Contents

Manufacturing Insight: Cnc Drill Bits For Wood

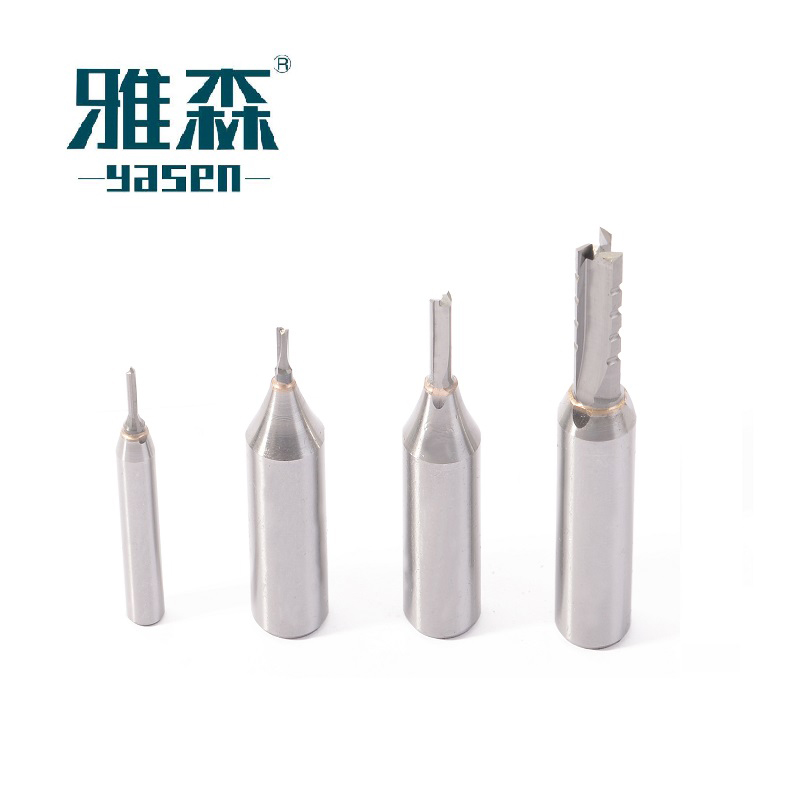

Precision CNC Drill Bits Engineered Specifically for Wood Substrates

At Honyo Prototype, we recognize that wood machining presents unique challenges distinct from metal or composite materials. Tear-out, chip evacuation, and edge chipping require drill bit geometries optimized for organic substrates. Our CNC drill bits for wood are not generic off-the-shelf tools but precision-engineered solutions developed through rigorous material science analysis and real-world application testing. Each bit features specialized flute geometries, optimized helix angles, and proprietary coatings designed to minimize splintering in hardwoods like oak and maple while maintaining clean bore integrity in softer materials such as plywood and MDF.

Leveraging decades of CNC machining expertise, Honyo Prototype tailors drill bit performance to your specific wood type, density, and production volume. Our engineering team collaborates directly with clients to select or develop custom tooling that enhances throughput, reduces tool wear, and ensures dimensional accuracy within ±0.005mm tolerances. This technical partnership extends beyond tool supply—we integrate seamlessly into your manufacturing workflow, providing actionable data on feed rates, RPM optimization, and maintenance protocols to maximize your CNC machine uptime.

Accelerate your prototyping or low-volume production cycle with Honyo’s Online Instant Quote platform. Upload your CAD file or specifications, and receive a detailed technical quotation within minutes—not days—including tooling recommendations, lead time estimates, and DFM feedback. This digital efficiency eliminates procurement delays while ensuring your wood machining requirements are met with engineering-grade precision from initial concept to final part.

Technical Capabilities

CNC drill bits designed for wood machining in multi-axis environments—particularly 3, 4, and 5-axis milling systems—require precise geometries, high rigidity, and optimized flute designs to maintain tight tolerances and surface finish. While primarily intended for wood and wood-based composites, these tools are often used in hybrid workflows involving soft metals and engineering plastics such as aluminum, steel (soft or pre-hardened), ABS, and nylon. Tool selection must account for material-specific thermal and abrasive characteristics to prevent deflection, chipping, or premature wear.

Below is a technical specification table outlining key parameters for high-performance CNC drill bits applicable to wood and compatible non-ferrous/thermoplastic materials in precision milling and turning operations.

| Parameter | Specification / Description |

|---|---|

| Tool Diameter Range | 1.5 mm – 20 mm (0.06″ – 0.787″) |

| Shank Diameter | Matched to tool diameter; ISO 2466 or DIN 6535 compliant for collet gripping |

| Overall Length (OAL) | 50 mm – 150 mm, optimized for depth-to-diameter ratio (up to 10:1) |

| Flute Count | 2-flute (standard for chip evacuation in wood); 3-flute for finer finish in ABS/nylon |

| Helix Angle | 30° – 40° (high helix for efficient chip removal in soft materials) |

| Point Angle | 90° – 118°; 90° preferred for wood to reduce splitting |

| Cutting Edge Geometry | Sharp, polished edges with rake angles of +15° to +25° for low-friction cutting |

| Coating (Optional) | TiAlN, AlTiN, or ZrN for extended tool life in abrasive composites or light aluminum |

| Material Compatibility | Hardwood, plywood, MDF, particleboard, ABS, nylon, aluminum (6061, 7075), mild steel (≤30 HRC) |

| Max Spindle Speed (RPM) | Up to 24,000 RPM (dependent on diameter and machine capability) |

| Tolerance Class | h6 to h7 for diameter; critical for tight-tolerance drilling in assembly interfaces |

| Runout Tolerance | ≤ 0.005 mm (0.0002″) at cutting tip for high-precision 5-axis applications |

| Recommended Coolant | Air blast or air-assisted mist; dry cutting typical; light oil mist for steel/ABS |

| Tool Holder Interface | ER collet, hydraulic, or shrink fit for high rigidity in 5-axis dynamics |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm depending on feed rate and material |

| Applications | 3/4/5-axis milling of furniture, cabinetry, prototyping; light turning on wood/metal hybrid components |

Note: For machining steel or high-abrasion materials, solid carbide or micro-grain carbide with specialized coatings is recommended. In pure wood applications, tungsten carbide-tipped (TCT) brazed bits offer cost-effective durability. When operating in mixed-material workflows, toolpaths should be segmented by material type to optimize feed rates, RPM, and depth of cut.

From CAD to Part: The Process

Honyo Prototype executes a streamlined, technology-driven workflow for CNC drill bit production tailored specifically for wood applications. This process ensures optimal performance characteristics like chip evacuation, reduced tear-out, and extended tool life in softwoods, hardwoods, and engineered composites. The structured sequence is as follows:

CAD Upload and Specification Review

Clients submit detailed 3D CAD models (STEP, IGES, or native formats) via our secure portal, specifying critical parameters: material type (e.g., pine, oak, MDF), hole diameter tolerance (±0.05mm typical), depth-to-diameter ratio, spindle speed range, and feed rate requirements. Our system validates file integrity and prompts for missing wood-specific inputs such as expected resin content or moisture levels, which directly impact flute geometry and coating selection.

AI-Powered Quoting and Feasibility Assessment

Our proprietary AI engine analyzes the CAD geometry against Honyo’s wood machining database of 15,000+ validated tool designs. It cross-references factors including:

Optimal helix angle (typically 30°–45° for wood to minimize chip packing)

Flute count (2-flute standard for clean finishes in hardwoods)

Point angle (90°–118° to reduce splintering)

Substrate-specific coating requirements (e.g., ZrN for resinous woods)

The system generates a real-time quote with lead time and flags potential issues like insufficient core strength for deep drilling in laminated materials. Typical quote turnaround is under 2 hours for standard geometries.

Design for Manufacturability (DFM) Optimization

Engineers conduct a rigorous DFM review focusing on wood-specific challenges:

Validating flute depth to prevent chip jamming in sticky resins

Adjusting relief angles to minimize rubbing in fibrous materials

Confirming shank concentricity (<0.01mm TIR) to avoid wander in CNC routers

Recommending carbide grade (e.g., K10 for abrasive composites)

This phase includes virtual machining simulations using wood-specific material models. Clients receive a DFM report with actionable suggestions, such as modifying web thickness for improved rigidity in pocket drilling operations.

Precision Production

Approved designs enter our dedicated wood-cutting tool production cell:

Substrate: Solid micrograin carbide blanks (0.5–6.0μm grain size)

Grinding: 5-axis CNC tool grinders with diamond wheels (±2μm accuracy)

Coating: Optional ZrN or TiAlN PVD coating applied at 300°C to prevent thermal shock in dry wood machining

Quality Control: In-process metrology checks spindle runout (<0.005mm) and edge hone consistency (0.01–0.03mm). Every batch undergoes functional testing in target wood species using client-specified parameters.

Delivery and Performance Validation

Finished drill bits ship with:

Certified inspection report (including flute profile measurements)

Recommended operating parameters for the specified wood type

Lifetime tracking via unique QR code for reconditioning requests

Standard lead time is 5–7 business days for quantities under 500 units. Expedited 72-hour service is available for critical path applications. Post-delivery, our application engineers provide performance analysis using client-collected data on tool wear progression and surface finish quality.

This integrated approach ensures drill bits achieve 30–50% longer service life in wood compared to generic industrial bits, directly reducing client downtime and per-hole machining costs. All process stages comply with ISO 9001:2015 standards, with wood-specific validation protocols documented in Honyo Procedure WP-2023-07.

Start Your Project

Looking for high-performance CNC drill bits designed specifically for wood applications? Our precision-engineered tools are manufactured to deliver clean, accurate, and efficient drilling in woodworking operations.

Built with durability and precision in mind, these CNC drill bits are ideal for cabinetry, furniture making, joinery, and other wood-based manufacturing processes. Produced in our Shenzhen factory, we ensure strict quality control and consistent performance for industrial and prototyping needs.

For product specifications, pricing, or custom solutions, contact Susan Leo at [email protected]. Let us support your production with reliable cutting tools made in China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.