Contents

Manufacturing Insight: Cnc Draaimachine

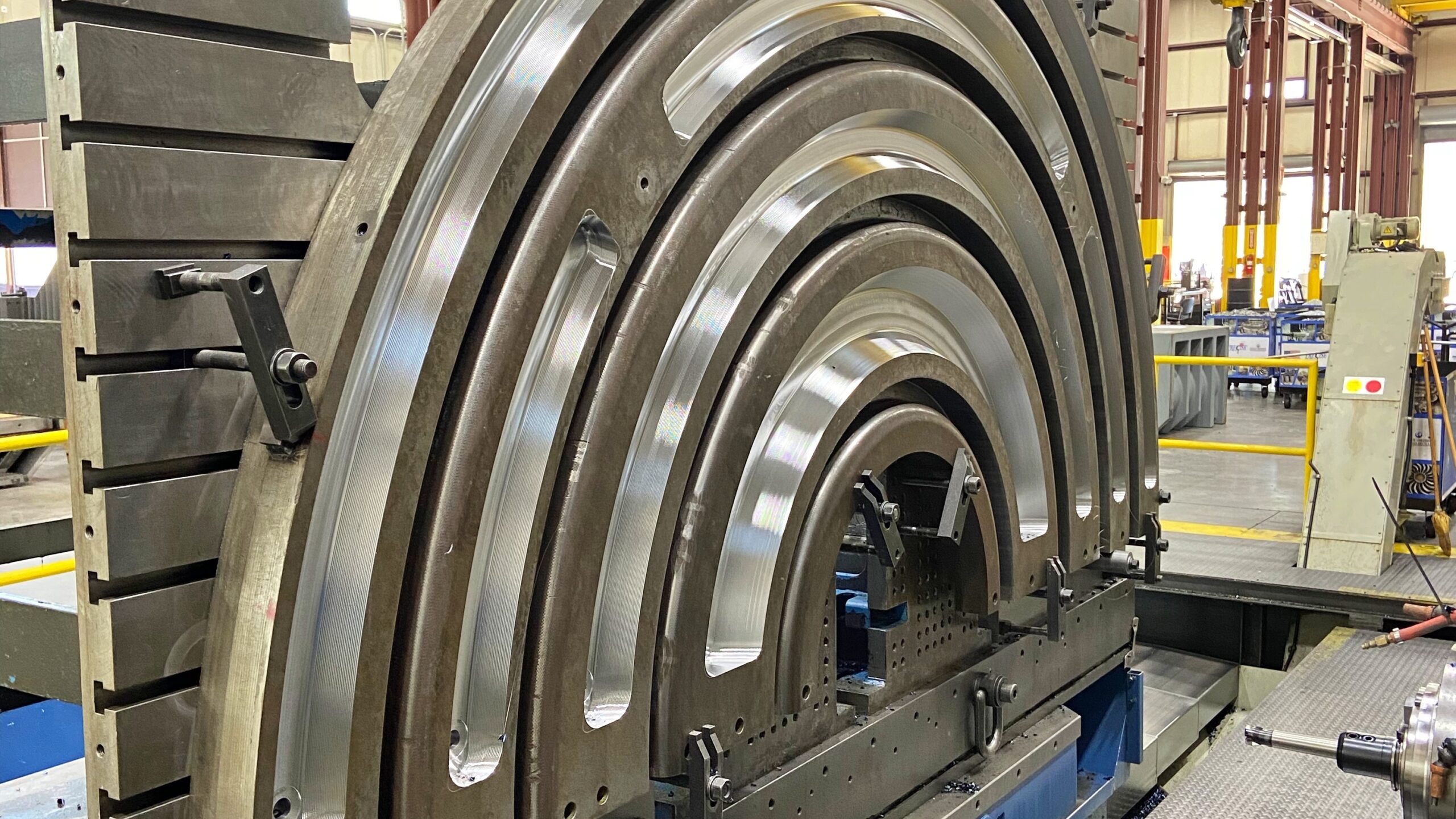

Precision CNC Turning Solutions for Demanding Industrial Applications

Honyo Prototype delivers advanced CNC turning capabilities through our state-of-the-art CNC draaimachine (CNC turning center) operations, engineered to meet the exacting standards of aerospace, medical, and industrial manufacturing sectors. Our multi-axis turning centers consistently achieve tolerances down to ±0.005 mm while machining complex geometries in materials ranging from hardened steels and titanium to exotic alloys and engineered plastics. This precision is backed by rigorous in-process metrology and ISO 9001-certified quality control protocols, ensuring every component meets stringent functional and regulatory requirements.

Optimized for Prototyping and Low-Volume Production Efficiency

We specialize in rapid turnaround for prototype development and bridge-to-production runs, leveraging automated tool changers and live tooling to consolidate milling, drilling, and threading operations in a single setup. This reduces lead times by up to 40% compared to traditional multi-machine workflows while minimizing cumulative error risks. Our engineering team collaborates directly with clients during DFM analysis to optimize part geometry for machinability without compromising performance, translating design intent into manufacturable realities.

Accelerate Your Sourcing Workflow with Online Instant Quoting

Eliminate procurement delays with Honyo’s Online Instant Quote platform, providing detailed cost and lead time estimates for CNC turning projects in under 60 seconds. Simply upload your STEP or IGES file, specify material and quantity requirements, and receive a transparent, binding quote with no hidden fees. This digital workflow integrates seamlessly with your supply chain planning, allowing engineers to validate budgets and timelines before committing to full production. For urgent requirements, our dedicated prototyping cell supports 5-day turnaround on qualified designs.

Partner with Honyo Prototype to transform precision turning challenges into competitive advantages, combining technical expertise with agile digital procurement tools. Initiate your next project with confidence through our instant quoting system or schedule a technical consultation with our manufacturing engineering team.

Technical Capabilities

CNC Draaimachine – Technical Specifications

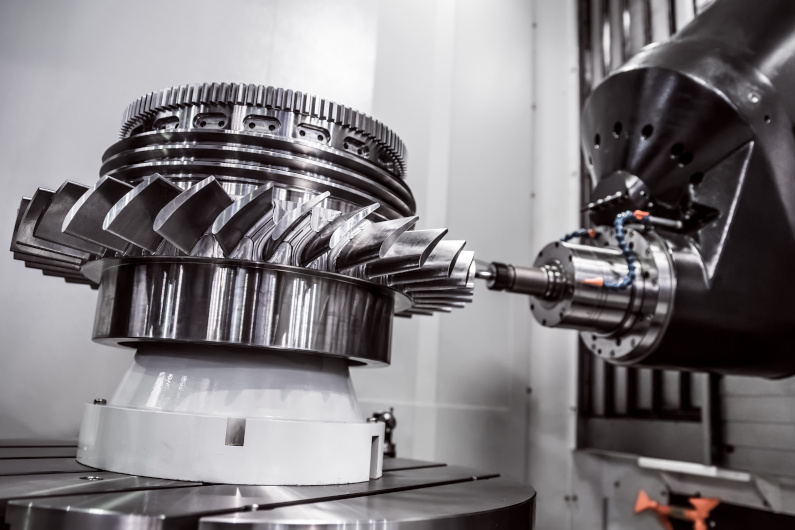

The term “CNC draaimachine” refers to a CNC turning machine, commonly used in Dutch-speaking regions. In modern manufacturing environments such as Honyo Prototype, CNC draaimachines are often integrated with milling capabilities, enabling multi-axis turning and milling operations. These machines are critical for producing complex, high-precision parts from a variety of engineering materials including aluminum, steel, ABS, and nylon. Below are the technical specifications focused on 3/4/5-axis milling-turning hybrid capabilities and tight tolerance production.

| Parameter | Specification Description |

|---|---|

| Machine Type | CNC Turning Center with Milling & Y-axis (Multi-Tasking) |

| Axis Configuration | 3-Axis (X, Z, C), 4-Axis (adds B or Y), 5-Axis (X, Z, C, Y, B) |

| Spindle Speed (Turning) | Up to 8,000 RPM (standard); High-speed options up to 15,000 RPM for aluminum and plastics |

| Live Tooling (Milling) | Integrated motor-driven tools with speeds up to 12,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Tolerance Capability | Achieves tight tolerances down to ±0.01 mm (standard), with micro-tolerances ±0.005 mm achievable under controlled conditions |

| Chuck Size | 6″ to 10″ (standard), depending on model and workpiece diameter |

| Bar Capacity | Up to Ø42 mm (common); larger for heavy-duty models |

| Control System | Fanuc, Siemens, or Heidenhain with 5-axis simultaneous interpolation |

| Coolant System | High-pressure through-spindle cooling; optional mist coolant for plastics |

| Material Compatibility | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), Engineering Plastics (ABS, Nylon 6/66) |

| Aluminum Machining | High-speed cutting with carbide tools; excellent surface finish and burr-free edges |

| Steel Machining | Hardened tooling (carbide/PVD coated); suitable for high-torque operations |

| ABS & Nylon Machining | Optimized feed rates and sharp tooling to prevent melting or deformation; no excessive heat buildup |

| Swiss-Type Option | Available for slender, high-precision turned parts with sub-millimeter tolerances |

| Automation Ready | Compatible with bar feeders and robotic loading for high-volume production |

These specifications reflect the capabilities of advanced CNC turning-milling centers used in precision prototyping and low-to-mid volume production at Honyo Prototype. The integration of 4 and 5-axis functionality allows for complete machining in a single setup, reducing lead times and enhancing dimensional accuracy across complex geometries.

From CAD to Part: The Process

Honyo Prototype CNC Machining Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for CNC machining projects, including CNC turning (draaimachine), designed to ensure precision, efficiency, and client transparency. The end-to-end process comprises five integrated phases, each optimized for rapid prototyping and low-volume production.

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native formats like SolidWorks, Fusion 360) via Honyo’s secure customer portal. Our system performs automated geometry validation to verify file integrity, detect potential errors (e.g., missing surfaces, unit mismatches), and confirm manufacturability within standard CNC turning parameters. All data is protected under ISO 27001-certified cybersecurity protocols to safeguard intellectual property.

AI-Powered Quoting Engine

Uploaded designs are processed through Honyo’s proprietary AI quoting system, which analyzes geometric complexity, material requirements, tolerances, and surface finishes against real-time machine availability, material costs, and labor rates. The AI generates a detailed quote within 2 hours, including cost breakdowns for material options (e.g., aluminum 6061, stainless steel 304, POM), secondary operations (e.g., anodizing, threading), and expedited lead times. Clients receive instant digital access to the quote with interactive adjustment capabilities for scope or timeline changes.

Engineering-Driven DFM Analysis

Upon quote acceptance, Honyo’s manufacturing engineers conduct a rigorous Design for Manufacturability (DFM) review. This phase combines automated simulation tools with expert human analysis to identify optimization opportunities, such as reducing setup changes, adjusting non-critical tolerances, or suggesting cost-effective material substitutions. Engineers collaborate directly with clients via video conference or annotated reports to resolve conflicts, ensuring design intent is preserved while maximizing efficiency. Typical DFM turnaround is 24–48 hours, with critical feedback prioritized for time-sensitive projects.

Precision Production Execution

Approved designs move to Honyo’s climate-controlled production floor, where CNC turning centers (including multi-axis live-tooling lathes) execute machining under strict ISO 9001 quality management. Each part undergoes in-process inspections via CMM and optical comparators at critical stages, with real-time SPC data logged to our MES. Material certifications and first-article inspection reports (FAIR) are generated per AS9102 standards for aerospace/medical clients. Production batches include traceability tags linking each component to machine logs, operator IDs, and calibration records.

Quality-Controlled Delivery

After final inspection and surface treatment (if specified), parts are packaged using anti-corrosion materials and shipped via tracked logistics partners. Honyo provides digital delivery confirmation including full inspection dossiers, material certs, and PPAP documentation where required. Standard lead times range from 3–10 business days for turning projects, with rush options available. Post-delivery, clients receive a project performance summary highlighting adherence to specifications and opportunities for future collaboration.

This integrated approach reduces time-to-part by 30% compared to industry averages while maintaining <0.005mm tolerances, positioning Honyo as a strategic partner for engineering teams requiring agile, high-integrity CNC solutions.

Start Your Project

Interested in high-precision CNC turning solutions? Contact Susan Leo at [email protected] to discuss your project requirements. Our advanced CNC machining services are supported by a fully equipped manufacturing facility in Shenzhen, ensuring fast turnaround and consistent quality for prototyping and low-volume production. Let Honyo Prototype be your trusted partner in precision manufacturing.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.