Contents

Manufacturing Insight: Cnc Cut Steel

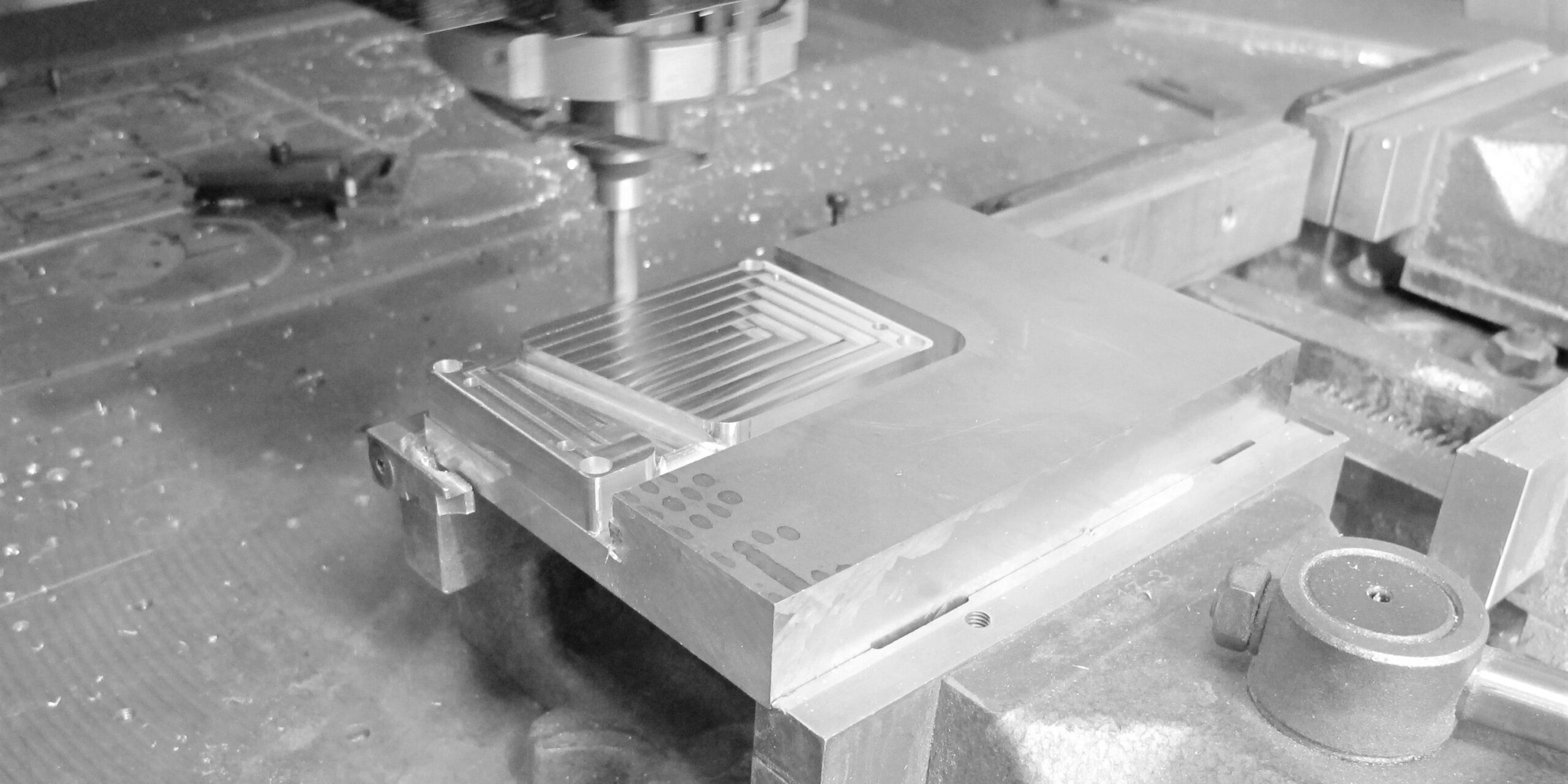

Precision Steel CNC Machining for Demanding Industrial Applications

Honyo Prototype delivers exceptional CNC machining services specifically engineered for complex steel components, meeting the stringent requirements of aerospace, medical, automotive, and industrial equipment sectors. Our advanced 3-, 4-, and 5-axis CNC milling and turning centers, coupled with rigorous in-process quality control, consistently achieve tight tolerances down to ±0.005mm on a wide range of steel alloys. We possess deep expertise in machining challenging materials including Stainless Steels (303, 304, 316, 17-4 PH), Carbon Steels (1018, 1045, 4140), Tool Steels (A2, D2, S7), and specialty alloys, ensuring optimal cutting parameters, surface finishes, and structural integrity for your critical parts.

Streamlined Procurement with Online Instant Quoting

Eliminate the traditional delay in project initiation with Honyo’s industry-leading Online Instant Quote system. Upload your STEP or IGES file directly to our platform and receive a detailed, accurate manufacturing quotation within seconds, not days. This proprietary system analyzes geometric complexity, material requirements, and tolerance specifications in real-time, providing transparent pricing and lead time estimates. Accelerate your prototyping and low-volume production timelines by bypassing lengthy manual quoting processes, allowing engineering teams to iterate faster and move confidently from design to physical part.

Common Steel Alloys Machined at Honyo Prototype

| Steel Alloy Type | Key Examples | Typical Applications | Key Machining Consideration |

|---|---|---|---|

| Stainless Steel | 303, 304, 316, 17-4 PH | Medical instruments, aerospace fittings, fluid systems | Work hardening, chip control |

| Carbon Steel | 1018, 1045, 4140 | Shafts, brackets, structural components | Hardenability, weld prep |

| Tool Steel | A2, D2, S7 | Dies, molds, cutting tools | Pre/post-heat treatment handling |

Leverage Honyo Prototype’s precision CNC steel machining capabilities and immediate quoting technology to reduce development cycles and ensure your critical components meet the highest standards of quality and performance. Initiate your project efficiently today.

Technical Capabilities

CNC Cut Steel – Technical Specifications Overview

Honyo Prototype delivers precision CNC machining services for a range of materials including aluminum, steel, ABS, and nylon. Our capabilities span 3, 4, and 5-axis milling as well as CNC turning, ensuring high accuracy and repeatability for complex geometries and tight tolerance requirements. Below are the technical specifications for our CNC machining processes.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + A (rotary around X) | X, Y, Z + A, B (dual rotary) | X, Z linear + C (rotary) |

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) |

| Tight Tolerance Capability | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) |

| Surface Finish (Typical) | Ra 0.8 – 3.2 µm | Ra 0.8 – 3.2 µm | Ra 0.8 – 3.2 µm | Ra 0.8 – 1.6 µm |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Max Work Envelope (mm) | 1000 × 600 × 500 | 800 × 600 × 500 | 600 × 500 × 400 | Ø 300 × 500 length |

| Spindle Speed (RPM) | Up to 24,000 | Up to 20,000 | Up to 20,000 | Up to 6,000 |

| Tool Changer Capacity | 24–30 tools | 24–30 tools | 24–30 tools | 8–12 tools |

| Applications | Flat parts, prismatic geometries | Indexing features, mid-complexity | Complex contours, aerospace components | Shafts, pins, rotational parts |

Material Notes:

Aluminum (e.g., 6061-T6, 7075-T6): Lightweight, high strength-to-weight ratio, excellent machinability. Ideal for aerospace and automotive prototypes.

Steel (e.g., 4140, 1018, Stainless 303/304): High strength, durability, and wear resistance. Suitable for high-load and high-temperature applications.

ABS (Acrylonitrile Butadiene Styrene): Thermoplastic with good impact resistance and machinability. Common in enclosures and prototyping.

Nylon (Polyamide): High toughness, chemical resistance, and low friction. Used in wear components and insulating parts.

All CNC operations are supported by in-process inspection and CMM validation to ensure tight tolerance compliance. Honyo Prototype maintains ISO 9001-compliant processes to guarantee part quality across production volumes.

From CAD to Part: The Process

Honyo Prototype CNC Steel Cutting Process Overview

Honyo Prototype executes CNC steel cutting through a rigorously defined workflow designed for precision, efficiency, and client transparency. This process begins with digital file submission and concludes with certified delivery, integrating automated and human expertise at critical stages to ensure manufacturability and quality. Below is a technical breakdown of each phase.

CAD File Upload and Validation

Clients initiate the process by uploading native CAD files (e.g., STEP, IGES, or native SolidWorks) via our secure portal. Our system performs automated validation checks for file integrity, unit consistency, and geometric completeness. Unsupported formats or corrupted files trigger immediate client notification for resubmission. All data is encrypted per ISO 27001 standards, with version control maintained throughout the project lifecycle.

AI-Powered Quoting Engine

Validated CAD files enter our proprietary AI quoting system, trained on 15+ years of shop floor data across 50,000+ steel fabrication projects. The algorithm analyzes part geometry, material requirements (ASTM A36, 4140, etc.), batch size, and machine-specific parameters to generate a preliminary quote within 90 minutes. Key outputs include:

Cost breakdown (material, machining, finishing)

Estimated lead time (standard or expedited)

Initial feasibility flags (e.g., thin-wall risks, tolerance conflicts)

The AI model continuously refines its accuracy using post-production cost variance data, maintaining a 95%+ quote accuracy rate for standard geometries.

Engineering Review and DFM Optimization

All quotes undergo mandatory Design for Manufacturability (DFM) review by our Senior Manufacturing Engineering team. This phase identifies and resolves potential production issues before machining begins:

Tolerance Analysis: Verifying GD&T callouts against CNC machine capabilities (±0.005″ standard; ±0.001″ achievable with metrology validation)

Material Utilization: Optimizing nest layouts to minimize waste (typical steel yield: 85–92%)

Process Sequencing: Determining optimal toolpaths, fixturing, and secondary operations (e.g., deburring, heat treatment)

Risk Mitigation: Flagging features requiring specialized tooling (e.g., internal radii <0.030″) or alternative processes (e.g., laser for >1″ plate)

Client collaboration is required for DFM recommendations, with revised quotes issued within 4 business hours post-review.

Production Execution

Approved designs move to production in Honyo’s climate-controlled facility, featuring:

Machine Fleet: HAAS VF-3 SS vertical mills (3-axis), DMG MORI CTX beta 1250 (5-axis), and Trumpf TruLaser 3030 (for sheet steel)

Material Verification: Incoming steel certified via MTRs (Mill Test Reports) and batch-tracked; hardness testing per ASTM E18 for alloy steels

In-Process QA: First-article inspection (FAI) per AS9102, with CMM checks at critical stages (e.g., pre/post-heat treatment)

Traceability: Real-time production tracking via barcode system, with digital work instructions synced to each machine

Quality-Controlled Delivery

Final inspection occurs against the original CAD model and client specifications:

| Checkpoint | Standard Protocol | Documentation |

|———————–|———————————————–|———————————–|

| Dimensional Accuracy | CMM scan of critical features (100% coverage) | FAIR (First Article Inspection Report) |

| Surface Finish | Ra measurement per ISO 1302 | Surface Roughness Certificate |

| Material Compliance | Cross-referenced MTRs + batch verification | Material Traceability Report |

| Packaging | VCI paper + custom crating for corrosion prevention | Packing List with Handling Instructions |

Certified parts ship via DHL/FedEx with real-time tracking. Standard lead time is 7–12 business days from DFM approval; expedited options (48–72hr) include overtime labor and priority scheduling. All deliveries include full quality documentation accessible via client portal.

This integrated workflow ensures Honyo Prototype delivers CNC-cut steel components that meet aerospace, medical, and industrial specifications while minimizing time-to-part and total project risk. Clients receive proactive updates at each phase transition through our dedicated project management interface.

Honyo Prototype | Precision Manufacturing Solutions

Senior Manufacturing Engineering Team

Start Your Project

Looking for precision CNC cut steel components? Contact Susan Leo at [email protected] to discuss your project requirements.

Honyo Prototype operates a fully equipped manufacturing facility in Shenzhen, specializing in high-accuracy CNC machining for steel and other engineering materials. Our Shenzhen factory supports rapid prototyping and low-to-mid volume production with tight tolerances, fast turnaround, and full quality control.

Whether you need custom brackets, enclosures, or structural parts, our team ensures consistent precision and on-time delivery. Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.