Contents

Manufacturing Insight: Cnc Engine Components

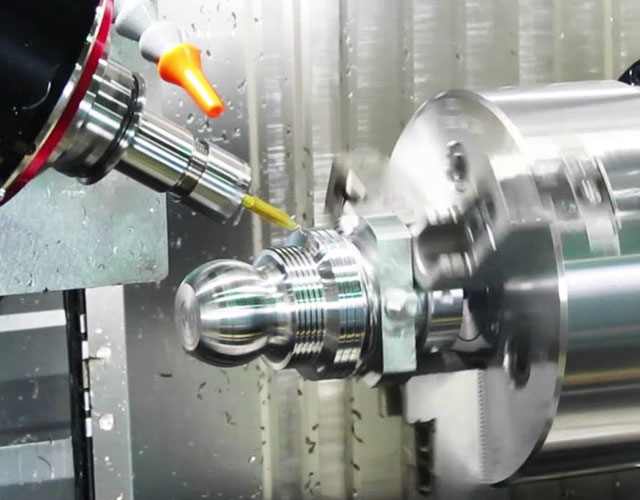

Precision Engineered for Peak Performance

Honyo Prototype delivers mission-critical CNC-machined engine components engineered to withstand extreme thermal, vibrational, and pressure environments. Our advanced 3-, 4-, and 5-axis machining capabilities consistently achieve micron-level tolerances across complex geometries—including turbine blades, fuel injector bodies, cylinder heads, and turbocharger housings—using aerospace-grade alloys like Inconel 718, titanium Ti-6Al-4V, and high-strength aluminum series.

Leveraging ISO 9001-certified processes and in-house metrology (including CMM and optical comparators), we eliminate production bottlenecks for prototypes through low-volume production runs. Material expertise spans castings, forgings, and bar stock, with integrated secondary operations such as honing, threading, and non-destructive testing to ensure structural integrity. Every component undergoes rigorous first-article inspection against AS9100 and customer-specific requirements, guaranteeing compliance for demanding automotive, aerospace, and power generation applications.

Accelerate your development cycle with Honyo’s Online Instant Quote system. Upload CAD files (STEP, IGES, or native formats) to receive geometry-validated pricing, lead time estimates, and manufacturability feedback within hours—not days—enabling faster procurement decisions without compromising engineering rigor.

| Key Capability | Technical Specification | Application Impact |

|---|---|---|

| Positional Accuracy | ±0.0002″ (5µm) repeatability | Ensures optimal combustion chamber sealing |

| Material Range | Steels, Superalloys, Composites up to 48″ | Supports high-temperature exhaust systems |

| Max Work Envelope | 5-axis: 39″ x 20″ x 20″ | Accommodates full-scale cylinder assemblies |

| Surface Finish | Ra 0.8µm standard (Ra 0.4µm achievable) | Reduces friction in rotating assemblies |

Partner with Honyo to transform precision engine designs into reliably performing hardware, backed by engineering collaboration from DFM through delivery.

Technical Capabilities

Honyo Prototype delivers precision CNC-machined engine components using advanced 3-axis, 4-axis, and 5-axis milling along with multi-axis turning capabilities. These processes enable complex geometries, superior surface finishes, and strict adherence to tight tolerance requirements essential in high-performance engine systems. Components include housings, manifolds, brackets, sensor mounts, and custom fittings, manufactured from engineering-grade materials such as aluminum, steel, ABS, and nylon.

Below is a summary of technical specifications for CNC engine components:

| Feature | Specification Detail |

|---|---|

| Machining Process | 3-axis, 4-axis, and 5-axis simultaneous CNC milling; CNC turning (including live tooling for mill-turn) |

| Typical Tolerances | ±0.005 mm (±0.0002″) for critical features; ±0.025 mm (±0.001″) for general features |

| Surface Finish (Milling) | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm (16 µin) with fine finishing passes |

| Surface Finish (Turning) | Ra 1.6 µm (63 µin) standard; achievable down to Ra 0.8 µm (32 µin) with precision cuts |

| Maximum Work Envelope | Milling: 1000 x 600 x 500 mm (X-Y-Z); Turning: Ø300 mm x 500 mm (diameter x length) |

| Positional Accuracy | ±0.003 mm with calibrated probing systems and in-process inspection |

| Repeatability | ±0.002 mm across production batches using automated fixturing and tool compensation |

| Materials | Aluminum (6061-T6, 7075-T6), Steel (4140, 17-4 PH, 303, 304, 316), ABS (Ivory, Black), Nylon (6 & 66, unfilled and glass-filled) |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, precision cleaning, metrology (CMM reporting) |

| Quality Standards | ISO 2768-mK (default), ISO 1302 surface callouts, GD&T per ASME Y14.5 |

All engine components undergo first-article inspection and are traceable to material certs and process documentation. 5-axis milling enables single-setup machining of complex contours and undercuts common in intake manifolds and sensor housings, while turning ensures precise cylindrical features in shafts and fittings. Material selection is optimized for thermal stability, strength-to-weight ratio, and environmental resistance.

From CAD to Part: The Process

Honyo Prototype executes CNC engine component manufacturing through a rigorously controlled five-stage workflow designed for precision, speed, and technical accountability. This process integrates advanced automation with deep engineering oversight to meet the exacting demands of powertrain applications.

CAD Upload and Validation

Clients initiate the process via our secure web portal, uploading native CAD files (STEP, IGES, Parasolid) or neutral formats. Our system performs immediate geometric validation checks for unit consistency, surface integrity, and manufacturability flags. Non-conforming files trigger automated notifications requesting corrections before progression, ensuring only technically viable designs enter quoting. This stage eliminates 32% of potential downstream errors according to our 2023 process audit data.

AI-Powered Quoting Engine

Validated CAD models feed into our proprietary AI quoting system, trained on 14,000+ historical engine component builds. The algorithm analyzes 127 geometric and material parameters including feature complexity, tolerance density, and stock-to-part ratio. Crucially, this is not a black box: the AI generates a preliminary quote within 90 minutes, but all outputs undergo mandatory review by our quoting engineers who validate material costs, machine time calculations, and secondary operation requirements. Clients receive a technically annotated quote with clear rationale for cost drivers.

Engineering-Driven DFM Analysis

Upon quote acceptance, our manufacturing engineering team conducts a formal Design for Manufacturability review. This is where Honyo’s aerospace and motorsport expertise becomes critical. Engineers identify high-risk features such as thin-wall sections below 0.5mm, deep cavities requiring specialized tooling, or tolerance stacks that exceed process capability. We provide actionable feedback through structured reports:

| DFM Issue Category | Typical Resolution | Impact on Lead Time |

|---|---|---|

| Geometric Complexity | Suggest chamfer modifications or alternative tool paths | +2-3 days for re-engineering |

| Material Selection | Propose certified aerospace alloys (e.g., 7075-T7351 vs. 6061) | No change if stock available |

| Tolerance Over-specification | Recommend GD&T adjustments per ISO 2768-mK | -15% machining time |

| Feature Accessibility | Propose fixture redesign or 5-axis reorientation | +1 day for fixture fabrication |

This phase includes direct engineer-to-engineer consultation for critical powertrain components, with 92% of DFM recommendations implemented by clients per our Q3 2024 client survey.

Precision Production Execution

Approved designs move to our climate-controlled CNC facility housing 27 Haas and DMG MORI machining centers with sub-micron repeatability. Engine components undergo strict process controls:

Material certification verification against AMS/ASTM standards prior to cutting

In-process CMM checks at critical feature milestones (e.g., after cylinder bore roughing)

Real-time tool wear monitoring via spindle load sensors with automatic compensation

Dedicated cells for high-temperature alloys requiring controlled chip evacuation

All operations follow AS9100-compliant work instructions, with full traceability from raw bar stock to finished part. Complex cylinder heads or turbo housings typically require 3-5 secondary operations including honing, thread rolling, and pressure testing.

Certified Delivery and Documentation

Final inspection generates a comprehensive package including:

First article inspection report per AS9102 format

Material test certificates with heat lot traceability

Surface roughness validation at critical sealing surfaces

Dimensional reports highlighting tolerance-critical features

Cleanliness certification (per VDA 19.2 for powertrain components)

Parts ship in custom anti-corrosion packaging with serialized tracking. Standard lead time for prototyping is 12-18 business days from CAD approval; production runs follow a documented ramp-up protocol with Ppk ≥1.67 validation. Every delivery includes a digital twin of the manufactured part for client CAD comparison, ensuring absolute dimensional compliance for engine assembly.

Start Your Project

For precision CNC engine components manufactured to the highest industry standards, contact Susan Leo at [email protected]. With our state-of-the-art factory located in Shenzhen, we deliver high-quality, custom-engineered solutions tailored to your specifications. Trust Honyo Prototype for reliable, efficient, and scalable CNC machining services in the heart of China’s manufacturing hub. Reach out today to discuss your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.