Introduction: Navigating the Global Market for cnc design files

Navigating the complex landscape of sourcing CNC design files can be a daunting task for international B2B buyers. With an increasing demand for high-quality, customizable products, understanding where to find reliable and relevant CNC design files has never been more critical. This guide aims to illuminate the various dimensions of CNC design files, from types and applications to supplier vetting and cost considerations. With insights tailored specifically for regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—this guide seeks to empower B2B buyers to make informed purchasing decisions.

As industries advance, the necessity for precise and efficient designs continues to grow, making it imperative for businesses to identify trustworthy sources that offer not only cost-effective solutions but also the quality required for successful implementation. This comprehensive overview will delve into the nuances of CNC design files, highlighting free resources alongside paid options, diverse applications in different sectors, and essential criteria for evaluating suppliers. By equipping decision-makers with the knowledge to confidently navigate the marketplace, this guide serves as an essential resource, aiding buyers in streamlining their sourcing processes and enhancing product offerings. Let’s embark on this journey to unlock the potential of CNC design files, driving innovation and success across global markets.

Understanding cnc design files Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DXF | CAD format supporting 2D vector graphics; widely used for analysis | Metal fabrication, woodworking, signage | Pros: Widely supported, easy to edit; Cons: Limited in 3D applications. |

| SVG | XML-based format for scalable vector graphics; supports animation | Web graphics, CNC routers | Pros: High scalability, preserves quality; Cons: Not as commonly used for industrial applications. |

| G-code | CNC machine language specifying tool paths; fundamental for CNC processes | Machining, milling, laser cutting | Pros: Directly controls machines; Cons: Requires understanding of CNC operations. |

| STL | Triangulated surface representation; used for 3D printing and modeling | 3D printing, prototyping | Pros: Suitable for complex shapes; Cons: May require conversion for CNC machines. |

| Portable document format; can contain vector graphics but less commonly used in CNC | Documentation, design previews | Pros: Universally accessible; Cons: Not optimized for CNC fabrication. |

What Are the Major Characteristics of DXF Files in CNC?

DXF (Drawing Exchange Format) files are prevalent in the CNC industry for their compatibility with numerous CAD applications. Their primary features include the ability to store both 2D and 3D geometry, making them a versatile choice for various projects, from simple cutouts to complex designs. B2B buyers, especially in sectors like metal fabrication and woodworking, find DXF files invaluable due to their widespread support across CNC machines, allowing for easy integration and scalability in production. However, buyers must recognize that while DXF files excel in 2D applications, they are often less suitable for comprehensive 3D modeling tasks.

How Is SVG Format Beneficial for Certain Applications?

SVG (Scalable Vector Graphics) files offer unique advantages in industries requiring scalable visual designs, such as web graphics and signage. Their XML-based structure allows for flexibility, including animation and interactivity, making them attractive for marketing-oriented applications. For B2B buyers focusing on decorative CNC work or branding, SVG files provide high scalability while maintaining image quality. However, because SVG is less common than formats like DXF in industrial CNC settings, buyers may need to consider translation to more universally accepted file types for machine compatibility.

Why Is G-code Critical for CNC Operations?

G-code, the programming language used to control CNC machines, is essential for executing specific instructions related to tool paths and machine movements. Every CNC operator or business should have a proficient understanding of G-code to effectively run their machines. B2B buyers investing in CNC technology must prioritize training their teams in G-code as it enhances operational efficiency and minimizes programming errors. While G-code provides unparalleled control over machining processes, its complexity can be a barrier for newcomers, necessitating investment in adequate training resources.

In What Scenarios Are STL Files Most Suitable?

STL (Stereolithography) files are vital in industries focusing on 3D printing and rapid prototyping. Their triangulated representation of surfaces allows for the creation of intricate designs and models. Businesses in product design or engineering can leverage STL files for testing and visualization before moving to machining. However, companies should be aware that while STL files excel in producing complex geometries, they often need to be converted to another format, such as DXF or G-code, for CNC applications, which can introduce additional steps and potential errors into workflow processes.

How Do PDF Files Fit Into the CNC Design Landscape?

While PDF (Portable Document Format) files are typically associated with document sharing and presentation, they occasionally serve a role in the CNC design landscape. A PDF can encapsulate both raster and vector graphics, offering a snapshot of design ideas. For B2B buyers exploring CNC projects, PDFs can be handy for sharing designs, specifications, and instructions across teams or with clients. However, PDFs are not optimized for direct CNC fabrication, requiring conversions to more machine-friendly formats, which can complicate processes and delay production timelines.

Key Industrial Applications of cnc design files

| Industry/Sector | Specific Application of cnc design files | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Custom Tooling and Fixture Design | Enhances production efficiency and precision | Availability of specialized DXF files for specific machinery and high-quality vector graphics. |

| Construction | Architectural and Structural Components | Reduces material waste and accelerates project timelines | Compatibility with local materials and adherence to regional building codes. |

| Home and Garden Decor | Metal Art and Furniture Design | Differentiates product offerings, catering to niche markets | Access to unique design files that cater to local aesthetics and cultural preferences. |

| Automotive | Prototype Parts and Components | Streamlined design iterations, saving time and cost | Availability of industry-specific files and scalability options for small or large production runs. |

| Electronics | Enclosures and Circuit Board Layouts | Optimizes space and improves thermal management | Compliance with electronic standards and modular designs to accommodate various components. |

How Are CNC Design Files Revolutionizing the Manufacturing Sector?

In manufacturing, CNC design files are critical in developing custom tooling and fixtures that ensure consistent and efficient production processes. By utilizing high-quality DXF files tailored for specific tooling requirements, businesses can significantly reduce lead times and improve precision. International buyers, particularly from regions like Africa or the Middle East, should consider sourcing files that meet local machinery compatibility standards and have robust technical support to address any customization needs.

In What Ways Do CNC Design Files Enhance Construction Projects?

CNC design files play an essential role in the construction sector by enabling architects and contractors to create intricate architectural and structural components with precision. The use of advanced DXF files allows for reduced material waste and shorter project timelines, which is particularly advantageous in price-sensitive markets such as South America. Buyers should be vigilant about sourcing files that comply with regional building codes and are adaptable to local material options.

What Role Do CNC Design Files Play in Home and Garden Decor?

The home and garden decor industry greatly benefits from CNC design files, particularly for producing unique metal art pieces and custom furniture. By downloading specialized designs, businesses can tap into niche markets and create innovative products. For international buyers targeting European or Middle Eastern customers, it’s crucial to ensure that the design files align with local aesthetics and cultural sensitivities.

Are CNC Design Files Key to Automotive Innovation?

In the automotive sector, CNC design files are vital for creating prototype parts and components that facilitate efficient design iterations. This speeds up the development process and reduces costs associated with prototyping. Buyers should prioritize sourcing DXF files that cater to automotive standards and provide scalability options, especially when aiming to cater to both small-scale and mass production.

How Are CNC Design Files Optimizing Electronics Manufacturing?

In electronics, CNC design files are instrumental in the development of enclosures and circuit board layouts that maximize space efficiency and thermal performance. Accessing precise DXF files can significantly enhance the assembly process and overall product quality. International B2B buyers should look for suppliers offering files that comply with electronic standards while allowing flexibility for modular designs to accommodate varying components and layouts.

3 Common User Pain Points for ‘cnc design files’ & Their Solutions

Scenario 1: Difficulty Finding High-Quality DXF Files for CNC Projects

The Problem: B2B buyers often struggle to find high-quality, compatible DXF files that meet their specific project requirements. With many free downloads available, it’s easy to encounter poorly designed files that can lead to machine errors or production delays. This inconsistency can result in wasted costs and resources, ultimately impacting the efficiency of operations, especially for businesses involved in precision manufacturing or custom design work.

The Solution: To overcome this challenge, buyers should prioritize sourcing DXF files from reputable platforms that specialize in high-quality designs. Look for providers that offer detailed descriptions of their files, including compatibility with various CNC machines. Ensure that the design files have been tested across different cutting technologies, such as laser and plasma. Utilizing platforms that provide user reviews or ratings can also help gauge the quality of the files. For frequent projects, consider investing in a subscription service that grants unlimited access to a library of verified designs, ensuring you have reliable options ready to go whenever you need them.

Scenario 2: Incompatibility Issues with CNC Machines and Design Files

The Problem: Many B2B buyers face the challenge of incompatibility between their CNC machines and the design files they acquire. Each CNC machine may have different specifications regarding file formats and cutting capabilities. When files do not align with machine capabilities, it can lead to operational disruptions, increased costs for redesigns, or even damage to the equipment.

The Solution: To mitigate compatibility issues, buyers should thoroughly document their CNC machine specifications prior to sourcing DXF files. This includes understanding the cutting beam width, material thickness limitations, and recommended file formats (such as DXF, DWG, or SVG). When selecting DXF files, always cross-check the specifications listed by the file provider with your machine’s requirements. If possible, use a software tool that allows conversion of file formats to ensure compatibility or consider reaching out to the file provider for custom adaptations. Building a close relationship with suppliers who can accommodate specific machine capabilities will provide ongoing support in overcoming these challenges.

Scenario 3: Limited Design Customization Options

The Problem: Buyers often find that the available CNC design files do not fully meet their unique project needs. This limitation can be particularly problematic for businesses that require customized aesthetic elements or specific functional features. The inability to modify designs easily can lead to suboptimal output and dissatisfaction with the final products.

The Solution: To address limited customization options, buyers can work with file providers who offer flexible design services. Consider utilizing platforms that allow for the adjustment of existing files or offer bespoke design services. Before finalizing a purchase, inquire if the provider permits modifications such as scaling or altering design details. For businesses with an in-house design team, investing in CAD software can empower teams to modify and enhance purchased DXF files themselves. Additionally, establish partnerships with graphic designers specializing in CNC designs. This collaboration will enable the creation of exclusive designs tailored to your specific projects, ensuring your offerings remain unique in the competitive landscape.

By understanding these common pain points and implementing the suggested solutions, B2B buyers can enhance their experience with CNC design files, improving operational efficiency and product quality in diverse markets across the globe.

Strategic Material Selection Guide for cnc design files

What Are the Key Properties of Common Materials for CNC Design Files?

When selecting materials for CNC design files, it is essential to understand their characteristics to optimize performance in various applications. The following materials are frequently used in the CNC industry, each possessing unique properties that cater to different end-product requirements.

Aluminum: A Lightweight Material with Versatile Applications

Aluminum is renowned for its excellent strength-to-weight ratio, corrosion resistance, and ease of machining. It is widely used in aerospace components, automotive parts, and decorative designs. When considering aluminum for CNC designs, buyers should be aware of its thermal conductivity, which can be advantageous in applications involving heat dissipation. However, it may not be suitable for high-pressure environments due to its lower strength compared to some alloys.

Pros of aluminum include its lightweight nature and good machinability, allowing for complex designs. Nonetheless, it can be relatively expensive compared to some other raw materials and may not perform as well under extreme conditions.

Steel: The Heavyweight Champion of Durability

Steel remains a staple in manufacturing due to its durability and high tensile strength. It excels in applications that require robustness, such as structural components, tooling, and automotive parts. The ability to heat-treat steel further enhances its hardness, making it an ideal choice for demanding applications. However, steel’s propensity to rust necessitates consideration of corrosion-resistant coatings or using stainless steel, particularly in humid environments.

The primary advantages of steel are its strength and low relative cost, even when considering alloy grades. On the flip side, steel can be heavier, making transport and installation more challenging, especially in the international market.

Plastic: A Lightweight Alternative with Chemical Resistance

Plastics, such as acrylic or polycarbonate, are commonly employed in CNC applications where lightweight and chemical resistance are critical. They are frequently used for protective covers, signs, and parts that do not require high strength. Factors such as temperature resistance can vary significantly among different plastic types, with some capable of withstanding considerable thermal stress.

The pros of plastic include lower manufacturing costs and ease of handling. However, they have limitations in terms of mechanical properties when compared to metals, making them unsuitable for high-stress applications.

Composite Materials: The Hybrid Solution for Weight and Strength

Composite materials offer a balance between the strengths of their individual components, often combining lightweight plastics with reinforcing fibers. This makes them suitable for applications in the aerospace and automotive industries where weight reduction is crucial without sacrificing strength. Composites can be tailored for specific applications, allowing for customization in performance.

The advantage of composites is that they can meet specialized requirements such as low thermal expansion or unique aesthetic properties. However, they may entail a higher manufacturing complexity and cost compared to traditional materials, making them a consideration for specialized sectors only.

Summary Table of Material Selection for CNC Design Files

| Material | Typical Use Case for cnc design files | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, decorative designs | Excellent strength-to-weight ratio and machinability | Higher cost and lower strength under pressure | Medium |

| Steel | Structural components, tooling | High durability and strength | Susceptibility to rust and heavier weight | Low |

| Plastic | Protective covers, signage | Lightweight and chemical resistance | Limited mechanical strength compared to metals | Low |

| Composites | Aerospace, automotive parts | Tailored performance with weight reduction | Higher complexity in manufacturing and cost | High |

In summary, the selection of materials for CNC design files requires careful consideration of properties like durability, cost, and application requirements. For international B2B buyers, compliance with relevant standards, material availability, and local preferences should influence choices to ensure optimal results across diverse markets such as Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc design files

What Are the Typical Manufacturing Processes for CNC Design Files?

Understanding the manufacturing process of CNC design files is pivotal for B2B buyers looking to ensure quality and efficiency in their production lines. The process generally encompasses several critical stages, including material preparation, forming, assembly, and finishing. Each stage incorporates various techniques to optimize the outcome.

How Is Material Prepared for CNC Manufacturing?

The first stage in the manufacturing process is material preparation, which involves selecting the right materials suitable for CNC machining. Buyers should consider materials such as aluminum, steel, plastics, and composites based on the end product requirements. The material is usually cut down to size, which can be done through traditional saws or other cutting machinery to ensure it fits the required dimensions for CNC machining.

Treatments such as surface cleaning, degreasing, and other pre-treatments are crucial at this stage to remove any contaminants that could adversely affect the machining process. A well-prepared material will lead to improved accuracy and longevity of the final product.

What Techniques Are Used for Forming CNC Design Files?

The forming stage primarily involves the actual CNC machining processes where the prepared material is transformed into a final product using CNC routers, lathes, and milling machines. Techniques vary widely based on the complexity of the design files. Common processes include:

-

Milling: This involves using rotary cutters to remove material from a workpiece. It’s effective for creating complex shapes and detailed designs.

-

Turning: A lathe machine rotates the workpiece against a stationary cutter, suitable for cylindrical shapes.

-

Plasma Cutting and Laser Cutting: Highly precise methods used for cutting through metal and other materials, ensuring clean edges.

These manufacturing processes are programmable via CNC design files, allowing for replicable and high-precision outputs vital for meeting international standards.

What Role Does Quality Control (QC) Play in CNC Manufacturing?

Quality control is a fundamental aspect of the CNC manufacturing process, ensuring that products meet the required specifications and serve their intended purpose effectively. It involves systematic processes for verifying and assuring quality during the different manufacturing stages.

What International Standards Govern CNC Design Files?

To maintain consistent quality, adherence to international standards such as ISO 9001 is crucial. This standard ensures that organizations meet customer and regulatory requirements consistently. Certification can be a significant selling point for suppliers, assuring buyers of a commitment to quality.

For specific industries, additional standards such as CE marking for compliance with EU safety and environmental requirements or API standards for oil and gas equipment may apply. B2B buyers must inquire about their suppliers’ conformance to these standards to mitigate risks associated with international procurement.

How Is Quality Control Implemented Across Manufacturing Stages?

Quality control can be integrated into various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Material inspections are performed upon arrival to ensure that they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): Continuous checks during manufacturing processes ensure that the specifications are maintained and any inconsistencies are addressed immediately.

-

Final Quality Control (FQC): A thorough inspection of the finished product ensures that everything meets the required specifications before delivery. This stage can include dimensional inspections, functional testing, and visual assessments.

Buyers should ensure that their suppliers implement these checkpoints rigorously to uphold product quality.

Which Testing Methods Are Commonly Used in CNC Manufacturing?

Various testing methods can be employed to assess the quality of CNC-manufactured products. Common techniques include:

-

Dimensional Inspection: Tools such as calipers and coordinate measuring machines (CMMs) check the dimensions against design tolerances.

-

Non-Destructive Testing (NDT): Methods such as ultrasonic, magnetic particle, and dye penetrant tests evaluate the integrity of materials without causing damage.

-

Performance Testing: Some products may undergo performance tests to ensure functionality under designated operating conditions.

Buyers should request information from suppliers regarding their specific testing methods and practices, as these will significantly affect the quality and reliability of the products they are procuring.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is essential for establishing trust and ensuring the reliability of delivered products. Potential strategies include:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s operations and quality control measures.

-

Quality Assurance Reports: Requesting reports detailing the results of quality checks can give a transparent view of a supplier’s performance and quality assurance practices.

-

Third-Party Inspections: Engaging with third-party inspection agencies can provide unbiased assessments of a supplier’s quality control measures.

B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, should consider these proactive measures to minimize risks associated with the complexities of international procurement.

What Nuances in Quality Certification Should International Buyers Consider?

Each region may have its own certification requirements, and international buyers need to be aware of these nuances to ensure compliance and mitigate logistical challenges. For example, European countries may have more stringent CE marking requirements compared to Brazil’s local regulations. Therefore, buyers should research and understand specific obligations for their target markets.

Furthermore, language and cultural barriers may pose challenges in communication. Establishing clear channels of communication and documenting all agreements can help in navigating these challenges effectively.

Conclusion: Ensuring Quality in CNC Manufacturing

A thorough understanding of the manufacturing processes and quality assurance practices in CNC design files can empower B2B buyers to make informed purchasing decisions. By assessing material preparation, manufacturing techniques, and rigorous quality control measures, companies can build strong partnerships with suppliers and ensure that they receive products that meet their specific needs while adhering to international standards. As the global market continues to expand, these insights will be invaluable for successful B2B engagements in diverse regions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc design files’

Before diving into the procurement process for CNC design files, it’s essential to have a structured approach. This guide offers actionable steps to ensure B2B buyers effectively source quality CNC design files, whether for decorative projects, functional items, or industrial applications.

Step 1: Define Your Technical Specifications

Understanding your project requirements is the first crucial step. Clearly outline the specific type of CNC design files you need, considering factors such as complexity, file formats (DXF, SVG, etc.), and compatibility with your CNC machinery. This clarity will help in targeting the right suppliers who can meet your expectations.

Step 2: Research Similar Projects

Investigate previous projects similar to yours. Analyzing existing designs can offer insights into trends, material choices, and the types of CNC design files that were effective. Look for case studies and samples, and consider how your needs align with successful implementations from other companies.

Step 3: Evaluate Potential Suppliers

Conduct a thorough assessment of potential suppliers. Request detailed information about their expertise, including:

– Portfolio of Design Files: Ask for samples or a portfolio that showcases their range of CNC design files.

– Customer Testimonials: Seek references or reviews from past clients, particularly those in your industry or region, to understand their reliability and the quality of their deliverables.

Step 4: Assess File Quality and Compatibility

Quality is paramount when sourcing CNC design files. Ensure that files are:

– Error-Free: Files should have clean vector paths and be free from overlapping lines that can cause issues during cutting.

– Compatible with Your Machinery: Verify that the files work seamlessly with your CNC machines. Inquire about the minimum cutting beam width and recommended software for use.

Step 5: Understand Licensing and Usage Rights

Clarify the licensing terms associated with the CNC design files. Determine whether the files are offered for free, under specific licenses, or available for purchase. Important aspects to consider:

– Commercial Use: Confirm if the files can be utilized for commercial products.

– Modification Rights: Understand if and how you can modify the designs to better suit your project.

Step 6: Request Customization Options

If standard designs don’t fully meet your needs, inquire about customization capabilities. Many suppliers are willing to work with clients to create tailor-made designs, which can significantly enhance your product’s uniqueness and marketability. Discuss any specific adjustments you may require and ask for associated costs and timelines.

Step 7: Finalize Arrangements and Place Your Order

Once you have selected a supplier that meets your criteria, finalize the purchasing details. Confirm lead times, costs, and delivery methods. Ensure that you have established a clear communication channel for any follow-up questions or support during the implementation of the CNC design files.

By following this checklist, B2B buyers can enhance their sourcing process for CNC design files, ultimately leading to higher efficiency and better project outcomes.

Comprehensive Cost and Pricing Analysis for cnc design files Sourcing

Analyzing the cost structure and pricing of CNC design files can be crucial for B2B buyers aiming to optimize their procurement strategies. By understanding the various cost components involved and the factors influencing pricing, businesses can make more informed decisions that align with their operational goals and budgets.

What Are the Key Cost Components for CNC Design Files?

The costs associated with CNC design file sourcing typically break down into several essential components:

-

Materials: While digital files do not directly involve physical materials, the choice of design quality and format (such as DXF or SVG) can reflect indirectly in the costs. High-quality, sophisticated design files often come from skilled designers whose work results in superior craftsmanship in the final product.

-

Labor: The complexity of the design and the expertise required to create it will influence the labor cost. Simple designs may be more affordable, while intricate, customized designs may require specialized skills and therefore a higher price.

-

Manufacturing Overhead: This includes any costs incurred in the creation of the CNC design files, such as software licenses, server costs for hosting, and the maintenance of digital platforms. Suppliers with more advanced tools may pass on these costs to buyers.

-

Tooling: Specific designs might necessitate tailored tooling or modifications compatible with particular CNC machines, translating to additional expenses that need to be considered.

-

Quality Control (QC): The presence of a rigorous QC process ensures that the design files are functional, match specifications, and minimize errors during CNC machining. This aspect can also heighten costs, especially if certifications or testing are involved.

-

Logistics: Although primarily a digital product, any physical delivery of tools or prototypes related to the design could incur logistics fees. For international transactions, understanding the logistics costs, including potential tariffs or shipping fees, is critical.

-

Profit Margin: Suppliers typically apply a margin to ensure profitability. This margin can vary widely, based on competition, market demand, and overall value provided by the design.

How Do Price Influencers Impact CNC Design File Costs?

Several influencers impact the pricing structure of CNC design files, including:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often result in reduced unit pricing. Businesses should consider negotiating for discounts on larger orders.

-

Specifications and Customization: Custom designs require additional effort, which can significantly increase costs. Buyers must clarify their needs upfront, weighing the benefits of tailored designs against potential expenses.

-

Materials and Quality Certifications: Quality assurance standards and the presence of certifications (e.g., ISO) may lead to higher costs but offer peace of mind regarding file reliability and performance.

-

Supplier Factors: The supplier’s experience, reputation, and location can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might have competitive pricing to gain market share.

-

Incoterms: Understanding the terms of shipping and responsibility (e.g., DDP, FOB) is crucial for budget planning, especially in international transactions.

What Are the Best Strategies for Negotiating Prices for CNC Design Files?

-

Compare Offers: Always gather quotes from multiple suppliers. This approach can give better insights into the market rate and facilitate negotiations.

-

Discuss Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also how the designs impact operational efficiency, maintenance costs, and durability over time.

-

Leverage Relationships: Building a long-term relationship with suppliers can result in better pricing and favorable terms. Regular communication and feedback can lead to mutually beneficial arrangements.

-

Explore Payment Terms: Negotiate for better payment flexibility or discounts for prompt payments, which can significantly lower costs.

-

Ask for Volume Discounts: If future orders are anticipated, discussing these with suppliers can lead to better pricing structures ahead of time.

B2B buyers from regions like Africa, South America, the Middle East, and Europe (e.g., Germany and Brazil) should be aware of local market conditions and logistics challenges that could affect overall costs. It’s advisable to remain vigilant about pricing trends in the CNC design file market and possible impacts from global supply chain changes.

Conclusion

Understanding the comprehensive cost structure and pricing influences for CNC design files is vital for international B2B buyers. By strategically approaching procurement with knowledge of cost components, negotiations, and regional factors, businesses can optimize their sourcing strategies, leading to enhanced operational efficiencies and reduced expenses. Always consider the implications of TCO and pricing nuances specific to your geographical context to make informed decisions.

Alternatives Analysis: Comparing cnc design files With Other Solutions

In the world of CNC machining, CNC design files are a primary solution for creating intricate designs across various industries. However, it’s essential to explore other viable alternatives that can also meet the design and production needs of businesses. By comparing CNC design files with alternative solutions, B2B buyers can make informed decisions that align with their project requirements and budget constraints.

| Comparison Aspect | Cnc Design Files | Free CAD Software | Custom CNC Design Services |

|---|---|---|---|

| Performance | High precision and versatility in designs | Varies based on software used; may offer basic functionalities | Typically high precision tailored to client’s specifications |

| Cost | Often low to free, especially for basic designs | Free options available; potential costs for premium features | Higher cost due to labor and expertise required |

| Ease of Implementation | Quick downloads and immediate use with CNC machines | Learning curve for new users; setup time varies | Typically requires a project consultation and timeline |

| Maintenance | Minimal, dependent on software updates | Varies with software; requires regular updates | Ongoing support typically included, but costs can accumulate |

| Best Use Case | Small to medium projects needing ready-made designs | Beginners looking to create custom designs | Large projects requiring complex or bespoke designs |

What Are the Pros and Cons of Free CAD Software as an Alternative?

Free CAD software provides a versatile platform for users to create their designs from scratch, offering options like AutoCAD and SketchUp. The primary advantage is that it gives users significant freedom to tailor their designs according to specific project needs. Moreover, many platforms offer community support and tutorials, which can be beneficial for beginners. On the flip side, the learning curve may deter some users, and the software’s performance can vary, affecting precision and final output quality.

How Do Custom CNC Design Services Stack Up?

Custom CNC design services offer a tailored solution where professionals create CNC designs based on client specifications. This method ensures high-quality output that meets specific requirements, making it ideal for large-scale or unique projects. Additionally, these services often include ongoing support, which can benefit operations that need frequent updates or changes. The downside is the higher cost compared to freely available design files and longer lead times due to project consultations.

Conclusion: Which Solution Should A B2B Buyer Choose for Their Needs?

The best solution ultimately hinges on the specific needs of the buyer. For small to medium projects, CNC design files can offer a cost-effective and efficient way to implement designs quickly. In contrast, buyers seeking complete customization and tailored support may find that custom CNC design services deliver the best results despite the higher price point. On the other hand, for those willing to invest time in learning, free CAD software might provide a middle ground, allowing for creative flexibility without significant financial commitment. Careful assessment of project requirements, budget constraints, and desired outcomes will lead to the most suitable choice.

Essential Technical Properties and Trade Terminology for cnc design files

What are the Key Technical Properties of CNC Design Files?

In the world of CNC (Computer Numerical Control) machining, understanding specific technical properties is critical for decision-makers, especially when sourcing materials for manufacturing projects. Here are several essential specs to consider:

1. Material Grade

Material grade refers to the category or type of raw materials used in production, such as aluminum, steel, or plastic. Different grades offer varying characteristics like strength, flexibility, and corrosion resistance. For B2B buyers, selecting the right material grade ensures the produced components can withstand intended applications and environmental conditions, preventing costly failures.

2. Tolerance

Tolerance defines the permissible limits of variation in a physical dimension. For example, a tolerance of ±0.01 mm means a component can measure anywhere between 10.01 mm and 9.99 mm. Accurate tolerances are crucial in CNC machining, as they determine the fit and functioning of mechanical parts. In a B2B context, ensuring tight tolerances can enhance product quality and reduce assembly issues, ultimately improving customer satisfaction.

3. Cutting Depth

Cutting depth indicates how deep the CNC machine will cut into the material in one pass. Managing cutting depths effectively can minimize wear on cutting tools while improving processing speed. For manufacturers, this translates to reduced tool replacement costs and higher efficiency, making it a key parameter in the production process.

4. Finish Type

Finish type refers to the surface finish of the machined part, such as matte, polished, or anodized. The finish not only contributes to the aesthetic appeal of the product but also plays a role in protecting it against environmental factors. Understanding the desired finish type helps buyers select suppliers that align with their product specifications, ensuring the final product meets market expectations.

5. File Format

The file format of CNC design files, such as DXF (Drawing Exchange Format) or DWG (Drawing), determines compatibility with various CNC machines. Materializing designs from compatible file formats enables a smoother transition from digital design to actual production. For B2B buyers, selecting a supplier that offers files in the necessary format can speed up the manufacturing process and reduce errors.

What Terms are Commonly Used When Discussing CNC Design Files?

Familiarity with trade terminology is essential for effective communication in the B2B realm. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products or components that are sold to another company for rebranding. Understanding OEM relationships is vital for B2B buyers as they navigate sourcing decisions, ensuring they choose reliable partners that meet quality standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ can help buyers plan their budgets and inventory effectively. This term helps enforce purchasing guidelines and can aid in negotiations with suppliers for better pricing.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific quantities of goods or services. For B2B transactions, issuing an RFQ streamlines the sourcing process, enabling buyers to compare offers from multiple providers and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk management, and liability, ensuring smoother cross-border transactions.

5. CAM (Computer-Aided Manufacturing)

CAM refers to software that automates the manufacturing process by translating designs into machine instructions. It’s crucial to comprehend CAM’s role in optimizing production efficiency and ensuring the accuracy of machined components.

Understanding these technical properties and trade terminology equips decision-makers with the knowledge to drive more effective purchasing decisions, resulting in higher quality outputs and streamlined industrial operations.

Navigating Market Dynamics and Sourcing Trends in the cnc design files Sector

What Are the Key Trends Driving the CNC Design Files Market?

The CNC design files sector is influenced by several global drivers, primarily facilitated by advances in automation and digital technologies. As manufacturers increasingly adopt Industry 4.0 methodologies, there’s a growing demand for precision-cut designs in both traditional industries and emerging sectors like personalized manufacturing and custom decor. This trend is particularly pronounced among B2B buyers from regions such as Africa and South America, where local artisans and manufacturers are tapping into digital design tools to enhance their product offerings.

Additionally, the rise of e-commerce platforms has democratized access for buyers in remote areas, enabling them to source CNC design files from established global suppliers with ease. Users now expect seamless user experiences—such as downloadable content without registration barriers or fees—which caters to immediate operational needs. The focus on versatility has led to a surge in demand for DXF files that accommodate various CNC machines, making multi-functional files a significant sourcing trend.

Emerging technologies, including artificial intelligence and machine learning, are being integrated into the design process, providing innovative ways to analyze customer needs and streamline file modifications. This capability not only increases efficiency but also fosters customization, creating unique opportunities for businesses seeking to differentiate themselves in competitive markets.

How Is Sustainability Impacting Sourcing Decisions for CNC Design Files?

Sustainability is becoming a cornerstone in the supply chain for CNC design files, influencing purchasing decisions across industries. As environmental consciousness rises, ethical sourcing practices are no longer optional; they are imperative for maintaining brand integrity and customer loyalty. International B2B buyers, particularly in Europe, demand transparency in supply chains, insisting that companies demonstrate responsible sourcing and manufacturing practices.

The usage of eco-friendly materials and processes in CNC fabrication—such as sustainable wood, recycled metals, and green adhesives—plays a crucial role in the sourcing landscape. Buyers prioritize partnerships with suppliers who hold certifications like FSC (Forest Stewardship Council) or similar green credentials, signifying a commitment to sustainable practices. For companies in Africa and South America, aligning with these values not only appeals to local consumers but also opens avenues for international collaborations.

Furthermore, the market is witnessing an increase in platforms dedicated to sustainable CNC design files that emphasize low-waste designs and processes. These innovations help companies mitigate their environmental impact while satisfying a growing segment of eco-aware consumers and businesses.

What Is the Historical Context Behind the CNC Design Files Sector?

The CNC design files industry has evolved significantly since the advent of computer-aided design (CAD) in the late 20th century. Initially, design files were rudimentary, limited by the capabilities of early CNC machines. However, as technology advanced, the introduction of high-speed precision cutting and sophisticated software transformed the landscape. The shift towards digital manufacturing in the early 2000s opened the floodgates for a diverse range of design files, with formats like DXF becoming industry standards for sharing and modifying CNC designs.

The growth of the internet further propelled the sector, allowing designers to share files globally, and giving rise to platforms that specialize in free and commercial CNC designs. This democratization of access not only bolstered innovation but also laid the groundwork for today’s rich ecosystem of design files tailored for various industries and applications.

The evolution of CNC design files is a testament to how technological progress shapes business operations, empowering companies worldwide to embrace digital transformation and resource efficiency, while meeting the complex demands of an increasingly global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc design files

1. How can I choose the right CNC design files for my project?

Selecting the appropriate CNC design files involves understanding your project requirements, machine compatibility, and desired outcomes. Assess the complexity and dimensions of the design, ensuring it aligns with your CNC machine’s specifications. It’s also beneficial to consider the file format (like DXF, SVG) that works best with your equipment. Moreover, reviewing user feedback on the design files can help gauge their quality and suitability for your needs.

2. What are the benefits of using free DXF files for CNC design projects?

Free DXF files can significantly lower project costs, especially for businesses starting in CNC machining. They offer a plethora of design options without financial commitment, allowing experimentation with various styles. Additionally, many free files are compatible with multiple CNC machines, facilitating diverse applications—from decorative art to functional components. Always verify file quality and machine compatibility to ensure optimal results.

3. How do I evaluate the quality of CNC design files before purchasing?

Evaluate the quality of CNC design files by looking for clean vectors, absence of crossed paths, and detailed descriptions of the files’ intended uses. A reliable supplier typically offers samples or previews of their designs. User reviews and ratings can provide insights into the ease of use and precision of the files. Ensuring compatibility with your CNC machine is also critical to avoid compatibility issues post-purchase.

4. What should I consider regarding customization when sourcing CNC design files?

Customization is a key consideration for many B2B buyers, as unique designs can differentiate products in the market. When sourcing CNC design files, check if the supplier offers customization options tailored to specific dimensions or design changes. Understanding their turnaround time for modifications and any associated costs is crucial. Ensure the supplier can adjust designs to fit various machines and meet your project needs.

5. What are typical minimum order quantities (MOQs) for CNC design files?

MOQs for CNC design files can vary significantly depending on the supplier. Many platforms offering digital files operate without MOQs, allowing buyers to purchase single files as needed. However, if you are sourcing from a manufacturer for customized designs, it is wise to inquire about quantity discounts or tiered pricing for bulk orders. Understanding the supplier’s policy on MOQs can help in budgeting and planning future projects.

6. How do international payment terms work when buying CNC design files?

When engaging in international transactions for CNC design files, clarity on payment terms is vital. Most suppliers accept various payment methods, including credit cards, bank transfers, and online payment platforms. Discuss upfront whether the pricing includes taxes or customs duties to avoid unexpected costs. Payment terms can vary based on the relationship with the supplier, so negotiate terms that ensure transparency and security for both parties.

7. What logistics considerations should I keep in mind for sourcing CNC design files internationally?

Logistics for sourcing CNC design files internationally primarily involves the digital transfer of files, which should be seamless and secure. Ensure the supplier uses reliable transfer protocols to protect your design files from unauthorized access. Consider the implications of timezone differences if needing support for file integration. Finally, assess the supplier’s policy on file retention and archiving to facilitate easy reorders.

8. How can I ensure quality assurance (QA) for CNC design files when sourcing?

Quality assurance for CNC design files is crucial to avoid costly mistakes during production. Choose suppliers who provide detailed specifications, including feed rates and cutting conditions. Request samples or conduct pilot tests to evaluate file performance on your machines. It’s also advisable to establish clear communication lines with the supplier for any modifications or support during the initial runs of the designs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Cnc Design Files Manufacturers & Suppliers List

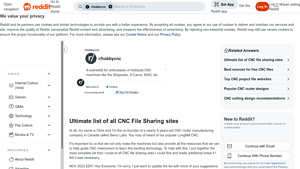

1. Reddit – CNC File Sharing Resources

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ultimate list of CNC file sharing sites including:

– Drawings

– Obrary

– Maslow Community Garden

– FreePatternsArea (templates and projects)

– Ameede (45 seconds wait for download)

– FreeDXF (signup required, free & paid content, 5 seconds wait for download)

– LaraDesignCnc (curated marketplace, mostly paid)

– CNC Cookbook (free DXF files)

– CNC File Sharing (signup required)

– ToolsToday Pattern …

2. AribaBox – Free DXF Files for CNC Designs

Domain: aribabox.com

Registered: 2017 (8 years)

Introduction: Free DXF Files for CNC, designs categorized for Workshop, Kids, Home, Game Room, and Bundles.

3. Broinwood – CNC Design Files

Domain: broinwood.com

Registered: 2018 (7 years)

Introduction: This company, Broinwood – CNC Design Files, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. CNC Cookbook – Free DXF Files for Cutting

Domain: cnccookbook.com

Registered: 2007 (18 years)

Introduction: Free DXF Files available for cutting today, categorized by: Animals, Vehicles, Nature, Maps, Music, Symbols, Holiday, Toys, Signs, Sports, Food, Religion, and Western. Files are in DXF format, which is a vector CAD file type used for CNC machines including Laser, Plasma Cutter, CNC Router, and Waterjet. DXF stands for Drawing eXchange Format, created by Autodesk for AutoCAD. The files include desi…

5. Langmuir Systems – FireShare Beta

Domain: langmuirsystems.com

Registered: 2017 (8 years)

Introduction: FireShare Beta supports uploading G-Code files for FireControl and Mach3. It allows users to download and share free cut ready project files. The platform features user-uploaded projects categorized into latest and popular projects, including tabs and brackets with various standoff sizes. Key products from Langmuir Systems include CrossFire CNC Plasma, CrossFire PRO CNC Plasma, CrossFire XR CNC Pl…

6. CNC Design Shop – Free DXF Files for CNC Machines

Domain: cncdesignshop.com

Registered: 2018 (7 years)

Introduction: Free DXF files for CNC machines including plasma, laser, and waterjet types. Categories include Home Decor (clocks, fireplace screens, signs), Outdoor & Garden (gates, garden art), Stock Art (animals, landscapes, religious themes), and more. Membership options provide access to hundreds of free DXF files and custom design services. Files are machine-tested and designed for various materials. Key f…

7. Modifile – CNC Furniture Design Templates

Domain: modifile.com

Registered: 2017 (8 years)

Introduction: Modifile offers digital design files for CNC cutting, specifically flat-packed furniture designer templates for laser and CNC machines. The products include various models and templates suitable for commercial licensing. Users can choose from a catalog organized into sections, select the appropriate commercial license for selling or personal use, and download templates with options for different d…

8. Etsy – CNC Files and Mega Pack

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: CNC Files available for digital download, with various items including:

– Oreo CNC file for cutting – catch all tray, $5.50

– Modular CNC Tool and Bit Organizer for Carbide 3D Shapeoko, Sale Price: $22.50 (Original Price: $25.00)

– 340+ GB CNC Router STL Mega Pack, Sale Price: $6.40 (Original Price: $25.59)

– MEGA BUNDLE CNC Files for Router Machines, Sale Price: $9.90 (Original Price: $19.80)

– C…

9. Free DXF – High Quality Vector Files

Domain: free-dxf.com

Registered: 2020 (5 years)

Introduction: Free DXF and vector files for download and ready to cut. High quality stock DXF files, SVG, CDR, and AI formats available. Categories include Doors, Panels, Wall screens, Decorative Cliparts, and more. Popular designs include Tree of Life wall art, Hummingbird floral art, Nautical compass, Harley Davidson logos, and various Wall decor items. Each design is tagged with relevant categories and searc…

Strategic Sourcing Conclusion and Outlook for cnc design files

As the global demand for CNC design files continues to rise, the importance of strategic sourcing cannot be overstated. By leveraging resources like free DXF files, international B2B buyers gain access to a diverse range of innovative designs, allowing them to enhance efficiency and reduce costs in their manufacturing processes. Strategic sourcing not only optimizes procurement processes but also fosters lasting supplier relationships, ensuring a steady supply of high-quality files tailored to specific machinery and applications.

For businesses in Africa, South America, the Middle East, and Europe, investing in reliable sources of CNC design files can lead to significant competitive advantages. With the ability to access unique and customizable designs from reputable platforms, buyers can offer distinctive products, meet market demands swiftly, and adapt to evolving trends.

Looking ahead, companies that prioritize strategic sourcing in their CNC design file procurement will position themselves for growth in an increasingly interconnected marketplace. Take the next step by exploring the wealth of free resources available, forging strategic partnerships, and enhancing your product offerings to captivate your target audience.