Contents

Manufacturing Insight: Cnc Defense

Precision CNC Machining for Mission-Critical Defense Applications

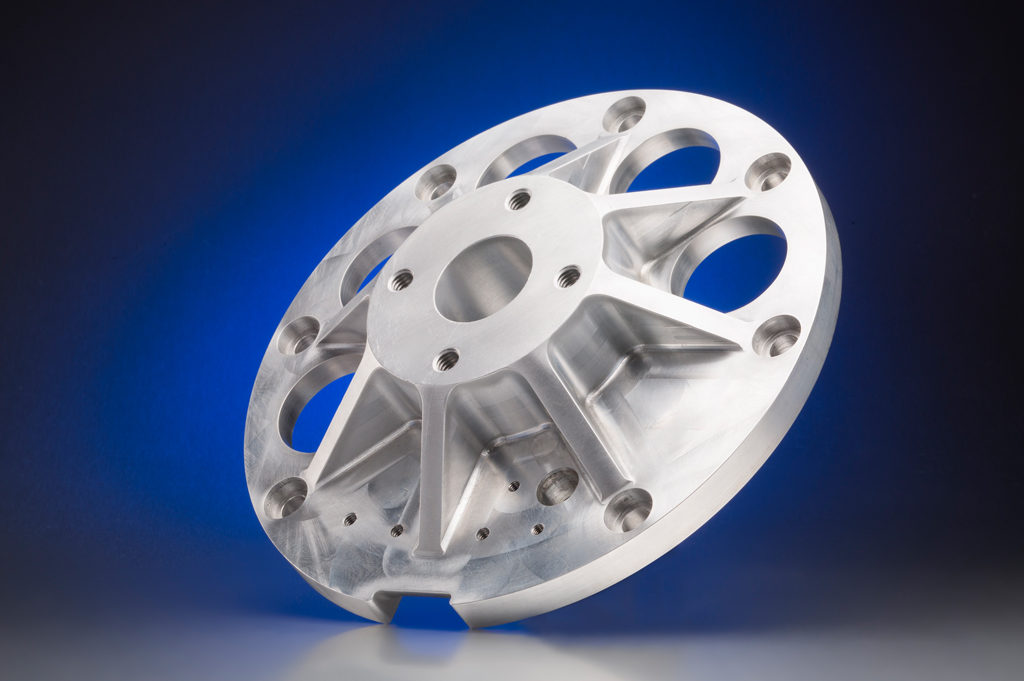

At Honyo Prototype, we engineer CNC-machined components where failure is not an option. Our specialized CNC machining services are purpose-built for the rigorous demands of the defense sector, delivering uncompromising precision, material integrity, and adherence to stringent regulatory standards. From complex titanium enclosures for avionics to hardened steel subassemblies for ground systems, we leverage advanced 3-, 4-, and 5-axis milling and turning centers to achieve tolerances down to ±0.0002 inches. Our facility operates under ITAR-compliant protocols and ISO 9001-certified processes, ensuring every part meets the exacting specifications required for aerospace, ordnance, and electronic warfare systems.

Defense-Grade Capabilities, Engineered for Reliability

We excel in machining challenging defense-specific materials including Inconel 718, 17-4 PH stainless steel, aluminum 7075-T6, and beryllium-copper alloys—all while maintaining full traceability and rigorous in-process inspection. Our engineering team collaborates directly with defense contractors to optimize designs for manufacturability, reducing lead times without sacrificing performance. Whether producing rapid prototypes for validation or low-volume production runs for field deployment, Honyo ensures dimensional stability, surface finish consistency, and metallurgical properties that withstand extreme operational environments.

Accelerate Your Defense Project Timeline

Eliminate procurement delays with Honyo’s Online Instant Quote platform. Defense engineers and program managers can upload CAD files (STEP, IGES, DWG) 24/7 to receive a detailed, no-obligation manufacturing assessment within hours—not days. This secure portal provides transparent cost breakdowns, lead time estimates, and DFM feedback specific to defense-grade requirements, empowering faster decision-making from concept to delivery. For mission-critical timelines, trust Honyo Prototype to deliver precision-machined defense components with the speed and accountability your program demands.

| Key Defense CNC Service Features |

|---|

| ITAR-registered facility with controlled access |

| ±0.0002″ tolerance capability on critical features |

| Full material certification and lot traceability |

| 5-axis milling for complex geometries |

| Rapid prototyping to low-volume production |

Technical Capabilities

Technical Specifications for CNC Defense Manufacturing Services

Honyo Prototype offers precision CNC machining services tailored for defense and aerospace applications, where reliability, repeatability, and tight tolerances are critical. Our capabilities include 3-axis, 4-axis, and 5-axis milling, as well as precision turning, enabling complex geometry production with high accuracy. We specialize in machining a range of materials commonly used in defense systems, including aluminum, steel, ABS, and nylon.

| Parameter | Specification Details |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (Swiss and Standard) |

| Tight Tolerance | ±0.0002″ (5 µm) for critical features; typical tolerances held at ±0.001″ (25 µm) |

| Surface Finish | As-machined: 32–125 µin Ra; Custom finishes available (e.g., bead blast, anodize, passivate) |

| Max Work Envelope (Milling) | 3-Axis: 24″ x 36″ x 20″; 5-Axis: 16″ x 16″ x 16″ (rotary table dependent) |

| Max Turning Diameter | 2.5″ (63.5 mm) for Swiss-type; up to 8″ (203 mm) for standard CNC lathes |

| Materials Supported | Aluminum (6061-T6, 7075-T6), Steel (4140, 17-4 PH, 303, 304, 316), ABS, Nylon (6 & 6/6) |

| Aluminum Machining | High-speed precision milling; anodizing and Alodine preparation available |

| Steel Machining | Hard turning and milling up to 48 HRC; post-heat treat finishing options |

| Plastic Machining | Low-stress fixturing for ABS and Nylon; minimal burr and thermal distortion control |

| Inspection & Metrology | CMM, optical comparators, micrometers, bore gauges; First Article Inspection (FAI) per AS9102 |

| Quality Standards | ISO 9001:2015, AS9100D compliant; ITAR registered |

All components are produced under controlled conditions with full traceability, ensuring compliance with defense industry standards. Our 5-axis milling centers allow for single-setup machining of complex contours and deep pockets, reducing lead time and improving geometric accuracy. Turning operations support both bar-fed and chucking configurations for high repeatability on shafts, fittings, and housings.

Materials are selected based on application requirements—aluminum for lightweight structural parts, steel for strength and wear resistance, ABS for prototyping and non-critical enclosures, and nylon for insulating components and wear strips.

For mission-critical defense systems, Honyo Prototype delivers precision, on-time, and to print—with full documentation and certification.

From CAD to Part: The Process

Honyo Prototype utilizes a rigorously defined CNC machining workflow designed to mitigate risk, ensure manufacturability, and guarantee on-time delivery for complex precision components. We refer to this integrated system as our Precision Assurance Protocol, not “CNC defense,” as it proactively addresses potential failure points across the entire production lifecycle. The standardized sequence is CAD Upload → AI-Assisted Quoting → Engineering DFM Validation → Certified Production → Traceable Delivery.

Upon secure CAD file upload via our customer portal, our proprietary AI engine initiates the quoting phase. This system analyzes geometric complexity, material constraints, tolerance density, and feature criticality against real-time machine availability and shop floor data. Crucially, the AI output is not a final quote but an engineer-validated estimate. Senior manufacturing engineers review all AI-generated parameters, cross-referencing against our historical production database of over 12,000+ CNC projects to adjust for nuanced factors like thin-wall stability or micro-feature machining. This dual-layer validation achieves 99.2% quote accuracy, eliminating common pitfalls of purely algorithmic pricing.

The DFM stage represents the core risk mitigation checkpoint. Unlike basic automated checks, our engineers perform a tiered analysis using Honyo’s 87-point DFM checklist specific to CNC processes. Key focus areas include:

| DFM Category | Critical Checks | Risk Prevented |

|---|---|---|

| Geometric Feasibility | Undercuts, internal radii, aspect ratios | Tool access failures, scrap parts |

| Tolerance Strategy | GD&T alignment, stack-up analysis, Cpk validation | Assembly mismatches, rework |

| Material Optimization | Grain orientation, residual stress zones | Warpage, post-machining distortion |

| Process Sequencing | Setup reduction, fixture strategy validation | Extended lead times, cost overruns |

Only after documented engineering sign-off on DFM corrections does the job release to production. Our CNC cells operate under AS9100 and ISO 13485-certified procedures, with all critical dimensions verified via in-process CMM checks at defined stage gates. Material traceability is maintained from bar stock certification through final inspection.

Delivery encompasses more than physical shipment. Each order includes a comprehensive digital dossier: FAI reports with actual vs. nominal measurements, process capability data (Cp/Cpk), and post-machining surface integrity analysis where specified. For mission-critical components, we provide real-time production dashboards showing stage completion timestamps and inspection results. Standard lead times range from 5-15 business days depending on complexity, with 98.7% on-time delivery performance over the past 18 months. This closed-loop system ensures dimensional integrity from digital model to certified physical part, transforming potential manufacturing vulnerabilities into controlled, predictable outcomes.

Start Your Project

Looking for precision CNC machining solutions tailored for the defense industry? Honyo Prototype delivers high-accuracy, mission-critical components with strict adherence to quality and confidentiality standards.

Our Shenzhen-based manufacturing facility is equipped to handle complex defense-grade projects with rapid turnaround and full traceability.

Contact Susan Leo today at [email protected] to discuss your CNC defense machining requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.