Introduction: Navigating the Global Market for cnc drawing software

Investing in CNC drawing software can be a complex decision for international B2B buyers navigating a landscape filled with diverse options and technologies. The challenge lies not only in finding software that meets specific production needs but also in ensuring it aligns with budget constraints and future scalability. This guide on CNC drawing software addresses these concerns by providing an in-depth exploration of various software types, including CAD and CAM solutions, alongside insights into their diverse applications across industries.

Here, you will discover the critical factors to consider when vetting suppliers, such as support services, user communities, and update policies, which can significantly influence the software’s value proposition. Additionally, we will delve into cost implications, offering a range of solutions from affordable open-source options to premium offerings, catering to the unique demands of buyers from regions like Africa, South America, the Middle East, and Europe—particularly in countries like Saudi Arabia and Brazil.

By equipping you with the knowledge needed to make informed decisions, this guide empowers your organization to invest in CNC drawing software that not only enhances productivity but also fosters growth and innovation. Whether you are a seasoned expert or new to CNC technology, our comprehensive insights will aid you in successfully navigating the global market.

Understanding cnc drawing software Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CAD Software | Focus on 2D/3D design capabilities; precise geometrical modeling | Product design, prototyping | Pros: Excellent for detailed and technical designs; High precision. Cons: Steeper learning curve; potentially costly. |

| CAM Software | Converts CAD drawings into toolpaths; creates G-code | CNC programming, manufacturing | Pros: Streamlines transition from design to production; Essential for CNC operations. Cons: Can be complex; may need training. |

| Integrated CAD/CAM | Combines design and machining functions in one software solution | End-to-end project management | Pros: Simplified workflow; saves time. Cons: May lack depth in specialized features compared to standalone software. |

| Free/Open Source | Freely available with community support and regular updates | Cost-sensitive projects, startups | Pros: Zero cost; customizable. Cons: May have limited features; varying support quality depending on the community. |

| Specialized Software | Tailored for specific industries (e.g., woodworking, metalworking) | Industry-specific manufacturing | Pros: Optimized for unique tasks; offers specialized tools. Cons: May not be as versatile for general use; higher cost on niche focus. |

What Are the Characteristics of CAD Software for CNC Drawings?

CAD (Computer-Aided Design) software is crucial for creating intricate 2D and 3D models essential in CNC operations. This software allows users to represent their designs accurately, making it ideal for product design and prototyping in various B2B sectors, including manufacturing and engineering. Buyers should consider the software’s precision, ease of use, and compatibility with CAM systems, as a smooth integration enhances workflow efficiency.

Why Invest in CAM Software for CNC Operations?

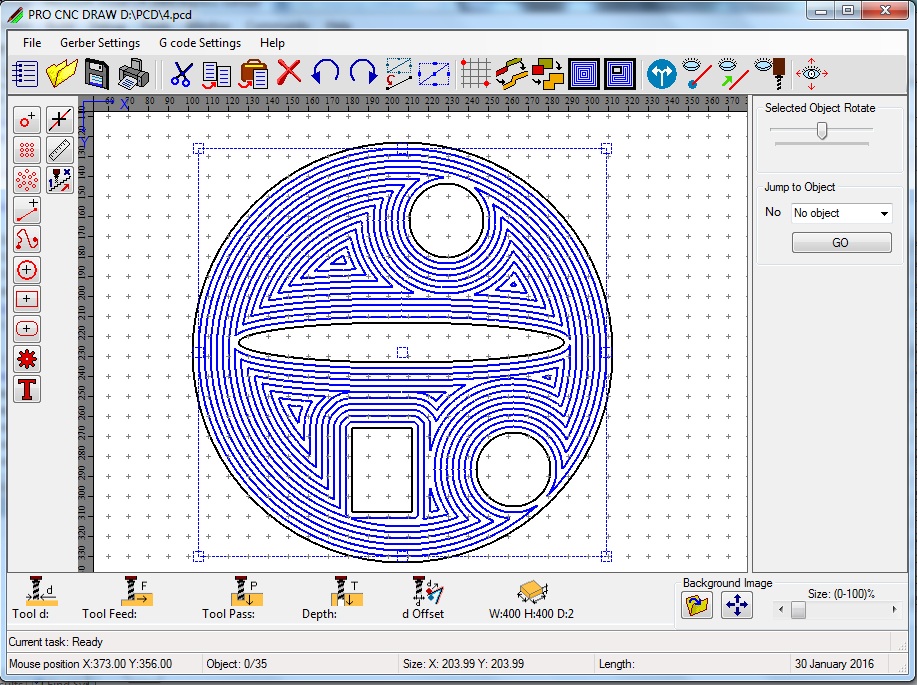

CAM (Computer-Aided Manufacturing) software is designed to translate CAD models into machine-readable G-code, enabling effective CNC programming. It excels in tasks involving machining, routing, and other manufacturing processes. When selecting CAM software, businesses should evaluate user-friendliness, the range of supported tools, and the ability to generate complex toolpaths. Procuring robust CAM software ensures a seamless production line and reduces lead times.

What Advantages Do Integrated CAD/CAM Solutions Offer?

Integrated CAD/CAM software combines design and machining functionalities, streamlining the workflow from concept to completion. This solution is ideal for companies seeking a holistic approach to project management, enhancing collaboration between design and production teams. Buyers should assess whether an integrated solution meets their specific needs, balancing ease of use against the depth of features available in specialized tools.

How Can Free or Open Source CNC Software Benefit Startups?

Free and open-source CNC software solutions provide budget-conscious businesses and startups with essential design and manufacturing tools without financial commitment. These platforms often come with community support and updates, making them appealing for those just entering the CNC realm. However, buyers should be aware of potential limitations in functionality and reliability compared to paid solutions, alongside the necessity for adequate self-support and training resources.

When Should Businesses Consider Specialized CNC Software?

Specialized CNC software is tailored for specific industries, such as woodworking or metalworking, incorporating features aimed at enhancing productivity within those sectors. This software often includes industry-specific tooling options and machining strategies that general-purpose CNC software may lack. Buyers should weigh the benefits of specialized functionalities against the flexibility of broader tools, especially if their operations span multiple domains.

Key Industrial Applications of cnc drawing software

| Industry/Sector | Specific Application of cnc drawing software | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision component fabrication | Increased accuracy and reduced waste during production | Compatibility with existing machinery; support for g-code formats |

| Furniture Design & Production | Custom furniture and cabinetry | Tailored designs to meet client specifications, optimizing material use and lowering costs | Material type; design flexibility for unique requests |

| Automotive | Prototyping and part production | Speeding up the development cycle and improving quality control in manufacturing | Scalability to production volumes; software integration with design tools |

| Aerospace | Fabrication of parts and tools | Enhanced precision improves safety and performance of products | Certification standards for software; international compliance |

| Electronics | Circuit board engraving and prototyping | Streamlined prototyping accelerates innovation timelines | Support for CAD standards; compatibility with PCB design software |

How is CNC Drawing Software Used in Manufacturing?

CNC drawing software is crucial in the manufacturing sector for precise component fabrication. The software allows engineers to create complex designs that can be seamlessly converted into tool paths for CNC machines. By enhancing accuracy and reducing material waste, businesses can optimize production efficiency. B2B buyers must consider the compatibility of the software with existing machinery and ensure it supports prevalent g-code formats, especially in international markets.

What is the Role of CNC Software in Furniture Design & Production?

In the furniture design and production industry, CNC drawing software is utilized for creating custom furniture and cabinetry designs. This software allows artisans to produce tailored designs that align with customer preferences, maximizing material efficiency. Key considerations for B2B buyers include the software’s flexibility to cater to unique design requests and compatibility with the various materials used in furniture production, essential for effective operations across diverse markets.

How Does CNC Software Aid Automotive Prototyping?

The automotive sector uses CNC drawing software for prototyping parts and tools. It accelerates the development cycle by allowing manufacturers to quickly visualize and fabricate components before mass production. This speed and precision lead to better quality control. International buyers should seek software that can scale with production needs and integrates well with existing design tools to streamline the entire workflow efficiently.

Why is CNC Software Critical in Aerospace Fabrication?

In aerospace, CNC drawing software plays a vital role in fabricating high-precision components and tools. The exacting standards of the industry require software that enhances accuracy, directly contributing to the safety and performance of aircraft. When sourcing, businesses should ensure that the software meets relevant certification standards and adheres to international compliance requirements, a critical factor for companies operating in globally regulated environments.

What Benefits Does CNC Drawing Software Offer Electronics Manufacturing?

CNC drawing software is integral to the electronics industry for tasks like circuit board engraving and prototyping. It allows for the rapid development of complex electronic components necessary for innovation. When sourcing CNC software, businesses must ensure compatibility with established CAD standards and PCB design software, which are often crucial for compliance and operational efficiency in electronics manufacturing, particularly in international settings.

3 Common User Pain Points for ‘cnc drawing software’ & Their Solutions

Scenario 1: Difficulties in Learning Complex Software

The Problem: Many businesses transitioning to CNC machining encounter CNC drawing software that appears powerful but is complex to master. This steep learning curve can leave users frustrated, especially if team members have varying levels of technical expertise. In regions such as Africa and South America, where access to robust training resources may be limited, this challenge can become a significant barrier to efficient production and innovation.

The Solution: To mitigate these learning difficulties, businesses should invest in CNC drawing software that offers comprehensive training resources. Software like Vectric provides free video tutorials and a supportive user community which can be invaluable for beginners. When selecting software, B2B buyers should prioritize options that include intuitive user interfaces and step-by-step guides. Additionally, organizing in-house training sessions or workshops can help build a skilled workforce. Collaborating with software providers for customized training programs can further enhance learning and retention, ensuring that all team members feel confident in using the software.

Scenario 2: High Costs of Licensing and Upgrades

The Problem: As businesses grow, the demand for advanced CNC functionalities increases, often leading to additional expenses. Many CNC drawing software packages charge high fees for licensing, upgrades, or premium features, which can strain budgets, particularly for small to mid-sized enterprises. Companies in regions like the Middle East and Europe may find themselves investing more in software than in equipment, creating an unsustainable model.

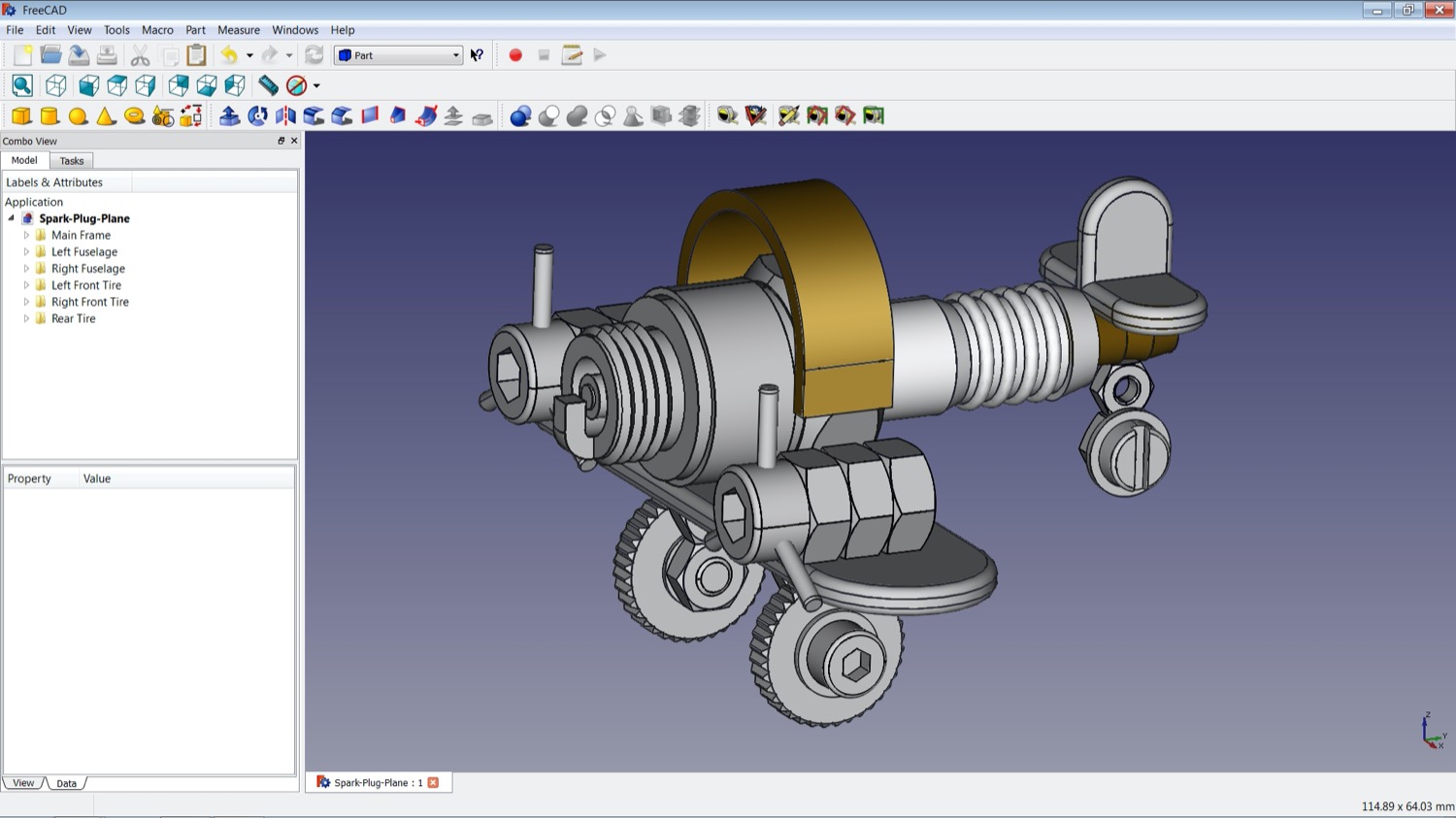

The Solution: To address this financial strain, organizations should conduct a thorough needs assessment to identify essential features versus nice-to-have options. Opting for CAD/CAM solutions like Carbide Create or Easel, which offer free versions or less expensive tiers, can drastically reduce costs while still providing necessary functionalities. Exploring open-source options such as FreeCAD can also help mitigate software expenses. When budgets allow, consider a software subscription that includes updates, ensuring you’re using the latest tools without incurring significant costs each time new features are released. Engaging in long-term contracts with providers can also create leverage for better pricing, provided you negotiate effectively.

Scenario 3: Compatibility Issues with Existing Equipment

The Problem: Many B2B buyers face compatibility challenges when integrating CNC drawing software with their existing machinery. For instance, specific CNC machines may only function properly with particular software systems, leading to wasted time and financial resources in the setup phase. Businesses that operate in diverse environments, such as those found in South America and Europe, may have equipment from various manufacturers, each with its software peculiarities.

The Solution: To overcome compatibility issues, it is crucial to conduct a compatibility analysis between existing machinery and potential CNC drawing software. Before purchase, B2B buyers should consult with software vendors to clarify compatibility requirements and look for software that supports multiple formats and integrates well with various CNC machines. Solutions like Easel, which is designed to work with a wide range of CNC routers, can simplify this process. A staged integration approach should also be considered; testing the software with one machine before full-scale implementation can help identify and resolve potential issues early on. Keeping an open dialogue with machinery manufacturers regarding updates and compatibility can also enhance operational efficiency as the software ecosystem evolves.

Strategic Material Selection Guide for cnc drawing software

When selecting materials compatible with CNC drawing software, understanding the properties and performance implications is crucial for B2B buyers. This analysis focuses on four common materials: wood, aluminum, plastics (specifically acrylic), and steel.

What Are the Key Properties of Wood in CNC Drawing Applications?

Wood is favored for its aesthetic appeal and ease of machining. It comes in various species with different hardness levels, making it essential to choose the right type for specific applications. Key properties include a moderate temperature rating, typically around 100°F-200°F (37°C-93°C) for optimal performance in CNC applications, and generally good workability, leading to less tool wear. Additionally, wood can absorb moisture, influencing its dimensional stability and density.

Pros include its versatility, cost-effectiveness, and the ability to produce high-quality finishes easily. Cons encompass potential warping, susceptibility to moisture damage, and variability in strength between different wood types. For international buyers, regulations regarding sustainable sourcing and local standards should be assessed; for instance, compliance with FSC (Forest Stewardship Council) is often required in Europe and some regions in South America.

Why Is Aluminum a Popular Choice for CNC Applications?

Aluminum is increasingly popular in CNC machining due to its lightweight nature and excellent corrosion resistance. It has a temperature rating of approximately 500°F (260°C) without sacrificing performance. Key properties like machinability, strength-to-weight ratio, and recyclability make it suitable for a range of applications, from aerospace components to custom furniture elements.

The advantages of aluminum include durability and the ability to achieve intricate designs with precise cuttings. However, it also has disadvantages, such as a relatively higher cost than wood and the potential for issues with tool wear if not machined correctly. For international buyers, conformity to standards such as ASTM in the U.S. or EN in Europe is crucial, particularly when producing components for industries that require specified material grades.

What Are the Benefits of Using Acrylic in CNC Drawing Projects?

Acrylic, a type of thermoplastic, has grown in popularity due to its clarity and ease of machining, with good long-term durability. It typically holds up well under a temperature range of -20°F to 180°F (-29°C to 82°C). The clarity of acrylic allows for creative designs that can incorporate lighting effects, making it ideal for signage and displays.

The pros of choosing acrylic include its lightweight properties, lower costs compared to glass, and resistance to UV light. On the downside, acrylic can be more prone to scratching than glass and may shatter if not handled properly. Internationally, factors such as compliance with ISO standards or local regulations regarding plastic use should be carefully reviewed, as there are varying preferences for recyclable materials in different regions.

How Does Steel Stack Up as a Material for CNC Drawing Techniques?

Steel, while heavier and more challenging to machine, offers unparalleled strength and durability, making it ideal for heavy-duty applications. It typically withstands temperatures well above those relevant to most ordinary machining needs, holding up in the range of 1300°F (704°C) in some cases. Its machinability depends heavily on the alloy used.

Strengths of steel include its ability to withstand heavy loads and a long lifecycle, but drawbacks involve higher machining costs and potential tooling issues, especially if quality cutting tools aren’t used. Additionally, international buyers must consider compliance with standards like ASTM and DIN (Deutsches Institut für Normung) or JIS (Japanese Industrial Standards) to ensure the received materials meet the necessary specifications.

| Material | Typical Use Case for CNC Drawing Software | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, decorative elements | Versatile and cost-effective | Susceptible to warping and moisture | Low |

| Aluminum | Aerospace parts, custom furniture | Excellent strength-to-weight ratio | Higher material costs | Med |

| Acrylic | Signage, display cases | Lightweight and UV resistant | Prone to scratching and shattering | Low |

| Steel | Heavy machinery, structural components | Unmatched strength and durability | High machining cost and tooling wear | High |

In-depth Look: Manufacturing Processes and Quality Assurance for cnc drawing software

What Are the Main Stages of CNC Drawing Software Manufacturing Processes?

The production of CNC drawing software is a nuanced process that involves multiple stages to ensure a reliable, high-quality product. Understanding these stages can significantly benefit B2B buyers when evaluating software providers.

1. Material Preparation: Developing the Core Software Structure

The initial phase involves outlining the software’s architecture. This includes deciding on the programming languages and tools to be utilized for development, often focusing on languages such as C++, C#, or Python for their robustness in handling CAD/CAM functionalities. Research and testing of libraries for mathematical computations and graphical rendering occurs here. Ensuring the software supports various file formats, such as DXF, STL, and SVG, is also imperative. Effective collaboration tools and version control systems are utilized at this stage to streamline processes and enable team integration.

2. Forming: Writing and Compiling Software Code

Once material preparation is complete, developers begin writing code following design specifications. This stage often incorporates agile methodologies to allow for flexibility and iterative improvements. Continuous integration and testing methods are employed to ensure that new code additions do not introduce bugs. The software undergoes execution of essential functions, such as converting drawn designs into toolpaths, ensuring that CAD/CAM integrations are seamless.

3. Assembly: Integration of Components and Features

After the code has been written and tested, the integration of various software components occurs. This includes joining the design interface with the toolpath generator and linking input and output functionalities. The user experience (UX) is refined at this stage, focusing on ease of use, which is particularly important in B2B environments where users may not be highly experienced with CNC technologies. Tools for project collaboration and community involvement are integrated here, allowing users to share experiences and solutions.

4. Finishing: Final Enhancements and Polishing

The final stage involves debugging, user testing, and refining the software. A beta version may be released to select users, allowing real-world feedback that can lead to last-minute adjustments. This step is crucial for ensuring that the software is user-friendly and meets industry standards. Documentation is compiled, and online training modules and video tutorials are produced to facilitate user adoption.

How is Quality Control Implemented in CNC Drawing Software Production?

Quality assurance (QA) in CNC drawing software development is an essential consideration for B2B buyers looking for reliable and efficient solutions. The focus on quality not only enhances software performance but also improves user satisfaction and productivity.

Relevant International Standards for Software Quality Management

Many software manufacturers adhere to established quality management standards, such as ISO 9001, which specifies guidelines for quality management systems. This standard ensures that the software development process is systematic, with defined processes aimed at continual improvement. Additionally, specific certifications related to software security and control, such as CE (Conformité Européenne), can assure buyers that the software meets European health and safety requirements.

What Are QC Checkpoints in the Software Development Lifecycle?

Quality Control (QC) checkpoints throughout the software lifecycle help ensure that any issues are identified and rectified early. Key QC checkpoints include:

-

Incoming Quality Control (IQC): Here, code contributions from various developers are assessed to verify their quality before they become part of the main software stream. Code reviews and static analysis are common practices in this phase.

-

In-Process Quality Control (IPQC): Continuous integration systems automatically run tests on compiled code to catch defects as they arise. Automated test suites can cover functionality and performance, ensuring adherence to specifications.

-

Final Quality Control (FQC): Prior to final software release, extensive testing is conducted which may include user acceptance testing (UAT) and load testing. This ensures the software can handle the expected volume of users and operations without degradation in performance.

How Can B2B Buyers Verify Supplier QC Practices?

For B2B buyers, ensuring that a software supplier adheres to strict quality control measures is paramount, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. Buyers can employ several strategies:

Supplier Audits and Compliance Checks

Conducting supplier audits can provide insights into the QC processes used during software development. Buyers should evaluate the supplier’s adherence to international standards like ISO 9001 and check if they have relevant industry-specific certifications, such as CE marking for software products used in safety-critical applications.

Requesting QC Reports and Documentation

B2B buyers should request detailed QA documentation from suppliers, including test reports, defect rates, and user feedback records. Comprehensive test data can reveal much about the reliability and functionality of the software. Manufacturers should be willing to provide historical performance metrics that underscore their commitment to quality.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can provide an unbiased assessment of a software supplier’s quality practices. These organizations often employ industry-expert evaluators to assess compliance with international standards and provide comprehensive analyses of QC methodologies.

What Are the QC/CERT Nuances for International B2B Buyers?

When engaging with suppliers across different geographic regions, B2B buyers should be conscious of nuanced aspects of quality assurance:

-

Regulatory Compliance Variability: Different regions may have unique regulations and compliance requirements. It’s essential for buyers to understand local market requirements, such as data protection laws in Europe (GDPR), which may affect software functionality and certification.

-

Technical Support and Updates: Due to varying levels of infrastructure and technical expertise, B2B buyers should ensure comprehensive support services are in place, including regular updates and effective customer service.

-

Cultural Context: The cultural and market context can impact how quality is perceived and implemented. Buyers must assess if the supplier’s quality assurance practices align with their commercial ambitions and market expectations.

By comprehensively understanding manufacturing processes, quality control checkpoints, and methods of verifying supplier practices, B2B buyers can make informed decisions on CNC drawing software that will meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc drawing software’

To facilitate an effective sourcing decision for CNC drawing software, international B2B buyers must navigate a complex landscape of options tailored to varying requirements. This practical sourcing guide outlines key steps to ensure that you select the right software to enhance your CNC machining capabilities and optimize your business processes.

1. Define Your Technical Specifications

It’s essential to outline what your business needs from CNC drawing software. Consider the specific features required, such as 2D or 3D design capabilities, tooling options, and compatibility with existing systems. Understanding these specifications will help streamline the selection process and ensure the software meets operational requirements.

2. Identify Key Software Features

Create a list of must-have features that your CNC drawing software should possess. Look for functionalities like:

– CAD Integration: The ability to create or edit designs seamlessly.

– CAM Capabilities: Ensure the software can generate G-code to facilitate CNC instruction.

– User-friendly Interface: A streamlined workflow can lead to increased productivity, especially for teams with varying levels of expertise.

Prioritizing these features will help in comparing different software solutions effectively.

3. Evaluate Potential Suppliers

Before making a selection, conduct thorough evaluations of potential suppliers. This involves:

– Requesting demos or trial versions: Engaging with the software allows you to assess usability and features firsthand.

– Checking credentials: Verify the supplier’s reputation through case studies and client testimonials that reflect their reliability and support.

This vetting process ensures you don’t just rely on marketing claims but gauge practical performance.

4. Assess Support and Training Resources

Consider the level of support offered post-purchase. A supplier that provides substantial training resources, whether through online tutorials, user forums, or live support, can greatly impact the efficiency of your team’s onboarding process. Look for:

– Community support: Access to forums or user groups can facilitate ongoing learning and problem solving.

– Documentation availability: Comprehensive guides and manuals are crucial for troubleshooting and maximizing software usage.

5. Compare Pricing Models

Understanding the pricing structure is vital before making a commitment. Prices may vary based on subscription models, one-time purchases, or tiered pricing based on feature sets. Factors to consider include:

– Total Cost of Ownership: Include potential upgrade costs and support fees over time.

– Licensing Options: Determine if the software is licensed per user or per machine, which could affect scalability.

This financial analysis ensures that you are budgeting effectively and getting value for your investment.

6. Seek Industry-Specific Adaptations

If your business operates within a niche market, find out if the software can be customized to meet specific industrial demands. Some suppliers offer tailored solutions that align with certain sectors, which can enhance workflow efficiency. Look for:

– Case studies from similar industries: This can provide insights into the software’s effectiveness in your specific market.

– Customizability: Explore whether the software can adapt to new developments or designs as your business evolves.

7. Finalize Your Decision

After compiling all relevant information and recommendations, review all findings with key stakeholders in your organization. Assess how each software aligns with your business’s strategic goals and operational capacities. By carefully weighing each option, you’ll make a more informed decision that supports your long-term objectives.

Comprehensive Cost and Pricing Analysis for cnc drawing software Sourcing

What Are the Key Cost Components Influencing CNC Drawing Software Pricing?

The cost structure for CNC drawing software encompasses several critical components that businesses must understand to make informed purchasing decisions. Key components include:

-

Materials: While software itself isn’t composed of physical materials, the underlying technology, such as cloud servers and data storage, has its costs. Companies investing in software development may incur expenses in hardware (servers, computers) and associated technologies.

-

Labor: Development teams consist of skilled software engineers, designers, and project managers. Labor costs can vary significantly based on geographical location and team experience. Regions with lower labor costs, such as parts of Africa and South America, may offer competitive pricing advantages.

-

Manufacturing Overhead: This includes indirect costs related to the production of software, such as utilities, administrative expenses, and facility rent. While these are less visible than direct costs, they contribute to the overall pricing strategy.

-

Tooling: For software, tooling costs refer to the development environments, testing tools, and infrastructure used during creation. These investments are factored into the final software price.

-

Quality Control (QC): Ensuring that software is reliable involves implementing rigorous testing processes. Companies that emphasize quality might incur higher QC costs, which can reflect in the pricing.

-

Logistics: For digital products like software, logistics costs may involve the distribution of licenses and software updates. Efficient distribution methods can help minimize these costs.

-

Margin: Finally, vendors will factor in their desired profit margin. This will vary significantly based on market positioning, competitive landscape, and business model.

What Influences Software Pricing in the CNC Market?

Several factors impact the pricing dynamics for CNC drawing software:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing typically results in volume discounts. When procuring software licenses, businesses may negotiate better rates for larger orders.

-

Specifications and Customization: Custom solutions can significantly raise costs. Buyers seeking tailored features should be prepared for higher development fees compared to off-the-shelf software.

-

Quality and Certification Standards: Software that complies with industry standards or possesses relevant certifications may command higher prices. This may be especially pertinent in regulated markets.

-

Supplier Factors: Brand reputation, customer support, and ongoing software maintenance options are critical considerations. Established vendors may charge a premium for reliability and support.

-

Incoterms: While software is often delivered electronically, understanding delivery terms and any associated costs (for example, fees for usage limitations or software licensing) can influence the total price.

How Can Buyers Negotiate Better Prices for CNC Software?

Given the complexity of software pricing, effective negotiation becomes paramount. Buyers can adopt several strategies:

-

Understand Total Cost of Ownership (TCO): Evaluate the long-term operational costs associated with all software solutions, including subscriptions, training, support, and upgrade costs. This understanding can support negotiations for better pricing.

-

Leverage Competitive Offers: Presenting offers from competing software vendors can enhance negotiating power. Vendors often aim to secure contracts and might be willing to match or beat competitors’ prices.

-

Seek Volume Pricing Agreements: If considering multiple licenses or long term contracts, engage with suppliers to establish pricing tiers based on expected use, allowing room for discussions to unlock discounts.

-

Explore Free Trials: Many vendors provide free trials, which can serve as an opportunity for assessment before committing financially. This can also provide leverage in discussing terms based on user experience.

-

Cost-Efficiency Awareness: Keep abreast of ongoing software innovations that may impact pricing. For example, if a new version or an alternative lower-cost option emerges, highlighting this can support efforts to negotiate better terms.

Conclusion: What Should International Buyers Consider in Their Procurement Process?

For international buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding local market dynamics and pricing nuances is crucial. Variability in software pricing can reflect differences in labor costs, market demand, and currency fluctuations. Furthermore, logistics and local support structures will vary, so weighing these factors can lead to more informed sourcing decisions.

Disclaimer: Prices may vary and are subject to change based on market conditions and vendor policies. Buyers are encouraged to conduct thorough research and consider multiple quotations to obtain the best deals.

Alternatives Analysis: Comparing cnc drawing software With Other Solutions

Understanding Alternative Solutions to CNC Drawing Software

In the world of CNC machining, utilizing the right software is critical for efficiency and accuracy. However, there are various alternative solutions that can serve similar functions as traditional CNC drawing software. By evaluating these alternatives, businesses can make informed decisions that align with their operational needs and budget constraints.

| Comparison Aspect | Cnc Drawing Software | Free CAD/CAM Software (e.g., Easel) | Open-Source CAD (e.g., FreeCAD) |

|---|---|---|---|

| Performance | High accuracy and speed for complex designs | Good for basic designs and small projects | Suitable for detailed designs, but may have slower performance due to complexity |

| Cost | Monthly/annual license fees, which can be substantial | Generally free to use, with limitations on features | Completely free, but may require additional funding for support |

| Ease of Implementation | User-friendly interfaces, often with tutorials available | Easy to start but limited to basic functions | Steeper learning curve; ideal for those with technical experience |

| Maintenance | Regular updates and customer support offered | Minimal, mostly community-driven support | Community forums available, but lacking structured support |

| Best Use Case | Professional settings needing robust tools for complex projects | Hobbyists and small business owners needing basic functionalities | Engineers or designers looking for customizable solutions |

Pros and Cons of Free CAD/CAM Software

Free CAD/CAM software, such as Easel, offers a valuable alternative primarily for budget-conscious users. It presents a compelling case for businesses that don’t necessitate advanced features. The intuitive user interface allows beginners to jump in quickly, but such software often lacks the depth needed for intricate designs, making it less suitable for complex projects. While it can facilitate straightforward operations, users might find themselves limited as their needs evolve.

Pros and Cons of Open-Source CAD Solutions

Open-source CAD solutions like FreeCAD cater to a more technically oriented audience. They provide robust features and customization options without any licensing costs, making them highly attractive, particularly for engineering applications. However, the trade-off here is the steep learning curve associated with mastering these platforms. For teams lacking technical expertise, the initial setup and ongoing use may require considerable training. Despite these challenges, the flexibility that comes with open-source software makes it a great fit for organizations able to invest time in learning and adaptation.

Making the Right Choice in CNC Software Solutions

For B2B buyers, choosing between CNC drawing software and its alternatives depends on several factors including budget, ease of implementation, and specific operational needs. Businesses must ask themselves how complex their projects typically are and whether they have the capacity for training in more complex software solutions. Additionally, considering the long-term scalability and support framework is crucial. Ultimately, whether a well-established software package, free tools, or open-source solutions are the right fit will depend on the unique business objectives and resources available.

Essential Technical Properties and Trade Terminology for cnc drawing software

What Are the Key Technical Properties of CNC Drawing Software?

When assessing CNC drawing software, several technical properties are crucial for ensuring efficient and precise operations. Here are some of the most important specifications:

-

File Compatibility:

This property indicates the software’s ability to work with various file formats such as DXF, STL, SVG, and G-code. Compatibility is essential as it allows seamless integration with other CAD/CAM tools and CNC machines, ensuring that designs can be effortlessly imported and exported. This helps in reducing errors and improving workflow efficiency, especially in diverse production environments. -

Precision and Tolerance Settings:

Precision refers to the degree of accuracy in the software’s ability to represent designs, while tolerance defines the allowable deviation from specified dimensions. High precision and manageable tolerance settings are crucial for producing parts that meet strict quality standards. In B2B scenarios, this ensures that parts fit together properly and function as intended, which can significantly affect product performance and customer satisfaction. -

User Interface and Usability:

A well-designed user interface facilitates easier navigation through the software, allowing both seasoned users and newcomers to operate it effectively. Good usability is especially important for companies seeking to onboard new employees quickly and reduce training costs. It enables teams to focus on production rather than grappling with software complexities. -

Toolpath Generation Capability:

This feature involves the software’s ability to create toolpaths for CNC machines efficiently. The more advanced the toolpath generation capability—like 2.5D and 3D machining strategies—the more versatile and capable a CNC setup becomes. This versatility can be a significant competitive advantage in manufacturing, allowing for more diverse products and reducing lead times. -

Support and Community Resources:

Many software providers offer extensive support and community-driven resources, including forums, tutorials, and free upgrades. This ensures that users can easily access help and resources to solve issues as they arise. For B2B buyers, robust support can reduce downtime and maintenance costs, enhancing productivity. -

Scalability:

Scalability measures how well the software can adapt to increased workload or complexity as a business grows. As companies expand their operations or product offerings, having scalable software ensures that it can accommodate new functionalities without requiring a complete overhaul of the existing systems.

What Essential Trade Terminology Should B2B Buyers Know in CNC Software?

Understanding key trade jargon can significantly enhance communication and decision-making in the CNC industry.

-

OEM (Original Equipment Manufacturer):

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of CNC drawing software, partnering with an OEM could ensure that the software integrates seamlessly with specific machinery, leading to improved compatibility and performance. -

MOQ (Minimum Order Quantity):

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers of CNC software, understanding MOQ can help in budgeting, inventory management, and avoiding overstock or stockouts, which could affect production schedules. -

RFQ (Request for Quotation):

An RFQ is a business process where an organization solicits bids from suppliers for the provision of specific goods or services. For CNC software procurement, issuing an RFQ can help businesses compare different software offerings and their respective costs, ensuring that they get the best value for their investment. -

Incoterms (International Commercial Terms):

Incoterms are a series of pre-defined international rules published by the International Chamber of Commerce (ICC) relating to international commercial law. For B2B transactions in software procurement and delivery, understanding these terms helps clarify responsibilities for shipping, insurance, and tariffs. -

SaaS (Software as a Service):

SaaS refers to software that is hosted in the cloud and offers access to users via the internet. This model is becoming popular in CNC software, providing flexibility, easy updates, and lower upfront costs, making it an attractive option for B2B buyers. -

Lead Time:

Lead time refers to the period between the initiation and completion of a production process. In the context of CNC drawing software, understanding lead times is vital for planning and meeting customer demands, as it directly impacts product availability and overall business efficiency.

By familiarizing themselves with these properties and terms, B2B decision-makers can make more informed choices, optimizing their investments in CNC drawing software to drive productivity and growth.

Navigating Market Dynamics and Sourcing Trends in the cnc drawing software Sector

Understanding the Current Landscape of CNC Drawing Software: What Are the Key Market Dynamics?

The CNC drawing software market is experiencing significant transformation, driven by the increasing integration of advanced technologies like artificial intelligence, machine learning, and automation. International B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, are actively seeking solutions that enhance operational efficiency and productivity. The demand for user-friendly interfaces that simplify the design-to-manufacturing process is also on the rise. For instance, software solutions that allow for rapid prototyping and quick iterations are becoming essential for companies aiming to stay competitive in a time-sensitive market.

Additionally, there is a notable shift towards software-as-a-service (SaaS) models, which provide businesses with flexibility and scalability without significant upfront costs. This model is particularly advantageous for smaller manufacturers in developing regions that may have limited capital for hefty software investments. Localized support and training are increasingly important as international companies seek to overcome language barriers and varying levels of technical expertise, ensuring smoother transitions and better integration of new tools into existing workflows.

Emerging trends also highlight the growing importance of collaboration and connectivity among software applications. B2B buyers are increasingly looking for software that seamlessly integrates with existing hardware and tools, allowing for a streamlined workflow from design to machining. This interconnectedness fosters a culture of adaptation, enabling companies to pivot quickly in response to market demands or changes in consumer preferences.

How Is Sustainability and Ethical Sourcing Influencing the CNC Drawing Software Market?

Sustainability and ethical sourcing are becoming paramount considerations for B2B buyers in the CNC drawing software sector. Companies are increasingly assessing the environmental impact of their software purchases and the sourcing practices of their technology suppliers. This trend is driven by a global movement towards more environmentally friendly manufacturing processes, with an emphasis on reducing waste and energy consumption in CNC machining.

B2B buyers are prioritizing software solutions that offer functionalities enabling sustainable practices, such as optimizing material usage and incorporating recycling at various stages of the product lifecycle. Certifications indicating adherence to green standards are crucial; buyers are more likely to choose software providers that demonstrate commitment to sustainability through recognized certifications or environmentally friendly policies.

Moreover, ethical supply chain practices are gaining traction as buyers seek transparency regarding the sourcing of software components. Establishing trust and accountability becomes critical, particularly when engaging with suppliers from different regions. This demand encourages software companies to provide more transparency in their business practices and forge partnerships with manufacturers that share similar values regarding sustainability and ethical sourcing.

What Is the Significance of the Evolution of CNC Drawing Software for Today’s B2B Buyers?

The CNC drawing software landscape has evolved significantly since the inception of computer-aided design (CAD) tools. Initially focused on 2D drafting and basic modeling, the evolution now encapsulates advanced 3D modeling, integrated CAM functionalities, and user-friendly interfaces. This evolution has been fueled by technological advancements and an increased need for precision in manufacturing processes.

For today’s B2B buyers, this evolution represents opportunities to leverage software that not only enhances design capabilities but also integrates seamlessly with advanced machining technology. Modern CNC software now offers cloud-based solutions, collaborative features, and vast libraries of pre-existing models and projects, which can significantly reduce time to market. As buyers evaluate software options, understanding this evolution allows them to make informed decisions that align with their operational needs and growth strategies.

In essence, the shift in CNC drawing software reflects broader technological trends that emphasize efficiency, sustainability, and user-centric design. For international B2B buyers, particularly in emerging markets, navigating these dynamics will be essential for remaining competitive and achieving long-term success in an increasingly complex global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc drawing software

-

How do I solve compatibility issues between CNC drawing software and my CNC machine?

To solve compatibility issues, first verify that the software output formats align with your CNC machine’s requirements. Most CNC machines accept G-code, so ensure your software can generate this. Check for supported file formats (like DXF, SVG, or STL) to ensure smooth data transfer. Additionally, consulting your machine’s user manual can help clarify compatibility specifics. Engaging with software vendors for their recommendations on compatible machines can also provide insights and help you establish a seamless workflow. -

What is the best CNC drawing software for small CNC machining businesses?

The best CNC drawing software for small businesses often depends on your specific requirements, including ease of use and budget. Popular options like VCarve offer user-friendly design capabilities with robust 2.5D toolpaths. Alternatively, if budget constraints are a concern, consider free options like FreeCAD for complex designs or Inkscape for 2D artwork. Evaluate software offering comprehensive training resources and community support, as these can be vital for maximizing productivity and reducing downtime while you ramp up operations. -

How do I vet suppliers of CNC drawing software?

To vet suppliers, conduct thorough research focusing on their industry reputation and customer reviews. Check for user testimonials and third-party evaluations to assess reliability and software performance. Additionally, confirm suppliers offer support services such as technical assistance, tutorials, and community forums, enhancing user experience. Engage with other businesses in your network regarding their experiences. Finally, request a demonstration or trial version of the software to evaluate compatibility and functionality for your specific needs. -

What customization options are typically available in CNC drawing software?

Many CNC drawing software solutions offer customization features, allowing users to tailor tools and functionalities to their specific needs. Look for software that enables you to modify toolpaths, design templates, and user interfaces. Some platforms allow the integration of unique design elements and the use of custom libraries, while others enable users to create bespoke toolpaths for specialized machining processes. Ensure to confirm the extent of these customization features during supplier discussions, which can greatly enhance your operational efficiency. -

What are the typical minimum order quantities (MOQ) for CNC drawing software licenses?

MOQs for CNC drawing software licenses can vary widely based on the vendor and the type of license you are interested in. Many software suppliers offer tiered pricing based on the number of licenses purchased, meaning lower prices for bulk orders. In some cases, there may not be a minimum order requirement for small enterprises or individual licenses. It’s advisable to discuss your needs directly with suppliers, as they may offer flexible arrangements or package deals designed for startups or smaller firms. -

What payment terms should I expect when sourcing CNC drawing software internationally?

Payment terms vary by supplier, but in general, you can expect options ranging from upfront payment to net 30 or net 60 terms. Some vendors may offer a tiered payment scheme for larger orders. It’s essential to clarify any international transaction fees and currency considerations, which can impact the total cost. Confirm the accepted payment methods (such as credit card, PayPal, wire transfer) to avoid issues during the purchasing process. Negotiate terms that support your cash flow while remaining competitive. -

How does quality assurance (QA) work for CNC drawing software products?

Quality assurance processes for CNC drawing software typically include rigorous testing phases during development. Press releases or vendor communications should detail specific QA methodologies, including version updates and bug fixes. It’s helpful to inquire about their support structure for troubleshooting and resolving quality issues after software deployment. Vendors that maintain strong customer feedback mechanisms tend to have greater accountability and responsiveness in addressing software quality, thus ensuring reliable performance for users. -

What logistics considerations should I keep in mind for SaaS-based CNC drawing software?

For Software as a Service (SaaS) CNC drawing software, consider server reliability and data storage policies, particularly if your operations rely heavily on constant access. Evaluate the software’s bandwidth requirements and whether it can integrate with your existing infrastructure. Data security and compliance with local regulations in your region—especially for businesses operating across different countries—should also be prioritized. Lastly, ensure the software provider offers a clear roadmap for updates and maintenance, minimizing disruptions to your production workflow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Drawing Software Manufacturers & Suppliers List

1. Carbide Create – Entry-Level Software

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Carbide Create – Entry-level software, free version available (unsupported) at https://carbide3d.com/carbidecreate/download.

2. Fusion 360 – Offers free use for home applications.

3. F-Engrave – Open source and free.

4. Vectric Cut2D – Inexpensive option, monthly payments possible.

5. ArtCAM – Requires monthly payments, inexpensive option.

6. PixelCNC – Low-cost CNC software.

7. EstlCAM – Affor…

2. Carbide 3D – Free CNC Software and 3D CAD Tools

Domain: carbide3d.com

Registered: 2013 (12 years)

Introduction: Free CNC Software, FreeCAD, 3D CAD parametric program, Outputs: STL, STEP, SVG, DXF, Runs on: Mac, Windows, Linux; Solvespace, Free 3D CAD program, Better for mechanical parts, Outputs: STL, STEP, Runs on: Mac, Windows, Linux; Inkscape, 2D design software, Exports: SVG, DXF, Runs on: Mac, Windows, Linux; Alibre Atom, Commercial CAD program, Costs: ~$200 USD, Runs on: Windows; Carbide Create, 2D CA…

3. Vectric – Key Products

Domain: vectric.com

Registered: 2005 (20 years)

Introduction: Key Products: Cut2D, VCarve, Aspire, Makerspace Edition, Laser Module, EasyCarve, Cut3D, PhotoVCarve.

1. Cut2D: Easy to use vector drawing and editing software for 2D machining strategies.

2. VCarve: Expands on Cut2D with 2.5D toolpaths including v-carving, chamfer, and the ability to import and machine 3D models.

3. Aspire: Combines 2D and 2.5D tools from Cut2D and VCarve with advanced 3D design …

4. Easel – All-in-One CNC Software

Domain: easel.com

Registered: 1997 (28 years)

Introduction: Easel® is an all-in-one CNC software solution designed for design and CNC machining that allows users to start carving in minutes. Key features include: 1) Design tools for creating stunning and functional designs, 2) Carve capabilities for achieving perfect cuts, and 3) Streamlined workflow for maximizing profitability. Easel includes a Project Gallery for inspiration, supports 3D Carving with ST…

5. Inventables – Easel® CNC Software

Domain: inventables.com

Registered: 2001 (24 years)

Introduction: Easel® CNC Software is an all-in-one solution designed for CNC operations, enabling users to start carving in minutes. It offers a 30-day free trial and includes features such as 3D carving capabilities available for Easel Pro users, with support for over 30 types of CNC routers, including X-Carve and X-Carve Pro. Users can import STL files, making it easy to create and sell high-quality 3D carves…

6. Carveco – Carveco Maker

Domain: carveco.com

Registered: 2018 (7 years)

Introduction: Carveco Maker is a powerful, entry-level CNC software solution designed for creating high-quality 2D and 3D products easily and quickly. Key features include:

– Affordable subscription at $15/month.

– Suitable for hobbyists, traditional craftsmen, and newcomers to CNC routing and engraving.

– Comprehensive design tools, including vector drawing, text addition, and bitmap import capabilities.

– Bit…

7. Autodesk – Fusion 3D CAD/CAM Software

Domain: autodesk.com

Registered: 1989 (36 years)

Introduction: CNC Software for Machining and Manufacturing: Autodesk Fusion is a CAD/CAM software designed for CNC machines. It integrates CAD, CAM, and CAE for a connected design and manufacturing workflow. Autodesk Fusion allows users to refine milling projects by creating toolpaths for CNC machines that control the motion of cutting tools. It supports various configurations of CNC machines (3-axis, 4-axis, 5…

Strategic Sourcing Conclusion and Outlook for cnc drawing software

In the rapidly evolving landscape of CNC drawing software, strategic sourcing remains paramount for international buyers. Companies aiming to optimize their production processes must prioritize selecting software that enhances design efficiency, accuracy, and cost-effectiveness. Emphasizing robust solutions like Vectric, Carbide 3D, and Easel not only boosts workflow but also mitigates the risk of overspending on inadequate software capabilities. Leveraging the right tools can dramatically reduce time-to-market and enhance the overall quality of manufactured goods.

For businesses in Africa, South America, the Middle East, and Europe, the key takeaway is to evaluate software that aligns with both current needs and future growth. Embracing platforms with strong community support, affordable trials, and comprehensive features allows companies to scale efficiently while staying competitive in a global market.

As CNC technology advances, the prospects for enhanced creativity and productivity are promising. Now is the time for buyers to act and invest in CNC drawing software that not only meets immediate operational requirements but also paves the way for sustainable growth in an interconnected world. Explore the options available and make strategic choices that will elevate your business to new levels of success.