Guide Contents

Project Insight: Cnc Cutter Diy

Manufacturing Insight: CNC Cutter DIY – Why Precision Matters More Than You Think

Why DIY CNC Isn’t Built for Professional Prototyping

Precision Limitations: DIY setups typically achieve ±0.1mm tolerances—far from the ±0.01mm required for functional prototypes and end-use parts.

Hidden Time Costs: Setup, calibration, and troubleshooting can consume weeks, delaying product launches.

Material Waste & Rework: Inconsistent results lead to costly material loss and design iterations.

Honyo Prototype: Precision at Speed, Simplified

Online Instant Quote: Get real-time pricing in seconds—no more waiting for manual quotes or hidden fees.

AI-Powered Design Optimization: Our platform analyzes your CAD files to recommend cost-saving adjustments without compromising quality.

48-Hour Turnaround: From quote to delivery, we accelerate your innovation cycle with industry-leading speed.

Why Startups Trust Honyo for Mission-Critical Parts

3/4/5-Axis Machining: Complex geometries, single-setup precision—no compromises on design complexity.

Tight Tolerances Guaranteed: ±0.01mm accuracy ensures parts function as intended, every time.

End-to-End Digital Workflow: Seamless collaboration from design to delivery, with transparent tracking at every step.

Honyo Prototype: Where innovation meets precision. Shenzhen, China | Founded by Susan Leo

Honyo Capabilities & Technology

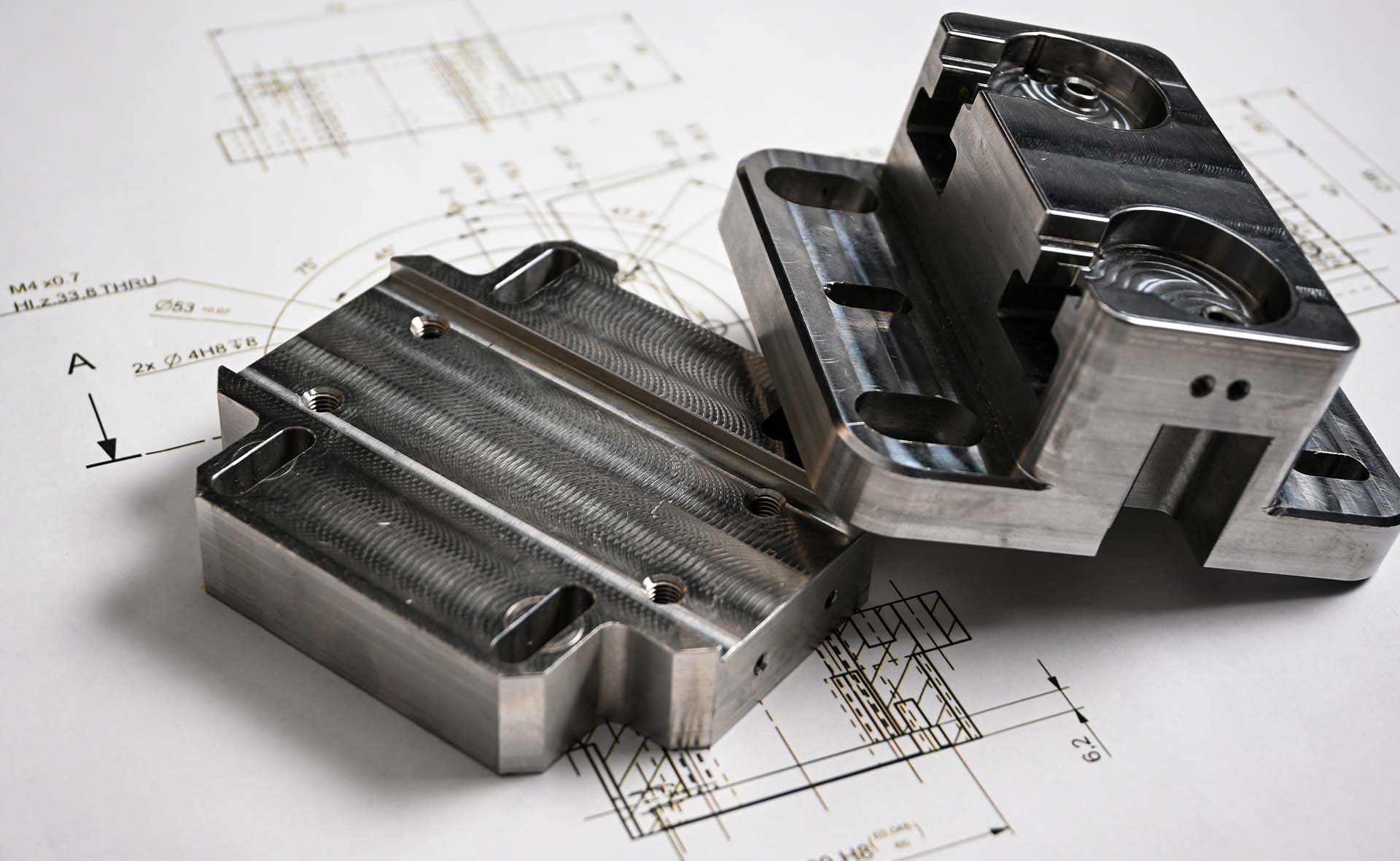

Honyo’s Precision CNC Manufacturing Capabilities

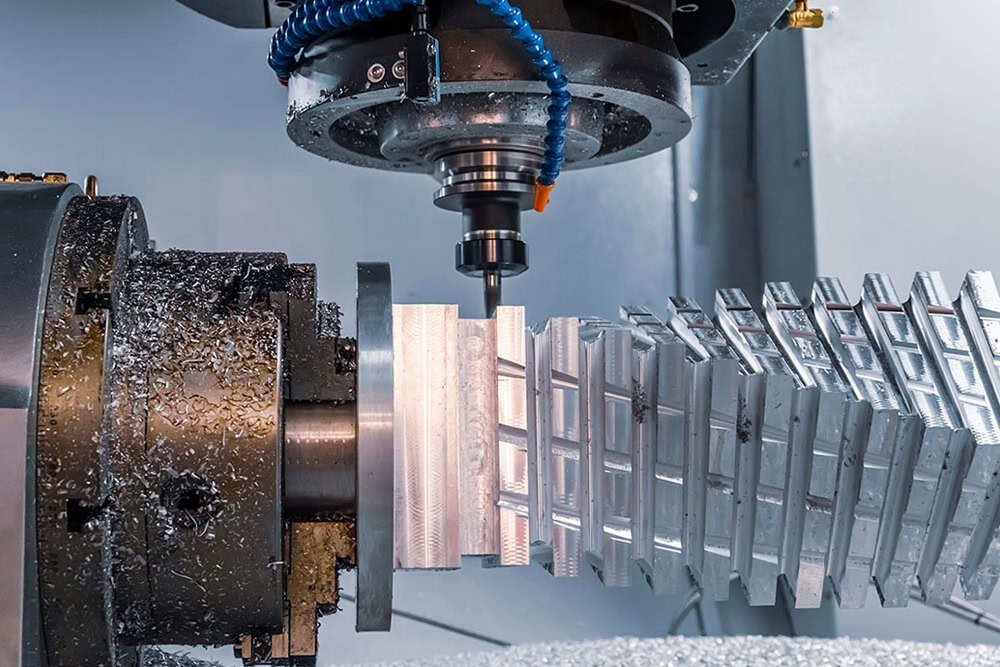

Advanced Multi-Axis Technology

3/4/5-Axis Precision Machining: Achieve complex geometries with ±0.01mm tolerances for functional prototypes and end-use parts—perfect for aerospace, medical, and robotics applications.

AI-Powered Optimization: Intelligent toolpath algorithms reduce material waste and machining time by up to 30%, cutting costs without compromising quality.

Real-Time Process Monitoring: Continuous feedback loops ensure consistent precision across every production run, eliminating human error.

Scalable Production with Rapid Turnaround

Flexible Volume Scaling: Seamlessly transition from 1 prototype to 10,000+ units with identical quality—no minimum order quantities.

Instant Online Quoting: Get accurate pricing in under 60 seconds via our AI-driven platform—no manual estimation required.

Fast Turnaround Guarantee: 24-48 hours for prototype quotes, 3-5 days for production delivery—accelerating your time-to-market.

ISO-Certified Quality Assurance

End-to-End Quality Control: Rigorous inspections at every stage, from material verification to final part validation.

AI-Driven Measurement: Automated inspection systems detect deviations before parts leave our facility, ensuring ±0.01mm accuracy.

ISO 9001 Certified: Trusted by global startups and enterprises for reliable, repeatable manufacturing excellence.

Why Honyo?

We don’t just machine parts—we engineer solutions. Our AI-powered platform and Shenzhen-based precision manufacturing hub deliver professional-grade results for hardware innovators who demand speed, accuracy, and scalability—no DIY compromises required.

Ready to accelerate your project? Get an instant quote in seconds.

Materials & Surface Finishes

Material Options & Finishes for Precision CNC Machining

Premium Materials for Every Application

Choose from industry-leading materials engineered for performance, durability, and cost efficiency:

Aluminum 6061: Ideal for aerospace, automotive, and structural prototypes. Balances strength, corrosion resistance, and machinability at a competitive price.

Aluminum 7075: High-strength alloy for military, aerospace, and high-load applications. Requires precision tooling but delivers unmatched rigidity.

Stainless Steel 304: Food-safe, non-magnetic, and corrosion-resistant. Perfect for medical devices, kitchen equipment, and outdoor fixtures.

Stainless Steel 316: Superior chloride resistance for marine, chemical processing, and surgical instruments. Meets stringent regulatory standards.

Brass: Exceptional electrical conductivity and aesthetic appeal. Used in connectors, decorative elements, and marine fittings.

PEEK: High-performance thermoplastic for extreme temperatures (-200°C to 250°C), chemical resistance, and biocompatibility. Critical for aerospace and medical implants.

Surface Finishes That Enhance Performance

Elevate part functionality and aesthetics with precision finishes tailored to your needs:

Anodizing (Type II & III):

Type II: Decorative colors + corrosion resistance (ideal for consumer electronics).

Type III (Hard Coat): Wear-resistant surface for industrial tools and high-stress components.

Powder Coating: UV-stable, scratch-resistant finishes in 200+ colors. Perfect for outdoor machinery and architectural elements.

Precision Polishing: Mirror-smooth surfaces (Ra < 0.1µm) for optical, medical, or high-end consumer products.

Electroplating (Nickel/Chrome): Adds hardness, conductivity, and corrosion protection for automotive and electronics.

Passivation: Removes surface contaminants from stainless steel without altering dimensions—critical for medical and food-grade parts.

How to Select the Right Material for Your CNC Project

Optimize your design with data-driven insights:

Mechanical Needs: Need lightweight strength? Aluminum 6061 or PEEK. For extreme loads, choose Aluminum 7075 or Stainless 316.

Environmental Exposure: Marine or chemical environments? Stainless 316 or PEEK. Outdoor use? Anodized aluminum or powder-coated steel.

Cost vs. Performance: Aluminum 6061 delivers 80% of high-end performance at 50% the cost of specialty alloys. PEEK is premium for extreme conditions but reduces long-term maintenance costs.

Machinability: Softer materials (Brass, Aluminum 6061) cut faster, reducing lead times and costs. Harder alloys require specialized tooling but deliver superior durability.

Regulatory Compliance: Medical or food applications? Stainless 304/316 or PEEK meet FDA, ISO 13485, and NSF standards.

Why Choose Honyo Prototype?

✅ Online Instant Quote

Upload your CAD file to our AI-powered platform and receive a real-time, itemized quote in under 60 seconds—no manual estimates, no delays.

✅ AI-Powered Optimization

Our smart system analyzes material properties, tolerances (±0.01mm), and finish requirements to recommend the most cost-effective solution without compromising precision.

✅ Fast Turnaround

From prototype to production—deliver parts in 3-5 business days with automated workflows and Shenzhen-based manufacturing. No compromises on speed or quality.

“At Honyo, we don’t just machine parts—we engineer solutions. Whether you’re prototyping a drone component or manufacturing medical devices, our platform ensures you get the right material, finish, and timeline—every time.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload CAD File

Simple drag-and-drop interface for all major formats (STEP, STL, IGES, etc.).

Automated file validation ensures compatibility and readiness for production—no technical expertise required.

2. Get Instant AI-Powered Quote

Real-time pricing in seconds with a fully transparent cost breakdown: materials, machining time, finishing, and shipping.

Online Instant Quote engine adapts to your design complexity, eliminating manual quotes and delays.

AI optimizes for cost-efficiency while preserving precision—no hidden fees, no surprises.

3. DFM Analysis & Optimization

Proactive design feedback from Honyo’s engineering team to eliminate manufacturability risks.

Smart suggestions for material selection, tolerances, and feature improvements—before production starts.

Collaborative platform ensures your design is perfected for function, cost, and speed.

4. Precision Production & Delivery

State-of-the-art 3/4/5-axis CNC machining with ±0.01mm tolerances for functional prototypes and end-use parts.

Fast Turnaround: Prototypes delivered in as little as 3 days; expedited options for urgent projects.

Real-time production tracking and eco-friendly shipping—from our Shenzhen hub to your door.

“Innovation isn’t just about precision—it’s about making it effortless. Our AI-driven workflow turns your vision into reality, faster and smarter than ever.”

— Susan Leo, Founder, Honyo Prototype

Start Your Project with Honyo

Start Your Project with Honyo

Get Started in Minutes, Not Days

Instant AI-Powered Quotes: Upload your CAD file and receive real-time pricing with intelligent cost optimization—no manual estimates, no delays.

72-Hour Delivery Guarantee: From design to finished part in record time. Our Shenzhen/Dongguan facilities leverage 24/7 production for rapid prototyping and low-volume manufacturing.

Industrial-Grade Precision: Achieve +/-0.01mm tolerances with advanced 3/4/5-axis CNC machining—perfect for functional prototypes and end-use parts that demand reliability.

Ready to accelerate your innovation? Connect with Founder Susan Leo and our engineering team:

📧 Email: [email protected]

📞 Phone: +86 139 2843 8620

🌍 Visit: Shenzhen & Dongguan facilities

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.