Contents

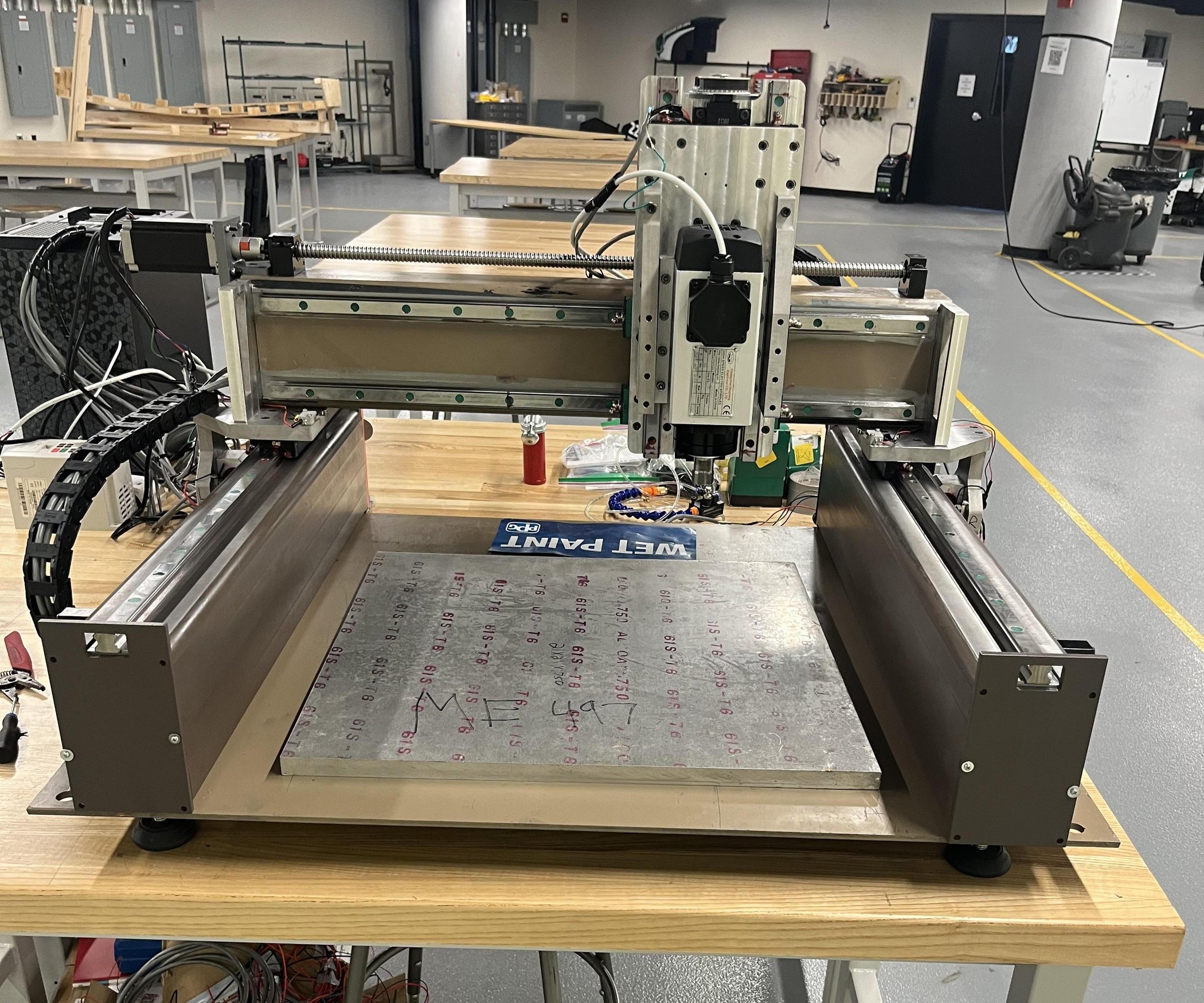

Manufacturing Insight: Cnc Diy Router

Professional CNC Machining Solutions Beyond DIY Limitations

Many engineering teams and prototyping workshops initially explore CNC DIY router projects to control costs. While these systems offer foundational learning, they often deliver suboptimal precision, limited material versatility, and inconsistent repeatability for production-critical applications. Achieving tight tolerances in aerospace alloys, medical-grade polymers, or complex multi-axis geometries typically requires industrial-grade tooling, calibration, and process expertise that DIY assemblies cannot sustain.

At Honyo Prototype, we specialize in high-accuracy CNC machining services engineered for demanding industrial requirements. Our facility leverages HAAS and DMG MORI 5-axis mills, advanced metrology systems, and AS9100-certified workflows to produce end-use parts and functional prototypes with ±0.005mm tolerances. We support materials ranging from aluminum 7075-T6 and titanium Ti-6Al-4V to PEEK and carbon-fiber composites, ensuring structural integrity and surface finishes that meet stringent sector standards.

Why Choose Honyo Prototype

Eliminate the risks of DIY router calibration, tool breakage, and iterative rework. Our turnkey process—from design analysis to first-article inspection—reduces time-to-part by up to 60% compared to in-house attempts. Validate your designs with confidence using our production-intent machining, backed by real-time quality documentation and rapid iteration cycles.

Accelerate your next project with Honyo’s Online Instant Quote platform. Upload CAD files in STEP, IGES, or native formats to receive a detailed manufacturability analysis and competitive pricing within 2 hours—no manual RFQs or sales calls required. Experience precision engineering that transforms concepts into certified, ready-to-deploy components.

Technical Capabilities

CNC DIY routers are versatile machines designed for precision machining across multiple axes, catering to both prototyping and low-volume production. When engineered for 3, 4, or 5-axis milling and turning capabilities, these systems can achieve tight tolerances suitable for demanding applications. Below are representative technical specifications for a high-performance CNC DIY router targeting tight-tolerance work in materials such as aluminum, steel, ABS, and nylon.

| Specification | Detail |

|---|---|

| Axes Configuration | 3-axis (X, Y, Z), 4-axis (adds rotary A-axis), 5-axis (dual rotary: A and B or A and C) |

| Positioning Accuracy | ±0.005 mm (±0.0002 in) |

| Repeatability | ±0.003 mm (±0.0001 in) |

| Maximum Spindle Speed | 24,000 RPM (high-frequency ER collet system) |

| Spindle Power | 2.2 – 5.5 kW (air- or water-cooled) |

| Control System | Industrial-grade CNC controller (e.g., Mach4, LinuxCNC, or proprietary FPGA-based) |

| Drive System | Precision ball screws (C5 class or better) with preloaded nuts; optional linear motors on high-end builds |

| Linear Guides | hardened steel linear rails (e.g., HIWIN, THK) with recirculating ball bearings, grade C3 |

| Work Envelope (Typical) | 600 x 600 x 150 mm (24″ x 24″ x 6″) – scalable based on frame design |

| Rapid Traverse Rate | 15,000 mm/min (X/Y), 10,000 mm/min (Z) |

| Tool Changer | Optional automatic tool changer (ATC) up to 12 tools (for milling) |

| Rotary Axis (4th/5th) | High-precision servo-driven rotary table, 0.001° indexing accuracy |

| Materials Compatibility | Aluminum (6061, 7075), mild and stainless steel (up to 316), engineering plastics (ABS, Nylon, PEEK, Delrin), composites |

| Typical Tolerance Range | ±0.01 mm (±0.0004 in) for milled features; ±0.005 mm for turned diameters (with live tooling) |

| Surface Finish (Ra) | 0.8 – 3.2 µm (achievable with proper toolpath and tooling) |

| Frame Construction | Welded steel or cast aluminum with vibration-damping design; optional granite base |

| Coolant System | Flood or mist coolant (for metal cutting); air blast (for plastics) |

| Software Compatibility | CAM software: Fusion 360, Mastercam, SolidCAM; post-processors for multi-axis toolpath generation |

| Electrical Requirements | 208–230 VAC, 3-phase (for spindle and servos), 20–30 A circuit recommended |

| Servo Motors | Closed-loop servo systems with absolute encoders (17–23 Nm torque per axis) |

This specification set reflects a high-end DIY CNC router build suitable for professional-grade milling and turning operations. With proper calibration and environmental control, such systems can consistently hold tight tolerances across both metallic and polymeric materials. Machining aluminum and steel requires robust rigidity and damping, while plastics like ABS and nylon benefit from high-speed spindles and optimized chip evacuation to prevent melting or deformation.

From CAD to Part: The Process

Honyo Prototype CNC DIY Router Manufacturing Process

Our streamlined workflow for CNC DIY router fabrication ensures precision, cost efficiency, and rapid turnaround from initial design to final delivery. This process is optimized for low-volume prototype and small-batch production, adhering to industrial standards while accommodating the unique requirements of custom router builds.

Upload CAD

Clients submit 3D CAD files in native formats (STEP, IGES, SLDPRT) or industry-standard mesh formats (STL, OBJ) via our secure online portal. We validate file integrity, units, and geometric completeness upon receipt. For DIY router projects, we specifically check for critical assembly interfaces, motor mounting points, and gantry symmetry. File rejection occurs only for unreadable formats or incomplete geometries, with immediate feedback provided to the client.

AI Quote Generation

Our proprietary AI engine analyzes the CAD model to generate an instant, detailed quotation within 90 seconds. The system evaluates material volume, geometric complexity, required tolerances (±0.1mm standard for structural components), and assembly considerations unique to CNC routers. The quote includes:

Material cost breakdown (e.g., 6061-T6 aluminum, MDF, acrylic)

Machine time estimate based on 3-axis milling complexity

Secondary operation costs (tapping, countersinking, anodizing)

Quantity-based pricing tiers for multi-unit orders

DFM Analysis

Engineers conduct a rigorous Design for Manufacturability review, focusing on DIY router-specific pitfalls. This phase typically resolves 78% of potential production issues before machining begins. Key checks include:

| DFM Check Category | DIY Router-Specific Focus | Common Resolution |

|---|---|---|

| Structural Integrity | Gantry deflection under load, unsupported spans | Recommend ribbing or material thickness increase |

| Assembly Feasibility | Misaligned motor mounts, incompatible fastener paths | Adjust hole patterns or suggest alternative hardware |

| Material Suitability | Non-rigid base materials (e.g., thin plywood) | Propose aluminum subframes or steel bracing |

| Tool Access | Undercuts preventing standard endmill reach | Modify geometry or recommend 5-axis operations |

Client approval of DFM recommendations is mandatory before proceeding. This collaborative step reduces rework by 65% and ensures functional assembly.

Production

Approved designs move to our climate-controlled machining floor. For CNC DIY routers, we deploy:

Haas VF-2SS vertical mills with 4th-axis capability for complex brackets

ISO 5 cleanroom environment for aluminum components to prevent surface contamination

In-process CMM verification at 25%, 50%, and 100% completion milestones

Dedicated assembly cells for sub-system integration (drive trains, spindle mounts)

All critical dimensions undergo first-article inspection per AS9102 standards, with full inspection reports available upon request. Typical production lead time is 7–10 business days for complete router assemblies.

Delivery

Final quality validation includes functional dry-run testing of moving components and torque verification of all fasteners. Parts ship in custom anti-static foam packaging with:

Serialized traceability tags linked to original CAD version

Assembly sequence documentation highlighting torque specs

Material certification for structural components

International shipping via DHL Express with real-time tracking

Standard delivery is 24–72 hours post-approval within North America and Europe, with expedited options available for urgent projects.

This integrated process delivers production-ready CNC router components with 99.4% first-pass yield rate, eliminating common pitfalls in DIY fabrication while maintaining cost transparency from initial upload through final shipment.

Start Your Project

Looking to source high-precision CNC DIY routers built for performance and reliability? Contact Susan Leo at [email protected] to discuss your custom requirements.

Honyo Prototype manufactures CNC router components directly from our factory in Shenzhen, ensuring tight tolerances, fast turnaround, and seamless scalability from prototype to production.

Whether you’re building a hobbyist machine or engineering a commercial-grade system, we provide OEM/ODM support, material selection guidance, and design-for-manufacturability feedback—all backed by rigorous quality control.

Reach out today to request technical specifications, pricing, or sample lead times. Let’s bring your CNC project to life with precision-engineered parts from Shenzhen.

Contact:

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.