Introduction: Navigating the Global Market for cnc delrin

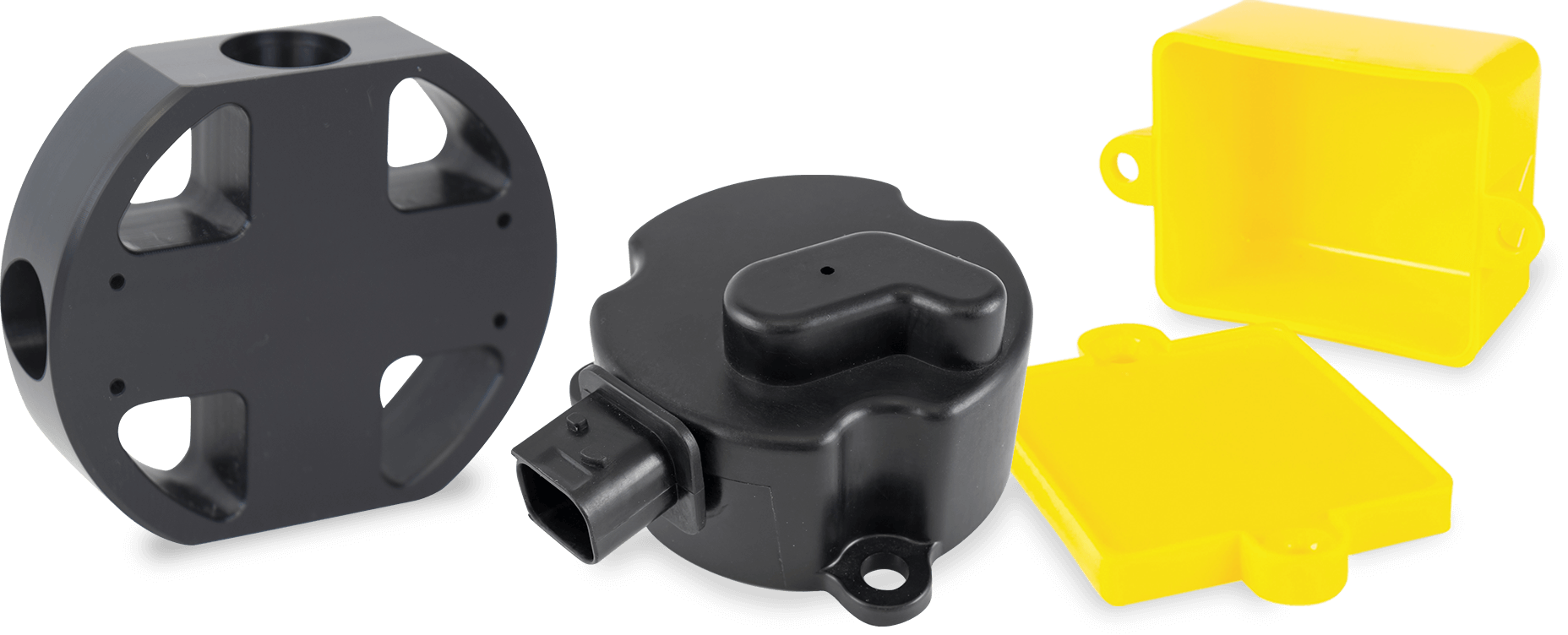

In the dynamic landscape of global manufacturing, sourcing CNC Delrin parts presents a unique set of challenges for international B2B buyers. As industries increasingly demand high-performance materials that bridge the gap between metal and plastic, Delrin—known for its exceptional durability, low friction, and versatility—has emerged as a top choice. However, navigating the complexities of sourcing, pricing, and supplier reliability can overwhelm even the most seasoned procurement professionals, particularly in regions like Africa, South America, the Middle East, and Europe, including countries such as Nigeria and Saudi Arabia.

This comprehensive guide delves into the critical aspects of CNC Delrin, including material specifications, types, and applications across diverse industries such as automotive, robotics, and consumer goods. It also provides actionable insights on vetting suppliers, understanding cost structures, and leveraging the unique properties of Delrin to meet specific project needs. With a focus on empowering buyers with knowledge, this guide aims to simplify the decision-making process, ensuring that businesses can confidently select the right materials and suppliers for their production requirements.

By equipping international B2B buyers with the tools and insights needed to make informed purchasing decisions, this guide serves as a valuable resource for those looking to harness the benefits of CNC Delrin in their operations while optimizing cost and quality.

Understanding cnc delrin Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Delrin 150 | High impact resistance, low friction, excellent wear resistance | Gears, bushings, valve components | Pros: Strong, versatile, cost-effective; Cons: Limited chemical resistance under certain conditions. |

| Delrin 100 (AF) | Infused with PTFE for enhanced wear resistance and low friction | Bearings, sliding applications | Pros: Superior wear properties, low friction; Cons: Lower tensile strength compared to Delrin 150. |

| Delrin 570 | Higher heat deflection temperature, improved toughness | High-temperature environments, automotive parts | Pros: Excellent dimensional stability; Cons: More expensive than standard Delrin grades. |

| Delrin Sheet | Available in various thicknesses and sizes, easy to machine | Custom parts, prototypes | Pros: Customizable, quick turnaround; Cons: Requires precise design specifications to avoid waste. |

| Delrin Rod | Solid cylindrical form, suitable for machining and fabrication | Mechanical components, fixtures | Pros: Versatile for various applications; Cons: Limited to round shapes, may require additional processing. |

What Are the Key Characteristics of Delrin 150 for B2B Buyers?

Delrin 150 is a homopolymer acetal known for its high impact resistance and low friction properties. This material is particularly suitable for applications requiring durability, such as gears, bushings, and valve components. B2B buyers should consider its versatility and cost-effectiveness, making it an excellent choice for industries like robotics and automotive. However, it has limited chemical resistance, which may restrict its use in environments exposed to harsh chemicals.

How Does Delrin 100 (AF) Enhance Performance in Specific Applications?

Delrin 100 (AF) is enhanced with PTFE fibers, providing superior wear resistance and low friction characteristics. This makes it ideal for applications such as bearings and sliding components where minimizing wear is crucial. For B2B buyers, the trade-off is a lower tensile strength compared to Delrin 150, but the enhanced properties can lead to longer service life and reduced maintenance costs, making it a valuable investment for high-performance applications.

Why Choose Delrin 570 for High-Temperature Applications?

Delrin 570 stands out due to its higher heat deflection temperature and improved toughness, making it suitable for high-temperature environments. This material is often used in automotive parts and other applications where thermal stability is critical. B2B buyers should note that while Delrin 570 offers excellent dimensional stability, it comes at a higher cost than standard Delrin grades, necessitating a careful evaluation of budget versus performance requirements.

What Advantages Does Delrin Sheet Offer for Custom Projects?

Delrin sheets are available in various thicknesses and sizes, providing flexibility for custom parts and prototypes. The ease of machining this material allows for quick turnaround times, making it an attractive option for B2B buyers in need of rapid prototyping. However, precise design specifications are essential to minimize waste, as any inaccuracies can lead to increased costs and extended lead times.

How Can Delrin Rod Be Utilized in Mechanical Fabrication?

Delrin rods, available in solid cylindrical forms, are versatile for various mechanical components and fixtures. They can be easily machined into custom shapes, offering flexibility for B2B buyers in manufacturing applications. While the limited shape options may require additional processing for specific designs, the overall versatility and reliability of Delrin rods make them a popular choice across multiple industries.

Key Industrial Applications of cnc delrin

| Industry/Sector | Specific Application of cnc delrin | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Gears and bushings | High durability and low maintenance costs | Ensure precision machining capabilities and material certifications. |

| Robotics | Custom robotic components | Lightweight yet strong parts enhance performance | Verify tolerances and dimensional stability for high-precision applications. |

| Industrial Equipment | Pump and valve components | Resistance to wear and chemicals, reducing downtime | Source from suppliers with experience in fluid dynamics and chemical resistance. |

| Electrical and Electronics | Insulators and connectors | Enhanced safety and reliability in electrical systems | Check for compliance with international safety standards and certifications. |

| Agriculture | Irrigation system components | Improved efficiency and longevity of agricultural tools | Consider local sourcing options for reduced lead times and import costs. |

How is CNC Delrin Used in the Automotive Sector?

In the automotive industry, CNC Delrin is predominantly utilized for manufacturing gears and bushings. Its high wear resistance and low friction properties significantly reduce maintenance costs and extend the lifespan of automotive components. Buyers should prioritize suppliers who can offer precision machining and material certifications to ensure the parts meet stringent industry standards. Additionally, sourcing from local manufacturers can mitigate shipping delays and costs, particularly for clients in regions like Africa and South America.

What Role Does CNC Delrin Play in Robotics Applications?

CNC Delrin is essential in the robotics sector, where it is used to produce custom robotic components such as joints and housings. The material’s lightweight nature combined with its strength allows for improved performance in robotic applications. International buyers need to focus on suppliers that can achieve tight tolerances and maintain dimensional stability, crucial for the precise movements required in robotics. Ensuring a reliable supply chain can also help mitigate risks associated with long lead times.

How Does CNC Delrin Benefit Industrial Equipment Manufacturing?

In industrial equipment, CNC Delrin is commonly used for pump and valve components due to its excellent resistance to wear and chemicals. This property minimizes downtime and maintenance, leading to increased operational efficiency. Businesses should consider sourcing from suppliers experienced in fluid dynamics to ensure compatibility with various chemicals and pressures. Additionally, understanding local market conditions can help optimize sourcing strategies for businesses in the Middle East and Europe.

Why is CNC Delrin Important in Electrical and Electronics?

CNC Delrin is widely used for insulators and connectors in the electrical and electronics sector. Its excellent electrical insulation properties enhance the safety and reliability of electrical systems. Buyers should prioritize suppliers who comply with international safety standards and provide certifications, ensuring that the components meet regulatory requirements. It’s also crucial to consider the availability of materials that can withstand varying environmental conditions, particularly for projects in diverse climates.

How is CNC Delrin Applied in Agricultural Equipment?

In agriculture, CNC Delrin is utilized in components for irrigation systems, such as fittings and valves. Its durability and resistance to moisture contribute to the efficiency and longevity of agricultural tools. Buyers should consider local sourcing options to reduce lead times and costs, particularly in regions like Africa, where agricultural demands can fluctuate seasonally. Additionally, ensuring that suppliers understand the specific agricultural challenges can lead to more tailored solutions.

3 Common User Pain Points for ‘cnc delrin’ & Their Solutions

Scenario 1: Inconsistent Quality of CNC Delrin Parts

The Problem: Many B2B buyers experience frustration with inconsistent quality in CNC machined Delrin parts. Variations in thickness, surface finish, and dimensional tolerances can lead to assembly issues, operational inefficiencies, and increased costs due to rework or replacement parts. This inconsistency can be particularly problematic for industries such as automotive and aerospace, where precision is critical for safety and performance.

The Solution: To mitigate quality issues, buyers should prioritize working with reputable CNC machining suppliers who provide detailed material specifications and quality assurance processes. Requesting sample parts before placing larger orders can help verify the supplier’s capabilities. Additionally, specifying exact tolerances and finishes in the initial design documentation is crucial. Make use of the supplier’s expertise by discussing the application requirements in detail, allowing them to recommend the optimal Delrin grade and machining techniques tailored to specific needs.

Scenario 2: Delrin’s Limited Chemical Resistance

The Problem: B2B buyers often overlook Delrin’s chemical resistance properties when designing components that will be exposed to harsh environments. Industries like chemical processing or oil and gas may find that certain chemicals can degrade Delrin, leading to premature failure of components such as fittings or seals. This oversight can result in costly downtimes and safety risks.

The Solution: Conducting a thorough analysis of the chemical environment where the Delrin parts will be used is essential. Buyers should compile a list of all chemicals the components will encounter and consult with suppliers to confirm the compatibility of Delrin with these substances. If necessary, consider alternative materials or modified versions of Delrin, such as Delrin 100 AF, which offers improved chemical resistance. Additionally, incorporating protective coatings or barriers can enhance the longevity of Delrin parts in challenging environments.

Scenario 3: Design Limitations and Machining Complexity

The Problem: Many B2B buyers struggle with the design limitations of CNC machining Delrin, particularly when creating intricate geometries or tight tolerances. Complex designs may require advanced machining capabilities that not all suppliers possess, leading to increased costs and longer lead times. This can be especially concerning for projects with strict deadlines and budget constraints.

The Solution: To overcome design challenges, buyers should engage in collaborative design reviews with their CNC machining partners early in the project. Utilizing CAD software to create detailed models can help identify potential machining difficulties upfront. Suppliers often provide design guidelines that highlight feasible geometries and machining techniques suitable for Delrin. Additionally, considering a phased approach to design, where parts are prototyped and tested before full-scale production, can minimize risks and ensure the final product meets all functional requirements. Leveraging the supplier’s capabilities can also lead to innovative solutions that optimize both design and manufacturability.

Strategic Material Selection Guide for cnc delrin

What Are the Key Properties of Delrin for CNC Machining?

Delrin, also known as Polyoxymethylene (POM), is a high-performance thermoplastic renowned for its exceptional mechanical properties. It exhibits high stiffness, low friction, and excellent wear resistance, making it ideal for demanding applications. Delrin maintains its performance across a temperature range of -40°C to 120°C, which is significantly broader than many other plastics. Its chemical resistance to solvents and fuels further enhances its suitability for various industrial applications.

What Are the Advantages and Disadvantages of Using Delrin?

The primary advantages of Delrin include its durability, low moisture absorption, and dimensional stability. These properties make it an excellent choice for components that experience wear, such as gears, bearings, and bushings. However, Delrin does have limitations, including a tendency to creep under constant load and limited chemical resistance compared to some metals. Additionally, while it is generally cost-effective, the price can vary based on the specific grade and machining requirements.

How Does Delrin Impact Application Performance?

Delrin’s unique properties allow it to perform exceptionally well in applications that require high mechanical strength and precision. Its low friction characteristics make it suitable for moving parts, while its wear resistance ensures longevity. For international B2B buyers, understanding the specific media compatibility is crucial, especially in industries such as automotive and robotics, where exposure to lubricants or chemicals is common.

What Should International Buyers Consider When Selecting Delrin?

For buyers in regions such as Africa, South America, the Middle East, and Europe, compliance with international standards like ASTM, DIN, and JIS is essential. These standards ensure that the materials meet quality and safety requirements. Additionally, buyers should consider local sourcing options to mitigate shipping costs and lead times, especially in regions where logistics can be challenging. Understanding the local market preferences and the availability of specific Delrin grades can also influence purchasing decisions.

Summary Table of Material Selection for CNC Delrin

| Material | Typical Use Case for cnc delrin | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Delrin 150 | Gears, bearings, and bushings | Excellent wear resistance and toughness | Limited chemical resistance | Medium |

| Delrin 100 AF | Low-friction applications (e.g., bearings) | Enhanced wear resistance due to PTFE | Higher cost due to added materials | High |

| Acetal Copolymer | General-purpose mechanical parts | Good dimensional stability | Lower impact resistance than homopolymer | Medium |

| Delrin 570 | High-temperature applications | Superior heat resistance | Slightly lower strength than Delrin 150 | Medium |

This guide aims to provide B2B buyers with actionable insights into selecting the right Delrin material for their CNC machining needs, ensuring optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc delrin

What Are the Key Manufacturing Processes for CNC Machining Delrin?

The manufacturing of CNC machined Delrin parts involves a series of well-defined stages, each critical to ensuring the quality and performance of the final product. Understanding these stages can empower B2B buyers to make informed decisions when sourcing components.

How Is Material Prepared for CNC Machining Delrin?

The initial step in the CNC machining process is material preparation. Delrin, or Polyoxymethylene (POM), is available in various thicknesses and forms, such as sheets, rods, or blocks. Suppliers typically offer Delrin in standard sizes, allowing for efficient cutting and machining. The material is often checked for consistency in density and thickness, as variations can affect the machining process.

Once the material is selected, it undergoes cutting to size based on the specific requirements of the part design. Buyers should ensure that suppliers have capabilities for precise cutting to avoid excess waste and ensure dimensional accuracy.

What Forming Techniques Are Commonly Used in CNC Machining Delrin?

After material preparation, the forming stage involves machining the Delrin material into the desired shape. CNC (Computer Numerical Control) machining is the predominant technique used. This method allows for high precision and repeatability, making it ideal for producing intricate designs with tight tolerances.

Key machining processes include:

- Milling: Utilized for creating complex geometries, milling allows for the removal of material from the Delrin block or sheet using rotating cutting tools.

- Turning: This process is often used for cylindrical parts, where the material rotates against a cutting tool to achieve the desired diameter and finish.

- Laser Cutting: Particularly effective for flat parts, laser cutting provides a clean edge and high accuracy, especially for detailed designs.

The choice of technique should be aligned with the part’s functional requirements and complexity.

How Are Delrin Parts Assembled and Finished?

Once the parts are machined, assembly may be necessary, depending on the design. This could involve joining multiple components or adding hardware such as fasteners. The assembly process should be carefully controlled to maintain the integrity of the parts.

Finishing processes are crucial for enhancing the performance and aesthetics of CNC machined Delrin parts. Common finishing techniques include:

- Deburring: This removes sharp edges and improves safety and functionality.

- Surface Treatment: Depending on the application, parts may undergo treatments to enhance wear resistance or to improve friction properties.

- Tapping and Countersinking: These processes allow for the integration of fastening hardware, ensuring parts fit together seamlessly.

Each finishing step should be executed with precision to meet both functional and visual standards.

What Quality Assurance Measures Are Essential for CNC Machined Delrin?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for B2B buyers seeking reliable components. Adherence to international and industry-specific standards is vital for ensuring product quality and consistency.

Which International Standards Should B2B Buyers Consider?

For CNC machined Delrin, ISO 9001 is a fundamental standard that outlines criteria for a quality management system. Compliance indicates that a supplier consistently meets customer and regulatory requirements.

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications may be relevant, depending on the end use of the parts. Buyers should inquire about these certifications when evaluating suppliers.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet specified standards before they enter the production line.

- In-Process Quality Control (IPQC): During machining, IPQC involves monitoring processes and measuring parts to ensure they remain within tolerance. This step helps identify any deviations early in the process.

- Final Quality Control (FQC): After machining and finishing, FQC involves thorough inspections of the final parts to verify they meet all specifications. Testing methods can include dimensional checks, mechanical performance assessments, and surface quality evaluations.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers should proactively verify the quality assurance practices of their suppliers to ensure they align with their standards. Here are several strategies:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. This can be done on-site or through remote assessments.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports, material certifications, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s processes and products, providing additional assurance of quality.

What Nuances Should International Buyers from Africa, South America, the Middle East, and Europe Consider?

B2B buyers from diverse regions face unique challenges when sourcing CNC machined Delrin parts. Understanding these nuances is essential for successful procurement.

-

Regulatory Compliance: Different regions have varying regulations regarding material sourcing and product safety. Buyers should familiarize themselves with local regulations and ensure that suppliers are compliant.

-

Cultural and Communication Differences: Effective communication is crucial in international transactions. Buyers should seek suppliers who are responsive and understand the nuances of their specific market needs.

-

Supply Chain Considerations: Logistics can significantly impact delivery times and costs. Buyers should consider suppliers with robust supply chain capabilities and those who can provide timely updates on order status.

By being informed about manufacturing processes and quality assurance practices, B2B buyers can make strategic decisions that lead to successful partnerships and high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc delrin’

Introduction

Navigating the procurement of CNC Delrin parts requires a methodical approach to ensure you receive high-quality materials that meet your specifications. This guide provides a step-by-step checklist tailored for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. Following these steps will help streamline your sourcing process and mitigate risks associated with material quality and supplier reliability.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for CNC Delrin components. Consider factors such as thickness, dimensions, and mechanical properties, such as tensile strength and wear resistance. This clarity will enable suppliers to provide accurate quotes and ensure the final product meets your expectations.

- Key Specifications to Include:

- Desired thickness (e.g., .125″ or .270″).

- Minimum and maximum part sizes (e.g., 1″ x 2″ to 23″ x 44″).

Step 2: Research Potential Suppliers

Identify suppliers who specialize in CNC machining of Delrin. Look for companies with a strong reputation in your target markets, as well as those that demonstrate experience with similar applications. This research will help you narrow down your options to the most qualified candidates.

- Where to Look:

- Industry directories and trade shows.

- Online reviews and customer testimonials.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is crucial in ensuring quality standards are met. Check for ISO certifications or other relevant industry-specific certifications that demonstrate a commitment to quality and continuous improvement. This step adds an extra layer of assurance regarding the supplier’s capabilities.

- What to Confirm:

- ISO 9001 certification for quality management.

- Compliance with industry standards relevant to your application.

Step 4: Request Samples and Prototypes

Before placing a bulk order, request samples or prototypes of the CNC Delrin parts. This allows you to assess the material quality, precision, and overall performance in your specific application. Evaluating samples helps identify potential issues early in the process.

- What to Evaluate:

- Tolerance levels and finish quality.

- Functional performance in your application context.

Step 5: Discuss Lead Times and Production Capabilities

Engage with your shortlisted suppliers to understand their lead times and production capabilities. Timely delivery is critical for project management, so ensure that the supplier can meet your deadlines without compromising quality.

- Questions to Ask:

- What is the typical lead time for orders of your size?

- Are there options for expedited production if needed?

Step 6: Understand Pricing Structures

Before finalizing your supplier, review their pricing structures. Ensure you comprehend what is included in the quoted price, such as machining, finishing, and any additional services like tapping or countersinking. Comparing quotes from multiple suppliers will help you identify the best value.

- Cost Considerations:

- Bulk order discounts.

- Additional fees for custom specifications or urgent requests.

Step 7: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Establish clear lines of communication with your chosen supplier to facilitate updates, inquiries, and feedback. This openness will help address any potential issues quickly and efficiently.

- Communication Strategies:

- Set regular check-in meetings or updates.

- Utilize project management tools for tracking progress.

By following this checklist, you will be better equipped to navigate the complexities of sourcing CNC Delrin parts, ensuring that you partner with reliable suppliers who can meet your technical and business needs.

Comprehensive Cost and Pricing Analysis for cnc delrin Sourcing

What Are the Key Cost Components in CNC Delrin Sourcing?

When considering the sourcing of CNC Delrin components, understanding the comprehensive cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: Delrin, or Polyoxymethylene (POM), is a high-performance plastic known for its durability and versatility. The cost of Delrin can vary based on grade and supplier, with Delrin 150 typically being more affordable than specialized grades like Delrin 100 AF, which has enhanced properties. Buyers should account for fluctuations in material prices due to market demand and geopolitical factors.

-

Labor: Labor costs encompass the wages paid to skilled technicians who operate CNC machines and oversee the production process. In regions with higher labor costs, such as parts of Europe, this can significantly influence the final pricing of CNC machined parts. Conversely, sourcing from countries with lower labor costs, such as those in Africa or South America, may yield savings.

-

Manufacturing Overhead: This includes the operational expenses necessary to run production facilities, such as utilities, maintenance, and administrative costs. High overhead can drive up prices, making it essential for buyers to assess suppliers’ operational efficiencies.

-

Tooling: Initial tooling costs for CNC machining can be substantial, especially for custom parts requiring specific designs. These costs are often amortized over larger production runs, so buyers should consider minimum order quantities (MOQs) to optimize tooling expenses.

-

Quality Control (QC): Ensuring the quality of Delrin components is non-negotiable, especially in industries where precision is critical. Investment in QC processes, including inspections and testing, contributes to the overall cost but is essential for maintaining product standards.

-

Logistics: Transportation costs can vary significantly depending on the supplier’s location and the chosen Incoterms. For international shipments, additional costs such as customs duties, insurance, and freight charges should be factored into the total cost.

-

Margin: Finally, suppliers will incorporate their profit margins into the pricing structure. Understanding the typical mark-up for CNC machined parts can help buyers gauge whether they are receiving a fair price.

What Factors Influence Pricing for CNC Delrin Components?

Several factors can influence the pricing of CNC Delrin components, making it essential for buyers to evaluate their sourcing strategies carefully.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide better pricing for larger orders. Buyers should assess their needs and consider consolidating orders to meet MOQs, thereby reducing per-unit costs.

-

Specifications and Customization: The complexity of the parts and any specific customization requirements will impact pricing. Simple designs are generally less expensive to manufacture than intricate ones that require advanced machining techniques.

-

Material Quality and Certifications: Higher-quality materials or those with specific certifications (e.g., FDA-approved for food applications) may come at a premium. Buyers should weigh the benefits of quality against the associated costs.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with proven track records may charge more but offer better service and quality assurance.

-

Incoterms: Understanding the implications of different Incoterms is crucial. Terms like FOB (Free on Board) can affect the total landed cost, so buyers should clarify responsibilities for shipping and insurance with their suppliers.

What Are Some Buyer Tips for Cost-Efficiency in CNC Delrin Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Terms: Always approach pricing discussions with a clear understanding of your needs and potential for long-term partnership. Volume commitments can be leveraged for better pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but the total cost throughout the product lifecycle, including maintenance, logistics, and potential downtime costs.

-

Understand Pricing Nuances: Familiarize yourself with regional pricing trends and supplier capabilities. Variations in local market conditions can lead to significant differences in cost.

-

Explore Alternative Suppliers: Don’t hesitate to seek multiple quotes from different suppliers. This not only provides competitive pricing but also enables comparisons of quality and service.

-

Plan for Logistics: Optimize shipping routes and methods. Consolidating shipments can reduce costs, and understanding local regulations can prevent unexpected fees.

In conclusion, a thorough understanding of the cost structure, pricing influencers, and strategic sourcing approaches will enable international B2B buyers to make informed decisions when sourcing CNC Delrin components.

Alternatives Analysis: Comparing cnc delrin With Other Solutions

Exploring Alternatives to CNC Delrin: A Comprehensive Comparison

In the realm of precision machining and custom part fabrication, the selection of materials and methods is crucial for achieving optimal performance and cost-effectiveness. CNC Delrin, known for its superior mechanical properties and versatility, often faces competition from other materials and technologies. Understanding these alternatives can help B2B buyers make informed decisions based on their specific applications.

| Comparison Aspect | Cnc Delrin | Alternative 1: CNC Aluminum | Alternative 2: 3D Printed Nylon |

|---|---|---|---|

| Performance | High wear resistance, low friction, and excellent dimensional stability | Excellent strength-to-weight ratio and thermal conductivity | Good flexibility, lightweight, and complex geometries possible |

| Cost | Medium ($$) | Higher ($$$) | Lower ($) |

| Ease of Implementation | Requires specialized CNC equipment and expertise | Requires CNC machining setup and tooling | Quick setup with 3D printers, minimal tooling needed |

| Maintenance | Low maintenance, durable under various conditions | Moderate maintenance, susceptible to corrosion | Low maintenance, but durability varies with environment |

| Best Use Case | High-precision parts like gears and bushings | Aerospace, automotive, and structural applications | Prototyping, custom shapes, and low-volume production |

Detailed Breakdown of Alternatives

CNC Aluminum

CNC aluminum offers an excellent strength-to-weight ratio, making it suitable for applications where weight savings are critical without compromising strength. It is particularly favored in aerospace and automotive industries due to its thermal conductivity and resistance to corrosion. However, the costs associated with aluminum machining can be significantly higher compared to CNC Delrin, particularly when dealing with intricate designs or large volumes. Additionally, while aluminum requires moderate maintenance to prevent oxidation, it can perform exceptionally well in demanding environments.

3D Printed Nylon

3D printed nylon is an increasingly popular alternative for producing complex geometries and custom parts quickly. Its flexibility and lightweight nature make it ideal for prototyping and low-volume production. The primary advantage of this method is its lower cost and faster turnaround time compared to CNC machining. However, nylon’s durability can be a concern, especially in high-stress applications where Delrin’s superior wear resistance and stability under load are required. 3D printed nylon may also exhibit variations in mechanical properties based on the printing process used, which could affect performance.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between CNC Delrin and its alternatives, B2B buyers must assess their specific application requirements, including performance, cost, and manufacturing capabilities. CNC Delrin stands out for its combination of strength, wear resistance, and ease of machining, making it ideal for high-precision components. In contrast, CNC aluminum may be more suitable for applications demanding high structural integrity, while 3D printed nylon offers flexibility and rapid prototyping advantages. Evaluating these factors will enable businesses to choose the best solution tailored to their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for cnc delrin

What Are the Key Technical Properties of CNC Delrin?

When considering CNC Delrin for various applications, understanding its technical properties is crucial for making informed decisions. Here are several critical specifications:

-

Material Grade: Delrin, or Polyoxymethylene (POM), is available in different grades, with Delrin 150 being the most common. The grade affects characteristics such as mechanical strength, wear resistance, and thermal stability. For B2B buyers, selecting the appropriate grade ensures that the material will perform effectively in specific applications, such as gears, bearings, and automotive components.

-

Tensile Strength: This metric indicates the maximum stress a material can withstand while being stretched or pulled before failing. For Delrin 150, the tensile strength at yield is around 9,000 psi. High tensile strength is essential for applications that require durability and resistance to deformation under load, making it an attractive alternative to metals in many cases.

-

Dimensional Stability: Delrin exhibits excellent dimensional stability, meaning it maintains its shape and size under varying environmental conditions. This property is vital for precision applications where tight tolerances are required, reducing the likelihood of part failure or malfunction.

-

Creep Resistance: This property refers to the tendency of a material to deform permanently under constant stress over time. Delrin’s high creep resistance allows it to maintain performance in high-stress applications, making it suitable for parts like bushings and gears that undergo repeated loading.

-

Chemical Resistance: Delrin is resistant to a wide range of chemicals, including fuels and solvents. This characteristic is particularly important for applications in automotive and industrial environments where exposure to harsh substances is common.

-

Heat Deflection Temperature (HDT): This refers to the temperature at which a material deforms under a specified load. For Delrin, the HDT is typically around 160-169°C. Understanding this property helps businesses ensure that the material can withstand the operational temperatures of their applications without compromising integrity.

What Trade Terminology Should B2B Buyers Understand When Working with CNC Delrin?

Navigating the CNC machining landscape involves familiarizing oneself with industry-specific jargon. Here are several key terms:

-

OEM (Original Equipment Manufacturer): An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for B2B buyers as they often dictate the quality and specifications of the components being sourced.

-

MOQ (Minimum Order Quantity): This term indicates the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ helps businesses plan their budgets and inventory, ensuring they meet supplier requirements without overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For B2B buyers, issuing an RFQ is essential for comparing prices and terms among various suppliers, facilitating better negotiation and procurement decisions.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, costs, and risks involved in their transactions.

-

CNC (Computer Numerical Control): CNC refers to the automated control of machining tools via computer programming. Understanding CNC technology is vital for buyers looking to produce high-precision parts, as it impacts production efficiency, accuracy, and cost.

-

Tolerance: This term defines the allowable deviation from a specified dimension. In CNC machining, achieving tight tolerances is crucial for ensuring parts fit together correctly and function as intended. Buyers should specify tolerances in their orders to avoid issues during assembly or operation.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions when sourcing CNC Delrin components, ensuring they meet their specific application needs effectively.

Navigating Market Dynamics and Sourcing Trends in the cnc delrin Sector

What Are the Current Market Dynamics and Key Trends in the CNC Delrin Sector?

The CNC Delrin market is witnessing robust growth fueled by its unique properties, which bridge the gap between metals and plastics. Delrin, known for its high wear resistance, low friction, and excellent dimensional stability, is increasingly favored in industries ranging from automotive to robotics. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable materials, the demand for custom CNC machined Delrin components is on the rise. Notably, the push for rapid prototyping and just-in-time manufacturing is driving buyers to source Delrin parts that meet specific tolerances and quick turnaround times.

Emerging technologies, such as advanced CNC machining and laser cutting, are revolutionizing the way Delrin is processed. These innovations allow for intricate designs and high precision, enabling manufacturers to produce complex geometries that were previously challenging. Additionally, the increasing adoption of automation in machining processes is enhancing productivity and reducing lead times, making CNC Delrin an attractive option for manufacturers aiming to streamline operations.

Moreover, global supply chain dynamics are evolving, with buyers increasingly prioritizing local sourcing to mitigate risks associated with international logistics. For instance, companies in Nigeria and Saudi Arabia are now looking for local suppliers who can provide high-quality Delrin components while ensuring compliance with regional standards. This shift towards localized sourcing is expected to reshape the competitive landscape, encouraging suppliers to enhance their service offerings and responsiveness.

How Is Sustainability and Ethical Sourcing Addressed in the CNC Delrin Market?

Sustainability has become a critical consideration for B2B buyers in the CNC Delrin sector. The environmental impact of production processes, particularly in the plastics industry, is under scrutiny. As a result, ethical sourcing and sustainable practices are becoming paramount. Buyers are increasingly seeking suppliers who demonstrate a commitment to reducing their carbon footprint and promoting environmental stewardship.

One avenue for achieving sustainability in the Delrin supply chain is through the use of recycled materials or bio-based plastics. These alternatives not only reduce waste but also cater to the growing consumer preference for eco-friendly products. Furthermore, manufacturers are encouraged to obtain certifications such as ISO 14001, which signifies an effective environmental management system, or other green certifications that validate their sustainability efforts.

In addition, the use of renewable energy in the manufacturing processes is gaining traction among suppliers. This not only enhances the sustainability of the production but also appeals to buyers who are focused on sourcing from environmentally responsible companies. As the global market continues to prioritize sustainability, B2B buyers must consider these factors when selecting suppliers in the CNC Delrin sector.

What Is the Brief Evolution and History of Delrin in the B2B Market?

Delrin, a homopolymer of acetal developed by DuPont in the 1960s, has evolved significantly over the decades. Initially utilized in applications requiring high strength and durability, it quickly became the material of choice for industries such as automotive, aerospace, and manufacturing due to its unique mechanical properties.

The introduction of CNC machining technologies has further expanded the applications of Delrin, allowing for precise and intricate part production. As the global demand for lightweight and high-performance materials has surged, Delrin’s role in bridging the gap between metals and plastics has solidified its position as a vital material in modern manufacturing processes. The continuous advancements in machining techniques and the growing emphasis on sustainability are likely to shape the future trajectory of Delrin in the B2B marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc delrin

-

How do I choose the right thickness of CNC Delrin for my project?

Selecting the appropriate thickness of CNC Delrin depends on the application requirements, such as load-bearing capacity and dimensional stability. Common thicknesses include .125″ (3.18mm) and .270″ (6.9mm). Consider the mechanical stresses your parts will encounter, such as friction or impact. Consult with suppliers to discuss your specific application and receive recommendations based on their expertise and experience with similar projects. -

What are the advantages of using CNC Delrin over traditional materials?

CNC Delrin offers numerous advantages, including high wear resistance, low friction, and excellent dimensional stability. Unlike metals, Delrin is lightweight and can be machined into intricate geometries, making it ideal for applications such as gears and bushings. Additionally, it exhibits good chemical resistance, which is beneficial in environments where exposure to solvents or fuels is common. -

What customization options are available when sourcing CNC Delrin parts?

Most suppliers offer a range of customization options, including various sizes, thicknesses, and machining features like countersinking and tapping. You can often submit CAD designs for tailored solutions. Discuss your specific requirements with potential suppliers to ensure they can accommodate your needs, such as tight tolerances or specific finishes, to meet your project specifications. -

What are the minimum order quantities (MOQs) for CNC Delrin parts?

Minimum order quantities can vary by supplier and are influenced by factors like material cost, production capacity, and complexity of the parts. Typically, MOQs range from a few pieces to several hundred. For international buyers, it’s essential to inquire about MOQs upfront to ensure they align with your project needs and budget constraints. -

How do I vet suppliers for CNC Delrin sourcing?

To effectively vet suppliers, evaluate their experience in CNC machining and specifically with Delrin. Request references or case studies showcasing their previous work. Assess their certifications (e.g., ISO) to ensure quality standards are met. Additionally, consider their production capabilities, lead times, and customer support to ensure they can meet your needs and expectations. -

What payment terms should I expect when sourcing CNC Delrin internationally?

Payment terms can vary widely depending on the supplier and your relationship with them. Common terms include upfront payments, net 30/60 days, or milestone payments for larger orders. It’s crucial to discuss payment options early in negotiations to avoid misunderstandings. Ensure that the payment methods are secure and suitable for international transactions. -

What quality assurance measures should be in place for CNC Delrin parts?

Quality assurance is critical in ensuring that the CNC Delrin parts meet your specifications. Suppliers should have robust QA processes, including material inspections, in-process checks, and final inspections before shipping. Request documentation of their QA procedures and certifications, and consider asking for sample parts to evaluate quality prior to placing larger orders. -

What logistics considerations should I be aware of when importing CNC Delrin parts?

When importing CNC Delrin parts, consider shipping times, customs duties, and import regulations specific to your country. Engage with suppliers who have experience with international shipping and can provide reliable logistics support. Ensure that your supplier can provide the necessary documentation for customs clearance, and factor in potential delays when planning your project timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Cnc Delrin Manufacturers & Suppliers List

1. Protolabs – Delrin (POM)

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Delrin (POM) is a high-performance plastic known for its high stiffness, low friction, and excellent wear resistance. Key benefits include good wear and abrasion properties, creep resistance, excellent performance at high temperatures, excellent dimensional stability, chemical resistance (to fuels and solvents), and low moisture absorption. Common applications include gears, bearings, electrical i…

2. Wayken – Delrin Acetal Homopolymer

Domain: waykenrm.com

Registered: 2013 (12 years)

Introduction: Delrin, also known as acetal (polyoxymethylene) homopolymer, is a semi-crystalline thermoplastic known for its impact and wear resistance. It features high rigidity, flexural modulus, superior friction resistance, low friction coefficient, high corrosion resistance, and moisture resistance. Delrin is suitable for low-temperature applications and is used in various industries including automotive, …

3. MakerStock – Black Acetal / Delrin for Laser Cutting and CNC Machining

Domain: makerstock.com

Registered: 2012 (13 years)

Introduction: Product Name: Black Acetal / Delrin for Laser Cutting and CNC Machining

Thickness Options: 3mm (1/8″), 6mm (1/4″)

Sizes Available: 12×12, 12×24, 24×24, 24×36

Price Range:

– 3mm: $16.25 (12×12), $30.75 (12×24), $56.25 (24×24), $81.75 (24×36)

– 6mm: $25.75 (12×12), $51.25 (12×24), $100.75 (24×24), $148.25 (24×36)

Shipping: $12 Flat Rate for most orders

Material Description: Opaque black acetal with…

4. Emco Plastics – Delrin Machined Parts

Domain: emcoplastics.com

Registered: 1997 (28 years)

Introduction: Delrin Acetal Machining & Fabrication – Delrin Machined Parts. Available grades include Delrin 13% AF Blend, Delrin 150, Delrin 525GR, Delrin 570, Delrin AF 100, Delrin AF 500, Delrin AF DE588. Services offered include CNC Machining, Custom Fabrication, and Plastic Welding.

5. Cox Manufacturing – Delrin Plastic Solutions

Domain: coxmanufacturing.com

Registered: 2003 (22 years)

Introduction: Delrin is a versatile low-cost plastic in the acetal family, ideal for parts that require strength and resilience while machining to very tight tolerances. It has excellent dimensional stability and friction resistance, making it long-wearing. Delrin has a very low moisture absorption rate, making it suitable for use in wet environments. The machining cost factor of Delrin is 0.7 when compared to …

6. Reddit – Delrin and Teflon Machining Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Delrin and Teflon are the plastics discussed. Key tips include using sharp tools (preferably 3-flute cutters for aluminum), high RPM, and coolant for better finishes. For Delrin, a two-flute 16mm end mill at 8000 RPM and 1200 mm/min is recommended. Sanding may not improve the finish and could make it worse. An ‘o flute’ end mill is suggested for plastics, known for producing excellent finishes.

7. Practical Machinist – Delrin Machining Tools

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: 1. Material: Delrin (a type of plastic)

2. Machining Techniques: Side-milling, face milling

3. Tools Used:

– Tormach Super Fly (3-inch fly cutter)

– HSS 4-flute 1/2-inch endmill

– Polished aluminum insert for Super Fly

– LH insert tool using TCMT or CNMG inserts

– 3/8″ 3-flute reverse spiral endmills (Harvey Tools)

4. Recommended Practices:

– Use brand new, shar…

Strategic Sourcing Conclusion and Outlook for cnc delrin

In today’s competitive landscape, strategic sourcing of CNC Delrin presents a unique opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The versatility and mechanical properties of Delrin—such as its high wear resistance, low friction, and dimensional stability—make it an ideal material for a wide range of applications, from automotive components to precision machinery parts.

Understanding the specific requirements of your projects, including tolerances and environmental conditions, is crucial for optimizing sourcing strategies. Engaging with reliable suppliers who can offer custom machining services, such as countersinking and tapping, enhances the efficiency of your production process and ensures high-quality outputs.

As global supply chains continue to evolve, the demand for materials that bridge the gap between plastics and metals will only grow. B2B buyers should proactively seek partnerships with suppliers who demonstrate innovation in CNC machining and are committed to meeting the unique needs of diverse industries. By leveraging the benefits of Delrin and strategic sourcing practices, you can position your business for success in a rapidly changing market. Embrace this opportunity and explore how CNC Delrin can elevate your operations today.