Introduction: Navigating the Global Market for cnc cutting files

In an increasingly competitive global landscape, sourcing high-quality CNC cutting files can pose significant challenges for international B2B buyers. With diverse applications ranging from metal art decor to intricate inlay designs, the need for reliable and efficient cutting files is paramount. This guide will explore the myriad types of CNC cutting files available, their practical applications across various industries, and essential considerations for supplier vetting. Additionally, we will delve into cost factors, licensing agreements, and the compatibility of different file formats with cutting machines.

For businesses in regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—navigating the complexities of CNC cutting file procurement is crucial for streamlining operations and enhancing product offerings. This comprehensive guide empowers decision-makers by providing actionable insights and practical strategies to make informed purchasing choices. By understanding the landscape of CNC cutting files, buyers can not only enhance their manufacturing capabilities but also foster innovation and creativity in their projects.

Whether you are looking for free downloadable designs or investing in custom files, this guide serves as your essential resource for optimizing your CNC cutting file sourcing process.

Understanding cnc cutting files Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| DXF (Drawing Exchange Format) | Vector-based format, widely supported, ideal for 2D designs | Metal art, signage, and architectural components | Pros: Easy to edit, compatible with various software. Cons: Limited in 3D capabilities. |

| G-Code | Machine-specific instructions for CNC machines | Manufacturing, machining, and milling | Pros: Direct control of CNC machines, precise operations. Cons: Requires knowledge of machine specifications. |

| SVG (Scalable Vector Graphics) | XML-based format, scalable without loss of quality | Laser cutting, engraving, and custom designs | Pros: High-quality graphics, versatile for web and print. Cons: Less commonly used in industrial settings compared to DXF. |

| CRV (Vectric) | Proprietary format with built-in toolpath settings | Woodworking, inlays, and detailed carvings | Pros: Optimized for specific machines, includes detailed parameters. Cons: Limited to Vectric software users. |

| AI (Adobe Illustrator) | Graphic design format, supports complex artwork | Custom graphics, branding, and promotional materials | Pros: High-quality design capabilities, widely used by designers. Cons: May require conversion for CNC compatibility. |

What Are the Characteristics of DXF Files and Their B2B Suitability?

DXF files, or Drawing Exchange Format files, are vector-based files that facilitate the exchange of 2D drawings between CAD software. Their widespread compatibility makes them ideal for applications in metal art, signage, and architectural components. B2B buyers should consider DXF files for projects requiring intricate designs that can be easily edited and manipulated. However, it’s important to note that DXF files are limited in their ability to handle 3D designs, which may be a drawback for certain applications.

How Does G-Code Function in CNC Cutting and What Are Its Applications?

G-Code is a language that instructs CNC machines on how to perform specific operations, including cutting, drilling, and milling. This format is essential for manufacturing processes where precision is paramount, such as in machining and milling operations. B2B buyers should prioritize G-Code files if they require direct control over machine operations. However, understanding machine specifications is crucial, as G-Code can vary significantly between different types of CNC equipment.

Why Choose SVG Files for CNC Projects?

SVG files are scalable vector graphics that maintain high quality regardless of size adjustments. They are particularly suited for laser cutting and engraving applications, making them a popular choice for custom designs in various industries. B2B buyers may find SVG files advantageous for their flexibility and quality, but they are less commonly used in industrial settings compared to DXF files, which could limit their accessibility in some manufacturing environments.

What Are the Benefits of Using CRV Files in CNC Work?

CRV files, associated with Vectric software, come with built-in toolpath settings tailored for specific CNC machines. They are particularly useful in woodworking applications, including inlays and detailed carvings. For B2B buyers, CRV files offer optimized designs that enhance efficiency and accuracy. However, their proprietary nature means they are primarily beneficial for users of Vectric software, which could restrict their usability for companies using different systems.

How Can AI Files Enhance Custom CNC Designs?

AI files, created in Adobe Illustrator, are renowned for their high-quality design capabilities and support for complex artwork. They are often used for custom graphics, branding, and promotional materials. B2B buyers should consider AI files for projects requiring intricate visual elements. However, these files may need conversion to a compatible format for CNC operations, which can add an extra step in the workflow, potentially causing delays in production.

Key Industrial Applications of cnc cutting files

| Industry/Sector | Specific Application of CNC Cutting Files | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Fabrication | Custom metal art and signage | Enhances aesthetic appeal, attracts customers, and increases sales | Quality of DXF files, compatibility with cutting machines |

| Furniture Manufacturing | Precision cutting for furniture components | Streamlines production, reduces waste, and ensures design fidelity | Availability of diverse designs, material specifications |

| Automotive | Production of automotive parts and components | Improves efficiency, reduces lead times, and enhances precision | Tolerance levels, material types, and file format support |

| Construction | Fabrication of structural components | Facilitates faster assembly, reduces labor costs, and improves safety | Compliance with local regulations, durability of materials |

| Craft and Hobby | DIY projects and custom crafts | Expands product offerings and engages customers creatively | Variety of designs, ease of use, and instructional support |

How Are CNC Cutting Files Used in Metal Fabrication?

In the metal fabrication industry, CNC cutting files are primarily used for creating custom metal art and signage. These files allow businesses to produce intricate designs that enhance the aesthetic appeal of products, thereby attracting more customers. By utilizing high-quality DXF files, companies can ensure compatibility with various cutting machines, which is crucial for maintaining efficiency and reducing production costs. International buyers should prioritize sourcing files that are designed specifically for their machine specifications and cutting capabilities to avoid operational disruptions.

What Role Do CNC Cutting Files Play in Furniture Manufacturing?

CNC cutting files are vital in the furniture manufacturing sector for precision cutting of components. They enable manufacturers to streamline production processes, significantly reducing material waste while ensuring design fidelity. This accuracy is essential for meeting the high standards expected in the industry, especially in markets like Germany and other European countries. Buyers should consider the availability of diverse design options and the specific material requirements when sourcing CNC files to maximize the quality of their final products.

How Are CNC Cutting Files Applied in Automotive Production?

In automotive manufacturing, CNC cutting files are used to produce various parts and components with high precision. This application improves operational efficiency and shortens lead times, allowing manufacturers to respond quickly to market demands. Given the stringent tolerance levels required in automotive parts, international buyers must ensure that the files they source are compatible with their production processes and meet the necessary industry standards for quality and safety.

Why Are CNC Cutting Files Important in Construction?

The construction industry benefits from CNC cutting files through the fabrication of structural components. These files facilitate faster assembly and reduce labor costs, which is crucial in large-scale construction projects. Additionally, the use of CNC technology enhances safety by minimizing human error during the cutting process. For international buyers, it’s essential to consider compliance with local regulations and the durability of the materials when sourcing CNC files for construction applications.

How Can Hobbyists Leverage CNC Cutting Files for Crafting?

CNC cutting files are also popular among craft and hobby enthusiasts, allowing them to create custom projects and unique crafts. By utilizing these files, hobbyists can expand their product offerings and engage customers in creative ways. When sourcing files, buyers should look for a variety of designs and consider the availability of instructional support to ensure a smooth crafting experience. This aspect is particularly important for emerging markets in Africa and South America, where DIY culture is on the rise.

3 Common User Pain Points for ‘cnc cutting files’ & Their Solutions

Scenario 1: Difficulty in Finding Quality CNC Cutting Files

The Problem: Many B2B buyers, particularly those in emerging markets like Africa and South America, struggle to find high-quality, ready-to-use CNC cutting files. This can lead to significant delays in production, increased costs, and frustration, especially when suppliers do not provide files that meet the necessary specifications for their machinery. Buyers often encounter files that are poorly designed or incompatible with their CNC systems, resulting in wasted materials and time during the cutting process.

The Solution: To overcome this challenge, buyers should prioritize sourcing files from reputable providers that specialize in CNC cutting files. It is advisable to look for platforms that offer a range of downloadable designs, ensuring they are compatible with various CNC machines and cutting techniques. For instance, platforms like DXFforCNC provide a vast library of free DXF files that are ready for immediate use without any registration, which saves time. Additionally, buyers should verify that the files include detailed specifications regarding compatibility with cutting beam widths and offer support for scaling designs to fit their machine specifications. By utilizing these resources, businesses can streamline their production processes and avoid the pitfalls of poorly designed files.

Scenario 2: Incompatibility Issues with CNC Software

The Problem: Incompatibility between CNC cutting files and the software used by manufacturers is a common pain point. For instance, a company might purchase a cutting file only to discover that it is not compatible with their CAD/CAM software, leading to wasted investment and operational downtime. This issue is particularly pronounced for companies operating in regions with limited access to specialized software or technical support.

The Solution: To mitigate this risk, buyers should conduct thorough research before purchasing CNC files. It is crucial to ensure that the files are offered in multiple formats such as DXF, SVG, and AI, which can be used across different software platforms. Additionally, buyers can opt for vendors that provide trial downloads or free samples to test compatibility before making a purchase. Engaging with community forums or user groups related to CNC machining can also be beneficial. These platforms often share insights on which software works best with specific file types and may even provide recommendations for reliable vendors. By being proactive and informed, businesses can significantly reduce the likelihood of encountering compatibility issues.

Scenario 3: Lack of Customization Options in Standard Files

The Problem: Standard CNC cutting files often do not meet the specific needs of businesses that require customized designs for their projects. Many B2B buyers find that the available files are too generic and do not align with their branding or product specifications. This can lead to missed opportunities for differentiation in a competitive market, especially for companies looking to create unique products that stand out.

The Solution: To address this issue, buyers should seek out suppliers that offer customization services alongside their CNC cutting files. Many providers are willing to modify existing designs or create entirely new files based on client specifications. Buyers can communicate their specific requirements, such as dimensions, design elements, or branding features, ensuring the final product aligns with their vision. Platforms that allow collaboration with designers or offer bespoke design services can provide significant value. Additionally, buyers can invest in CNC design software that allows them to modify or create files internally, empowering them to tailor designs to their exact needs. This approach not only enhances product uniqueness but also strengthens brand identity in the marketplace.

Strategic Material Selection Guide for cnc cutting files

What Are the Key Properties of Common Materials Used in CNC Cutting Files?

When selecting materials for CNC cutting files, several common options stand out due to their unique properties and suitability for various applications. Understanding these materials is crucial for international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe.

1. Aluminum

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance and a high strength-to-weight ratio. It can withstand temperatures up to 660°C (1220°F) without losing structural integrity.

Pros & Cons: Aluminum is durable and easy to machine, making it ideal for intricate designs. However, it can be more expensive than other metals, and its softness may lead to wear on cutting tools over time.

Impact on Application: Aluminum is compatible with various CNC machining processes, including milling and laser cutting, allowing for versatility in design.

Considerations for Buyers: Buyers should ensure compliance with international standards such as ASTM B221 for aluminum extrusions. Preference for aluminum may vary based on local availability and cost.

2. Stainless Steel

Key Properties: Stainless steel is known for its high corrosion resistance and durability, withstanding temperatures up to 870°C (1600°F). It is also non-reactive, making it suitable for food-related applications.

Pros & Cons: While stainless steel is incredibly strong and resistant to wear, it is more challenging to machine compared to aluminum, which can increase manufacturing complexity and costs.

Impact on Application: Its robust nature makes stainless steel ideal for applications requiring high strength and durability, such as industrial components and decorative items.

Considerations for Buyers: Compliance with standards like ASTM A240 for stainless steel is essential. Buyers in regions with high humidity, such as parts of Africa, may prefer stainless steel for its corrosion resistance.

3. MDF (Medium Density Fiberboard)

Key Properties: MDF is a composite material made from wood fibers, wax, and resin, providing a smooth surface for cutting. It is lightweight and can be easily shaped and painted.

Pros & Cons: MDF is cost-effective and easy to work with, making it suitable for prototypes and decorative items. However, it is less durable than solid wood or metal and can be sensitive to moisture.

Impact on Application: MDF is ideal for intricate designs and is commonly used in furniture and interior decor. It is compatible with laser cutting and CNC routing.

Considerations for Buyers: Buyers should consider the environmental impact and ensure compliance with local regulations regarding formaldehyde emissions. In regions like Europe, adherence to E1 standards for low emissions is crucial.

4. Acrylic

Key Properties: Acrylic is a transparent thermoplastic known for its clarity and UV resistance. It can withstand temperatures up to 100°C (212°F) and is lightweight.

Pros & Cons: Acrylic is easy to cut and shape, making it popular for signage and displays. However, it can scratch easily and may not be as durable as glass.

Impact on Application: Acrylic is suitable for applications requiring visual appeal, such as retail displays and decorative items. Its compatibility with laser cutting makes it a preferred choice for intricate designs.

Considerations for Buyers: Buyers should ensure compliance with relevant safety standards, especially for applications involving food contact. In regions like South America, understanding local preferences for aesthetics can influence material choice.

Summary Table of Material Selection for CNC Cutting Files

| Material | Typical Use Case for cnc cutting files | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace parts, decorative items | Lightweight and corrosion-resistant | Higher cost and tool wear | Medium |

| Stainless Steel | Industrial components, kitchenware | High strength and corrosion resistance | Difficult to machine | High |

| MDF | Furniture, prototypes | Cost-effective and easy to shape | Less durable and moisture-sensitive | Low |

| Acrylic | Signage, displays | Visual appeal and easy to cut | Prone to scratching | Medium |

This strategic material selection guide provides B2B buyers with actionable insights to make informed decisions when sourcing CNC cutting files, ensuring they choose the right material for their specific applications and compliance needs.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc cutting files

What Are the Key Manufacturing Processes for CNC Cutting Files?

The manufacturing of CNC cutting files involves several key stages that ensure precision and quality. Understanding these processes is crucial for B2B buyers who require reliable and effective CNC solutions.

Material Preparation: How Is the Right Material Chosen?

The first step in the manufacturing process is material preparation, which entails selecting the appropriate materials based on the intended application. Common materials include metals, plastics, and wood. The choice of material significantly influences the final product’s durability, appearance, and cost-effectiveness.

Additionally, proper preparation involves cutting raw materials to manageable sizes, ensuring compatibility with CNC machines. Suppliers often utilize laser cutting or water jet cutting techniques during this stage to achieve precise dimensions before the actual CNC programming begins.

What Techniques Are Used in CNC File Formation?

Once the materials are prepared, the next phase is forming. This stage typically involves the use of Computer-Aided Design (CAD) software to create detailed digital models. These models serve as the foundation for generating CNC cutting files, which are usually in DXF, SVG, or G-code formats.

After the design is completed, the CNC machine translates these digital files into physical objects through a process known as CNC machining. Techniques such as milling, turning, and laser cutting are commonly employed, depending on the complexity and specifications of the design. The accuracy of this process is vital, as it dictates the quality and fit of the final product.

How Is Quality Assurance Implemented in CNC Cutting File Production?

Quality assurance (QA) is critical in ensuring that CNC cutting files meet the required standards. B2B buyers should be familiar with the various QA processes that suppliers implement.

What International Standards Should Buyers Be Aware Of?

Many suppliers adhere to international quality standards, such as ISO 9001, which focuses on maintaining consistent quality management systems. Additionally, specific industries may require compliance with standards like CE for safety and environmental considerations, or API for products related to the petroleum and natural gas sectors.

These standards provide a framework for quality management and are crucial for international buyers looking to verify the credibility of their suppliers. Buyers should inquire about certifications and compliance documentation during the procurement process.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is generally divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards. This is the first line of defense against substandard materials entering the production process.

-

In-Process Quality Control (IPQC): During the manufacturing phase, regular inspections are conducted to ensure that the CNC machining processes are operating within defined parameters. This may include monitoring cutting speeds, tool wear, and dimensional accuracy.

-

Final Quality Control (FQC): Once the cutting process is complete, the final products undergo rigorous testing to confirm that they meet the design specifications. This may involve dimensional checks, surface finish evaluations, and functional testing.

How Can B2B Buyers Verify Supplier Quality Control Procedures?

B2B buyers must take proactive steps to ensure that their suppliers maintain robust QC processes. Here are some recommended strategies:

What Documentation and Reports Should Buyers Request?

Buyers should ask for comprehensive documentation, including quality control reports, inspection records, and compliance certificates. These documents provide insight into the supplier’s quality management practices and can help assess their reliability.

Why Are Audits and Third-Party Inspections Important?

Conducting audits of potential suppliers can provide an in-depth understanding of their manufacturing processes and quality assurance practices. B2B buyers may also consider third-party inspections, which offer an unbiased evaluation of the supplier’s capabilities and adherence to quality standards.

What Unique Challenges Do International Buyers Face in Quality Assurance?

International B2B buyers, particularly from regions such as Africa, South America, and the Middle East, may encounter unique challenges when it comes to quality assurance. Differences in regulatory standards, communication barriers, and varying levels of supplier capabilities can complicate the procurement process.

To mitigate these challenges, buyers should:

- Establish clear communication channels with suppliers to discuss quality expectations.

- Familiarize themselves with local regulations and standards that may impact quality assurance.

- Build relationships with reliable local partners who can assist in evaluating suppliers.

What Testing Methods Are Commonly Used in Quality Control?

Various testing methods are employed to ensure the quality of CNC cutting files. Some common techniques include:

- Dimensional Inspection: Using calipers and gauges to verify that the final product meets specified dimensions.

- Surface Roughness Testing: Assessing the finish of the cut surface to ensure it aligns with design requirements.

- Functional Testing: If applicable, conducting tests to ensure the product performs as intended in its final application.

Conclusion: Ensuring Quality in CNC Cutting Files for International B2B Buyers

For B2B buyers, understanding the manufacturing processes and quality assurance measures in the production of CNC cutting files is essential for making informed purchasing decisions. By familiarizing themselves with material preparation, forming techniques, international standards, and quality control checkpoints, buyers can select suppliers that meet their specific needs and maintain high-quality standards. This knowledge will empower buyers to navigate the complexities of international procurement effectively, ensuring successful collaborations and superior end products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cnc cutting files’

Introduction

Navigating the procurement of CNC cutting files can be a complex process, especially for international B2B buyers. This guide provides a practical checklist to ensure you make informed decisions, securing high-quality files that meet your technical needs and business objectives.

Step 1: Define Your Technical Specifications

Begin by clearly defining the technical requirements for your CNC cutting files. Consider factors such as the material you will be cutting, the type of CNC machine you are using, and the desired file format (e.g., DXF, SVG, G-Code). This clarity will help you avoid compatibility issues and ensure that the files you source are suitable for your production processes.

Step 2: Research Reputable Suppliers

Thoroughly research potential suppliers to ensure they have a good reputation in the market. Look for reviews, testimonials, and case studies from other businesses, especially those operating in your region. Reputable suppliers are more likely to provide high-quality, accurate cutting files and reliable customer support.

Step 3: Evaluate File Quality and Compatibility

Assess the quality of the CNC files offered by suppliers. High-quality files should have smooth vectors and no crossed paths, which is essential for efficient cutting. Ensure that the files are compatible with your CNC software and machine specifications; ask for sample files if possible to verify compatibility before making a purchase.

Step 4: Check for Licensing and Usage Rights

Understand the licensing agreements associated with the CNC cutting files. Some suppliers may offer free files but limit their commercial use, while others may charge for files that come with broader usage rights. Ensure that you have the appropriate rights to use the files in your intended applications to avoid legal issues down the line.

Step 5: Inquire About Customization Options

Inquire whether the supplier offers customization options for their CNC cutting files. Many suppliers can modify existing designs to better suit your specific needs or create bespoke files from scratch. Customization can enhance your product offerings and ensure that the designs align with your brand identity.

Step 6: Assess Customer Support and Resources

Evaluate the level of customer support provided by the supplier. Reliable suppliers should offer assistance with file scaling, machine specifications, and troubleshooting. Additionally, check if they provide resources such as tutorials or design templates that can help you maximize the use of their files.

Step 7: Request a Trial or Sample Files

Before committing to a large order, request trial or sample files to test in your production environment. This step allows you to verify the quality and compatibility of the files, ensuring they meet your standards. A good supplier should be willing to provide samples to help you make an informed decision.

By following this checklist, you can enhance your sourcing strategy for CNC cutting files, ensuring that you acquire the right products to meet your manufacturing needs effectively.

Comprehensive Cost and Pricing Analysis for cnc cutting files Sourcing

What Are the Key Cost Components in Sourcing CNC Cutting Files?

When considering the cost structure for CNC cutting files, several components contribute to the overall expense. These include:

-

Materials: The choice of materials can significantly impact costs. For instance, files designed for intricate work may require higher-quality vector graphics to ensure precision during cutting. The availability of materials can also vary by region, affecting pricing.

-

Labor: The cost of labor encompasses both the design and technical expertise needed to create and modify CNC files. Skilled labor often commands higher wages, especially in regions with a scarcity of qualified technicians.

-

Manufacturing Overhead: This includes expenses related to maintaining equipment, software licenses, and utilities. Overhead costs can fluctuate based on the operational efficiency of the supplier.

-

Tooling: The creation of specific tools or templates for custom projects can add to costs. Buyers should consider whether they need generic files or highly specialized designs, as this will affect tooling expenses.

-

Quality Control (QC): Ensuring that files meet specific standards often involves additional QC processes. Suppliers may charge extra for rigorous testing to guarantee that files are cut-ready and meet the required specifications.

-

Logistics: Depending on the supplier’s location, logistics can play a crucial role in pricing. International shipping, customs fees, and handling charges can add up, particularly for buyers located in Africa and South America.

-

Margin: Finally, the supplier’s profit margin will influence the final price. Buyers should be aware of typical margins in the industry to better understand pricing dynamics.

How Do Price Influencers Affect CNC Cutting File Costs?

Several factors can influence the pricing of CNC cutting files:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often come with discounts, making it crucial for buyers to assess their needs and negotiate accordingly.

-

Specifications and Customization: Customized files typically incur higher costs due to the added labor and time involved in their creation. Buyers should evaluate whether they require bespoke designs or if standard files will suffice.

-

Material Quality and Certifications: High-quality files may demand a premium price, especially if they come with industry certifications. Buyers should assess the quality required for their applications to avoid overspending.

-

Supplier Factors: Supplier reputation, experience, and location can affect pricing. Established suppliers may charge more for their expertise and reliability.

-

Incoterms: Understanding Incoterms is vital for international buyers. Terms like FOB (Free On Board) or CIF (Cost Insurance Freight) can significantly impact the total landed cost of CNC files.

What Buyer Tips Can Help in Negotiating CNC Cutting File Prices?

When sourcing CNC cutting files, buyers can employ several strategies to enhance cost-efficiency:

-

Negotiation: Approach suppliers with clear expectations regarding volume and customization needs. Bulk orders or long-term contracts can often lead to better pricing.

-

Total Cost of Ownership (TCO): Consider all associated costs, including shipping, potential rework, and downtime, when evaluating suppliers. A lower upfront price might not translate to overall savings.

-

Pricing Nuances for International Buyers: International buyers should be mindful of currency fluctuations, tariffs, and local market conditions. Engaging with local suppliers can sometimes yield better pricing due to reduced shipping and customs complexities.

-

Requesting Samples: Before committing to large orders, consider requesting sample files. This can help assess quality and compatibility with your machinery without incurring significant costs.

-

Building Relationships: Establishing long-term relationships with suppliers can lead to preferential pricing and better service. Regular communication about needs and expectations is key to fostering these relationships.

Conclusion

While the costs associated with sourcing CNC cutting files can vary widely, understanding the underlying components and influencers can empower buyers to make informed decisions. By leveraging negotiation tactics and considering the total cost of ownership, international B2B buyers can navigate the complexities of pricing and secure the best value for their investments. Always remember to request indicative prices, as they can fluctuate based on market conditions and supplier changes.

Alternatives Analysis: Comparing cnc cutting files With Other Solutions

Introduction to Alternative Solutions for CNC Cutting Files

In the realm of digital fabrication and design, CNC cutting files play a pivotal role in streamlining production processes. However, businesses often explore alternative solutions that could complement or even replace CNC cutting files, depending on their specific needs. This analysis will compare CNC cutting files with two viable alternatives: Laser Cutting Files and 3D Printing. Understanding these alternatives will help B2B buyers make informed decisions based on performance, cost, ease of implementation, and maintenance.

Comparison Table

| Comparison Aspect | CNC Cutting Files | Laser Cutting Files | 3D Printing |

|---|---|---|---|

| Performance | High precision and efficiency | Excellent for intricate designs | Versatile but slower for large runs |

| Cost | Moderate initial investment | Higher material costs | Varies widely; can be expensive for materials |

| Ease of Implementation | Requires CNC machine setup | Requires compatible laser cutter | Requires 3D modeling skills |

| Maintenance | Regular maintenance of CNC machines | Low; mainly software updates | Moderate; depends on printer type |

| Best Use Case | Metal and wood fabrication | Thin materials and detailed work | Prototyping and complex geometries |

Detailed Breakdown of Alternatives

Laser Cutting Files

Laser cutting files are designed for use with laser cutters, which employ focused light beams to cut or engrave materials. The primary advantage of laser cutting lies in its ability to execute intricate designs with high precision, making it ideal for decorative items and detailed patterns. However, the cost of materials can be higher, especially for thicker or denser materials, which may deter budget-conscious buyers. Additionally, while laser cutting is efficient for specific applications, it may not match the speed of CNC operations for bulk production.

3D Printing

3D printing is a revolutionary technology that builds three-dimensional objects layer by layer from digital files. Its versatility allows for the creation of complex geometries and customized designs that traditional cutting methods struggle to achieve. This method is particularly useful for prototyping and small-batch production, where unique designs are essential. However, the initial investment in a quality 3D printer and the variability in material costs can be significant drawbacks. Furthermore, while 3D printing can produce highly detailed items, the speed of production is often slower compared to CNC cutting, making it less ideal for larger runs.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between CNC cutting files and alternative solutions like laser cutting files and 3D printing, B2B buyers must consider several factors, including the specific requirements of their projects, budget constraints, and production volume. CNC cutting files excel in efficiency and precision for metal and wood applications, while laser cutting files offer exceptional detail for thinner materials. On the other hand, 3D printing provides unmatched design flexibility but may not be as cost-effective for high-volume production. By carefully evaluating these aspects, businesses can choose the solution that best aligns with their operational goals and customer demands.

Essential Technical Properties and Trade Terminology for cnc cutting files

What Are the Key Technical Properties of CNC Cutting Files?

Understanding the essential technical properties of CNC cutting files is critical for B2B buyers to ensure compatibility and efficiency in production processes. Here are some key specifications:

-

File Format: The most common file formats for CNC cutting files include DXF, SVG, and G-Code. Each format serves different machines and purposes. DXF (Drawing Exchange Format) is widely used for 2D designs, while SVG (Scalable Vector Graphics) is ideal for web applications and laser cutting. G-Code is the machine language that CNC routers and mills understand, dictating movement and operation.

-

Material Compatibility: Different CNC cutting files are designed for specific materials, such as wood, metal, or plastics. Knowing the material compatibility helps in selecting the right file for the intended application. For instance, files meant for metal cutting will often require different settings compared to those used for wood, affecting the choice of machine and tools.

-

Tolerance: Tolerance refers to the allowable variation in dimensions during the cutting process. Tight tolerances are crucial in precision engineering applications, while looser tolerances may be acceptable in decorative pieces. Understanding tolerance levels helps buyers ensure that the final product meets their specifications, reducing waste and rework.

-

Feed Rate and Spindle Speed: These parameters define how quickly the cutting tool moves through the material and the speed at which the spindle rotates. They are vital for achieving optimal cutting quality and efficiency. A higher feed rate may speed up production but can compromise the quality of the cut, making it essential to find the right balance.

-

Plunge Rate: This is the speed at which the cutting tool enters the material. A controlled plunge rate is essential to avoid tool breakage and ensure a clean entry into the material. Buyers should consider plunge rates when selecting files to prevent production delays and equipment damage.

-

Cutting Beam Width: This property relates to the precision of the cutting tool’s beam. For instance, a cutting beam width of 0.0625″ (1.6 mm) is standard for many CNC applications. Understanding beam width is crucial for buyers looking to achieve intricate designs without compromising on quality.

What Are Common Trade Terms in CNC Cutting Files?

Familiarity with trade terminology is essential for effective communication and negotiation in the B2B landscape. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer): An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC cutting files, OEMs often provide specialized files tailored for specific machinery, ensuring optimal performance.

-

MOQ (Minimum Order Quantity): This term signifies the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to assess whether they can meet the supplier’s requirements without overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a standard business process where a buyer requests a quote from suppliers for specific products or services. This term is particularly relevant in the CNC industry, where buyers may need multiple quotes to compare pricing and services.

-

Incoterms (International Commercial Terms): These are predefined international trade terms that clarify the responsibilities of buyers and sellers during shipping. Understanding Incoterms helps businesses manage logistics and avoid misunderstandings related to shipping costs, risk, and delivery obligations.

-

CAD (Computer-Aided Design): CAD refers to software used to create precision drawings or technical illustrations. In the CNC cutting industry, CAD files are essential for generating the necessary cutting paths and ensuring accurate production.

-

CAM (Computer-Aided Manufacturing): CAM software translates CAD designs into machine instructions. Understanding CAM processes helps buyers ensure their CNC machines can interpret and execute the designs provided in the cutting files.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, streamline their procurement processes, and enhance their operational efficiency in CNC cutting applications.

Navigating Market Dynamics and Sourcing Trends in the cnc cutting files Sector

What Are the Current Market Dynamics and Key Trends Impacting CNC Cutting Files?

The global market for CNC cutting files is experiencing significant growth, driven by advancements in technology, increased automation in manufacturing, and a rising demand for customized solutions. The accessibility of free and premium DXF files has democratized design capabilities, enabling small and medium enterprises (SMEs) in regions such as Africa, South America, the Middle East, and Europe to leverage CNC technology without substantial upfront investments. Moreover, the integration of cloud-based solutions allows for real-time collaboration and file sharing, enhancing the efficiency of design processes.

In the B2B sector, there is a marked shift towards sourcing files that are not only high-quality but also compatible with various CNC machines. This trend is particularly relevant in markets like Germany and Nigeria, where businesses are increasingly seeking files that align with specific machine specifications. Additionally, the emergence of platforms facilitating user-generated content, such as FireShare, allows companies to access a diverse range of designs while fostering community engagement. As the demand for personalized products grows, businesses that offer customizable file options are likely to gain a competitive edge.

Furthermore, the move towards Industry 4.0 is influencing sourcing trends, with an emphasis on digital integration and data analytics. Companies are investing in software that optimizes cutting paths and material usage, which leads to cost savings and improved production timelines. International buyers should stay abreast of these technological advancements to ensure they are sourcing the most efficient and effective CNC cutting files.

How Is Sustainability and Ethical Sourcing Shaping the CNC Cutting Files Market?

As environmental concerns continue to rise, sustainability and ethical sourcing are becoming pivotal factors in the CNC cutting files sector. Businesses are increasingly aware of their environmental impact, pushing for materials and processes that minimize waste and reduce carbon footprints. For instance, sourcing files that promote efficient cutting patterns can significantly decrease material waste, aligning with sustainability goals.

Moreover, the demand for ‘green’ certifications and sustainable materials is influencing procurement strategies. Companies are seeking CNC cutting files that are designed with eco-friendly materials in mind, such as recycled metals or sustainably sourced woods. This shift not only supports corporate social responsibility initiatives but also appeals to a growing consumer base that prioritizes sustainability.

Ethical supply chains are also under scrutiny. Buyers are encouraged to partner with suppliers who demonstrate transparency in their sourcing practices and comply with environmental regulations. By prioritizing ethical sourcing, businesses can enhance their brand reputation and foster customer loyalty, particularly in regions like Europe where consumers are increasingly making purchasing decisions based on ethical considerations.

What Is the Evolution of CNC Cutting Files in the B2B Landscape?

The evolution of CNC cutting files has been marked by significant technological advancements and changing market demands. Initially, CNC files were predominantly proprietary and limited to specialized industries. However, the advent of digital design software and the proliferation of online platforms have transformed this landscape, making CNC files more accessible to a wider audience.

With the rise of open-source design communities and platforms offering free and paid DXF files, businesses of all sizes can now access high-quality designs tailored to their specific needs. This democratization of design resources has spurred innovation and creativity, allowing companies to experiment with unique projects without the barrier of high costs.

In summary, the CNC cutting files sector has evolved from a niche market to a dynamic ecosystem that emphasizes collaboration, sustainability, and technological integration, presenting lucrative opportunities for international B2B buyers. As this sector continues to grow, staying informed about market trends and sourcing strategies will be crucial for businesses aiming to maintain a competitive edge.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc cutting files

1. How do I choose the right CNC cutting files for my project?

Selecting the right CNC cutting files involves understanding your project’s specific requirements, including material type, thickness, and desired finish. Start by assessing the compatibility of the file format with your CNC machine—common formats include DXF, SVG, and G-code. Additionally, consider the design intricacies; for instance, complex designs may require higher precision settings. It’s also beneficial to review user feedback on files to gauge their effectiveness in real-world applications. Lastly, ensure that the supplier offers support for scaling or modifying files to meet your exact specifications.

2. What is the best format for CNC cutting files?

The best format for CNC cutting files largely depends on your machine’s capabilities and the complexity of your project. DXF files are widely used for 2D designs and are compatible with most CNC software. SVG files are excellent for vector graphics and can be easily scaled without loss of quality. For machines that require G-code, ensure the files are pre-configured for your specific settings. It’s advisable to choose a supplier that provides multiple formats to offer flexibility and ease of use across different CNC machines.

3. How can I ensure the quality of CNC cutting files?

To ensure the quality of CNC cutting files, start by sourcing files from reputable suppliers known for their precision and attention to detail. Look for files that include smooth vectors and no crossed paths, which can complicate cutting. Additionally, request samples or trial files to test in your machine before committing to a larger order. Supplier reviews and testimonials can also provide insights into the reliability of their files. Lastly, inquire about the supplier’s quality assurance processes, including any testing they perform on their designs.

4. What are the typical minimum order quantities (MOQ) for CNC cutting files?

Minimum order quantities (MOQ) for CNC cutting files can vary significantly among suppliers. Many digital file providers offer the flexibility of single file purchases, especially for downloadable files. However, if you’re looking to buy custom designs or bulk files, MOQs may apply, often ranging from 5 to 100 files depending on the complexity and customization required. Always clarify MOQs before placing an order to avoid unexpected costs, and consider negotiating terms if you plan to establish a long-term supplier relationship.

5. How can I customize CNC cutting files to fit my needs?

Customization of CNC cutting files can often be done by communicating directly with the supplier. Many offer services to modify existing designs, such as resizing, altering details, or creating new designs based on your specifications. When requesting customization, provide clear instructions and any necessary design references. Ensure the supplier can meet your specific requirements, including file formats and compatibility with your CNC machine. Additionally, inquire about potential costs and turnaround times associated with custom modifications.

6. What payment terms should I expect when purchasing CNC cutting files internationally?

Payment terms for purchasing CNC cutting files can differ significantly based on the supplier and the buyer’s location. Common terms include full payment upfront, especially for digital files, or partial payment with the balance due upon delivery for custom orders. For international transactions, consider using secure payment methods such as PayPal or wire transfers to protect against fraud. Always clarify the currency used and any potential fees related to currency exchange or international transactions to avoid surprises.

7. What are the logistics involved in sourcing CNC cutting files internationally?

When sourcing CNC cutting files internationally, logistics primarily involve digital delivery, which is generally straightforward. Files are typically provided via email or through a secure download link. However, if you require custom files or large orders, consider the supplier’s turnaround time and any potential delays in communication due to time zone differences. It’s also important to ensure that the supplier complies with any international trade regulations that may apply, especially if files are tailored to specific regional standards.

8. How do I vet suppliers of CNC cutting files effectively?

Vetting suppliers of CNC cutting files is crucial for ensuring reliability and quality. Start by reviewing their website for professionalism and the range of files offered. Check for customer testimonials and reviews on independent platforms to gauge previous buyers’ experiences. It’s also beneficial to contact the supplier directly with questions about their design process, quality assurance, and support services. If possible, request samples of their work to evaluate the quality firsthand. Additionally, consider the supplier’s responsiveness and willingness to accommodate your needs as indicators of their customer service standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Cnc Cutting Files Manufacturers & Suppliers List

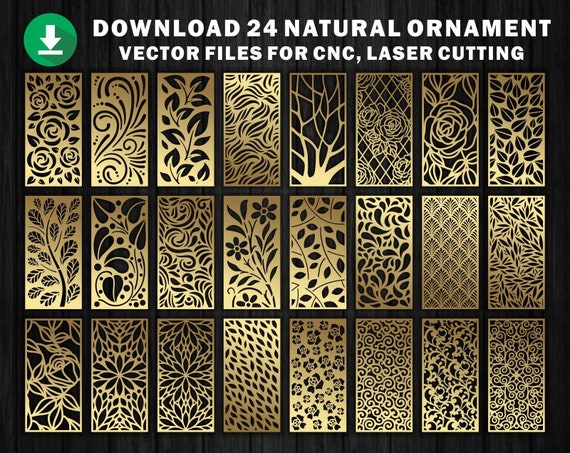

1. Broinwood – CNC Design Files

Domain: broinwood.com

Registered: 2018 (7 years)

Introduction: This company, Broinwood – CNC Design Files, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Langmuir Systems – FireShare Beta

Domain: langmuirsystems.com

Registered: 2017 (8 years)

Introduction: FireShare Beta allows users to download free cut-ready CNC project files. It supports uploading G-Code files for FireControl and Mach3. Users can explore and download user-uploaded projects, including various home and garden decor items and popular projects like flat weld tabs and standoffs. The product offerings include CrossFire CNC Plasma, CrossFire PRO CNC Plasma, CrossFire XR CNC Plasma, ArcF…

3. CNC Cookbook – Free DXF Files & Patterns

Domain: cnccookbook.com

Registered: 2007 (18 years)

Introduction: Free DXF Files and CNC Patterns available for download. Categories include Animals, Vehicles, Nature, Maps, Music, Symbols, Holiday, Toys, Signs, Sports, Food, Religion, and Western. DXF files are vector CAD files used as CNC Patterns for cutting with machines like CNC Routers, Laser Cutters, Plasma Cutters, and Waterjets. Each download includes a .dxf file for cutting and a .jpg file for viewing….

4. AribaBox – Free DXF Files for CNC

Domain: aribabox.com

Registered: 2017 (8 years)

Introduction: Free DXF Files for CNC, available for various categories including Workshop, Kids, Home, Game Room, and Bundles.

5. CNC DXF Files – Everything Collection

Domain: cncdxffiles.com

Registered: 2016 (9 years)

Introduction: [{‘name’: ‘Everything Collection’, ‘price’: 125.0}, {‘name’: ‘Master Collection 2 CNC DXF Files’, ‘price’: 100.0}, {‘name’: ‘Master Collection 1 CNC DXF Files’, ‘price’: 100.0}, {‘name’: ‘Animals 2’, ‘price’: 85.0}, {‘name’: ‘Signs’, ‘price’: 85.0}, {‘name’: ‘Layered Wall Scenes’, ‘price’: 85.0}, {‘name’: ‘Clocks CNC DXF Files’, ‘price’: 80.0}, {‘name’: ‘Entryway Gates’, ‘price’: 80.0}, {‘name’: ‘…

6. Etsy – CNC Files & Mega Bundles

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: CNC Files available on Etsy, including various bundles and individual designs. Price range from $2.34 to $55.89. Digital downloads include formats such as STL, DXF, DWG, EPS, SVG, and AI. Discounts available, with some items up to 75% off. Popular products include mega bundles with hundreds of files, specific designs for cutting boards, and themed projects like the USA map and geometric panels.

Strategic Sourcing Conclusion and Outlook for cnc cutting files

In the rapidly evolving landscape of CNC cutting files, strategic sourcing emerges as a pivotal factor for businesses aiming to optimize operations and enhance product offerings. By leveraging a diverse range of high-quality DXF and SVG files, international buyers can significantly reduce lead times and improve production efficiency. The availability of free and customizable cutting files allows companies to innovate without incurring substantial costs, making it an attractive option for businesses in regions such as Africa, South America, the Middle East, and Europe.

Moreover, understanding the nuances of file formats and compatibility with various CNC machines is essential for maximizing the value derived from these resources. As the demand for unique and customized designs continues to grow, businesses that proactively engage in strategic sourcing will position themselves advantageously within their respective markets.

Looking ahead, international B2B buyers are encouraged to explore these opportunities further. Embrace the potential of CNC cutting files to unlock creativity and efficiency in your projects. By staying informed and adaptable, you can elevate your business operations and meet the evolving needs of your customers with confidence.