

Pros: Its durability and resistance to rust make stainless steel ideal for outdoor and industrial applications. It also provides a premium finish that can enhance the aesthetic value of engraved items.

Cons: The primary drawback is its high cost compared to other materials. Additionally, engraving stainless steel requires specialized equipment, which can increase manufacturing complexity and lead times.

International buyers must consider the implications of sourcing stainless steel, including compliance with international standards like JIS in Japan or ASTM in the U.S. Understanding local regulations regarding metal imports is also crucial.

Summary Table of Material Selection for CNC Engraving

| Material | Typical Use Case for cnc engraving software | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Signage, decorative items | Inexpensive and easy to source | Prone to warping and cracking | Low |

| Acrylic | Indoor/outdoor signage, displays | Lightweight and weather-resistant | Scratches easily, can be costly | Medium |

| Aluminum | Mechanical parts, outdoor signage | High strength and corrosion-resistant | Higher cost, requires specialized tools | High |

| Stainless Steel | High-end signage, industrial applications | Exceptional durability and finish | High cost, complex machining | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of common materials used in CNC engraving applications, enabling informed decision-making for their projects.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc engraving software

What Are the Main Stages in the Manufacturing Process of CNC Engraving Software?

The manufacturing process of CNC engraving software typically involves several critical stages that ensure the final product meets the required specifications for functionality and performance. Understanding these stages can help B2B buyers assess the capabilities and reliability of potential suppliers.

Material Preparation: What Is Involved?

Material preparation is the foundational step in the manufacturing process of CNC engraving software. This phase includes gathering the necessary resources, such as design specifications and programming languages, that are essential for software development. Software developers must also consider hardware compatibility, ensuring that the software can effectively communicate with various CNC machines.

A robust material preparation phase may involve the use of simulation tools to visualize how the software will interact with different engraving tasks. Additionally, user feedback from previous versions can guide enhancements, ensuring that the software is user-friendly and meets market demands.

How Is the Software Formed and Developed?

The formation of CNC engraving software involves several programming techniques and methodologies. Agile development practices are often employed, allowing for iterative design and testing. During this stage, developers create the core functionalities, such as CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) capabilities.

Key techniques used in this stage include algorithm design for toolpath generation and user interface (UI) design for ease of use. Developers may also integrate features such as G-code generation, which instructs CNC machines on how to execute engraving tasks. This stage is critical for ensuring the software is not only functional but also intuitive for end-users.

What About Assembly and Integration of Software Components?

Once the core functionalities are developed, the assembly stage involves integrating various software components into a cohesive product. This may include linking CAD and CAM modules, ensuring they communicate effectively to streamline the user experience.

Quality assurance teams will typically conduct preliminary tests during this phase to verify that all components work seamlessly together. This integration is crucial for enabling features such as real-time machine control and accurate toolpath visualization, which are essential for successful CNC engraving.

How Is Finishing Achieved in Software Development?

The finishing stage focuses on polishing the software before its release. This involves rigorous testing to identify and rectify bugs, enhance performance, and improve user experience. Developers may employ beta testing with selected users to gain insights into usability and functionality.

Moreover, this phase includes creating comprehensive documentation and tutorials to assist users in navigating the software. The goal is to ensure that the final product is reliable, efficient, and ready for the market.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is a crucial aspect of CNC engraving software manufacturing. For B2B buyers, understanding the relevant international standards and industry-specific certifications is vital for ensuring product reliability.

Which International Standards Are Relevant for CNC Engraving Software?

ISO 9001 is one of the most recognized international standards for quality management systems. This standard emphasizes a process-oriented approach to quality management, ensuring that organizations consistently meet customer and regulatory requirements. B2B buyers should look for suppliers who are ISO 9001 certified, as this indicates a commitment to quality and continuous improvement.

In addition to ISO 9001, other standards such as CE marking and API certification may apply, depending on the specific functionalities and target markets of the software. CE marking is particularly relevant for products sold in the European Union, ensuring compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Software Development?

Quality control (QC) checkpoints are essential throughout the software development process. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves reviewing the quality of inputs, such as design specifications and coding practices, before they are used in the development process.

-

In-Process Quality Control (IPQC): Continuous monitoring during the development phase ensures that the software adheres to quality standards and allows for immediate corrections if issues arise.

-

Final Quality Control (FQC): Comprehensive testing of the finished product is conducted to verify that all functionalities work as intended. This may involve user acceptance testing (UAT) to gather feedback from actual users.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are several effective methods:

What Are the Best Practices for Conducting Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a supplier’s quality control practices. Audits can be scheduled regularly or conducted on an as-needed basis. During an audit, buyers should evaluate the supplier’s compliance with international standards, the effectiveness of their QC checkpoints, and their overall manufacturing capabilities.

How Can Buyers Utilize Quality Assurance Reports?

Requesting quality assurance reports from suppliers can provide valuable insights into their QC processes and outcomes. These reports should detail the testing methods used, results from previous quality checks, and any corrective actions taken to address identified issues.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can add an extra layer of confidence in the quality of CNC engraving software. These independent inspections can validate the supplier’s claims regarding their quality control processes and help identify any potential risks before a purchase is made.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have varying regulations and standards that suppliers must comply with. Buyers should familiarize themselves with these local requirements to ensure that the software meets all necessary compliance criteria.

What Should Buyers Know About Cultural and Operational Differences?

Cultural differences can also impact supplier relationships and quality assurance practices. Buyers should be aware of these differences and consider how they may affect communication and operational efficiency. Establishing clear expectations and maintaining open lines of communication can help mitigate potential misunderstandings.

By understanding the manufacturing processes and quality assurance measures associated with CNC engraving software, B2B buyers can make informed decisions that align with their business needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc engraving software’

Introduction

Navigating the procurement of CNC engraving software can be complex, especially for businesses looking to enhance their machining capabilities. This checklist serves as a practical guide for B2B buyers in diverse regions, including Africa, South America, the Middle East, and Europe. By following these steps, you can ensure a well-informed purchasing decision that meets your operational requirements and budget constraints.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your CNC engraving software. This includes understanding the types of materials you will be engraving, the complexity of designs, and the machine compatibility. Knowing your needs will help you narrow down software options that can effectively support your projects.

- Consider:

- Material types (wood, metal, plastic).

- Required precision and complexity of engravings.

Step 2: Research Available Software Options

Conduct thorough research on the various CNC engraving software available in the market. Look for software that fits your defined specifications and offers additional features like 3D modeling or user-friendly interfaces. This initial research is crucial to identify both free and paid options that align with your budget.

- Key considerations:

- Availability of free trials or demo versions.

- Reviews and ratings from other users in your industry.

Step 3: Evaluate Integration Capabilities

Assess how well the software integrates with your existing CNC machinery. Compatibility is critical to ensure seamless operations and minimize downtime. Look for software that can generate G-code that your specific CNC router or mill can interpret without extensive modification.

- Ask yourself:

- Is the software compatible with my CNC machine’s controller?

- Can it easily import/export files from other CAD/CAM systems?

Step 4: Check for Support and Resources

Ensure that the software provider offers adequate support and resources. This includes customer service, user manuals, tutorials, and community forums. A robust support system can significantly reduce the learning curve and enhance your team’s efficiency.

- Look for:

- Availability of online tutorials and training.

- Access to a user community for troubleshooting and advice.

Step 5: Verify Licensing and Costs

Before making a purchase, thoroughly review the licensing agreements and total costs associated with the software. Understand whether it’s a one-time purchase, subscription-based, or requires additional payments for upgrades or support. This clarity will help you manage your budget effectively.

- Consider:

- Hidden costs, such as additional modules or customer support fees.

- Scalability options if your business grows.

Step 6: Request Demonstrations and Trials

Before finalizing your decision, request demonstrations or trial versions of the software. This hands-on experience allows you to assess usability, features, and overall functionality in a real-world context. It’s a critical step to ensure the software meets your expectations.

- Focus on:

- User interface and ease of navigation.

- Performance during the engraving process.

Step 7: Review and Compare Suppliers

Finally, conduct a comparative analysis of the software suppliers you’re considering. Look for testimonials, case studies, and references from businesses similar to yours. This step can provide insights into the supplier’s reliability and the software’s long-term performance.

- Evaluate:

- Supplier reputation and history in the market.

- Quality of customer feedback and user experiences.

Following this structured approach will empower you to make an informed decision when sourcing CNC engraving software, ultimately enhancing your operational efficiency and output quality.

Comprehensive Cost and Pricing Analysis for cnc engraving software Sourcing

What are the Key Cost Components in CNC Engraving Software?

When evaluating the cost structure for CNC engraving software, several key components play a crucial role:

-

Materials: Software development requires robust coding frameworks and platforms. The choice of programming languages and development tools can affect initial costs. Additionally, if the software integrates with specific hardware, licensing fees may apply.

-

Labor: Skilled developers, designers, and quality assurance (QA) professionals are essential for creating reliable software. Labor costs vary significantly based on location, expertise, and project complexity. In regions such as Africa and South America, labor may be more cost-effective compared to Europe, potentially influencing sourcing decisions.

-

Manufacturing Overhead: This includes the costs associated with maintaining server infrastructure, software updates, and technical support. For cloud-based solutions, ongoing costs can be tied to server uptime and data security, both of which are critical for maintaining user trust.

-

Tooling: While not directly applicable to software, the term can refer to the tools used for development, such as integrated development environments (IDEs) and debugging tools, which can add to the overall cost.

-

Quality Control (QC): Rigorous testing phases are essential to ensure that software performs as intended. This involves additional labor and tools, which contribute to overall expenses.

-

Logistics: For software distribution, logistics may include server costs for cloud solutions, as well as potential fees for maintaining user accounts and managing subscriptions.

-

Margin: Software companies typically aim for a profit margin that reflects the value of their product and the competitive landscape. Margins can vary based on market positioning and target audience.

How Do Price Influencers Impact CNC Engraving Software Costs?

Several factors can influence the pricing of CNC engraving software:

-

Volume/MOQ: Larger orders or longer subscription commitments often result in discounts. Companies looking to implement software across multiple machines or locations may negotiate better terms.

-

Specifications and Customization: Custom software solutions tailored to specific needs can drive up costs. Buyers should assess whether off-the-shelf solutions meet their needs or if customization is necessary.

-

Materials: The underlying technology and frameworks used can affect the price. Higher-quality, more secure software may come at a premium.

-

Quality and Certifications: Software that meets industry standards and certifications may be priced higher but could save costs in the long run by reducing downtime and improving efficiency.

-

Supplier Factors: Reputation and experience of the supplier can influence pricing. Established suppliers may charge more due to their reliability and support services.

-

Incoterms: Understanding international shipping terms can affect the total cost when sourcing software from foreign suppliers, particularly for cloud-based solutions that may incur different service agreements.

What Are the Best Buyer Tips for Cost-Efficiency in CNC Engraving Software?

For international B2B buyers, particularly from diverse regions, several strategies can help maximize cost-efficiency:

-

Negotiate Terms: Always negotiate pricing and terms. Suppliers may offer discounts for long-term contracts or bulk purchases.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term expenses associated with maintenance, updates, and support.

-

Evaluate Pricing Nuances: Understand the nuances in pricing models, such as subscription vs. one-time purchase, and how they align with your business needs.

-

Research Local Alternatives: For buyers in regions like Africa or South America, local software providers may offer competitive pricing and support, potentially reducing logistics costs.

-

Stay Informed on Market Trends: Keep an eye on industry trends and emerging technologies, as these can influence pricing and the availability of new software features.

Disclaimer on Indicative Prices

Prices for CNC engraving software can vary widely based on the factors mentioned above. It is crucial for buyers to conduct thorough research and obtain quotes tailored to their specific needs to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing cnc engraving software With Other Solutions

Introduction: Exploring Alternatives to CNC Engraving Software

In the fast-evolving landscape of manufacturing and design, businesses are continuously seeking efficient methods for engraving and machining. While CNC engraving software is a popular choice for automating these processes, several alternative solutions exist that can also achieve similar outcomes. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs and operational contexts.

Comparison Table

| Comparison Aspect | CNC Engraving Software | Free CAD/CAM Software | Manual Engraving Techniques |

|---|---|---|---|

| Performance | High precision and automation | Variable; depends on user skill | Moderate precision; labor-intensive |

| Cost | Subscription-based, can be high | Free or low-cost | Low, but requires skilled labor |

| Ease of Implementation | Moderate; requires training | Moderate; learning curve for complex tools | Simple for basic designs, complex for detailed work |

| Maintenance | Regular updates and support needed | Minimal; user-managed | Low; no software maintenance needed |

| Best Use Case | High-volume production and intricate designs | Prototyping and small-scale production | Artistic projects or custom one-offs |

Detailed Breakdown of Alternatives

Free CAD/CAM Software

Free CAD/CAM software options, such as FreeCAD or Carbide Create, provide a cost-effective alternative for businesses needing design capabilities without the investment of commercial software. These tools often come with basic functionalities that allow users to create designs and generate toolpaths for CNC machines. However, the user experience can vary significantly, with a steeper learning curve for more complex features. For small businesses or startups, this solution offers a practical way to engage in CNC machining without incurring significant software costs.

Manual Engraving Techniques

Manual engraving techniques involve traditional methods such as hand tools or engraving machines operated without CNC automation. This approach is particularly suited for artistic projects or custom one-off designs, where precision is less critical than creativity. The major advantage of manual engraving is its low cost and the ability to produce unique, handcrafted items. However, it requires skilled labor and can be time-consuming, making it less viable for high-volume production. Companies focusing on artisanal products may find this method beneficial, but it lacks the efficiency and scalability of CNC software solutions.

Conclusion: Choosing the Right Engraving Solution

When deciding between CNC engraving software and its alternatives, B2B buyers should consider their specific operational needs, budget constraints, and desired outcomes. CNC engraving software excels in precision and efficiency for large-scale production, making it ideal for manufacturers looking to streamline their processes. In contrast, free CAD/CAM software offers a budget-friendly option for businesses that prioritize flexibility and experimentation in design. Meanwhile, manual engraving techniques can provide a unique touch for artistic endeavors but may not meet the demands of modern production environments. By assessing these factors, companies can select the most suitable engraving solution to enhance their operational capabilities.

Essential Technical Properties and Trade Terminology for cnc engraving software

What Are the Essential Technical Properties of CNC Engraving Software?

Understanding the technical specifications of CNC engraving software is crucial for making informed purchasing decisions. Here are some key properties that B2B buyers should consider:

1. Material Compatibility

CNC engraving software must support a wide range of materials, including wood, metal, plastic, and composite materials. The ability to handle various materials allows businesses to diversify their product offerings and cater to different customer needs. Buyers should ensure that the software can generate toolpaths optimized for specific materials to achieve high-quality engravings.

2. Precision and Tolerance

Precision in CNC engraving is measured in microns, and tolerance refers to the acceptable deviation from a desired measurement. High precision and tight tolerances are essential for achieving detailed engravings and intricate designs. For B2B buyers, selecting software that meets industry standards for precision ensures that the final products meet customer expectations and regulatory requirements.

3. User Interface (UI) and Usability

The complexity of the software’s user interface can significantly impact productivity. A user-friendly UI allows operators to quickly learn and effectively use the software, reducing training time and minimizing errors. B2B buyers should prioritize software that provides intuitive design tools and clear workflows to enhance operational efficiency.

4. G-code Generation Capabilities

G-code is the language that CNC machines understand, dictating their movements and actions. The software must accurately generate G-code from designs created within its environment or imported from CAD programs. For businesses, reliable G-code generation is critical to prevent machine malfunctions and ensure precise execution of engravings.

5. Integration with Other Software

Many engraving projects require a combination of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) functionalities. Software that seamlessly integrates with existing CAD programs can streamline the design-to-manufacturing process. B2B buyers should look for solutions that facilitate easy data exchange between different software applications, enhancing overall workflow efficiency.

6. Support and Updates

Ongoing technical support and regular software updates are essential for maintaining operational efficiency. Buyers should consider the availability of customer support, including tutorials, forums, and direct assistance. Moreover, software that receives regular updates can adapt to new technologies and industry standards, ensuring long-term viability.

What Are Common Terms in the CNC Engraving Software Industry?

Familiarity with industry jargon is vital for effective communication and negotiation. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC engraving, buyers often deal with OEMs when sourcing machines or software solutions tailored for specific applications.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to manage inventory and budget effectively, particularly when considering software licenses or hardware components that may have bulk purchasing requirements.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. For CNC engraving software, submitting an RFQ helps businesses compare different solutions and negotiate better pricing based on their needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Understanding these terms helps B2B buyers navigate shipping and logistics, ensuring that they are aware of who bears the cost and risk at various points during transportation.

5. CAM (Computer-Aided Manufacturing)

CAM software is used to control machine tools and automate manufacturing processes. In CNC engraving, CAM software translates designs into machine-readable instructions, making it a critical component of the workflow.

By grasping these essential technical properties and industry terms, B2B buyers can make informed decisions when selecting CNC engraving software that aligns with their operational needs and business objectives.

Navigating Market Dynamics and Sourcing Trends in the cnc engraving software Sector

What Are the Key Trends Influencing the CNC Engraving Software Market?

The CNC engraving software market is currently undergoing a transformative phase, driven by several global factors. The rising demand for customized products across various industries, such as manufacturing, automotive, and consumer goods, is propelling the need for sophisticated engraving solutions. Additionally, advancements in automation and artificial intelligence are enhancing the capabilities of CNC engraving software, enabling businesses to streamline their operations, reduce costs, and improve precision. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly adopting these technologies to remain competitive.

Emerging trends such as cloud-based software solutions are gaining traction. These platforms offer flexibility and scalability, allowing businesses to access powerful tools without the burden of high upfront costs. Furthermore, the integration of IoT (Internet of Things) within CNC systems is facilitating real-time data analysis and machine monitoring, which enhances operational efficiency. Companies are also recognizing the importance of user-friendly interfaces, as they minimize the learning curve and improve productivity. For international buyers, these advancements represent not just tools but strategic assets that can significantly enhance their operational efficiency and product offerings.

How Is Sustainability Shaping the CNC Engraving Software Sector?

Sustainability and ethical sourcing are increasingly becoming critical considerations in the CNC engraving software sector. As businesses face mounting pressure to reduce their environmental impact, the demand for sustainable practices is on the rise. This includes the choice of software that supports eco-friendly manufacturing processes, such as optimizing material usage and reducing waste during production.

Moreover, many software providers are now focusing on developing solutions that facilitate the use of ‘green’ materials, which can help companies meet their sustainability goals. Certifications related to environmental standards are becoming essential for B2B transactions, as buyers increasingly seek partners who prioritize ethical supply chains. For instance, software that allows for easy integration with sustainable materials can enhance a company’s marketability and compliance with international environmental regulations.

By prioritizing sustainability, businesses not only align with global trends but also position themselves as responsible players in their markets, which can lead to increased customer loyalty and improved brand reputation. For B2B buyers, investing in CNC engraving software that emphasizes sustainability can yield long-term benefits, both environmentally and economically.

What Has Been the Evolution of CNC Engraving Software?

The evolution of CNC engraving software has been marked by significant technological advancements and shifts in market demand. Initially, CNC engraving was limited to basic manual programming, which required specialized knowledge and extensive training. However, with the advent of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technologies, the process has become more accessible and efficient.

Over the years, software solutions have transitioned from complex, high-cost systems to more user-friendly, cost-effective options that cater to a wider range of businesses, including small and medium enterprises. This democratization of technology has opened new markets and opportunities, particularly in developing regions. The introduction of open-source software and cloud-based solutions has further accelerated this trend, allowing businesses to leverage advanced functionalities without significant capital investment.

Today, CNC engraving software not only enhances precision and speed but also integrates seamlessly with other technologies, such as IoT and AI, paving the way for smarter manufacturing solutions. This evolution reflects the ongoing need for adaptability in a rapidly changing market, allowing businesses to stay competitive and meet the diverse needs of their customers.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc engraving software

-

How do I select the right CNC engraving software for my business needs?

Choosing the right CNC engraving software involves assessing your specific requirements, such as the types of materials you plan to engrave, the complexity of designs, and the scale of production. Consider whether you need 2D or 3D capabilities, as well as features like toolpath generation and compatibility with your CNC machine. Additionally, evaluate the user-friendliness of the software and the availability of technical support. Testing free trials can also help determine which software aligns best with your operational goals. -

What are the key features to look for in CNC engraving software?

Essential features of CNC engraving software include a user-friendly interface, robust CAD/CAM capabilities, support for multiple file formats (like DXF and SVG), and advanced toolpath strategies. The software should also offer simulation capabilities to visualize the engraving process before execution. Additionally, consider customization options and integration with other software tools you might be using, as well as customer support and community resources for troubleshooting and learning. -

Can I customize CNC engraving software to fit my specific applications?

Many CNC engraving software solutions offer customization options tailored to specific industries or applications. This can include creating unique toolpath strategies, integrating specialized plugins, or adjusting settings for different materials. When evaluating software, inquire about customization capabilities and whether the vendor provides support for developing bespoke features. This is particularly important for businesses with unique engraving needs or specialized production processes. -

What are the typical payment terms for CNC engraving software purchases?

Payment terms for CNC engraving software can vary widely among suppliers. Common practices include full upfront payment, installment options, or subscription models that may charge monthly or annually. It’s essential to clarify payment terms before committing to a purchase. Additionally, inquire about any potential hidden fees, such as costs for software updates or technical support, to ensure a comprehensive understanding of your financial commitment. -

What should I consider when vetting suppliers of CNC engraving software?

When vetting suppliers, consider their reputation in the market, the quality of their software, and the level of customer support they provide. Look for reviews and testimonials from other businesses, and assess their experience in your industry. Additionally, ensure that the supplier complies with international standards and regulations relevant to your region. Engaging with the supplier through demos or trial versions can also help gauge their responsiveness and the software’s functionality. -

Are there minimum order quantities (MOQ) for CNC engraving software licenses?

Most CNC engraving software does not have a minimum order quantity since licenses are typically sold on a per-user basis. However, some vendors may offer discounts for bulk purchases or enterprise licenses. If you plan to deploy the software across multiple machines or users, inquire about volume pricing or enterprise solutions. This can significantly reduce costs while ensuring all team members have access to necessary tools. -

What quality assurance measures should I expect with CNC engraving software?

Quality assurance measures vary by supplier but generally include software testing protocols, regular updates, and user feedback mechanisms. Reputable vendors will provide documentation detailing their QA processes, including how they handle bug fixes and feature updates. Additionally, consider suppliers that offer warranties or guarantees on their software performance, as this can provide peace of mind regarding your investment. -

What are the logistics and support options for international buyers of CNC engraving software?

International buyers should inquire about logistical considerations, such as software delivery methods (digital download vs. physical media) and installation support. It’s also essential to understand the level of customer service available in your region, including language support and time zone considerations. Many suppliers offer online resources, including tutorials and forums, which can be invaluable for troubleshooting and maximizing software use across different locations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cnc Engraving Software Manufacturers & Suppliers List

1. Carbide 3D – Free CNC Software

Domain: carbide3d.com

Registered: 2013 (12 years)

Introduction: Free CNC Software options available for various CNC machines including CAD, CAM, and CNC control software. Key software includes: 1. FreeCAD – Free 3D CAD parametric program, supports STL, STEP, SVG, DXF, runs on Mac, Windows, Linux. 2. Solvespace – Free 3D CAD program, better for mechanical parts, exports STL, STEP, runs on Mac, Windows, Linux. 3. Inkscape – Free for 2D designs, exports SVG, DXF,…

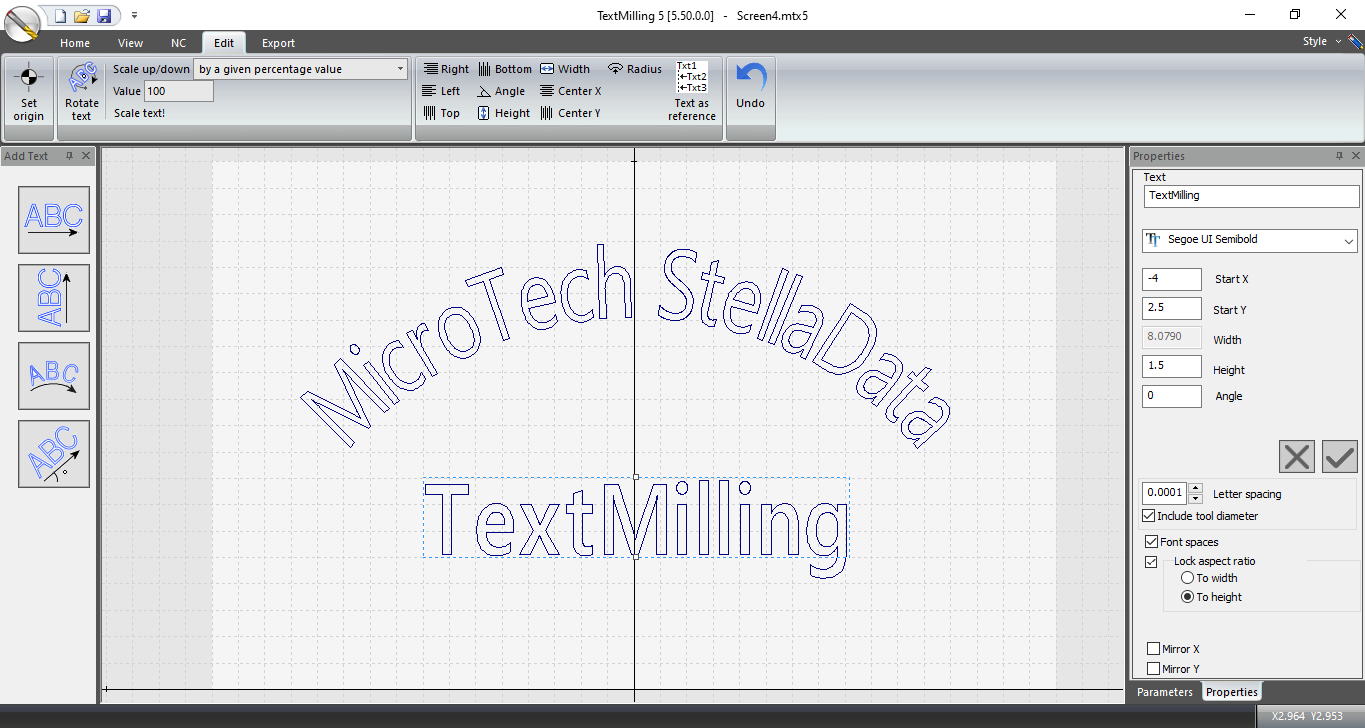

2. Vectric – Cut2D & VCarve

Domain: vectric.com

Registered: 2005 (20 years)

Introduction: Vectric offers powerful and easy-to-use design software for CNC machining, including the following products: 1. Cut2D: A vector drawing and editing software package with powerful 2D machining strategies for CNC routing, milling, or engraving. 2. VCarve: Built on the same interface as Cut2D, it adds 2.5D toolpath functionalities such as v-carving, chamfer, fluting, prism, and moulding toolpaths, al…

3. CNC-Step – ConstruCAM-3D

Domain: cnc-step.com

Registered: 2005 (20 years)

Introduction: CNC Software includes various milling and engraving software for CNC machines, such as CAD CAM programs and 3D-CAD software. Key software products include: 1. ConstruCAM-3D: Universal software for 90% of applications, generates G-Code, included for free with most milling machines. 2. KinetiC-NC: Network CNC Controller Software for all CNC milling machines. 3. 3D-PhotoFormer: Engraving photos as 3D…

4. Easel – All-in-One CNC Software Solution

Domain: easel.com

Registered: 1997 (28 years)

Introduction: Easel is an all-in-one CNC software solution designed for design and CNC machining. Key features include:

1. **Design Tools**: Create stunning designs with tools for artisans and professionals, including a design library with over 3 million designs and a customizable font library with 300+ fonts.

2. **Carving Capabilities**: Supports 3D carving with STL file imports, intricate details, and bold s…

5. Centroid CNC – CNC Engraving Solutions

Domain: centroidcnc.com

Registered: 1997 (28 years)

Introduction: CNC Engraving, Letters, Numbers, Symbols, DXF import; CAD/CAM system recommended for G-code generation; compatible software includes Fusion 360, Vectric Cut 2D, VCarve Pro, Millwrite; G-code smoothing feature for short vectors; Vectric Engraving software recommended; Cut2D: affordable, easy to use, converts CAD DXF and graphics to GCode; VCarve Pro: industrial strength, design and machining functi…

6. Inventables – Easel Software

Domain: inventables.com

Registered: 2001 (24 years)

Introduction: Easel is a web-based software for designing and controlling CNC machines. It allows users to create, import, and modify designs easily. Key features include an intuitive interface, built-in design tools, and compatibility with various CNC machines. Easel supports SVG file formats and offers a library of pre-made designs. It also provides real-time simulation and toolpath generation, making it suit…

7. CNC Write – G-Code Generation Software

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: CNC Write is a software program designed to generate G-Codes for engraving text with CNC machines, compatible with both linear and rotary axes. It is particularly useful for engraving serial numbers, part numbers, and other utilitarian text on parts. The software is noted for its speed and efficiency, especially when engraving on curved surfaces or using rotary axes, which some existing software d…

8. Carveco – Carveco Maker

Domain: carveco.com

Registered: 2018 (7 years)

Introduction: Carveco Maker is an entry-level CNC software solution designed for creating high-quality 2D and 3D products. It features easy-to-use design tools, accurate toolpaths, and is suitable for hobbyists and professionals alike. Key features include:

– Subscription cost of $15/month.

– Tools for creating artistic designs from scratch or using imported models, bitmaps, and vectors.

– Bitmap-to-Vector t…

9. Instructables – CNC Router and Open Source Software

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: CNC Router, Open Source Software, CAD/CAM, CAELinux 2013, Inkscape 0.91, Hershey Text, PyCAM 0.5.1, CAMotics 1.0.6, LinuxCNC, V-bit, Ubuntu Linux, engraving process, eraser stamp, step-by-step instructions, woodworking safety.

Strategic Sourcing Conclusion and Outlook for cnc engraving software

Why is Strategic Sourcing Essential for CNC Engraving Software?

In the ever-evolving landscape of CNC engraving software, strategic sourcing emerges as a crucial factor for B2B buyers aiming to maximize efficiency and cost-effectiveness. Understanding the diverse range of software options—from free tools like FreeCAD and Inkscape to robust paid solutions such as Vectric’s Aspire—enables businesses to tailor their sourcing strategies to meet specific operational needs. This approach not only reduces costs but also enhances productivity by ensuring the right tools are in place for the job.

Moreover, as global markets expand, especially in regions like Africa, South America, the Middle East, and Europe, the demand for high-quality, versatile engraving software continues to grow. Buyers should prioritize software that offers comprehensive support, ease of use, and adaptability to various CNC machines, ensuring they remain competitive.

What’s Next for International Buyers in CNC Engraving?

As you navigate the complexities of CNC engraving software, consider leveraging partnerships with software providers that understand your unique market challenges. The future of CNC engraving is bright, with innovations on the horizon poised to further streamline processes and enhance capabilities. Embrace this opportunity to invest strategically in software solutions that not only meet your current needs but also pave the way for future growth and success. Reach out to software vendors today to explore how their solutions can elevate your business operations.